A multi-station turntable

A multi-station, turntable technology, used in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems of wasting manpower, poor winding accuracy, and the working efficiency of winding machines cannot meet mass production, etc. To achieve the effect of simplifying the structure and space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described below in conjunction with accompanying drawing.

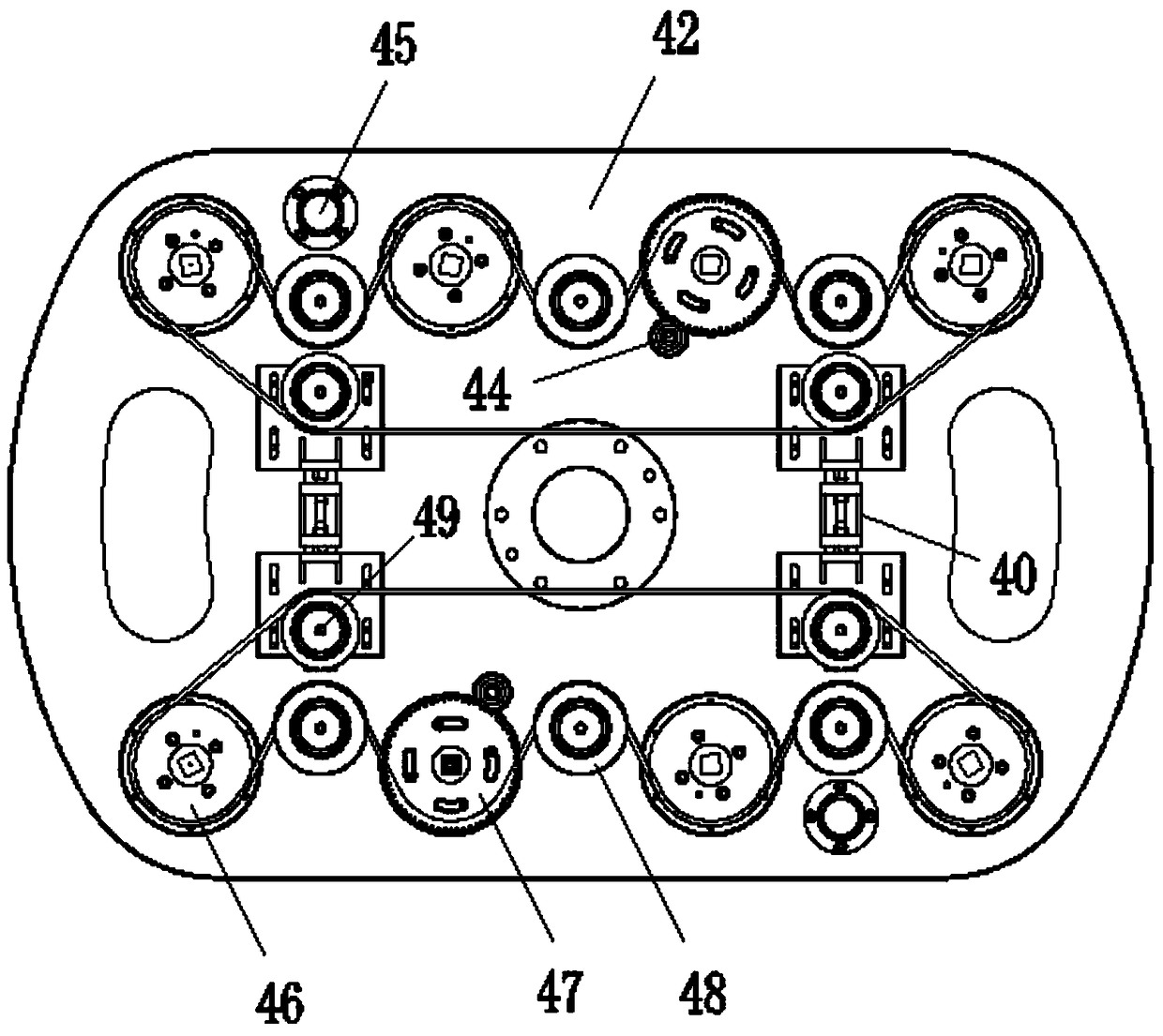

[0012] Such as figure 1 As shown, a multi-station turntable according to the present invention includes a turntable body 42, and two sets of indexing transmission assemblies symmetrical along the axis of the conversion spindle, two indexing positioning pins 44 and Two turntable positioning holes 45; the indexing transmission assembly described in each group includes 3 large tensioners 48, 2 small tensioners 49 and 4 wire cup mounting seats 46 arranged side by side, and the same group of wire cups The mounting seat 46 and the tensioning wheel are linked through the same belt transmission mechanism, and one of the thread cup mounting seats 46 is provided with an indexing main gear 47; the three large tensioning wheels 48 are arranged on the four thread cup mounting seats 46 at intervals Between them, two small tensioning wheels 49 are arranged on the side close to the two sets of indexin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com