A kind of automatic assembly device and assembly method of small solid rocket

An automatic assembly device and small rocket technology, which is applied in the direction of assembly machines, transportation and packaging, aircraft parts, etc., can solve the problems of large number of tooling, high labor intensity, and low efficiency, so as to reduce the number of tooling, reduce labor intensity, avoid The effect of human error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

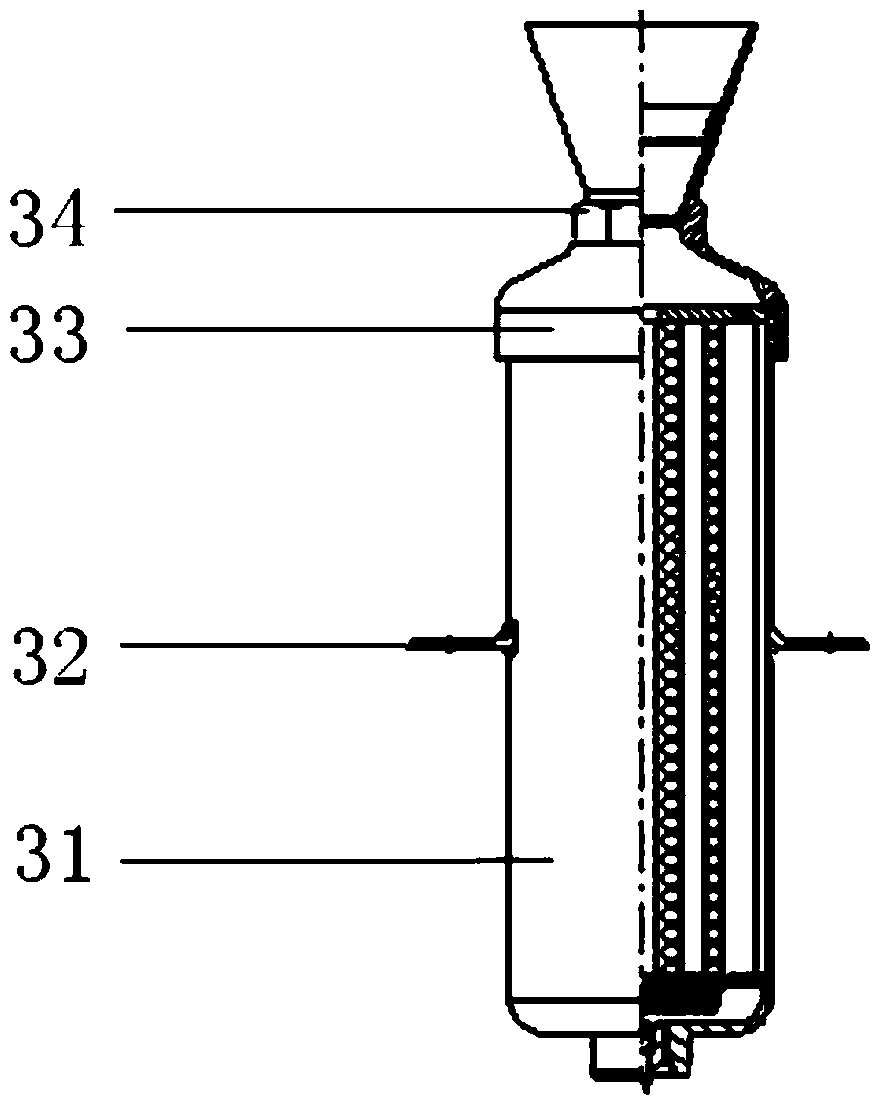

[0037] At present, in the assembly process, special tooling is used to clamp the shell lug 32 to ensure that the small solid rocket does not rotate when torque is applied. The number of clamping tooling for the small solid rocket is not only related to the radius of the shell 31, but also related to the size (length) of the lug. , width), resulting in a large number of tooling, and almost every product requires a tooling; in order to reduce the number of tooling, the use of solid small rocket shells is cylindrical, and the method of directly clamping the cylindrical shell is used. Holds solid small rockets.

