Broaching device for lathe

A technology for lathes and lathe spindles, applied in broaching devices, turning equipment, turning equipment, etc., can solve the problems of different workpiece quality, unfavorable production, excessive funds, etc., and achieve the effect of highlighting substantive features and significant progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

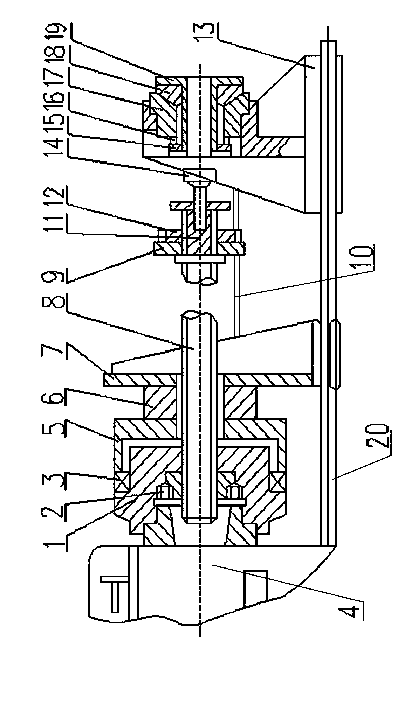

[0019] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0020] As can be seen from the accompanying drawings, the broaching device for a lathe of this program includes a lathe support 20 and a lathe main shaft 4, the front support 7 is arranged at the lathe main shaft 4, and a rear support 13 is also fixed on the lathe support 20. The front bracket 7 is provided with a lead screw 8, and a first nut 1 engaged with the lead screw 8 is arranged. The first nut 1 is fixed on the lathe spindle 4, and the end of the lead screw 8 away from the first nut 1 is fixed. There is a broach chuck 14; the rear support 13 is provided with a positioning sleeve 19, and the outside of the positioning sleeve 19 is provided with a spherical ring 18, and the outside of the spherical ring 18 is provided with a spherical support 17. The positioning sleeve 19 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com