Gathering and transportation pipeline directional drilling bundling laying construction method

A construction method and directional drilling technology, which are applied in drilling equipment and methods, directional drilling, pipeline laying and maintenance, etc., can solve the problems of large crossing area and long construction period, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

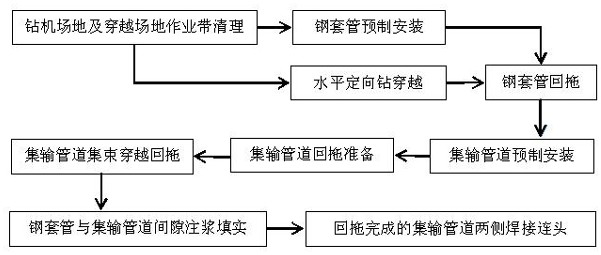

[0030] The construction flow chart of an embodiment of the present invention is as figure 1 As shown, the directional drilling cluster laying construction method of the gathering and transportation pipeline in this embodiment is carried out according to the following steps. First, the site cleaning operation is carried out before the steel casing prefabrication installation step and the horizontal directional drilling crossing step, specifically for the horizontal directional drilling Level the positions of the exit and entry points of the drilling rig, clean up the steel casing and the pipeline site that needs to be bundled and dragged back, and make sure that the working belt and the pipeline directional drilling are crossed in a straight line. The trajectory of the excavation point is straight and straight.

[0031] Then it also includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com