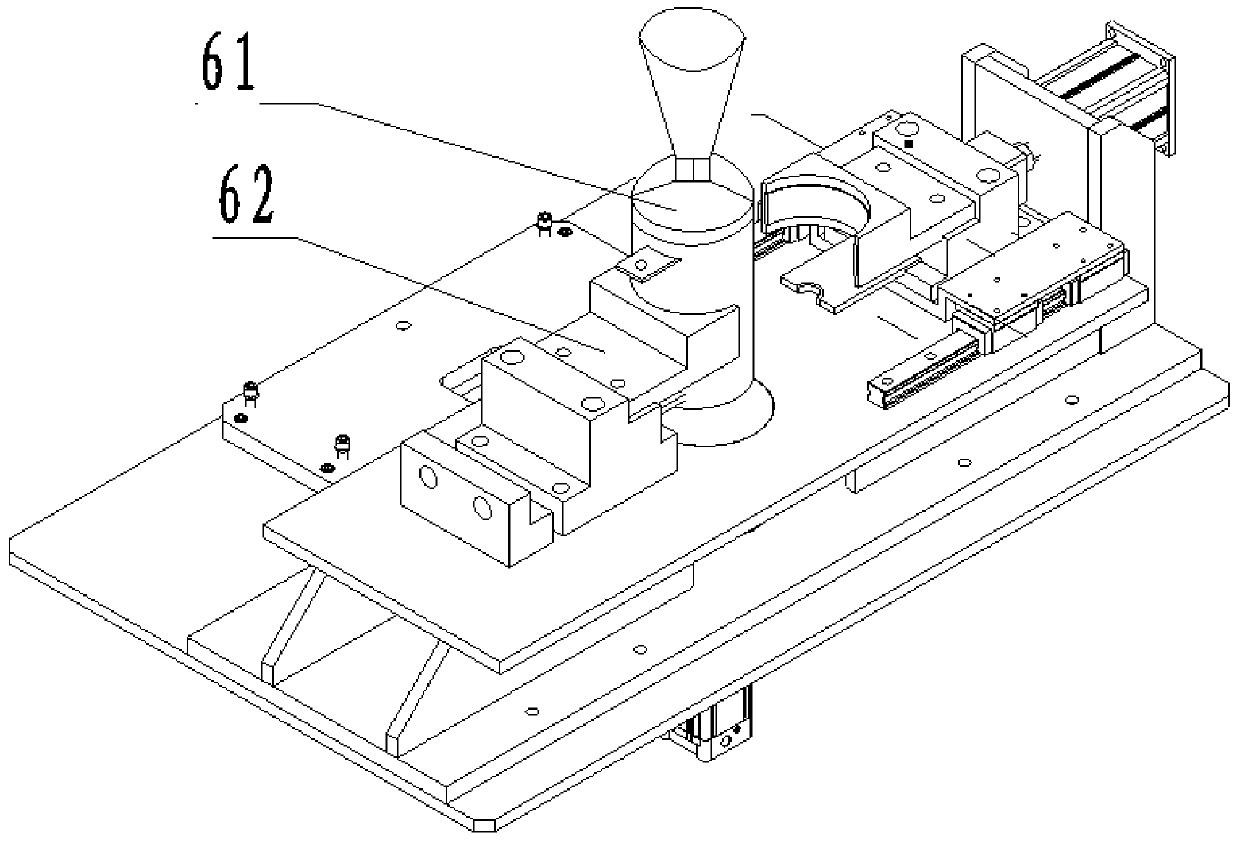

[0038] see Figure 7 , the solid small rocket automatic assembly device includes: a clamping tool 62, a tightening shaft 63, a tightening tool 64, a base and a control device 65;

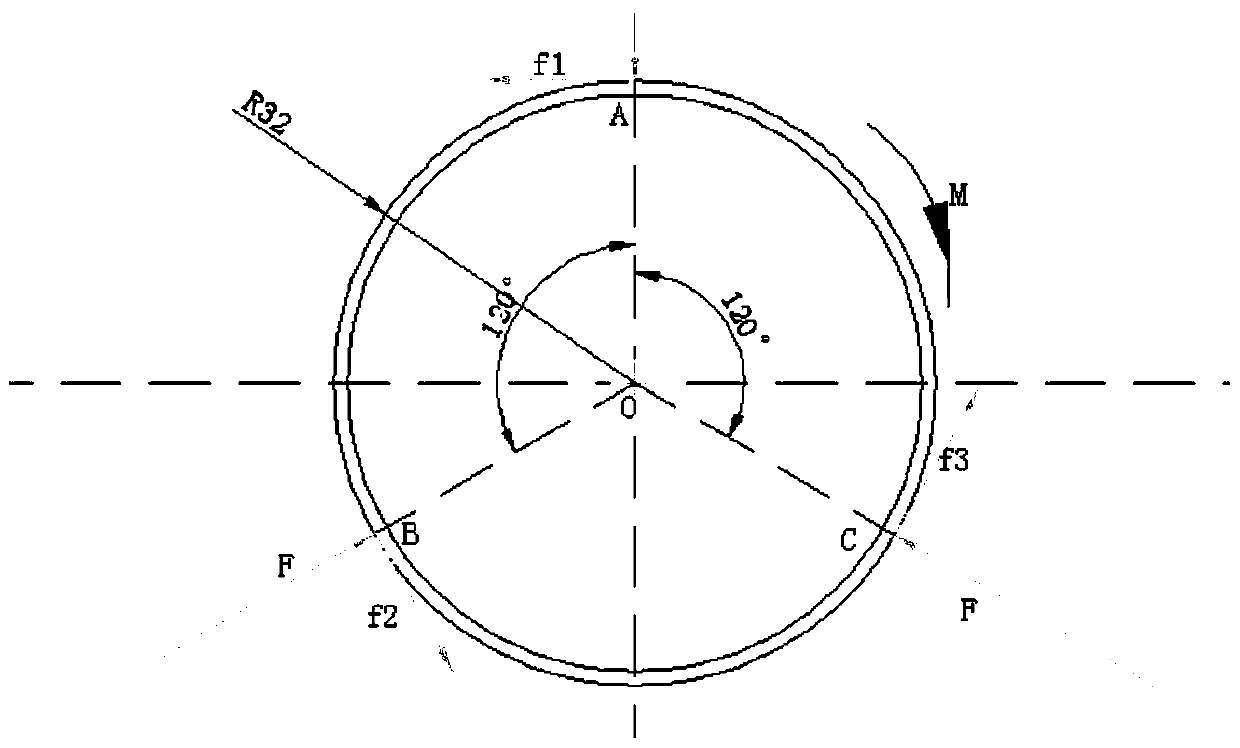

[0039] 1. Design of clamping tooling

[0040] (1) Determine the clamping method

[0041] The shell of the small solid rocket has the characteristics of a cylinder, and the small solid rocket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com