Patents

Literature

40results about How to "Guaranteed not to rotate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

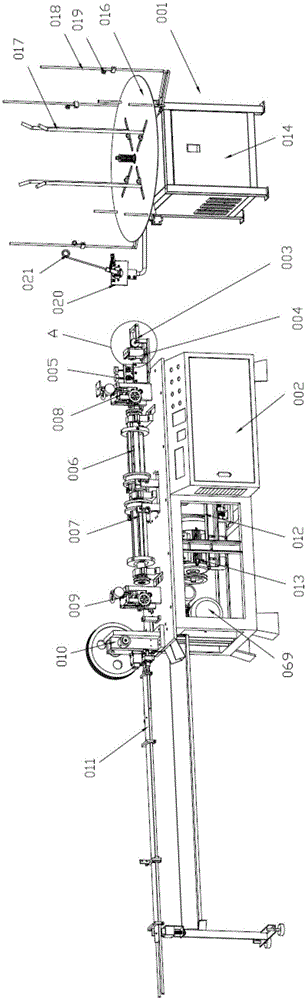

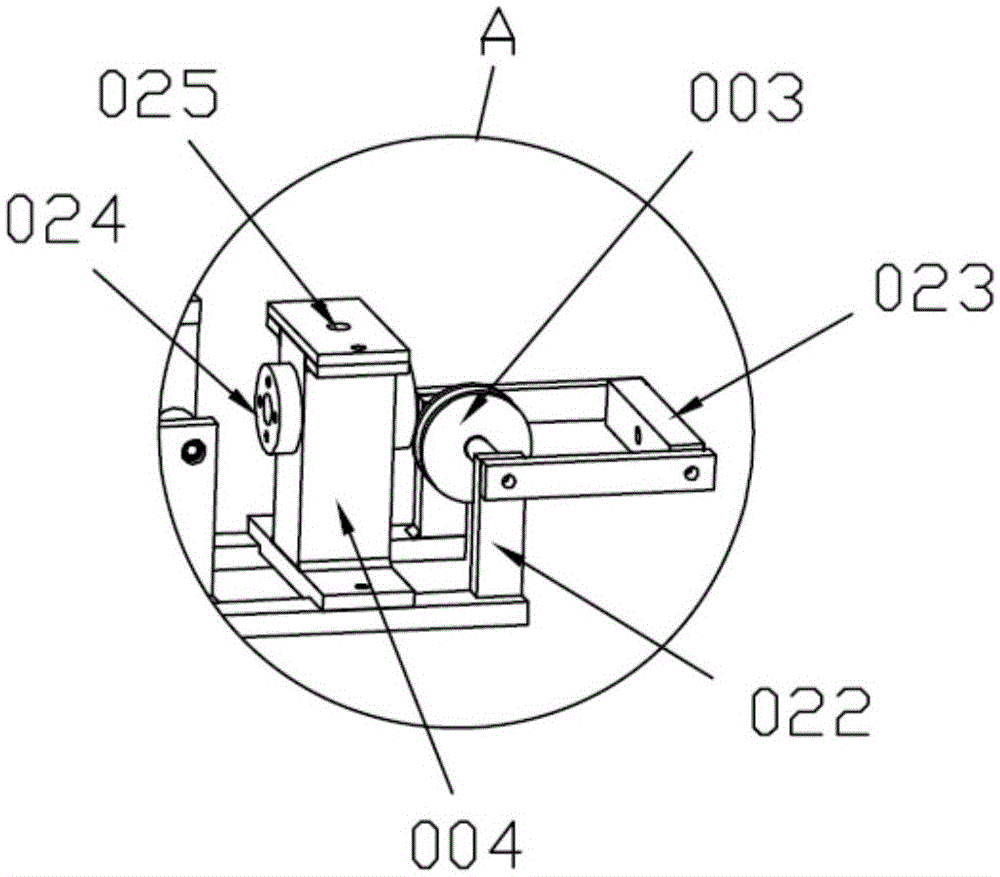

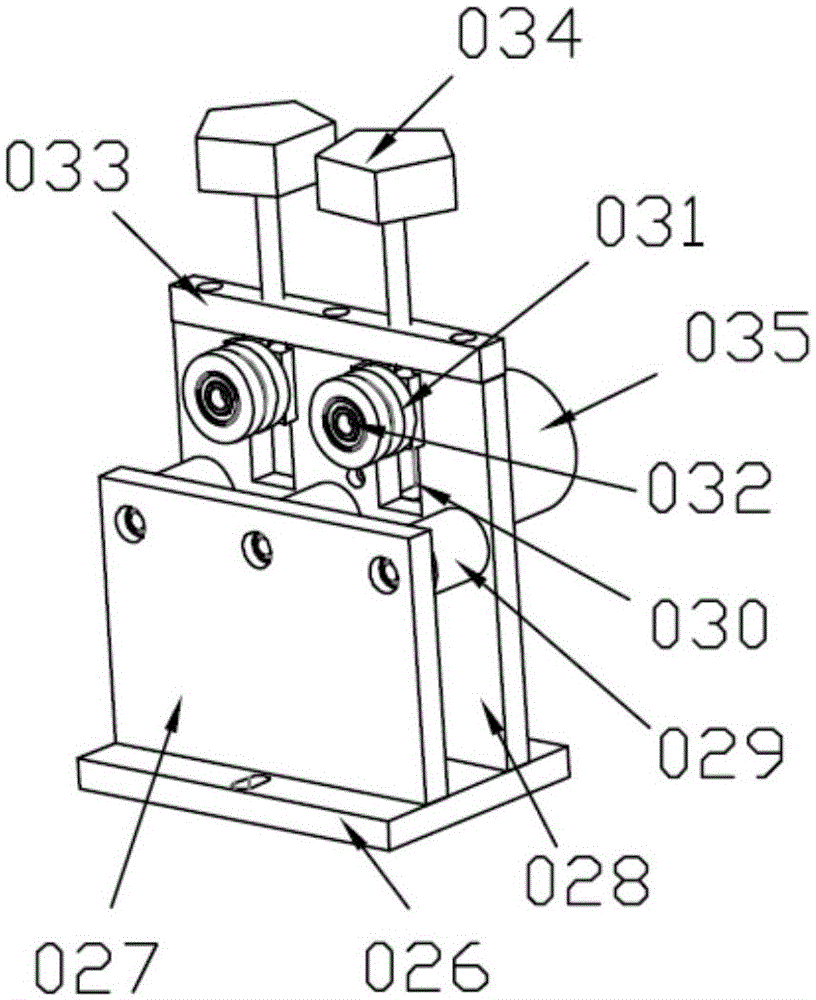

Automatic straightener

The invention discloses an automatic straightener. The automatic straightener comprises an automatic loading wire holder and a main machine base. A wire guide-in wheel, an oil can and a coding mechanism are sequentially arranged on the side, close to the automatic loading wire holder, of the main machine base. A first straightening roller and a second straightening roller connected in an end-to-end mode are arranged in the middle of the main machine base. A first wire pressing mechanism is arranged between a coder base and the first straightening roller. A second wire pressing mechanism is connected to the tail end of the second straightening roller. A cutter mechanism is arranged on the rear side of the second wire pressing mechanism and connected with a receiving frame. The first straightening roller and the second straightening roller are both connected with a shifting fork mechanism, straightening of the first straightening roller and the second straightening roller is controlled by a mismatch mechanism, and an arranged three-phase asynchronous motor supplies driving power to the first straightening roller, the second straightening roller, the first wire pressing mechanism and the second wire pressing mechanism. Notches are smoother, the cutting accuracy is higher, unattended operation of the straightener is achieved, wire waste in the straightening process is reduced, and time is shortened.

Owner:广东领航精密机械设备科技有限公司

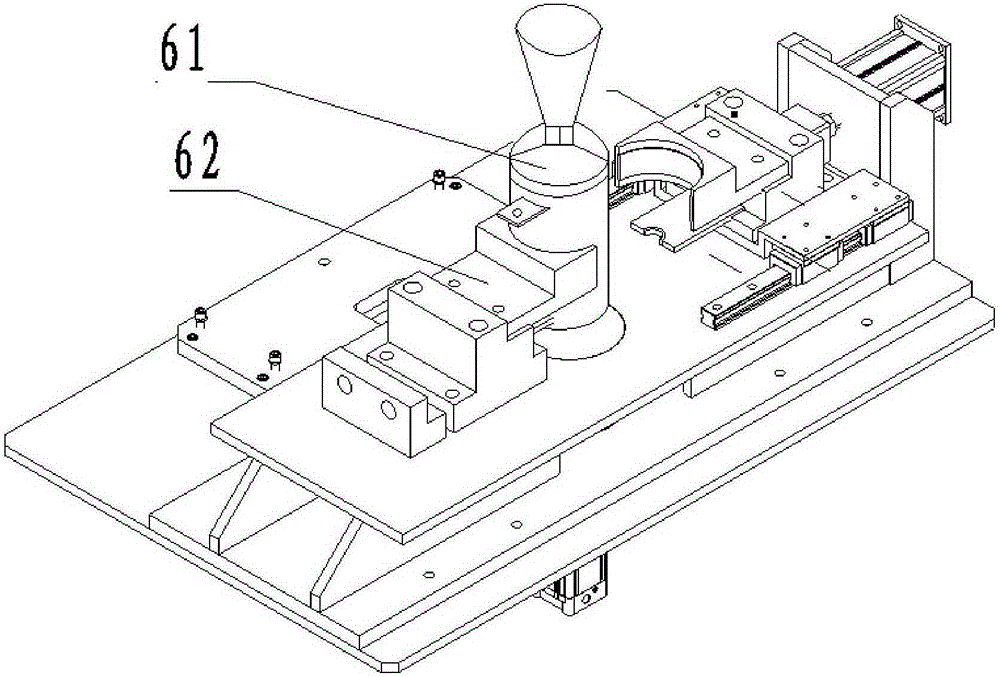

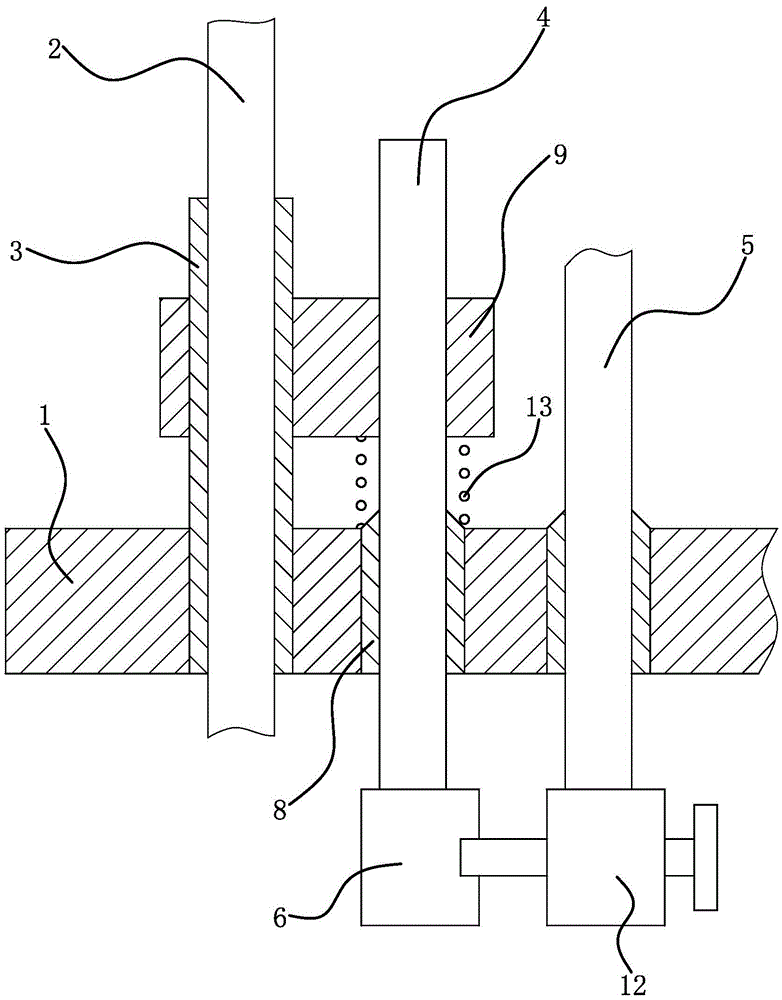

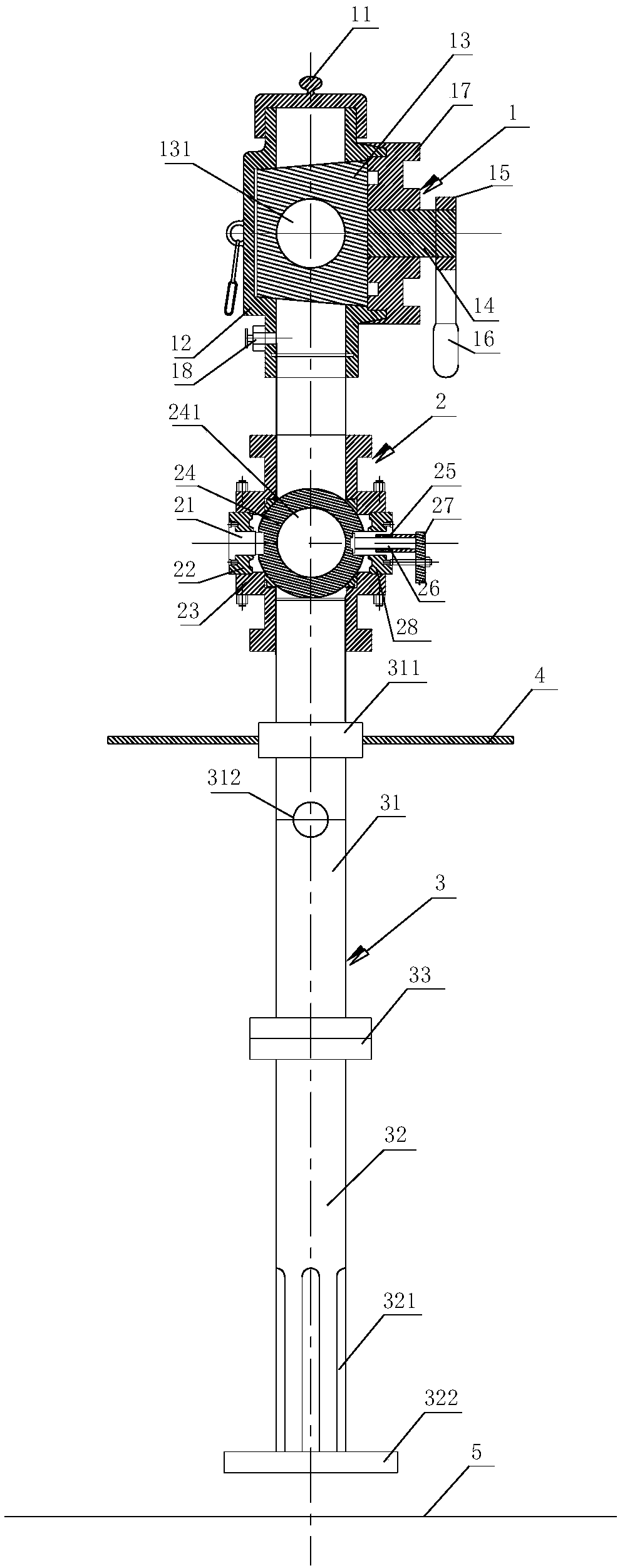

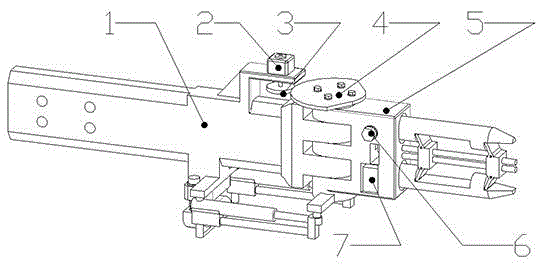

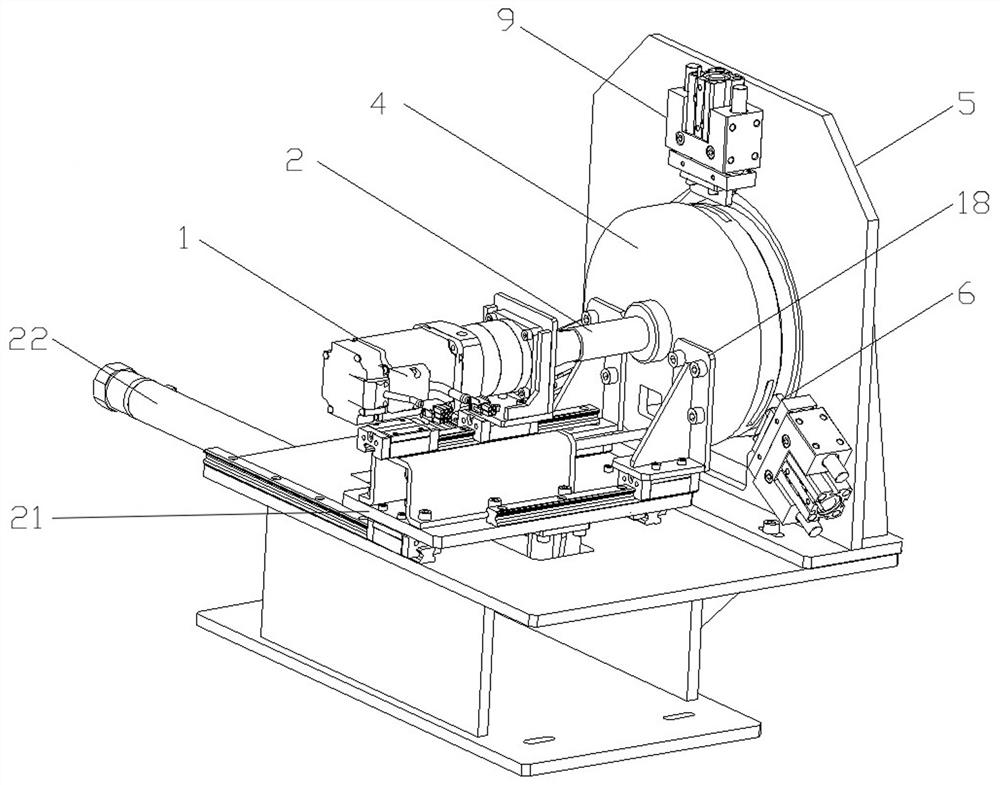

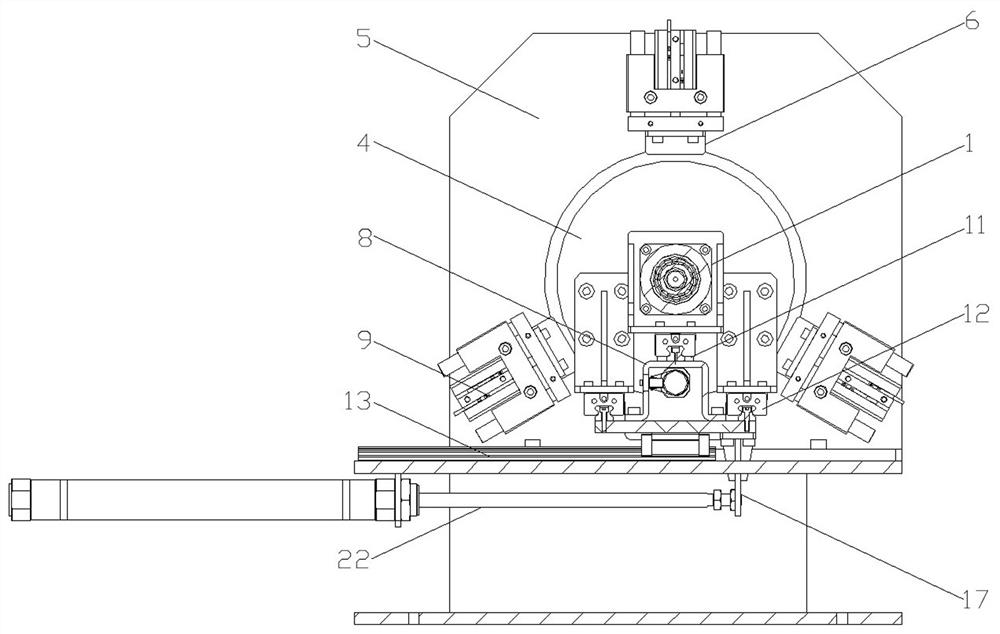

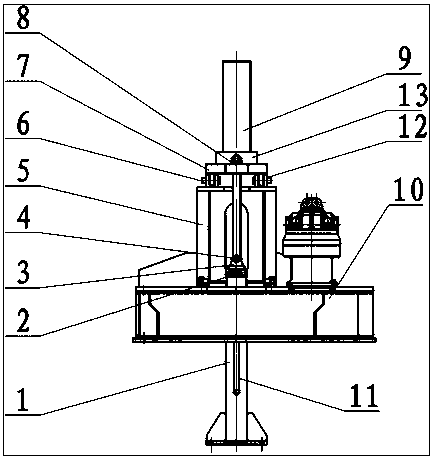

Automatic assembling device and method for small solid rocket

ActiveCN105171413AReduce in quantityReduce labor intensityAircraft componentsAssembly machinesEngineeringRocket

The invention discloses an automatic assembling device and method for a small solid rocket. The assembling device comprises a clamping tool, a tightening shaft, a tightening tool, a base and a control device. The clamping tool comprises a fixed part and a movable part and can clamp the small solid rocket. The semi-cylindrical curved surfaces of the fixed part and the movable part are made of antiskid materials with the pasting and friction coefficient of [0.3,0.5]. The tightening shaft comprises a drive mechanism and an output shaft. The drive mechanism outputs the assigned torque to drive the output shaft to rotate. A hexagonal part of a spray pipe of the small solid rocket is tightened through the hexagonal tightening tool. In the assembling process, the opening part of the hexagonal tightening tool is clamped on the hexagonal part of the spray pipe of the small solid rocket, the tightening shaft runs downwards, the output shaft is inserted in the connector part of the tightening tool, and the drive mechanism outputs the assigned torque to drive the output shaft to rotate; and the assigned torque is exerted to the small solid rocket through the tightening tool so that the spray pipe and a shell can be tightened. By means of the assembling method, the number of tools is decreased, the labor intensity is lowered, and the assembling efficiency is improved.

