Rake lifting device of center-drive concentrator automatically lifting rake at center

A technology of central transmission and transmission device, which is applied in the direction of chemical instruments and methods, separation methods, precipitation separation, etc., can solve problems such as defective bearing fastening, difficulty in lifting and lowering of the main shaft, and long processing cycle, so as to achieve easy maintenance and maintenance. The effect of fewer points and shortened production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

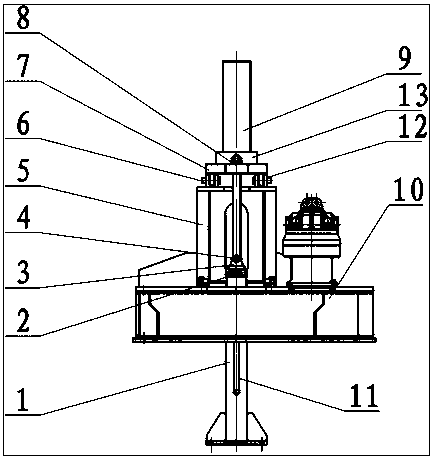

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

[0011] As shown in the accompanying drawings, as shown in the accompanying drawings, the present invention consists of a main shaft 1, a slewing bearing 2, a connecting seat 3, a pin shaft I4, a lifting support 5, a pin shaft II6, a rotating seat 7, a bearing seat 8, an oil cylinder 9, Transmission device 10, key 11, hinge support 12, oil cylinder base 13 etc. are formed. The hinge support 12 is installed on the upper part of the lifting support 5, and the hinge support 12 is connected to the rotating seat 7 through the pin shaft II6; On the bearing blocks 8 on both sides.

[0012] The slewing bearing 2 is a transitional connection device, which can bear axial force, radial force and turning moment. The inner and outer rings can rotate relative to each other. The inner ring is connected to the main shaft 1, and the outer ring is connected to the oil cylinder 9 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com