Flying fork winding mechanism with eccentric shaft positioning middle guard

A winding mechanism and eccentric shaft technology, applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of inability to realize continuous and gapless winding, affecting the full rate of stator slots, and winding chaos, etc. Achieve continuous gapless winding, improve slot fullness, and stable winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Now in conjunction with the accompanying drawings, the present invention is described in further detail. The following are only preferred embodiments of the present invention, and are not intended to limit the protection scope of the present invention. Any equivalent or similar replacements without departing from the concept of the present invention shall fall within the protection scope of the present application. And the following parts that are not exhaustive should be carried out according to the existing technology or conventional technology in this field, such as "fixing", "fixing in a conventional way", "connecting", etc., can all adopt conventional fixed connection methods such as bolts and screws, and The following descriptions of "bearing housings" refer to bearing housings that already contain bearings.

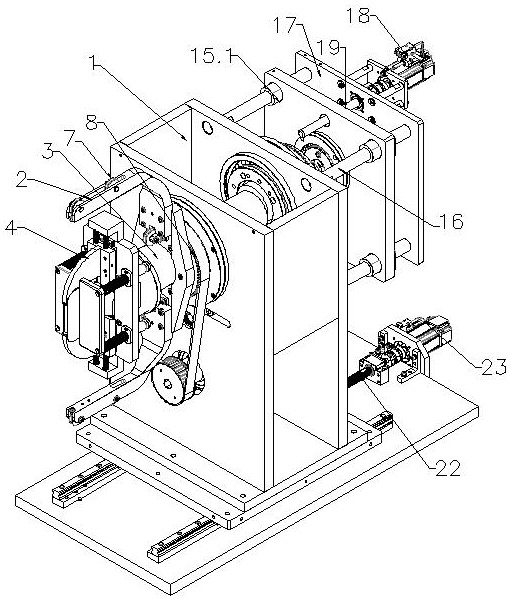

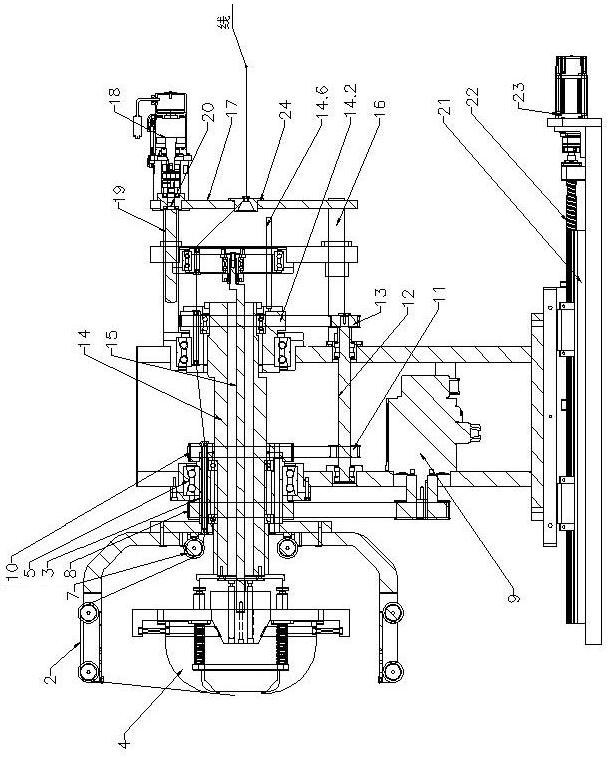

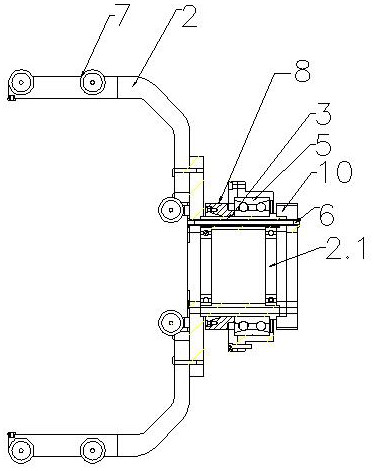

[0027] Such as Figure 1-8As shown, the flying fork winding mechanism with an eccentric shaft positioning the middle claw of the present invention include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com