Owner:CHUANNAN MACHINERY PLANT CHINA ASTRONAUTIC SCI &TECH GROUP CORP

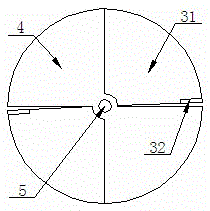

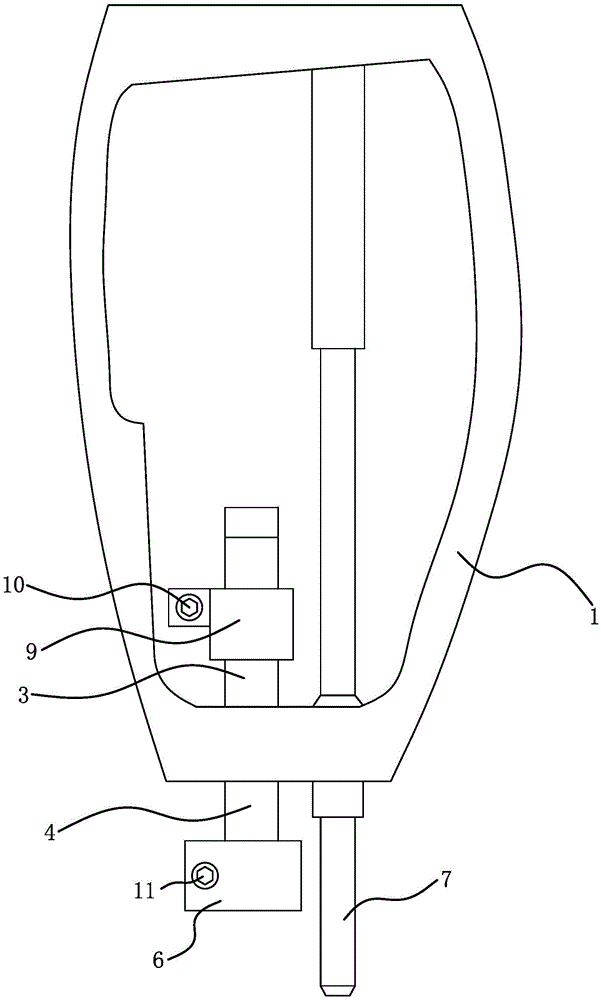

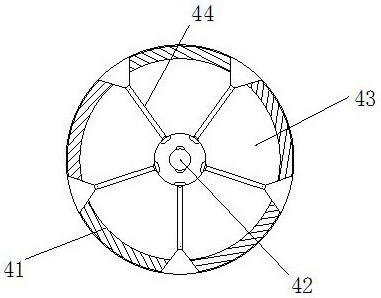

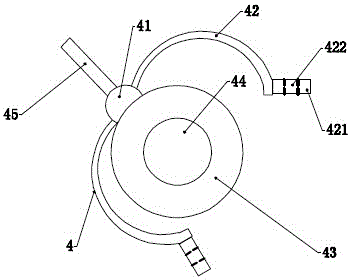

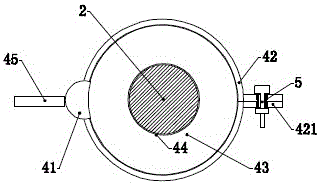

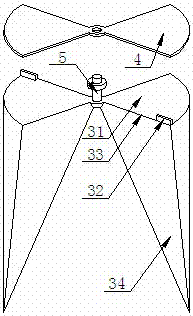

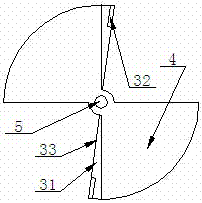

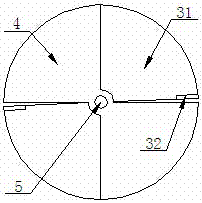

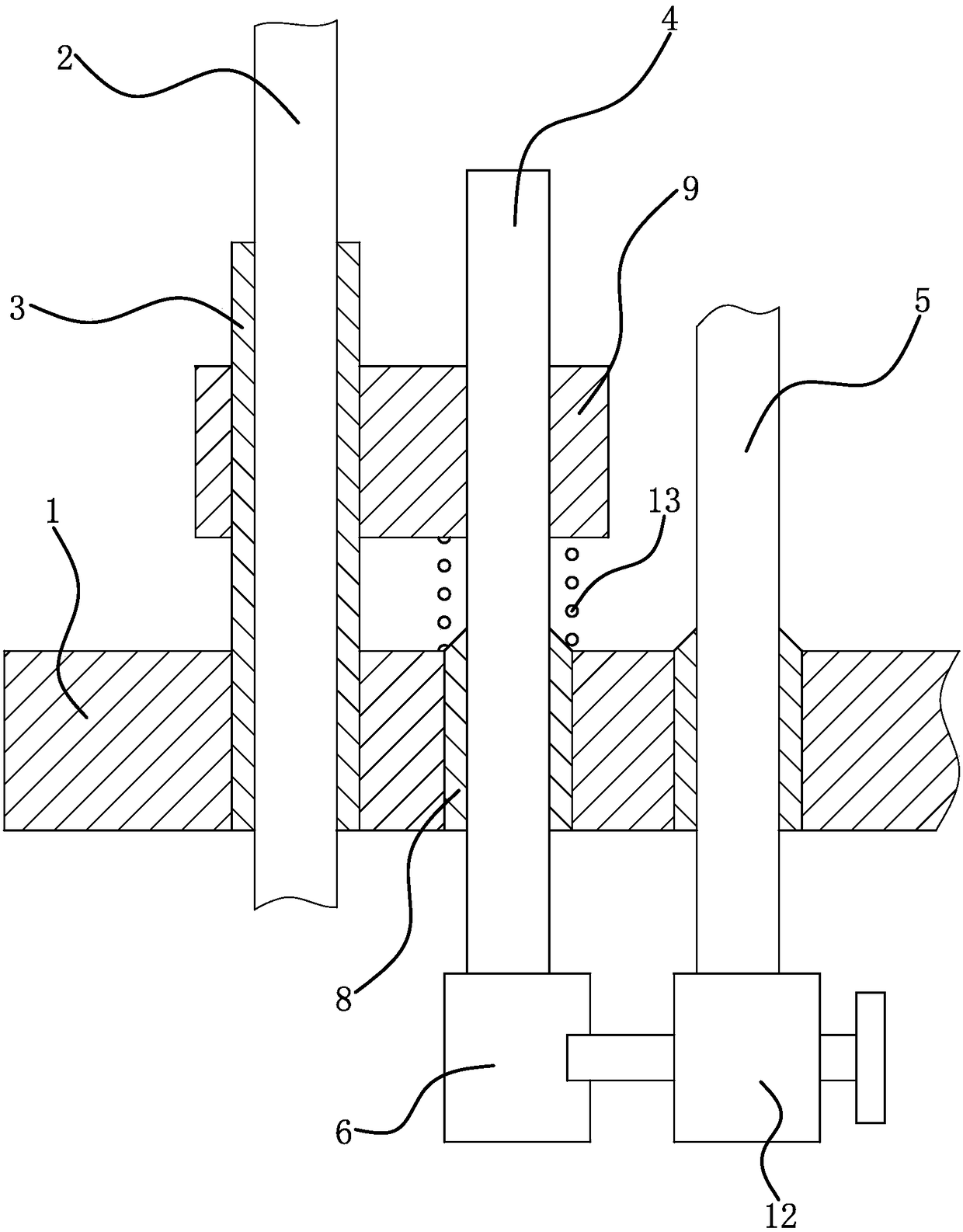

Cohesionless soil sampling apparatus

ActiveCN105486539AEasy to closeImprove accuracyWithdrawing sample devicesAnalysis workingSoil horizon

The invention discloses a cohesionless soil sampling apparatus. The apparatus comprises a cylindrical sampling cylinder, the sampling cylinder comprises a sampling top and a sampling bottom which are in threaded connection, the sampling bottom is provided with a fixed separation blade and a movable separation blade, the fixed separation blade is fixedly arranged on the inner wall of the sampling bottom, the movable separation blade is connected with the fixed separation blade through a center rotating shaft, the movable separation blade is positioned below the fixed separation blade, the center rotating shaft and the sampling cylinder are coaxially arranged, the top surface of the fixed separation blade is formed by two sector-shaped plates symmetrical to the center rotating shaft, the radian of each of the sector-shaped plates is 90DEG, the structure of the movable separation plate is same to the top surface of the fixed separation plate, and the top surface of the movable separation blade and the fixed separation blade are respectively vertical to the center rotating shaft. The bottom of the sampling cylinder can be conveniently closed without loss of a sampling amount, so the soil horizon sampling analysis working accuracy is improved.

Owner:ANHUI UNIV OF SCI & TECH

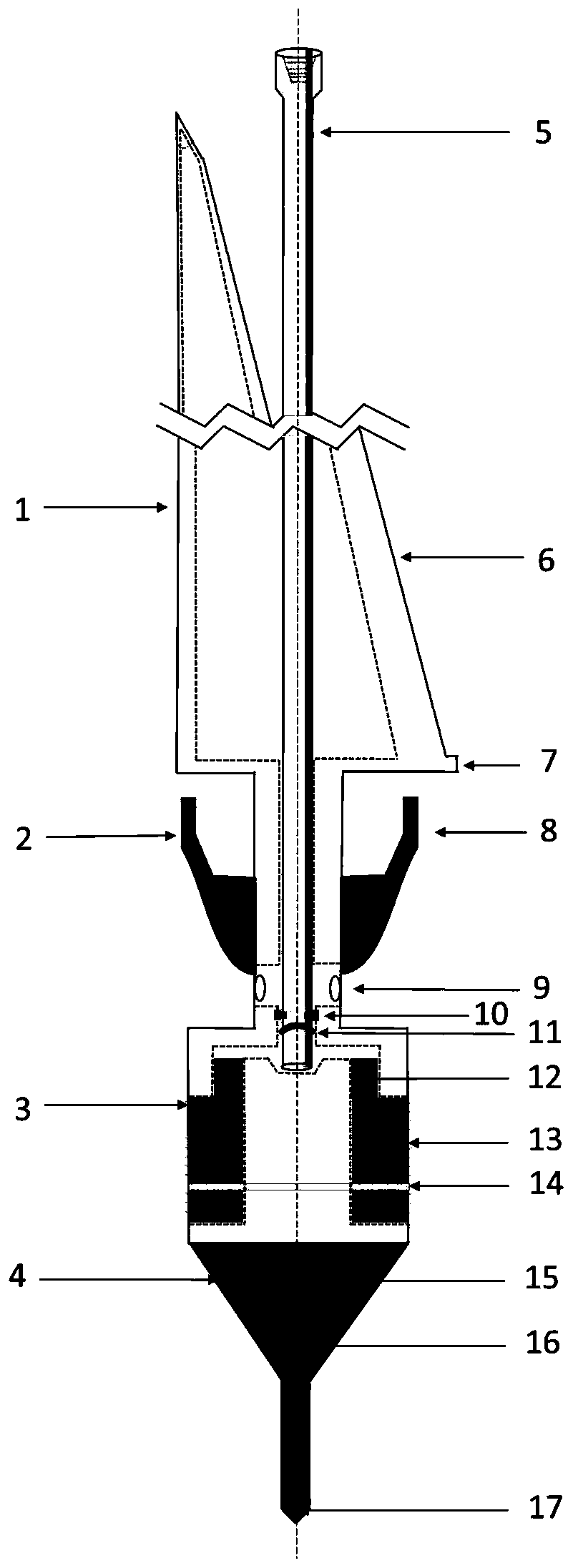

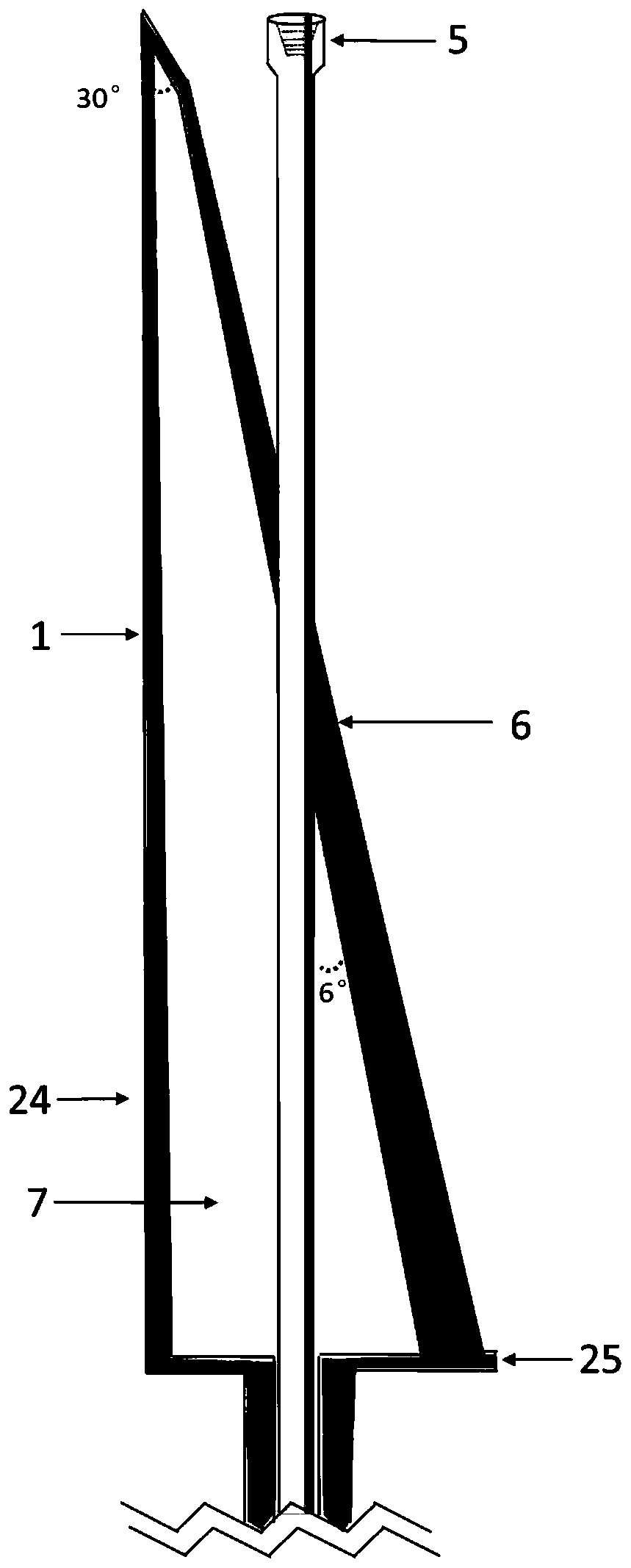

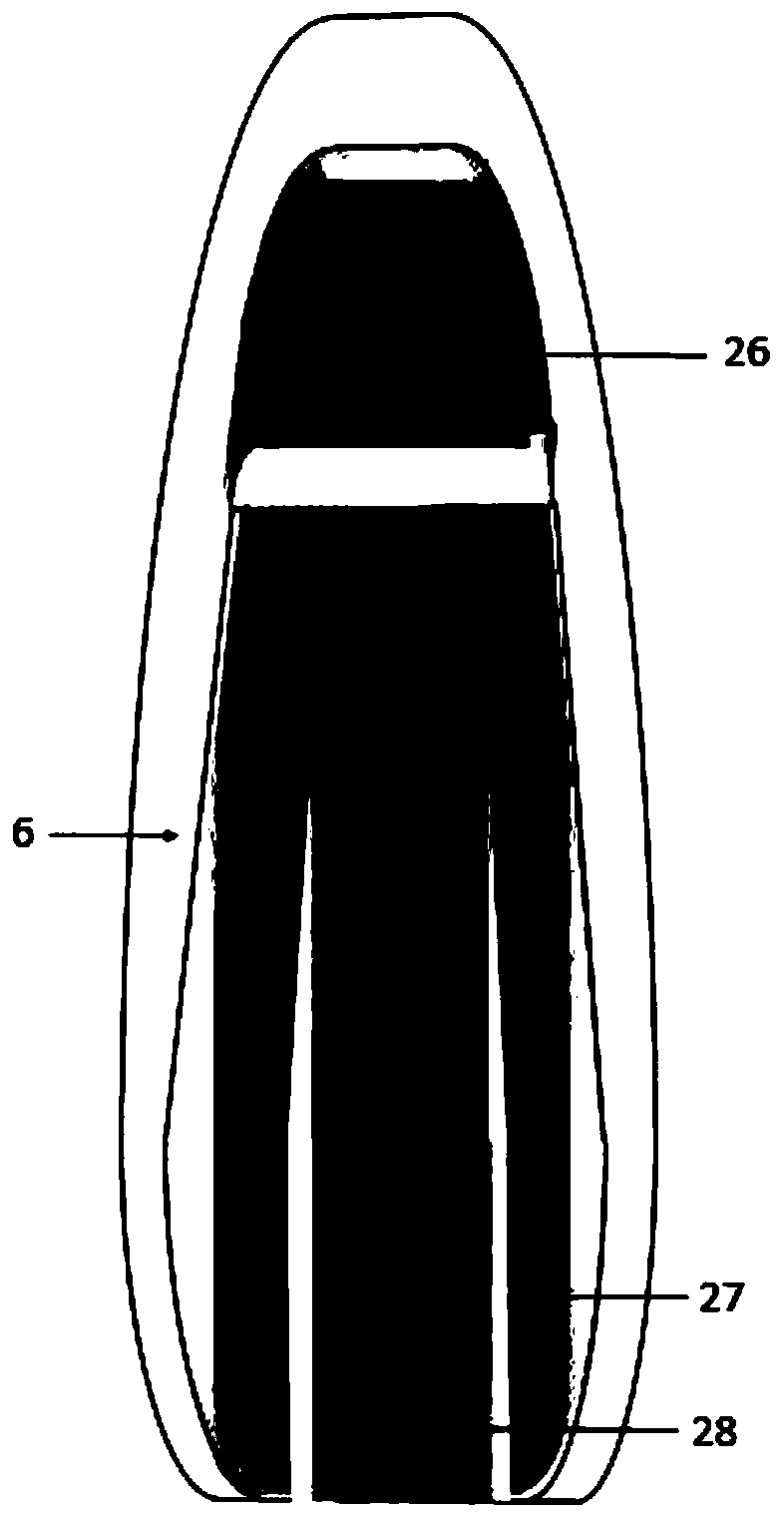

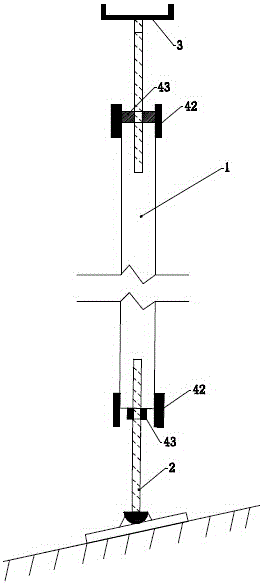

Riser reentry whipstock

ActiveCN110965966ASimple structureEasy to processDrilling rodsFluid removalClassical mechanicsStructural engineering

The invention relates to the technical field of underwater detection devices, and particularly discloses a riser reentry whipstock. The whipstock comprises an inclined plane body, a straightening unit, a sleeve, an anchoring unit and a lead-in head. The inclined plane body is fixed to a casing cutting opening, the inclined plane body is straightened through the straightening unit, and the inclinedplane body is provided with a longitudinal groove and a transverse groove to play a role in guiding in a riser and a drilling tool. The straightening unit is provided with a straightening cone plate,and performs the preliminary fixing while straightening the inclined plane body; the sleeve is provided with a hollow hole, and cementing sealing can be conducted after the whipstock is disengaged from a hand; the anchoring unit is arranged below the straightening unit and can fix the depth and direction of the inclined plane body; the leading-in head is located below the anchoring unit, and thebottom of the leading-in head is a conical head, so it is guaranteed that the whipstock smoothly descends into a casing cutting opening. The whipstock achieves the reutilization of an abandoned well groove, and effectively solves the problem that an inner-layer casing pipe is not centered; the longitudinal groove and the transverse groove provide guidance for the waterproof guide pipe and a drilling tool, and the risks of well hole finding and orientation deviation are avoided.

