Jacking system for fixing scaffold

A scaffolding and jacking technology, which is applied to scaffolding accessories, house structure support, house structure support, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

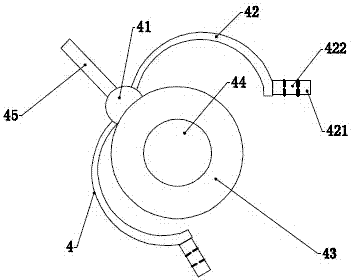

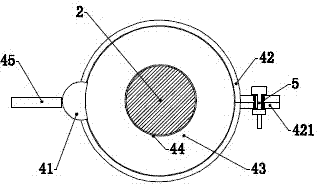

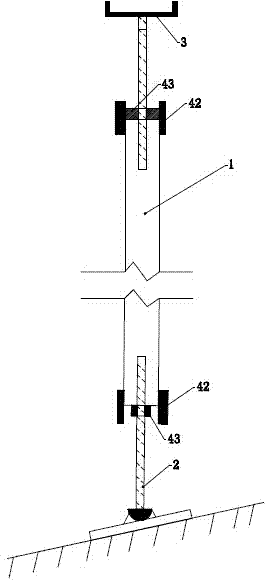

[0027] Such as image 3 As shown, when the base surface of the scaffold to be erected is an inclined plane, and the length of the steel pipe 1 is not enough, a vertical pole 2 is vertically arranged at both ends of the steel pipe 1, and the vertical pole 2 at both ends is fixed by an adjustable mounting support 4 . Wherein, the bottom end of the vertical rod 2 positioned at the lower end is fixed to the anti-skid bottom bracket (not shown in the figure) arranged on the slope. The anti-skid bottom bracket is composed of a base plate and a bump fixedly connected to the upper end of the base plate. A downwardly concave spherical surface is arranged on the top of the bump; Cap, the connecting cap fits with the spherical surface in the non-slip bottom bracket. The connection structure between the upright bar 2 and the anti-skid bottom bracket not only ensures the stability of the upright bar, but also prevents the upright bar from moving or even hanging in the air when the fr...

Embodiment 2

[0029] Such as Figure 4 As shown, when the base surface of the scaffolding needs to be erected as a plane, the steel pipe 1 is vertically installed on the wooden block (not shown in the figure) installed on the ground, and an adjustable mounting support is set on the top of the steel pipe 1 4. Match a vertical rod 2 with the positioning nut 43 in the adjustable mounting bracket 4 and fasten it. During the fastening process, the height of the scaffold can be adjusted by moving up and down the fastening position of the vertical rod 2 and the positioning nut 43 .

Embodiment 3

[0031] Such as Figure 5 As shown, when the base surface for scaffolding needs to be set up as a plane and the steel pipe is not long enough, adjustable mounting supports 4 can be installed at the upper and lower ends of the steel pipe 1, and an adjustable mounting support 4 can be installed in the middle of each adjustable mounting support 4 A vertical pole 2 and a supporting plate 3 are arranged vertically. Wherein, the supporting plate 3 positioned at the lower end of the steel pipe 1 is engaged with a wooden spacer block (not shown in the figure) installed on the ground. In this case, adjusting the height of the scaffold is achieved by rotating the adjustable mounting supports 4 at the upper and lower ends, and then moving up and down the vertical rod 2 and the fastening position of the positioning nut 43 in the adjustable mounting supports 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com