Owner:CHINA NAT OFFSHORE OIL CORP +1

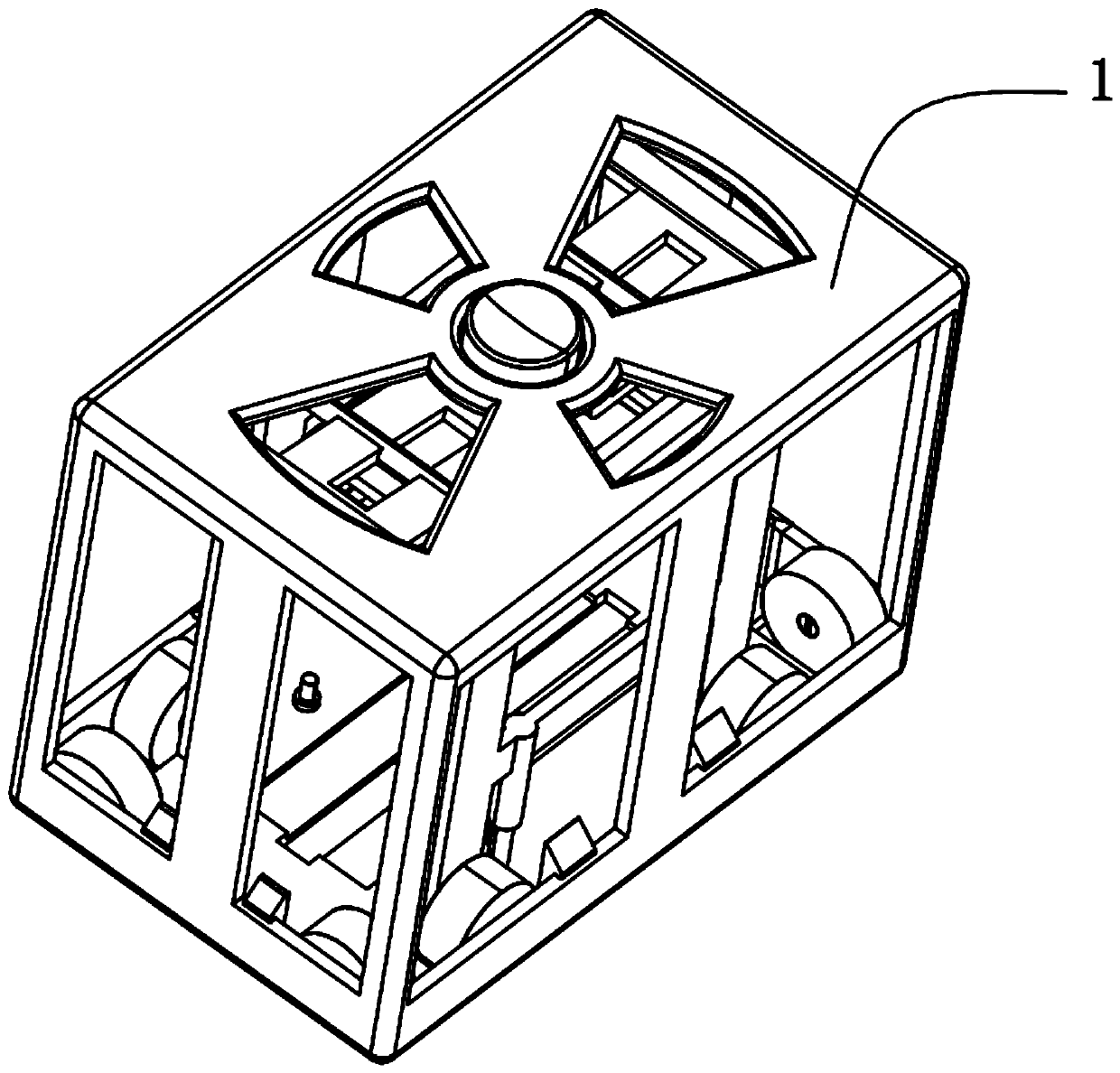

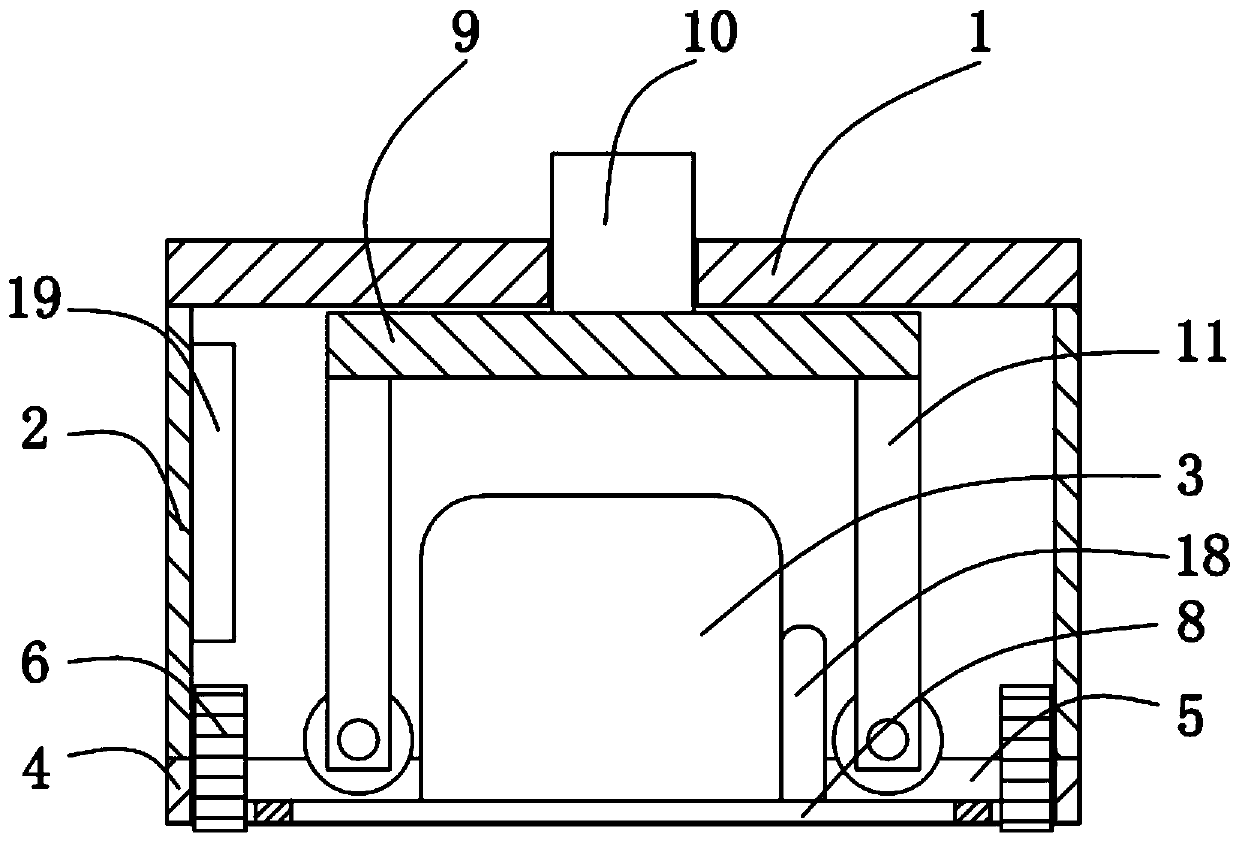

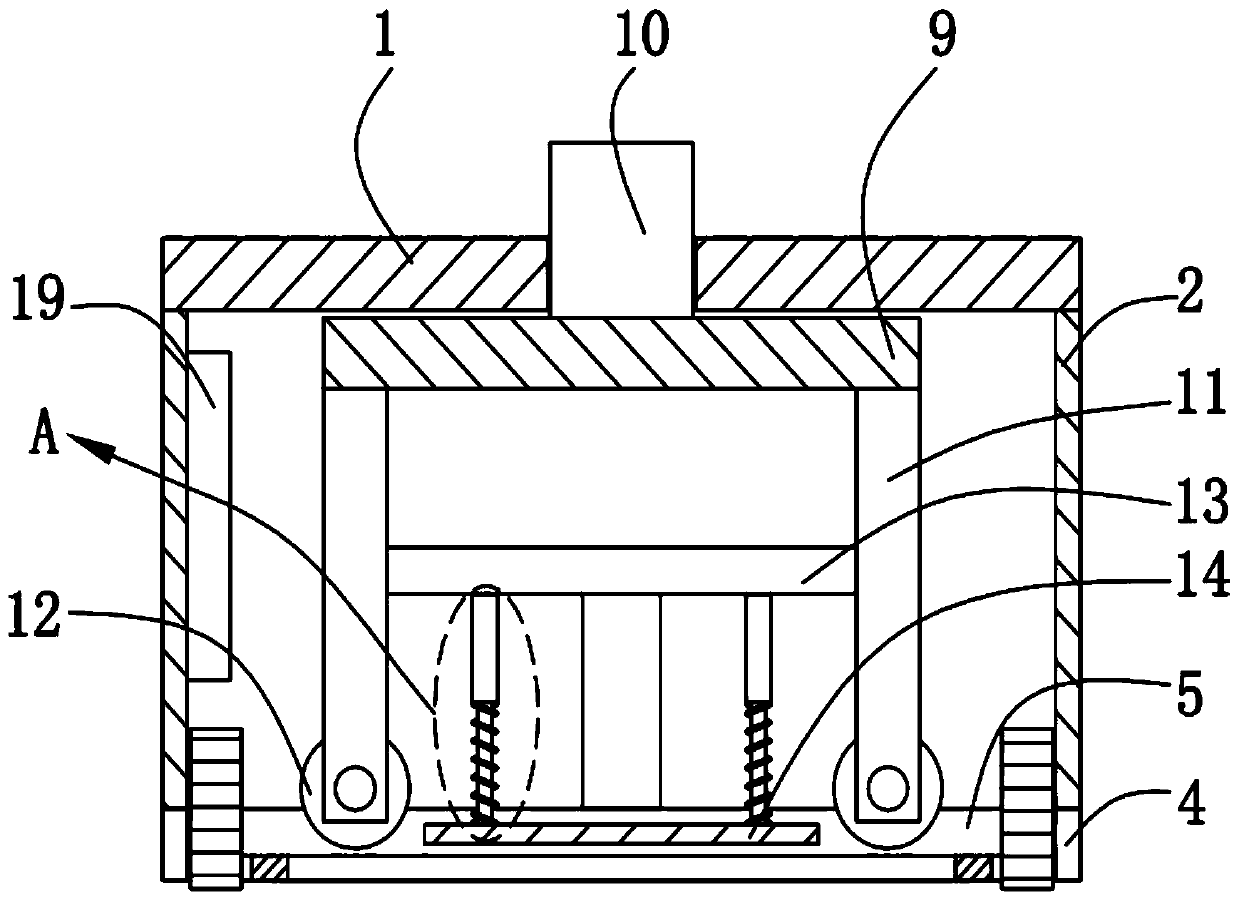

Eight-station jack assembling machine

ActiveCN111168378AWork resistance is smallImprove disassembly efficiencyAssembly machinesMetal working apparatusElectric machineryEngineering

The invention relates to an eight-station jack assembling machine, which comprises a jack assembling machine. The jack assembling machine is slidably arranged on a track, and a motor arranged at one end of the track drives the jack assembling machine to slide on the track through a chain belt; and the eight-station jack assembling machine further comprises a cylinder body positioning mechanism arranged at the lower part of a head of the jack assembling machine and comprising a first positioning mechanism and a second positioning mechanism, the first positioning mechanism and the second positioning mechanism have the same structure except for different frame heights, and frames with different heights are used for positioning jacks with different specifications. According to the eight-station jack assembling machine, when a vertical assembly jack is adopted, the working resistance is small, the disassembly efficiency is high, and the disassembly reliability is high; the cylinder body positioning mechanism adopts an eight-station structure, and has functions of cylinder bottom positioning and cylinder top centralization; and cylinder bottom fixation ensures that a cylinder body does not rotate in the process of guide sleeve assembly, and cylinder top centralization ensures that the cylinder body is in a vertical state in the process of movable column and guide sleeve assembly.

Owner:阳泉煤业华益机械有限公司

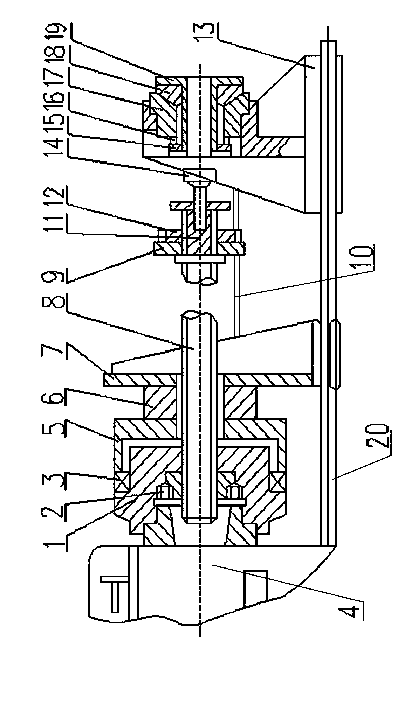

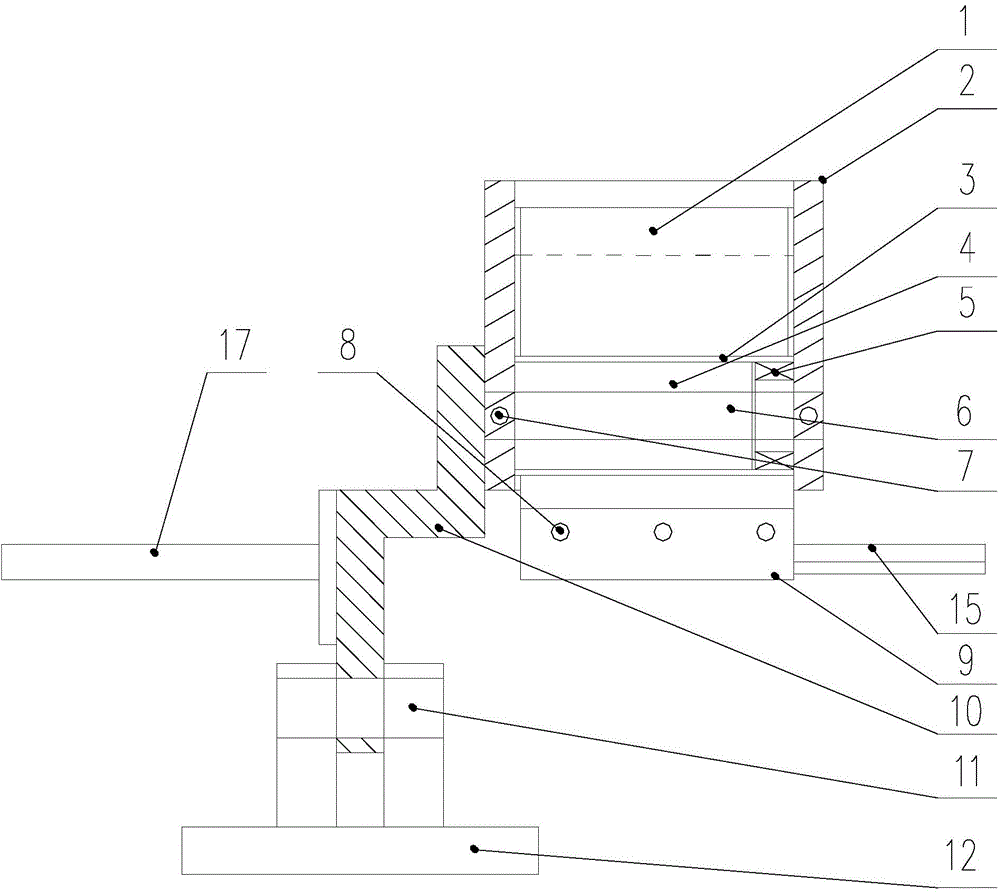

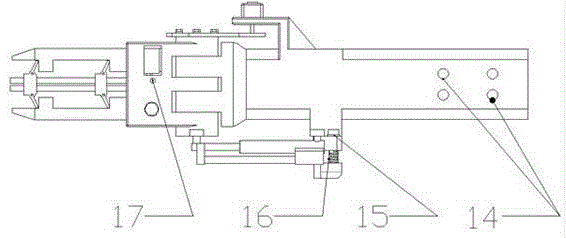

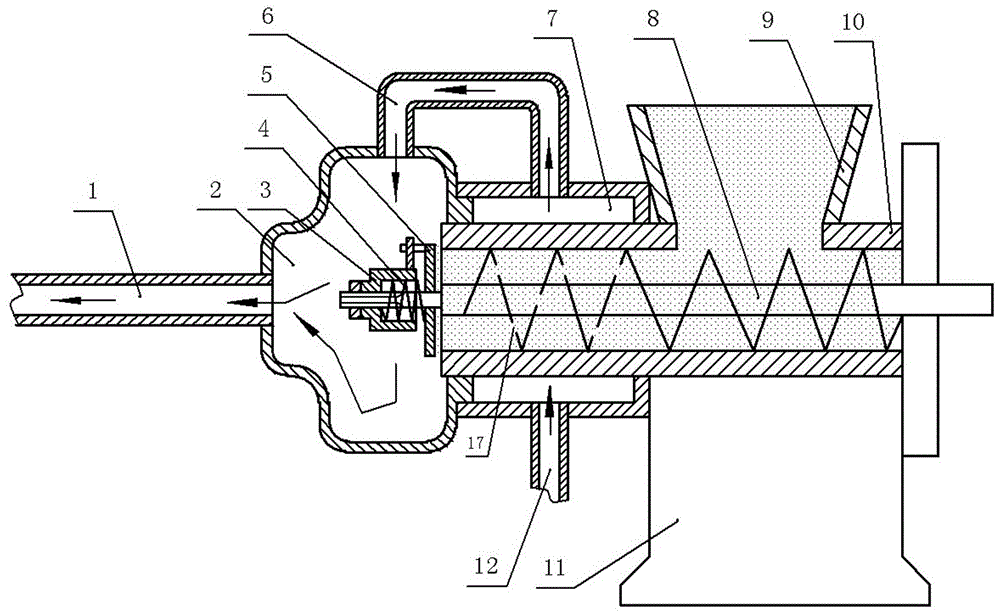

Broaching device for lathe

InactiveCN103433512AGuaranteed not to rotateCompensation errorAutomatic/semiautomatic turning machinesBroaching machinesReciprocating motionEngineering

The invention provides the technical scheme of a broaching device for a lathe. According to the technical scheme, the broaching device for the lathe comprises a lathe support and a lathe main shaft, wherein a front support is arranged on the lathe main shaft, a rear support is further fixed to the lathe support, a lead screw and a first nut which is meshed with the lead screw are arranged on the front support, the first nut is fixed to the lathe main shaft, a broach clamping head is fixed to the end, away from the first nut, of the lead screw, a positioning sleeve is arranged on the rear support, a spherical ring is arranged outside the positioning sleeve, and a spherical support is arranged outside the spherical ring. According to the technical scheme, the rotational motion of the lathe is converted into the linear reciprocating motion through lead screw connection so that the broaching function can be achieved, the lathe main shaft is guaranteed to output the torque and not to bear tension force through a positioning support and is guaranteed to be easy to detach, the broaching device is used for various ordinary lathes, and therefore the efficient broaching function is achieved.

Owner:JIGANG GRP

Sewing machine

ActiveCN105586725ASimple structureGuaranteed not to rotateLubrication/cooling devicesWorkpiece carriersSewing machineEngineering

The invention provides a sewing machine, and belongs to the technical field of sewing. The sewing machine solves the problem that the heating and clamping phenomena are likely to happen on a guiding component between a cutter holder and a machine head of an existing sewing machine. The sewing machine comprises a machine head and a cutter holder located on the lower side of the machine head. A presser bar guiding sleeve is fixedly arranged inside the machine head. A guiding base arranged on the guiding sleeve in a sleeving mode is arranged inside the machine head. A cutter bar is fixedly arranged on the cutter holder. The upper end of the cutter bar penetrates into the machine head and is fixedly connected with the guiding base. According to the sewing machine, it is ensured that the cutter bar does not rotate and a cutter fixed to the cutter holder is operated stably. Lubricating oil for lubricating a needle bar, a presser bar and other components is contained inside the machine head of the sewing machine, obviously, the lubricating oil can also lubricate and cool a gap between the guiding base and the presser bar guiding sleeve and a gap between the cutter bar and the machine head in an auxiliary mode, the sewing machine can be operated at high speed for a long time, and it is still ensured that the guiding base and the cutter bar are operated stably. The advantage that the structure of the sewing machine is simplified is achieved due to the fact that the guiding base achieves guiding through the presser bar guiding sleeve.

Owner:曹卫明

Mechanical false stepping prevention accelerator device

InactiveCN104354594ASimple structureEasy to installAutomatic initiationsPropulsion unit arrangementsEngineeringMechanical engineering

The invention relates to a mechanical false stepping prevention accelerator device which comprises a main body, a fixed block, a brake pressure block, a main body bracket, a knurling pressure shaft, a fastening belt, an adjustable clamping block and a rotating device. One end of the main body bracket is fixed on an upright baffle positioned on the right side of the main body; the other end of the main body bracket is rotationally connected with the upper part of the fixed block; one end of the brake pressure block is fixedly connected with the middle part of the main body bracket and the brake pressure block and the main body are respectively positioned on both sides of the main body bracket; the knurling pressure shaft is arranged between the upright baffles on both sides of the upper part of the main body; the two ends of the knurling pressure shaft can slide along chutes; the knurling pressure shaft slides to the adjustable clamping block along the chutes to be blocked; and one end of the fastening belt is fixed on the rotating device and the other end of the fastening belt is fixedly connected with an accelerator pedal shaft. The mechanical false stepping prevention accelerator device has a simple structure, is convenient to install, has stable performance and can still implement an emergency braking effect when a driver uses an accelerator pedal as a brake pedal for carrying out emergency braking under the emergency condition so as to avoid causing a major casualty accident.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

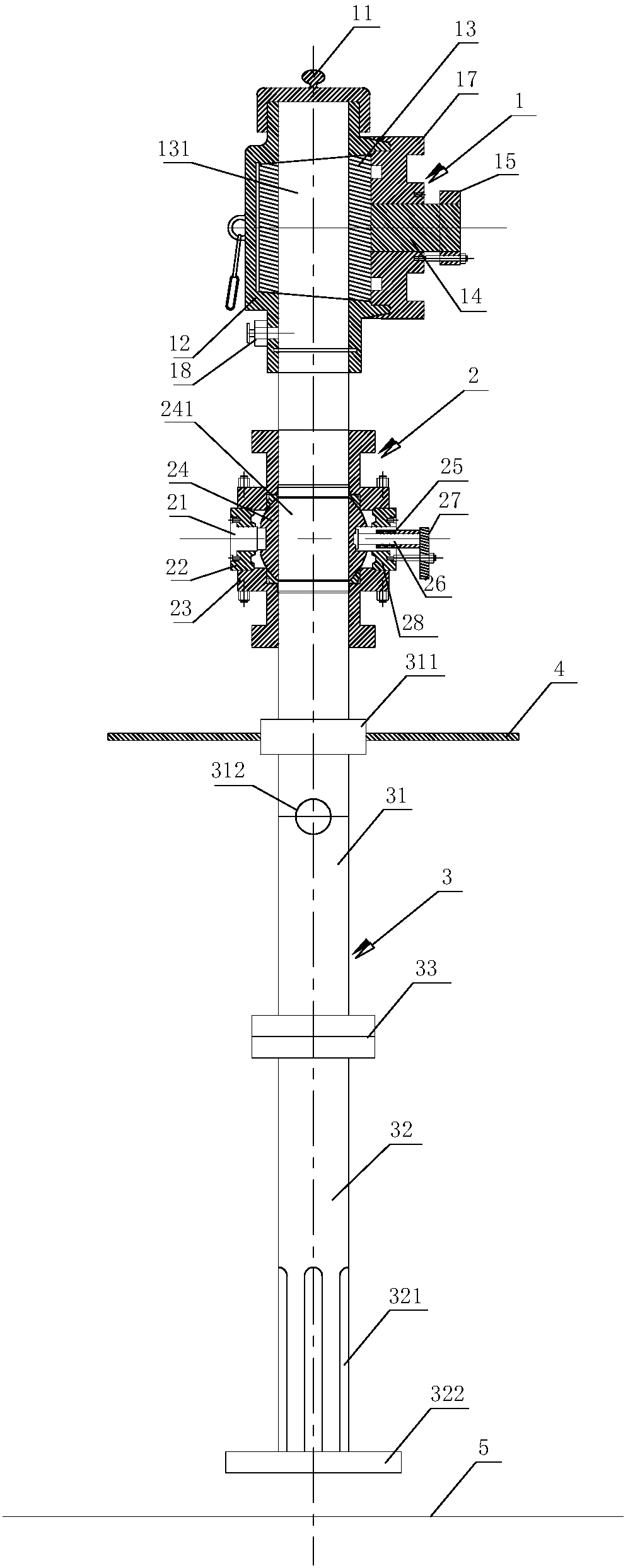

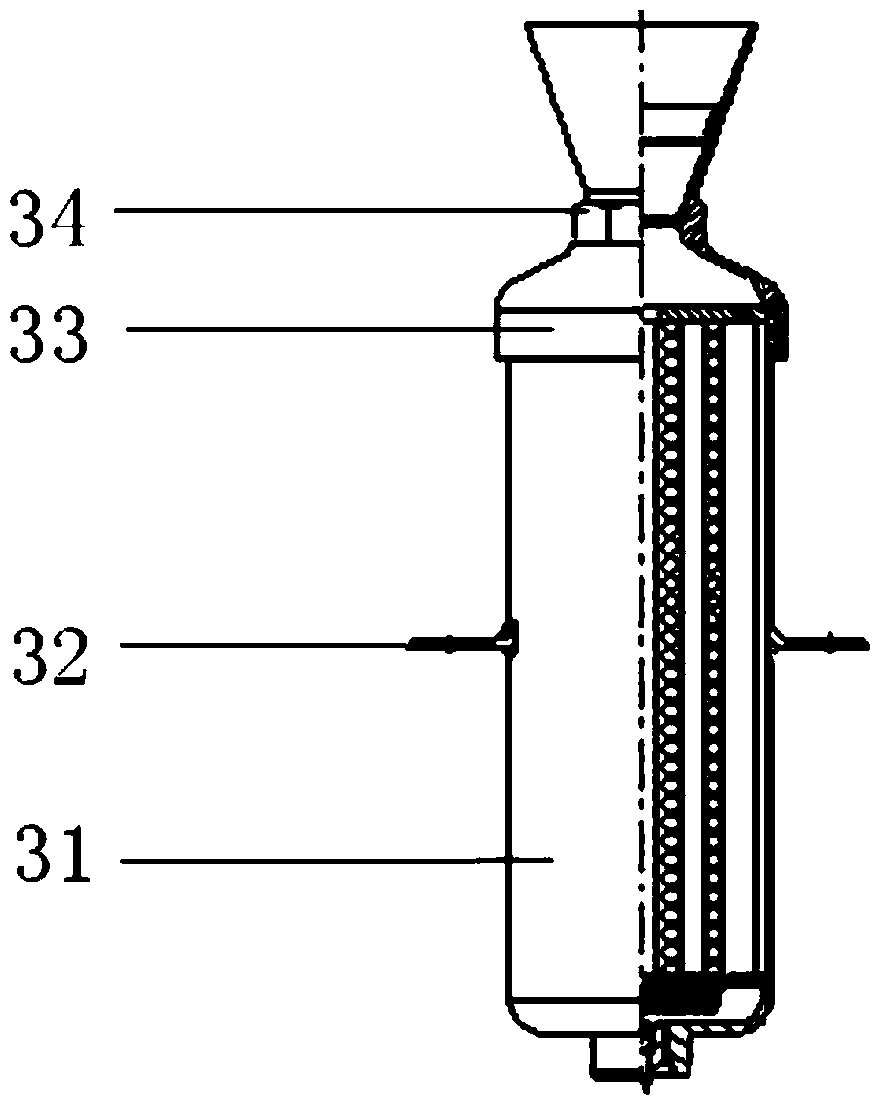

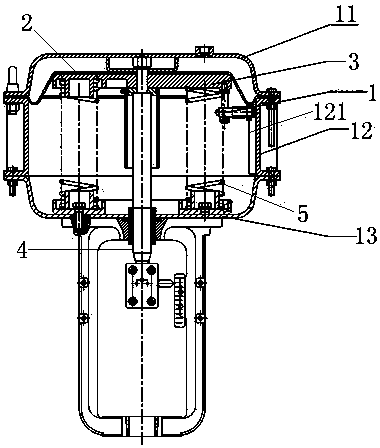

Marine nuclear power platform sounding device and sounding method thereof

ActiveCN108266547AGuaranteed watertightnessGuaranteed damage stabilityPlug valvesWaterborne vesselsNuclear powerStopcock

The invention discloses a marine nuclear power platform sounding device and relates to the technical field of liquid tank sounding devices. The sounding device comprises a sounding self-closing valve,a ball valve and a sounding pipe which are connected from top to bottom in sequence. The sounding self-closing valve comprises a self-closing valve seat, a plug cock, a valve shaft and a self-closingvalve handle. The self-closing valve seat is provided with a vertical through hole. The plug cock is located in the self-closing valve seat. The plug cock is provided with a first communicating hole.The two ends of the valve shaft are connected with the plug cock and the self-closing valve handle. The ball valve comprises a ball valve seat, a ball body, a valve rod and a ball valve handle. The ball valve seat is provided with a vertical through hole. The ball body is located in the ball valve seat. The ball body is provided with a second communicating hole. The two ends of the valve rod areconnected with the ball body and the ball valve handle. A sounding method comprises the steps of turning on the sounding self-closing valve, turning on the ball valve and measuring the depth. Throughthe marine nuclear power platform sounding device and the sounding method thereof, the requirement for water tightness of an opening of the upper end of the sounding pipe can be met.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

Automatic restoring channel gate bumper

InactiveCN105625215ALight in massHigh hardnessTraffic restrictionsProtection systemElectrical and Electronics engineering

The invention relates to an automatic restoring channel gate bumper which is characterized by comprising a framework, an automatic response system, an anticollision system, a variable clamping system and a safe protection system. By virtue of the design, compared with a conventional bumper, the channel gate bumper has the advantages that the channel gate bumper can avoid collision bidirectionally and restore automatically, a channel brake bar is convenient to mount and replace, and the automatic restoring channel gate bumper is good in adaptability, safe and reliable to use, good in development property and the like.

Owner:青岛工学院

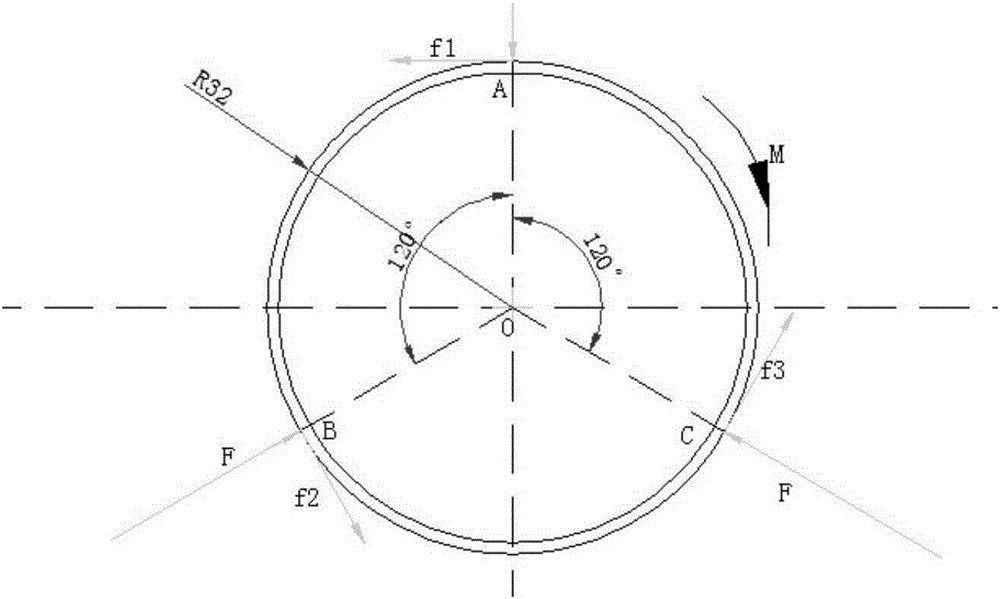

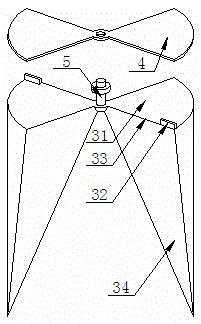

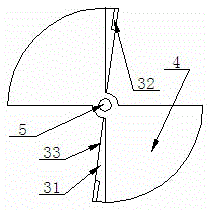

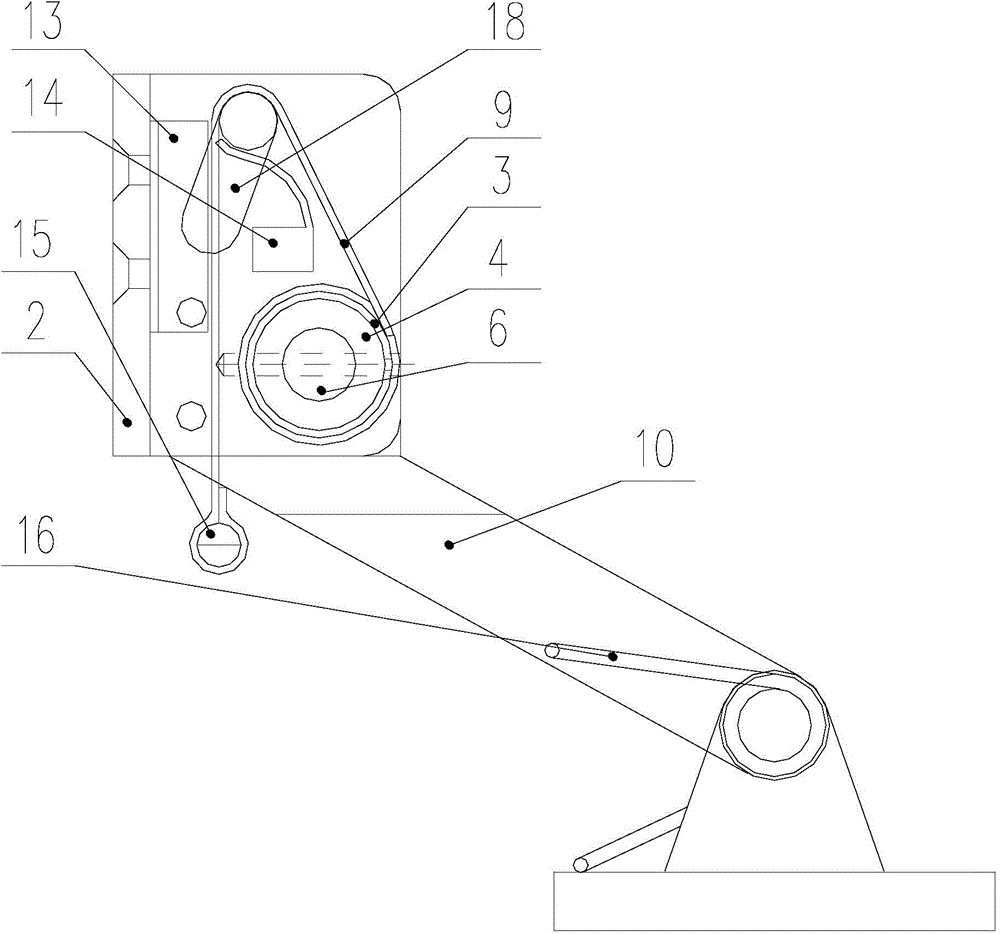

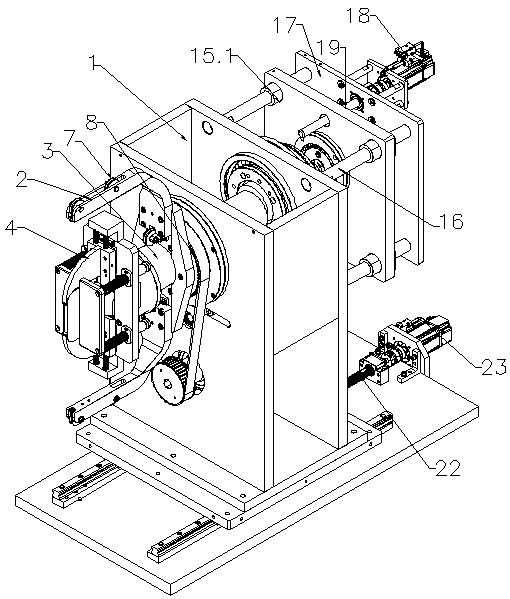

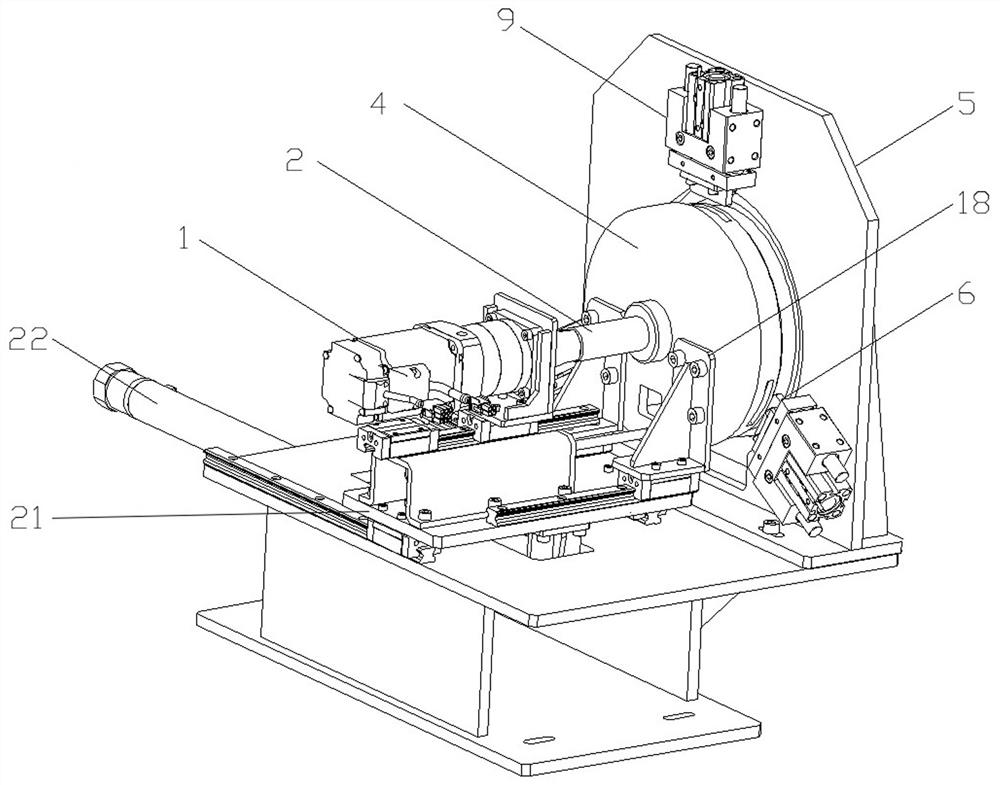

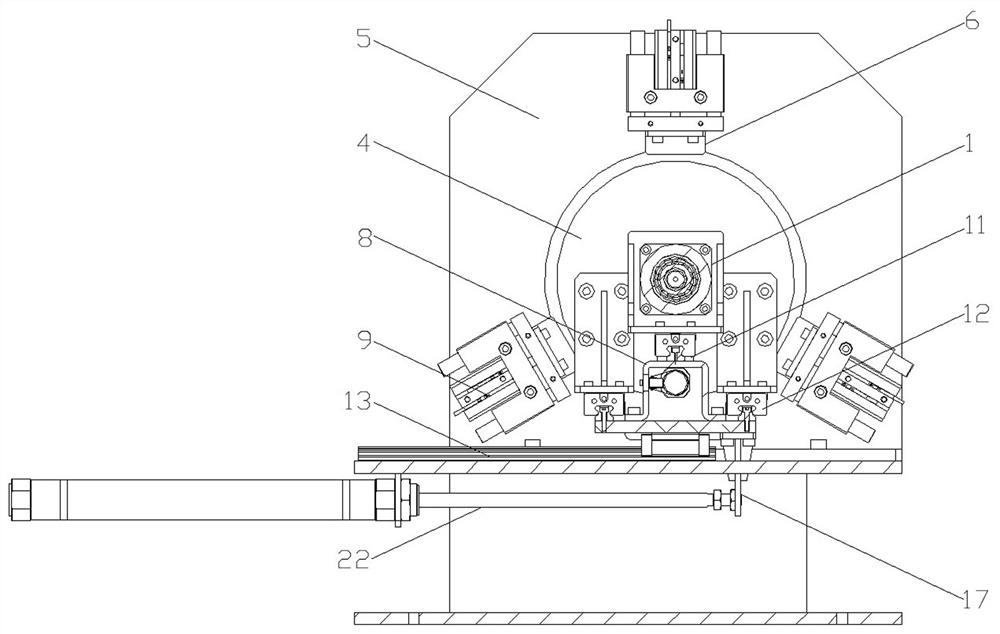

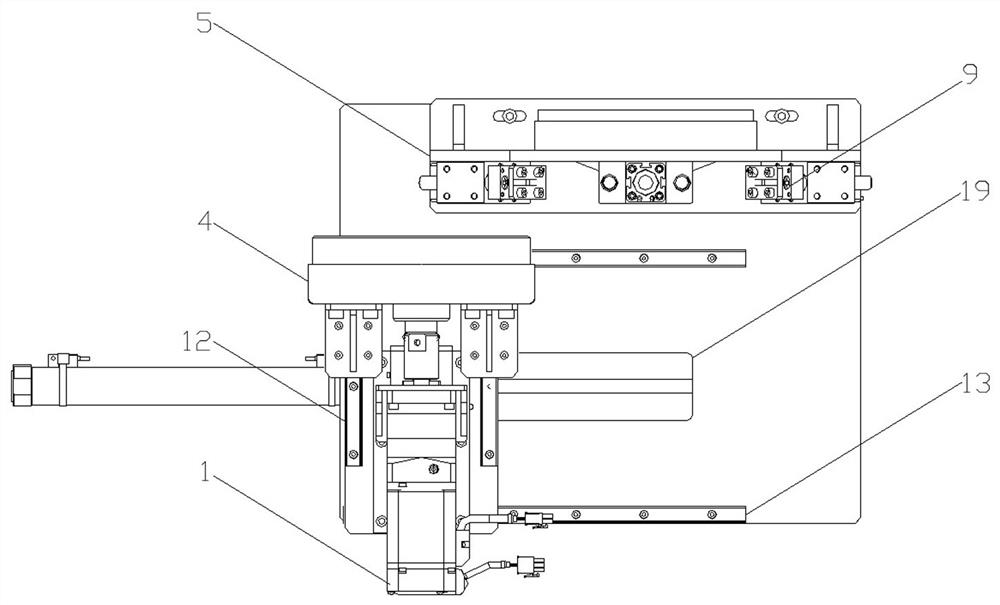

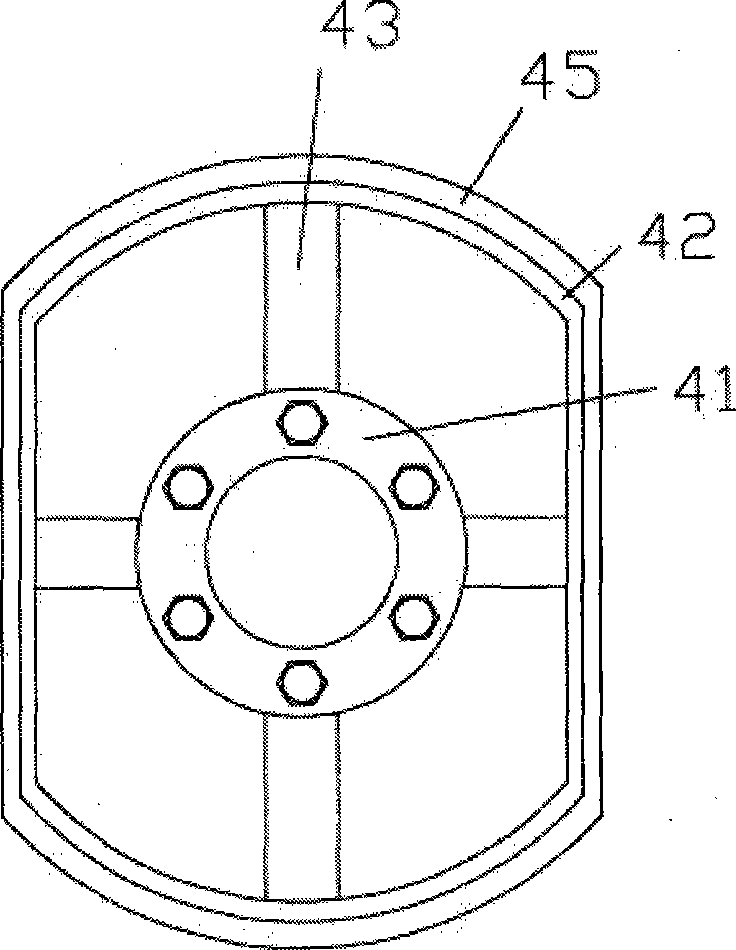

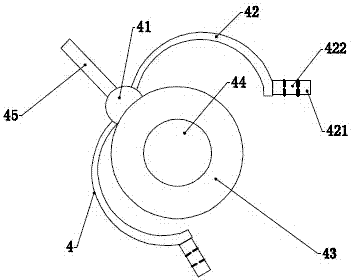

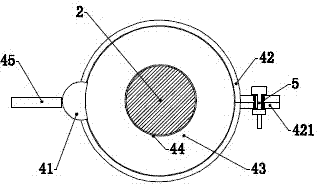

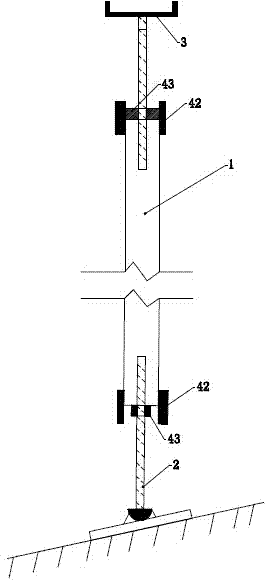

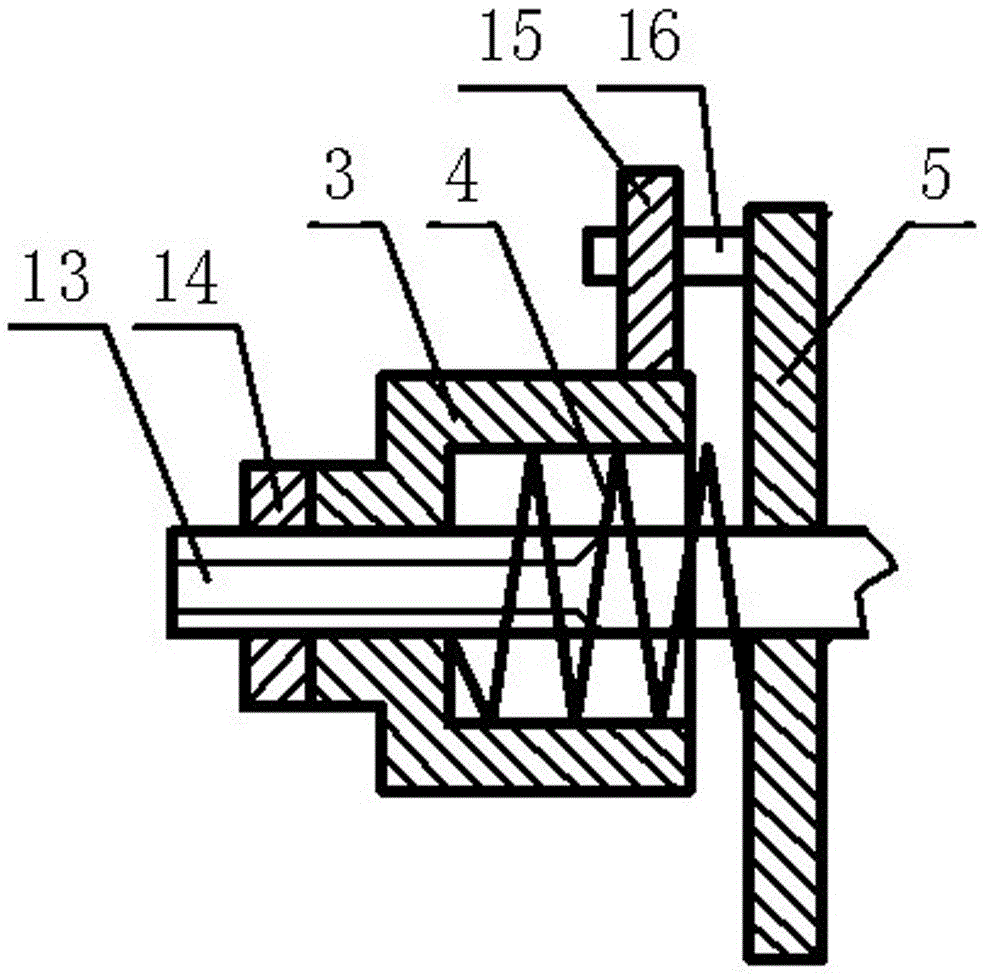

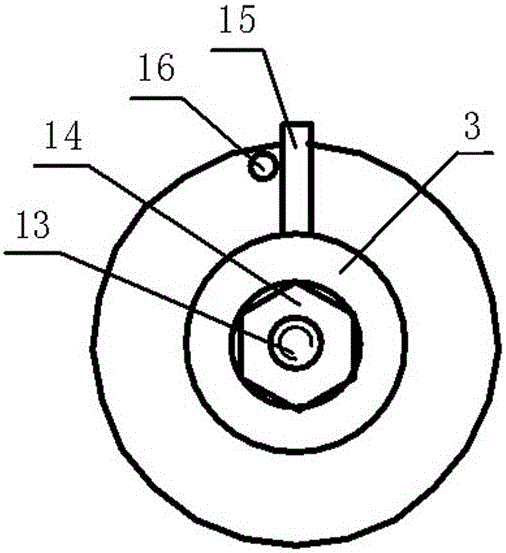

Flying fork winding mechanism of eccentric shaft positioning middle protection claw

ActiveCN111262401AAchieve positioningWind evenlyManufacturing dynamo-electric machinesWinding machineRotation - action

The invention discloses a flying fork winding mechanism of an eccentric shaft positioning middle protection claw, which comprises a base, a flying fork mechanism and a protection claw module, whereinthe flying fork mechanism comprises a flying fork rod, a flying fork main shaft and a first driving mechanism for driving the flying fork main shaft to rotate, and the flying fork main shaft is a hollow shaft; an eccentric shaft module and an eccentric rod module which do not rotate along with the flying fork main shaft are also fixed on the base; an eccentric shaft in the eccentric shaft module penetrates through the hollow flying fork main shaft and then positions the protection claw module, and an eccentric rod in the eccentric rod module penetrates through the hollow eccentric shaft and then pushes the protection claw module to act under the driving of a second driving mechanism. The flying fork winding mechanism is very reasonable in structural design and more accurate compared with an existing structure, wound motor stator coils are continuous, uniform and gapless, and the flying fork winding mechanism is particularly suitable for winding external rotor motor stators and straightbar stators.

Owner:周长松

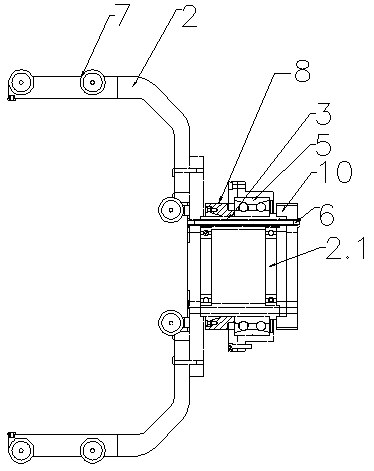

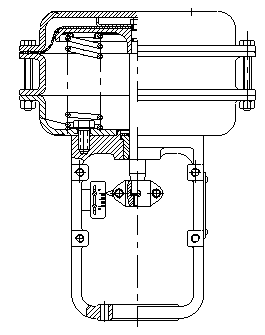

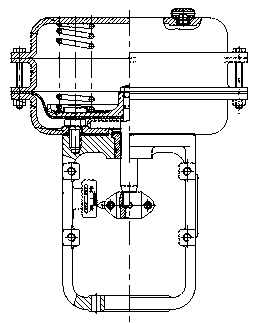

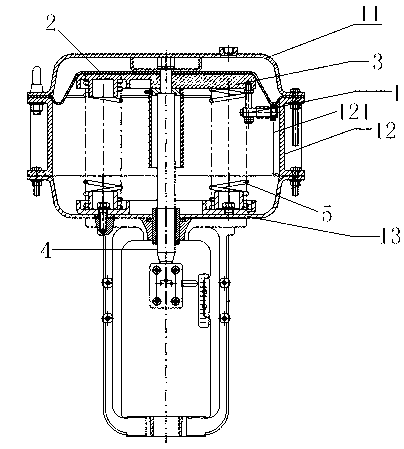

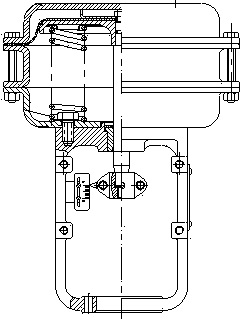

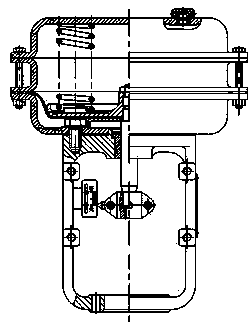

Pneumatic thin film performing mechanism with built-in type anti-rotating device

ActiveCN103104741APrevent rotationAvoid breakingOperating means/releasing devices for valvesEngineering

The invention discloses a pneumatic thin film performing mechanism with a built-in type anti-rotating device. The performing mechanism comprises a film cover component, a membrane, a tray, an elastic element and a push bar, wherein the membrane is fixed on the inner side of the film cover component, the tray is fixed on membrane, two ends of the elastic element are respectively connected with the film cover component and the tray, one end of the push bar is fixed on the tray, and the other end of the push bar penetrates through the film cover component and is exposed outside the film cover component. The pneumatic thin film performing mechanism is further provided with the built-in type anti-rotating device. The film cover component comprises an upper film cover, a connecting pipe and a lower film cover, wherein the upper film cover, the connecting pipe and the lower film cover are sequentially connected, and an anti-rotating guide component used for limiting a moving track of the built-in type anti-rotating device is arranged on the inner side of the connecting pipe. One end of the built-in type anti-rotating device is fixedly connected to the tray, and the other end of the built-in type anti-rotating device is connected with the anti-rotating guide component. The built-in type anti-rotating device can move along a track limited by the anti-rotating guide component. The built-in type anti-rotating device is arranged in the pneumatic thin film performing mechanism, not only is travel of the pneumatic thin film performing mechanism not affected, but also the push bar can be prevented from rotating.

Owner:ZHEJIANG SUPCON FLUID TECH

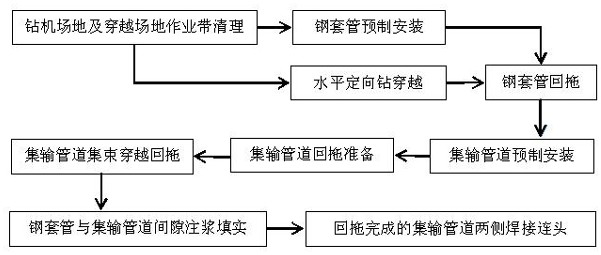

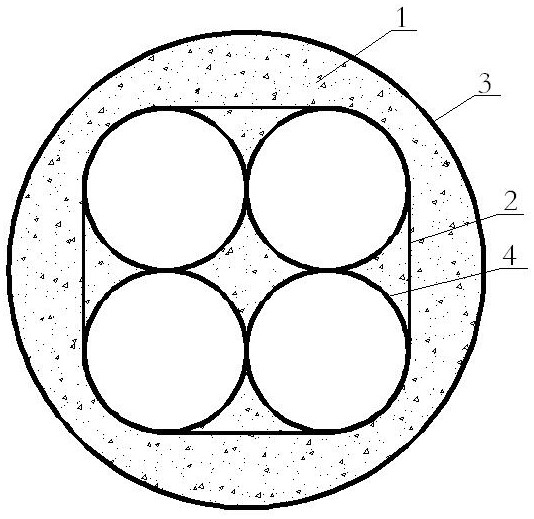

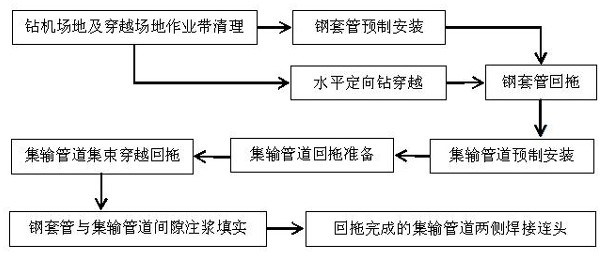

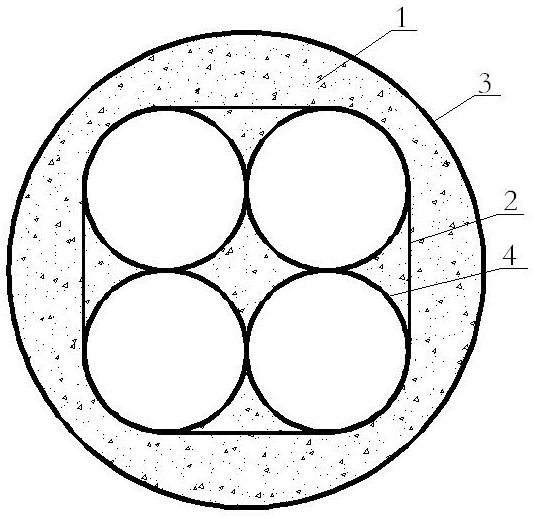

Gathering and transportation pipeline directional drilling bundling laying construction method

ActiveCN111810714AEffectively fixedGuaranteed not to rotatePipe laying and repairHydro energy generationArchitectural engineeringSlurry

The invention discloses a gathering and transportation pipeline directional drilling bundling laying construction method, and belongs to the technical field of gathering and transportation pipeline trenchless crossing. In the gathering and transportation pipeline directional drilling bundling laying construction method provided by the invention, firstly, dragging back a steel sleeve through a modeof horizontal directional drilling, then, a gathering and transportation pipeline is enabled to pass through in the steel sleeve through a mode of gathering and transportation, thus, trenchless crossing of the gathering and transportation pipeline is completed, further, a gap between the steel sleeve and the gathering and transportation pipeline is fully filled with grout, and finally, a weldinghead connection work for the gathering and transportation pipeline is completed. The construction method provided by the invention can drag back the gathering and transportation pipeline through the mode of gathering and transportation, thus, a work of passing through a river can be realized successfully, the whole dragging back and passing through process is smooth, a drag-back sleeve is connected with a cardan joint, a pipe bundle is guaranteed to be not twisted in the steel sleeve, the gathering and transportation pipeline and the sleeve are consistent in a guiding curve, an anti-corrosionlayer of the gathering and transportation pipeline is not liable to be damaged, after dragging back and passing through, the gap between the steel sleeve and the bundling pass-through gathering and transportation pipeline is filled with cement grout so as to be solid, and safety during a period of pipeline operating is guaranteed more.

Owner:SINOPEC NANJING ENG & CONSTR +1

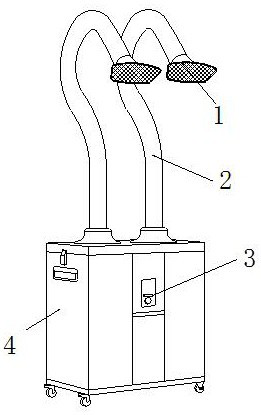

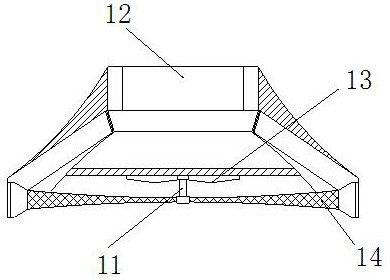

Environment-friendly range hood for smart home

InactiveCN112032794AAvoid affecting actual trafficGuaranteed not to rotateDomestic stoves or rangesLighting and heating apparatusEngineeringStructural engineering

The invention discloses an environment-friendly range hood for smart home. The environment-friendly range hood structurally comprises a sucking head, a communicating pipe, a control center and an equipment cabin; the sucking head is fixedly installed at the tail end of the communicating pipe in an embedded mode, the communicating pipe is installed on the outer end face of the upper side of the equipment cabin in a welded mode, the control center is embedded in the outer side end face of the equipment cabin, and the equipment cabin is embedded under the sucking head. Due to the fact that a converging opening and a supporting mechanism are arranged in a flow guiding opening, in the rotating process of a filter screen mechanism, movable clamping between the converging opening and the supporting mechanism can be formed by embedding a groove formed by the outer contour of the embedding and fixing block and a containing groove, and air can be driven into the containing groove through centrifugal force on the premise that rotation of the filter screen mechanism is not limited, the situation that when the equipment is used in a kitchen, smoke and grease particles adhere to the surface of the sucking head, and consequently the actual air sucking flow of the equipment is affected is avoided.

Owner:广州国智机电设备有限公司

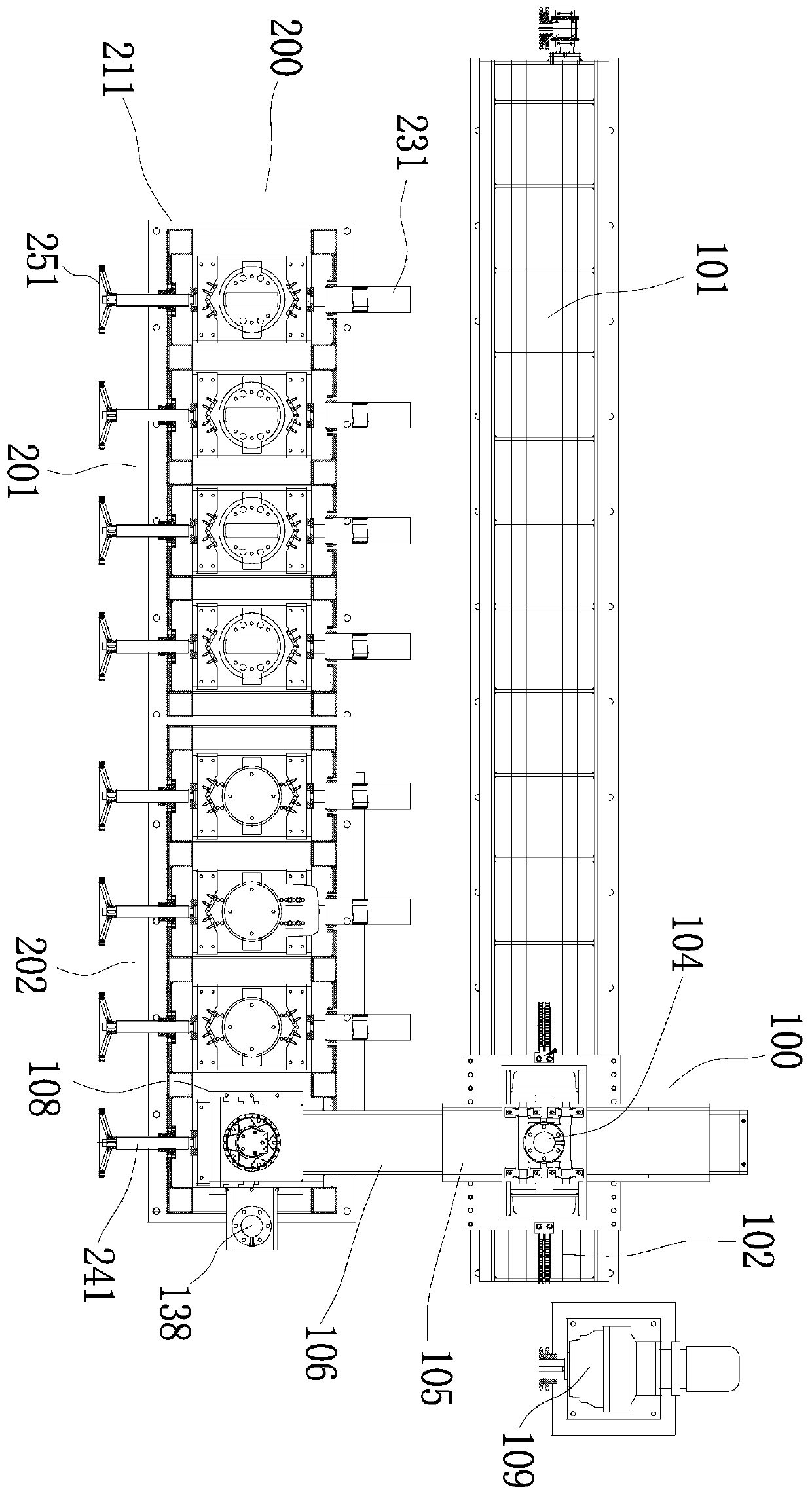

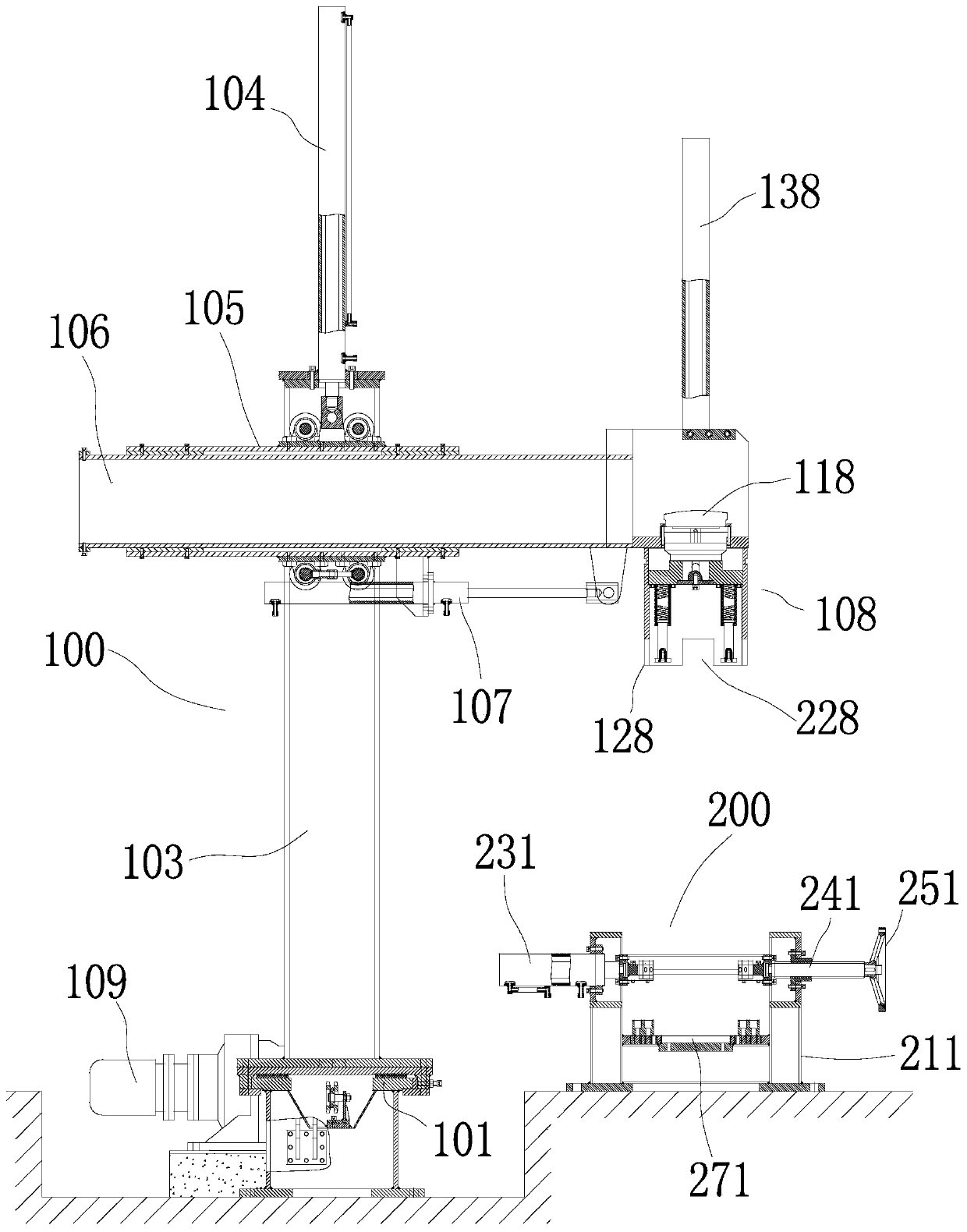

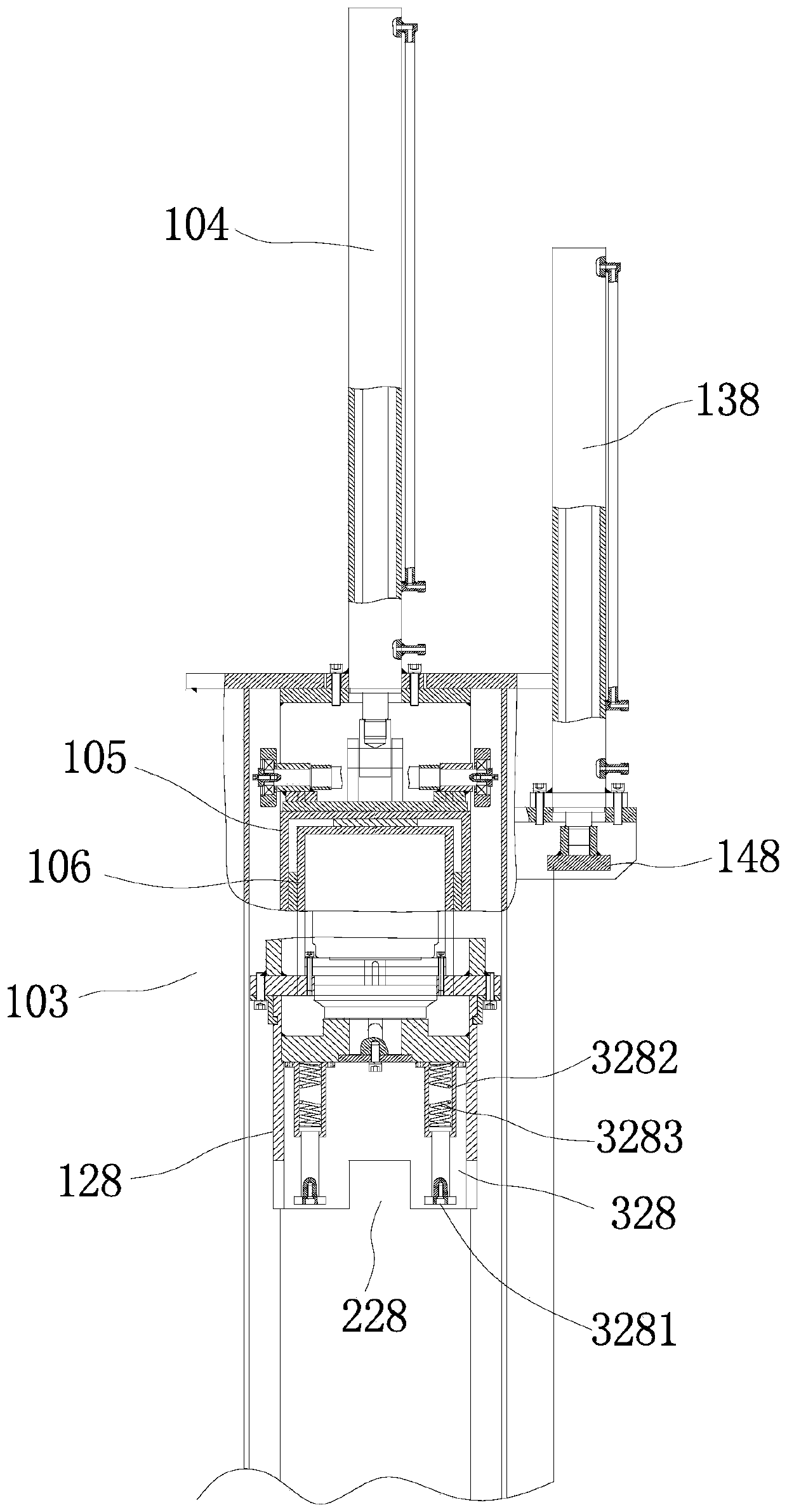

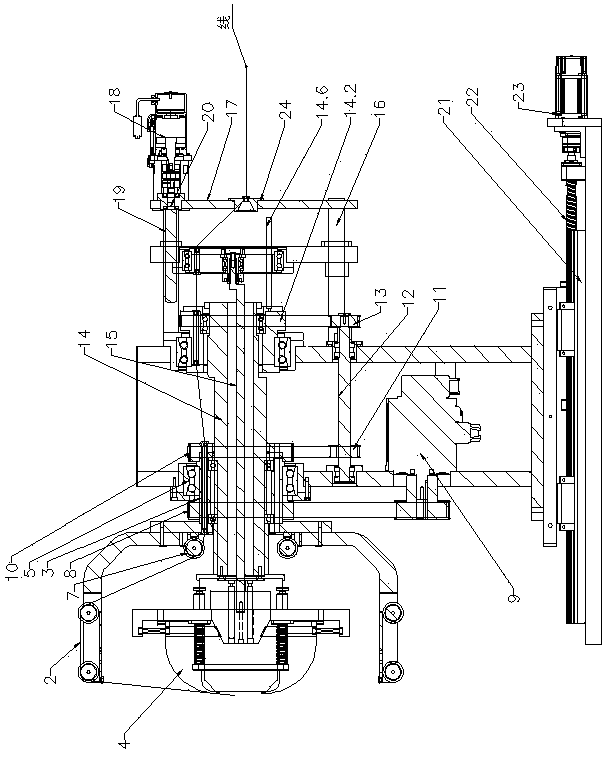

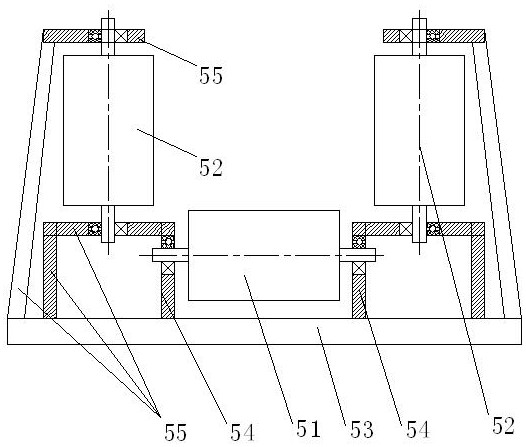

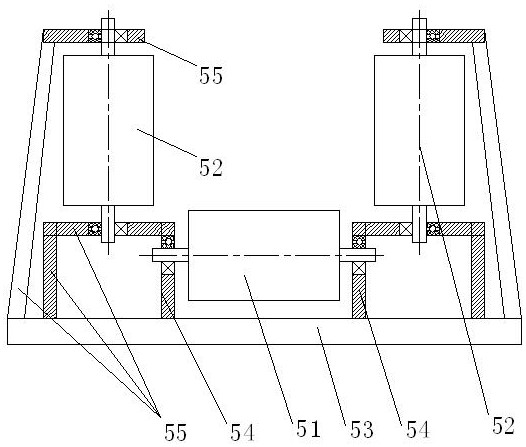

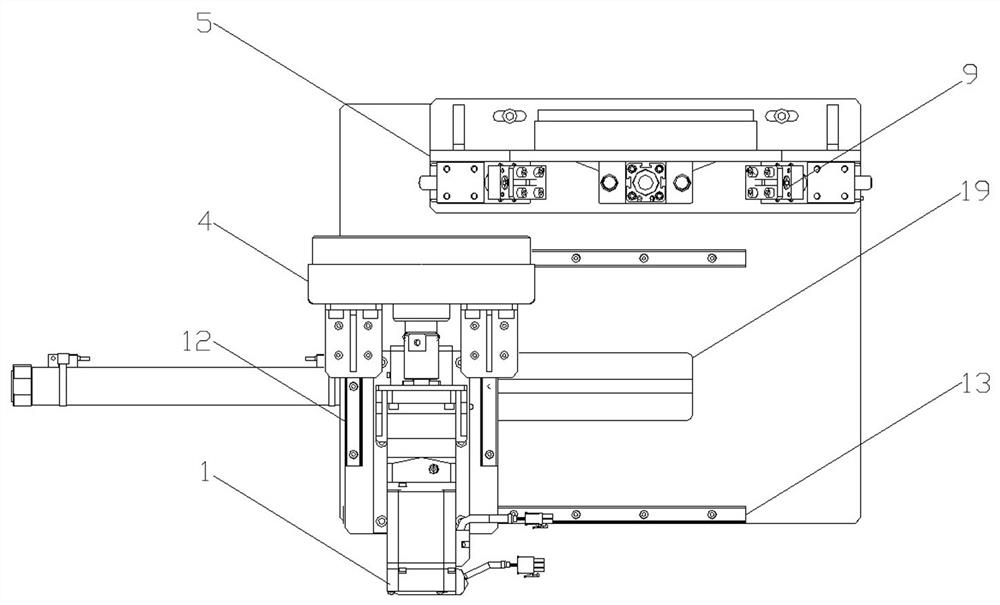

Large-diameter end cover propelling mechanism, assembling method and press-fitting tightening equipment

ActiveCN113118747ALabor savingReduce labor intensityMetal working apparatusElectric machineryEngineering

The invention discloses a large-diameter end cover propelling mechanism, an assembling method and press-fitting tightening equipment. The large-diameter end cover propelling mechanism comprises a press-fitting assembly and a positioning assembly, the press-fitting assembly provides propelling force to propel an end cover to enter a press-fitting end of a barrel, the press-fitting assembly comprises a press-fitting motor, a connecting screw and a screw block, one end of the connecting screw is connected with a power output shaft of the press-fitting motor, and the other end of the connecting screw is connected with the screw block; and the positioning assembly is used for fixedly connecting an end cover positioning seat and the barrel and comprises an end plate and the end cover positioning seat, the end plate is located at one end of the barrel, a through hole for the end cover and the end cover positioning seat to penetrate through is formed in the center of the end plate, and a positioning insertion block for integrally connecting the end cover positioning seat and the barrel is installed on the end plate on the outer edge of the through hole. The large-diameter end cover propelling mechanism has the advantages that the end cover can be automatically grabbed, a tool can be automatically placed, the tool can be automatically propelled and jacked, meanwhile, threaded parts can be automatically centered, automatic assembly is achieved under the condition that the coaxiality is guaranteed, manpower is reduced, the labor intensity is lowered, and therefore the working efficiency is improved.

Owner:HENAN UNIV OF SCI & TECH

Novel ink-jet printer

PendingCN110356113AGuaranteed not to rotateReduce volumeTypewritersPower drive mechanismsEngineeringParallel motion

The invention provides a novel ink-jet printer. The novel ink-jet printer comprises a first mounting plate, a bottom plate, a longitudinal traveling mechanism, a transverse traveling mechanism and a control assembly,wherein the bottom plate is arranged below the first mounting plate,the longitudinal traveling mechanism is arranged below the first mounting plate,the transverse traveling mechanism is arranged below the first mounting plate, the control assembly is arranged on one side of the longitudinal traveling mechanism. The novel ink-jet printer does not need a paper advancemechanism, so that the size is greatly reduced, the carry is convenient and the novel ink-jet printer can directly conduct parallel motion on a printing carrier, can print on carriers with any size almost, and can print on more kinds of carriers.

Owner:安奉阳

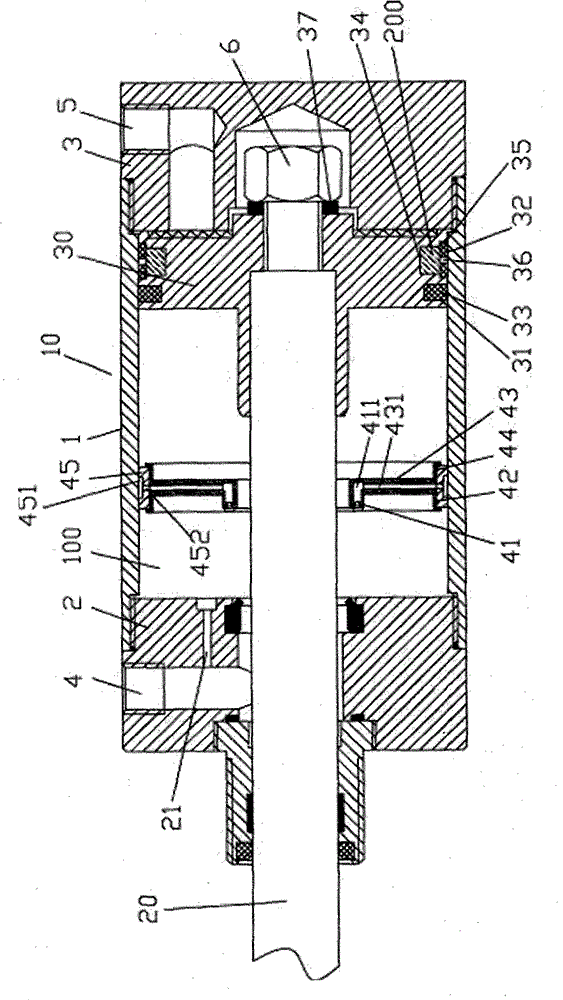

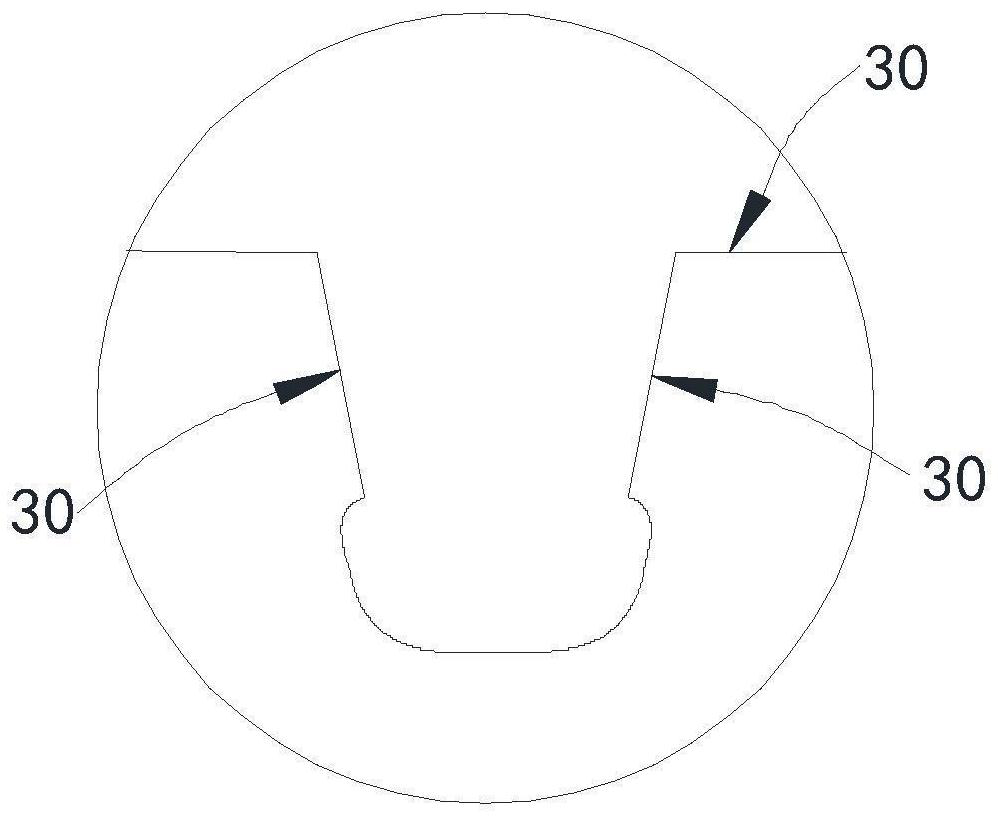

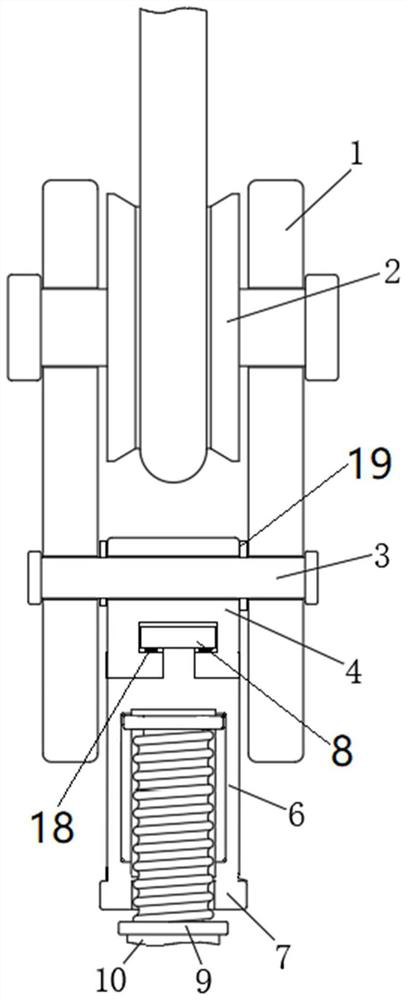

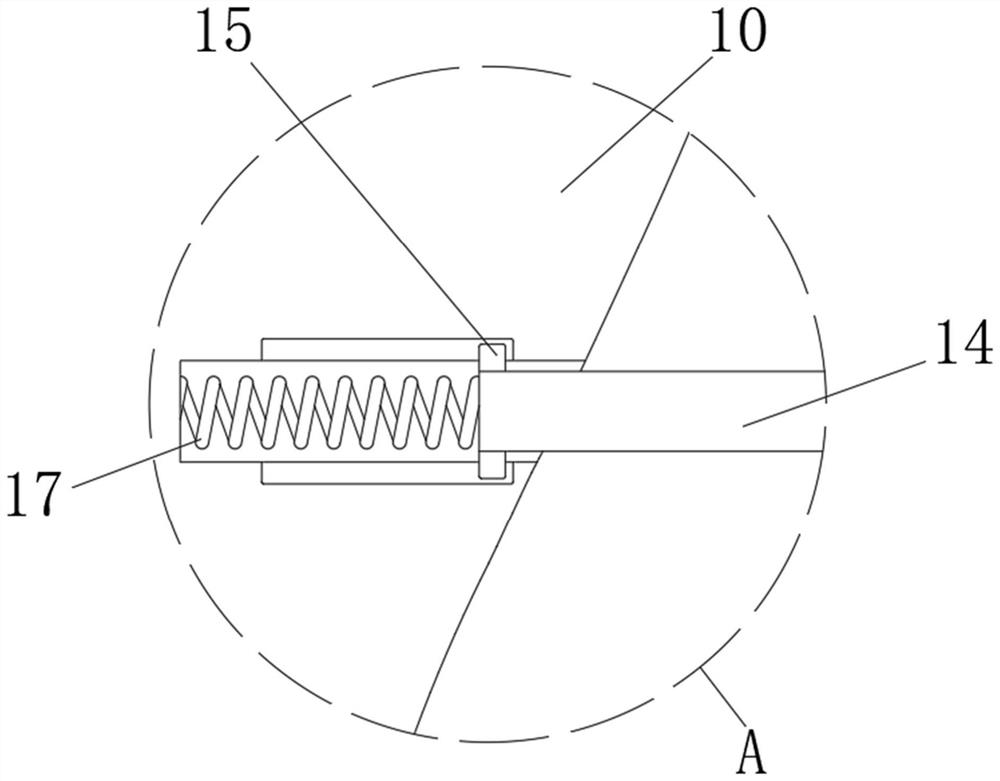

Air cylinder with non-rotatable piston and non-rotatable piston rod

InactiveCN105090156AGuaranteed not to rotateGuaranteed uptimeFluid-pressure actuatorsEngineeringCylinder block

The invention discloses an air cylinder with a non-rotatable piston and a non-rotatable piston rod. The air cylinder comprises a cylinder block (10) and the piston rod (20) arranged in the cylinder block (10), wherein a cylindrical inner cavity (100) is formed in the cylinder block (10), the piston (30) is fixed to the piston rod (20), the outer surface of the piston is closely attached to the side wall of the inner cavity (100) of the cylinder block (10), and the cross section of the inner cavity (100) and the cross section of the piston (30) are both in the shape of a kidney-shaped hole. The air cylinder with the non-rotatable piston and the non-rotatable piston rod operates smoothly and is balanced in wear, it is guaranteed that the piston and the piston rod cannot rotate, the using requirement in specific occasions is met, and the inner wall of a barrel body can be continuously oiled for lubrication so that wear can be reduced.

Owner:FENGHUA KAINA AUTOMATION MACHINERY

Jacking system for fixing scaffold

ActiveCN104727542AAdjustable installation heightGuaranteed not to rotateScaffold accessoriesArchitectural engineeringSteel tube

The invention discloses a jacking system for fixing a scaffold. The jacking system for fixing the scaffold comprises a steel tube, vertical rods and supporting plates, wherein the steel tube and the vertical rods are vertically arranged, and the supporting plates are mounted at the tail ends of the vertical rods. The vertical rods are provided with threads, and one ends of the vertical rods are sleeved with the steel tube. The jacking system for fixing the scaffold further comprises adjustable mounting supports which are mounted at the upper end and / or the lower end of the steel tube. Each adjustable mounting support comprises a mounting cylinder, two pinch plates which are symmetrically arranged on the two sides of the mounting cylinder and are semicircular, and a set screw nut which is connected with the mounting cylinder and located in the pinch plates. The pinch plates are rotatably connected to the left sides and the right sides of the mounting cylinders, the tail ends of the pinch plates can be fixedly connected through bolts, and every two pinch plates are closed to be in a cylinder shape to be used for clamping the steel tube. The set screw nuts are matched with the steel tube, and center holes of the set screw nuts are connected with the vertical rods through the threads. According to the jacking system for fixing the scaffold, the stress of the steel tube and the stress of the vertical rods are located on the same central axis, the vertical rods, the steel tube and the supporting plates are connected to form a whole, and the jacking system can be widely applied to supporting different formworks.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

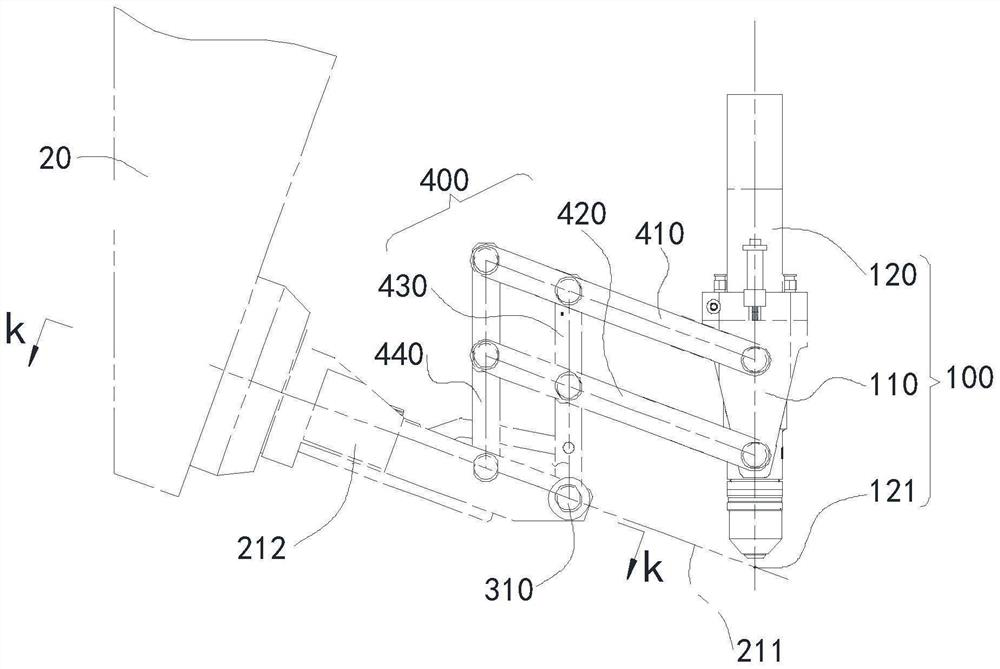

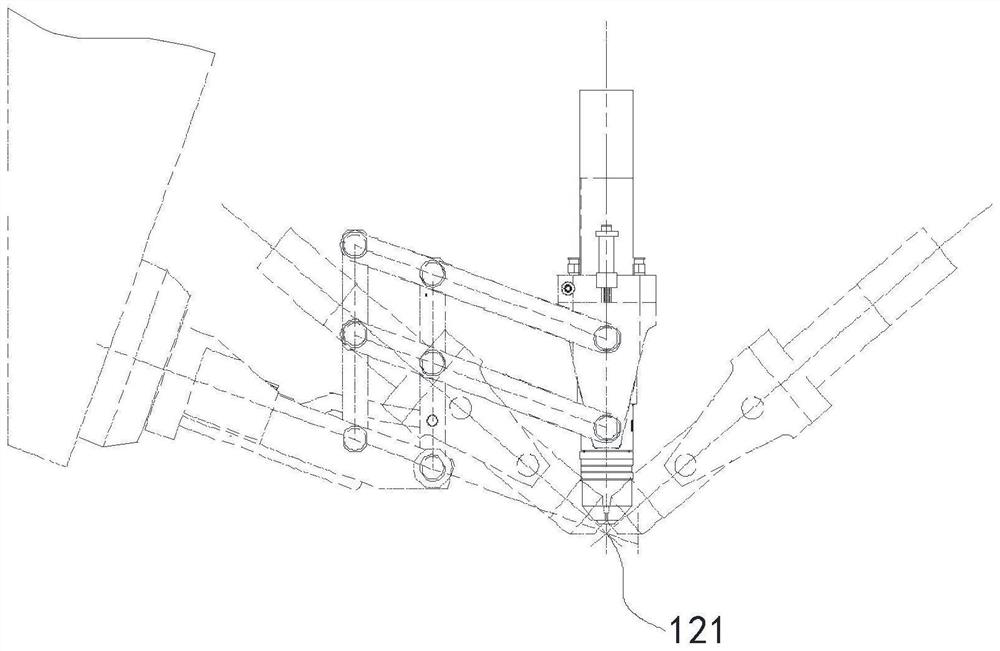

Automatic beveling device for flame cutting

PendingCN114054893AGuaranteed not to rotatePosition unchangedGas flame welding apparatusDrive shaftEngineering

The invention discloses an automatic beveling device for flame cutting, relates to the technical field of oxygen cutting processing, and solves the technical problem of high flame cutting difficulty caused by uncertain size and cutting position of a plate to be subjected to flame cutting in the prior art. In the device, a gun body clamping assembly comprises a clamping piece and a flame cutting torch arranged on the clamping piece in a penetrating mode; a transverse rotating mechanism comprises a rotating shell and a first driving assembly for driving the rotating shell to rotate; a longitudinal rotating mechanism comprises a driving shaft and a second driving assembly for driving the driving shaft to rotate; and the driving shaft is rotatably arranged on the rotating shell in a penetrating mode; and a four-bar mechanism comprises a first bar, a second bar, a third bar and a fourth bar. According to the device, the flame cutting torch is driven to rotate in one direction through the transverse rotating mechanism, and the flame cutting torch is driven to rotate in the other direction through cooperation of the driving shaft, the four-bar mechanism and the gun body clamping assembly, so that the positions of the cutting original points can be kept unchanged, software programming is well simplified, and the cutting quality and efficiency are improved.

Owner:WUCHUAN HEAVY ENG

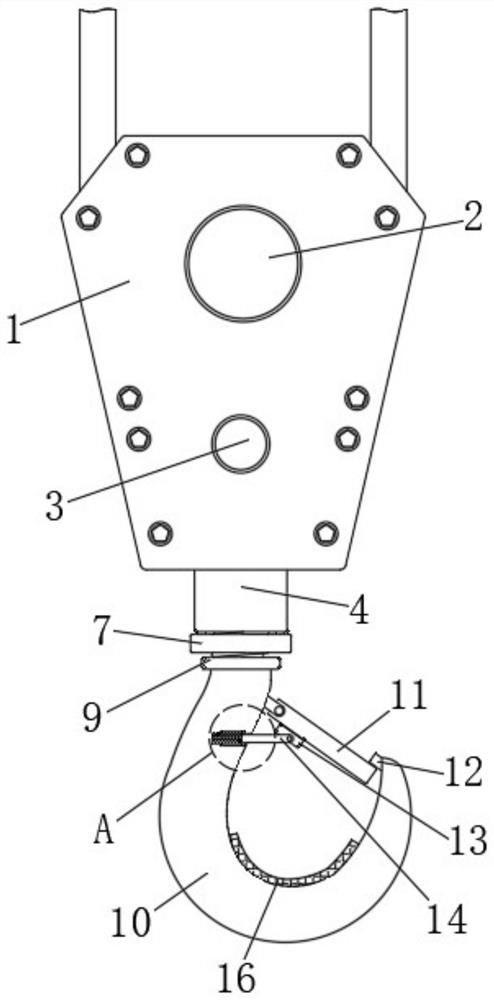

Lifting point device for embedded sleeve

PendingCN112694007AHigh accuracy of degree adjustmentGuaranteed not to rotateLoad-engaging elementsScrew threadShort distance

The invention discloses a lifting point device for an embedded sleeve. A traction wheel is rotatably installed on a lifting point device body to achieve adjustment of the large lifting height, then a rotary connecting block is rotatably installed at the lower end of the lifting point device body, and a rotary connecting sleeve is rotatably connected to the lower end of the rotary connecting block. The other end of the rotary connecting sleeve is connected with one end of a lifting hook through a rotary connecting shaft, one end of the rotary connecting shaft is provided with external threads, the other end of the rotary connecting sleeve is provided with internal threads, one end of the rotary connecting shaft is connected with the other end of the rotary connecting sleeve through threads, and the other end of the rotary connecting shaft is fixedly connected with one end of the lifting hook. The rotary connecting sleeve and the rotating connecting shaft are connected through the threads to form a structure capable of extending and retracting the lifting hook in a short distance, when a heavy object is lifted, it can be guaranteed that the lifting hook does not rotate, extending and retracting are achieved through the rotary connecting sleeve, the structure is simple, installation is convenient, and the height adjusting precision of a lifting point is greatly improved; and the rotary connecting block can also rotate axially, and a multidirectional rotation angle is provided.

Owner:SCEGC EQUIP INSTALLATION GRP COMPANY

A jacking system for fixing scaffolding

ActiveCN104727542BAdjustable installation heightGuaranteed not to rotateScaffold accessoriesArchitectural engineeringSteel tube

The invention discloses a jacking system for fixing a scaffold. The jacking system for fixing the scaffold comprises a steel tube, vertical rods and supporting plates, wherein the steel tube and the vertical rods are vertically arranged, and the supporting plates are mounted at the tail ends of the vertical rods. The vertical rods are provided with threads, and one ends of the vertical rods are sleeved with the steel tube. The jacking system for fixing the scaffold further comprises adjustable mounting supports which are mounted at the upper end and / or the lower end of the steel tube. Each adjustable mounting support comprises a mounting cylinder, two pinch plates which are symmetrically arranged on the two sides of the mounting cylinder and are semicircular, and a set screw nut which is connected with the mounting cylinder and located in the pinch plates. The pinch plates are rotatably connected to the left sides and the right sides of the mounting cylinders, the tail ends of the pinch plates can be fixedly connected through bolts, and every two pinch plates are closed to be in a cylinder shape to be used for clamping the steel tube. The set screw nuts are matched with the steel tube, and center holes of the set screw nuts are connected with the vertical rods through the threads. According to the jacking system for fixing the scaffold, the stress of the steel tube and the stress of the vertical rods are located on the same central axis, the vertical rods, the steel tube and the supporting plates are connected to form a whole, and the jacking system can be widely applied to supporting different formworks.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

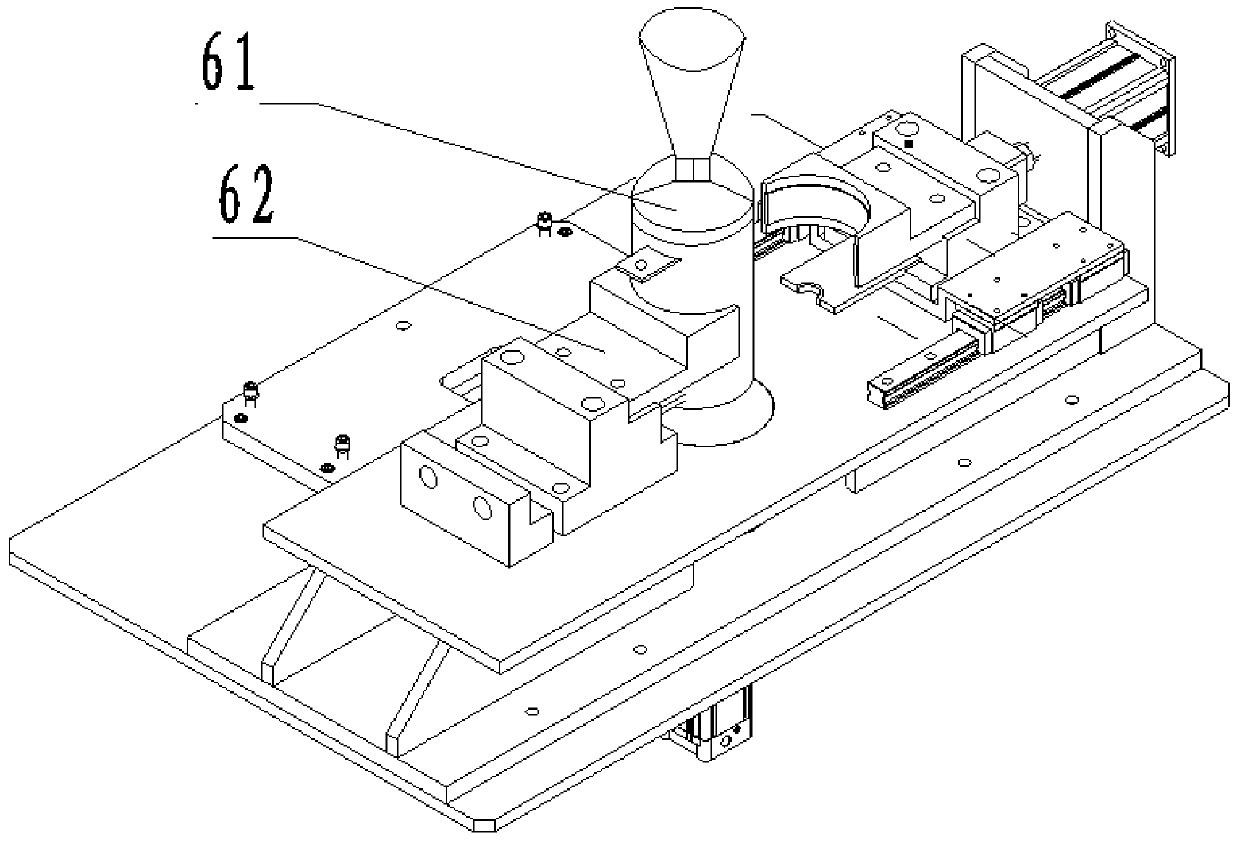

A kind of automatic assembly device and assembly method of small solid rocket

ActiveCN105171413BReduce in quantityReduce labor intensityAircraft componentsAssembly machinesEngineeringRocket

The invention discloses an automatic assembling device and method for a small solid rocket. The assembling device comprises a clamping tool, a tightening shaft, a tightening tool, a base and a control device. The clamping tool comprises a fixed part and a movable part and can clamp the small solid rocket. The semi-cylindrical curved surfaces of the fixed part and the movable part are made of antiskid materials with the pasting and friction coefficient of [0.3,0.5]. The tightening shaft comprises a drive mechanism and an output shaft. The drive mechanism outputs the assigned torque to drive the output shaft to rotate. A hexagonal part of a spray pipe of the small solid rocket is tightened through the hexagonal tightening tool. In the assembling process, the opening part of the hexagonal tightening tool is clamped on the hexagonal part of the spray pipe of the small solid rocket, the tightening shaft runs downwards, the output shaft is inserted in the connector part of the tightening tool, and the drive mechanism outputs the assigned torque to drive the output shaft to rotate; and the assigned torque is exerted to the small solid rocket through the tightening tool so that the spray pipe and a shell can be tightened. By means of the assembling method, the number of tools is decreased, the labor intensity is lowered, and the assembling efficiency is improved.

Owner:CHUANNAN MACHINERY PLANT CHINA ASTRONAUTIC SCI &TECH GROUP CORP

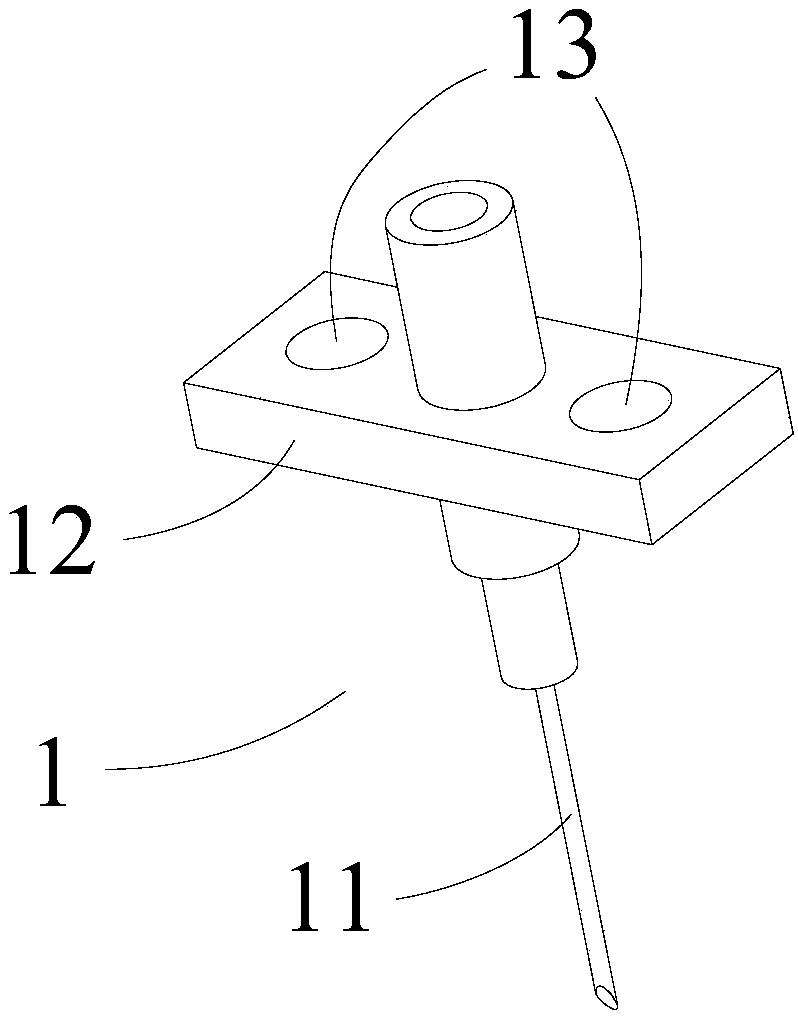

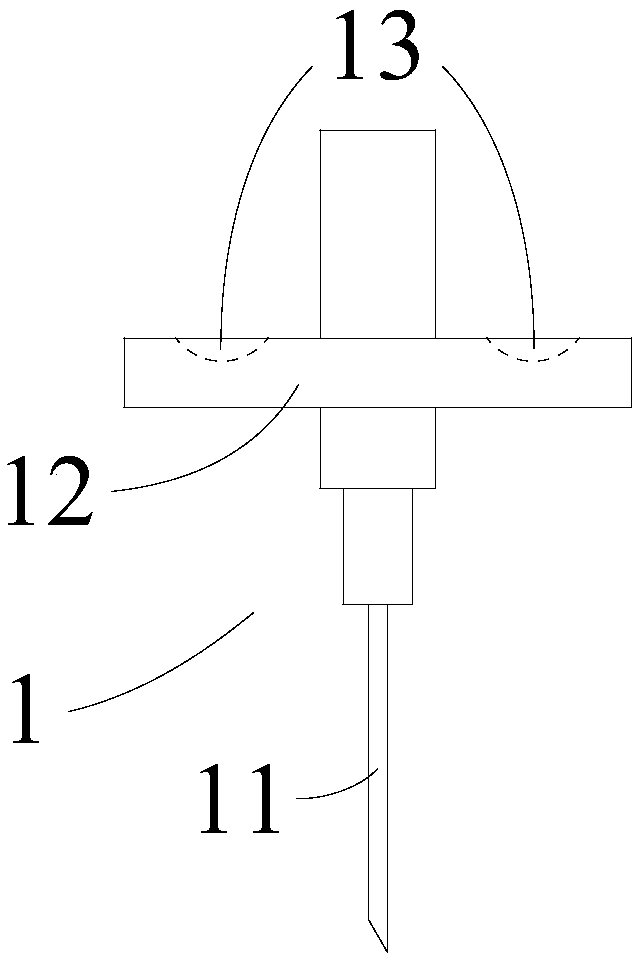

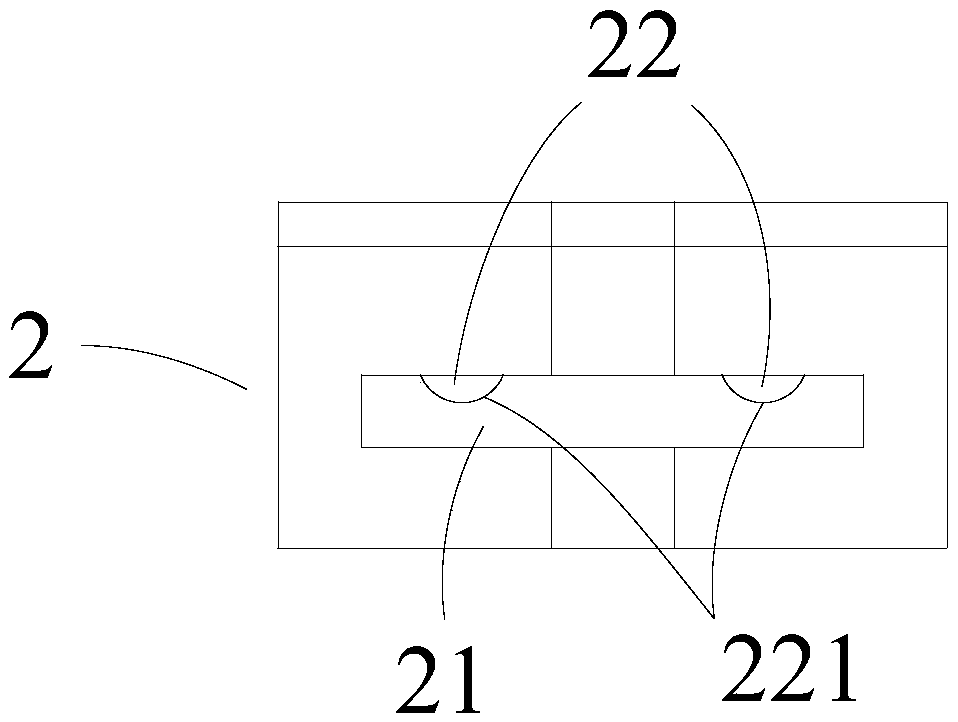

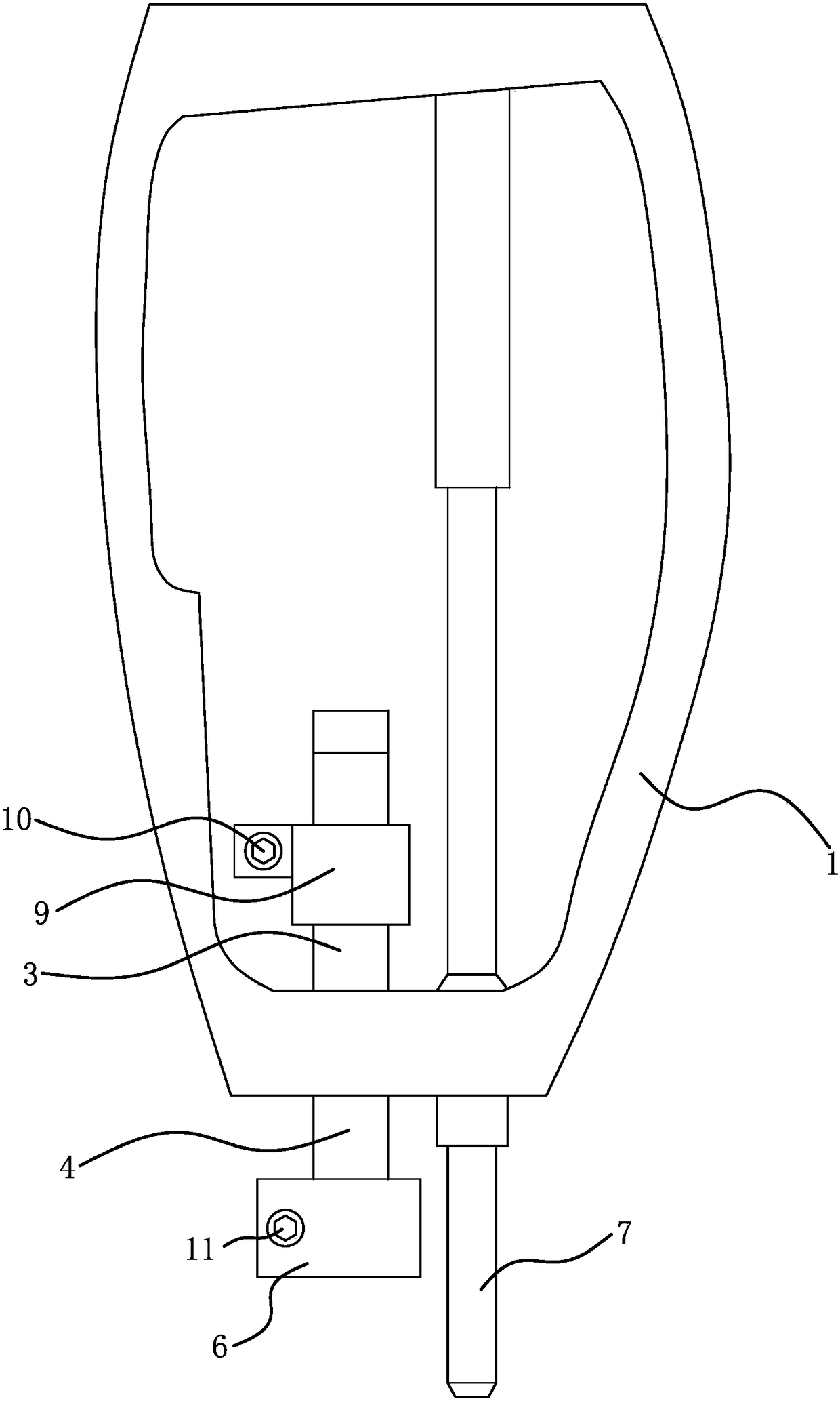

A needle clamp kit

ActiveCN106511081BEasy to installRestricted degrees of freedomPharmaceutical containersMedical packagingBiomedical engineering

Owner:CHENGDU JIESHIDE SCIENCE AND TECHNOLOGY CO LTD

A Construction Method for Gathering and Transportation Pipeline Directional Drilling and Cluster Laying

ActiveCN111810714BEffectively fixedGuaranteed not to rotatePipe laying and repairHydro energy generationUniversal jointArchitectural engineering

The invention discloses a construction method for directional drilling and cluster laying of a gathering and transportation pipeline, which belongs to the technical field of non-excavation crossing of the gathering and transportation pipeline. The construction method of directional drilling and cluster laying of gathering and transportation pipelines in the present invention first drags back the steel casing by means of horizontal directional drilling, and then passes the gathering and transportation pipelines into the steel casing by adopting a clustering method, thereby completing the non-opening of the gathering and transportation pipelines. Dig through, then fill the gap between the steel casing and the gathering and transportation pipeline with slurry, and finally complete the welding joint work of the gathering and transportation pipeline. The construction method of the present invention can smoothly achieve the work of dragging the collection and transportation pipelines back and crossing the river in a bundled manner, the whole process of dragging back and crossing is smooth, and the dragging sleeve is connected with the universal joint to ensure that the tube bundle does not twist in the steel casing The gathering pipeline is consistent with the guide curve of the casing, and the anti-corrosion layer of the gathering pipeline is not easily damaged. After the pullback crossing, cement grout is used to fill the gap between the steel casing and the gathering pipeline crossed by the cluster, which further ensures the safety of the pipeline during operation. safety.

Owner:SINOPEC NANJING ENG & CONSTR +1

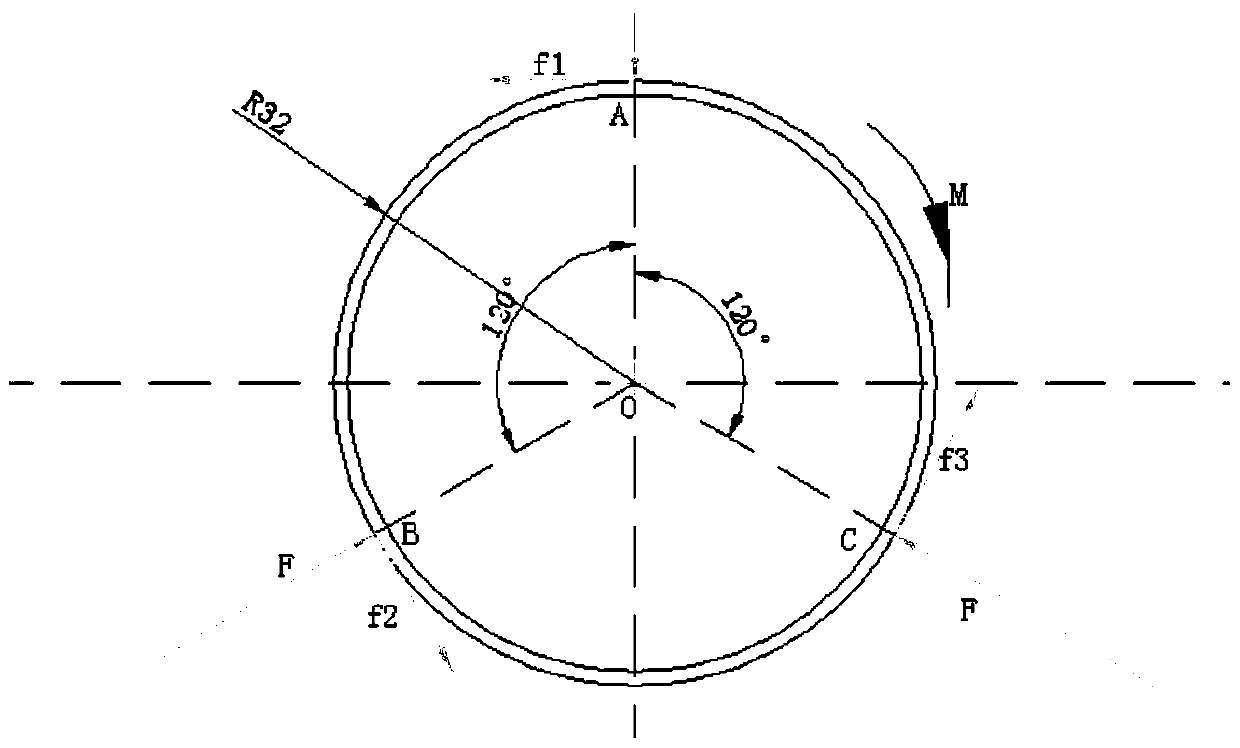

A non-cohesive soil sampling device

ActiveCN105486539BEasy to closeImprove accuracyWithdrawing sample devicesAnalysis workingEngineering

The invention discloses a cohesionless soil sampling apparatus. The apparatus comprises a cylindrical sampling cylinder, the sampling cylinder comprises a sampling top and a sampling bottom which are in threaded connection, the sampling bottom is provided with a fixed separation blade and a movable separation blade, the fixed separation blade is fixedly arranged on the inner wall of the sampling bottom, the movable separation blade is connected with the fixed separation blade through a center rotating shaft, the movable separation blade is positioned below the fixed separation blade, the center rotating shaft and the sampling cylinder are coaxially arranged, the top surface of the fixed separation blade is formed by two sector-shaped plates symmetrical to the center rotating shaft, the radian of each of the sector-shaped plates is 90DEG, the structure of the movable separation plate is same to the top surface of the fixed separation plate, and the top surface of the movable separation blade and the fixed separation blade are respectively vertical to the center rotating shaft. The bottom of the sampling cylinder can be conveniently closed without loss of a sampling amount, so the soil horizon sampling analysis working accuracy is improved.

Owner:ANHUI UNIV OF SCI & TECH

A large-diameter end cover propulsion mechanism, assembly method, and press-fitting and tightening equipment

ActiveCN113118747BRealize automatic top tighteningEasy for automatic loadingMetal working apparatusElectric machineryControl theory

The invention discloses a large-diameter end cover propulsion mechanism, assembly method, and press-fitting and tightening equipment, including a press-fit assembly, which provides a driving force to push the end cover into the press-fit end of the barrel, which includes a press-fit motor, a connecting screw and Screw block, one end of the connecting screw is connected to the power output shaft of the press-mounted motor, and the other end is connected to the screw block; the positioning component is used for the fixed connection between the end cover positioning seat and the cylinder, including the end plate and the end cover positioning seat. The end plate is located at one end of the cylinder, and a through hole for the end cover and the end cover positioning seat to pass is formed at the center of the end plate, and the end plate on the outer edge of the through hole is installed for realizing the end cover positioning seat and The positioning insert block is integrally connected with the cylinder; this device can realize the automatic grabbing of the end cap, automatically put it into the tooling, the tooling will automatically push and tighten, and at the same time, it can realize the automatic centering of the threaded parts. Realize automatic assembly, reduce labor and labor intensity, thereby improving work efficiency.

Owner:HENAN UNIV OF SCI & TECH

Pneumatic thin film performing mechanism with built-in type anti-rotating device

ActiveCN103104741BPrevent rotationAvoid breakingOperating means/releasing devices for valvesEngineering

The invention discloses a pneumatic thin film performing mechanism with a built-in type anti-rotating device. The performing mechanism comprises a film cover component, a membrane, a tray, an elastic element and a push bar, wherein the membrane is fixed on the inner side of the film cover component, the tray is fixed on membrane, two ends of the elastic element are respectively connected with the film cover component and the tray, one end of the push bar is fixed on the tray, and the other end of the push bar penetrates through the film cover component and is exposed outside the film cover component. The pneumatic thin film performing mechanism is further provided with the built-in type anti-rotating device. The film cover component comprises an upper film cover, a connecting pipe and a lower film cover, wherein the upper film cover, the connecting pipe and the lower film cover are sequentially connected, and an anti-rotating guide component used for limiting a moving track of the built-in type anti-rotating device is arranged on the inner side of the connecting pipe. One end of the built-in type anti-rotating device is fixedly connected to the tray, and the other end of the built-in type anti-rotating device is connected with the anti-rotating guide component. The built-in type anti-rotating device can move along a track limited by the anti-rotating guide component. The built-in type anti-rotating device is arranged in the pneumatic thin film performing mechanism, not only is travel of the pneumatic thin film performing mechanism not affected, but also the push bar can be prevented from rotating.

Owner:ZHEJIANG SUPCON FLUID TECH

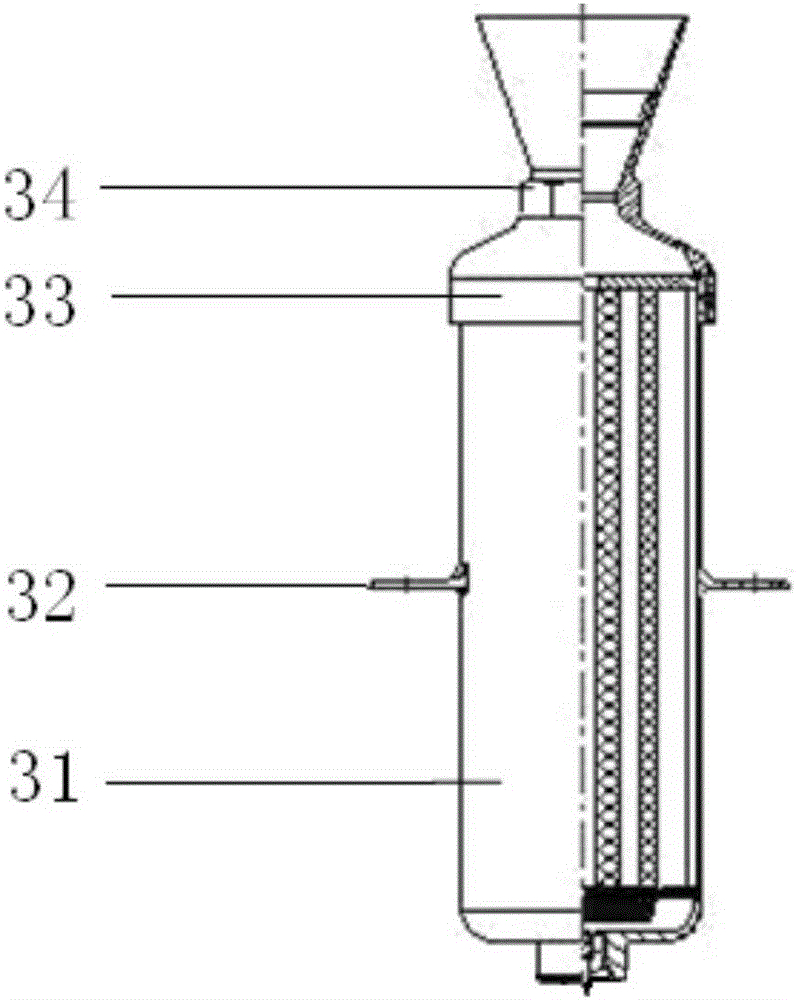

Novel pressurization type powdery accelerator adding device

The invention discloses a novel pressurization type powdery accelerator adding device. The novel pressurization type powdery accelerator adding device comprises a screw propeller which is composed of an outer shell and a screw shaft, the upper portion of the head end of the outer shell communicates with a hopper, the tail end of the outer shell is movably connected with a jet cavity, and a spiral blade at the tail portion of the screw shaft is of an intermittent structure which is spirally composed of spiral blade segments at intervals or is composed of notches formed in the continuous spiral blade at intervals. A thread shaft section is arranged at the tail end of the screw shaft and provided with a pressing plate, a spring and a pressing sleeve, an axial stop rod is arranged on an end surface of the pressing plate, a radial stop rod is arranged on a cylindrical wall of the pressing sleeve, and the radial stop rod corresponds to the axial stop rod. The novel pressurization type powdery accelerator adding device can tightly pressurize a powdery accelerator output by the screw shaft, so that the capacity of the powdery accelerator for resisting impact from high-pressure gas is improved. The pressing plate can move axially on the thread shaft section but can not rotate, and thus the screw shaft is effectively prevented from being damaged.

Owner:岳双喜

sewing machine

ActiveCN105586725BSimple structureGuaranteed not to rotateLubrication/cooling devicesWorkpiece carriersEngineeringSewing machine

The invention provides a sewing machine, and belongs to the technical field of sewing. The sewing machine solves the problem that the heating and clamping phenomena are likely to happen on a guiding component between a cutter holder and a machine head of an existing sewing machine. The sewing machine comprises a machine head and a cutter holder located on the lower side of the machine head. A presser bar guiding sleeve is fixedly arranged inside the machine head. A guiding base arranged on the guiding sleeve in a sleeving mode is arranged inside the machine head. A cutter bar is fixedly arranged on the cutter holder. The upper end of the cutter bar penetrates into the machine head and is fixedly connected with the guiding base. According to the sewing machine, it is ensured that the cutter bar does not rotate and a cutter fixed to the cutter holder is operated stably. Lubricating oil for lubricating a needle bar, a presser bar and other components is contained inside the machine head of the sewing machine, obviously, the lubricating oil can also lubricate and cool a gap between the guiding base and the presser bar guiding sleeve and a gap between the cutter bar and the machine head in an auxiliary mode, the sewing machine can be operated at high speed for a long time, and it is still ensured that the guiding base and the cutter bar are operated stably. The advantage that the structure of the sewing machine is simplified is achieved due to the fact that the guiding base achieves guiding through the presser bar guiding sleeve.

Owner:曹卫明

Rake lifting device of center-drive concentrator automatically lifting rake at center

InactiveCN108310819AImprove reliabilitySimple structureSedimentation separationAxial forceSlewing bearing

The invention discloses a rake lifting device of a center-drive concentrator automatically lifting a rake at a center. The existing device has a complex structure, is high-cost, has a long processingcycle, and has difficulty in lifting and lowering a main shaft. The device solves the above problem. The rake lifting device is characterized by further comprising a slewing bearing, a connection base, a rotating base, a bearing base, and a hinge support, wherein the hinge support is installed on the upper part of a lifting support, the hinge support is connected with the rotating base, the bearing base is installed at two sides of the upper plane of the rotating base, an oil cylinder body is installed on the bearing base, a piston rod of the oil cylinder is connected with an outer ring of theslewing bearing through the connection base, and the inner ring of the slewing bearing is connected with the main shaft. The slewing bearing which can bear an axial force, a radial force and a turning torque is adopted as a transition connection device, so that the structure is simplified, and the connection structure is more reliable; the rake lifting device uses fewer elements, has fewer faultpoints, has a shorter production cycle, has low processing and manufacturing cost, and is easy to maintain on site.

Owner:HEFEI RUIHONG HEAVY MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com