Product boxing system

A product and box technology, which is applied in the field of processing line equipment, can solve problems such as shortage of boxes, inability to pick up products, failure of boxing, etc., and achieve the effect of overcoming technical defects and overcoming the shortage of clothing boxes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

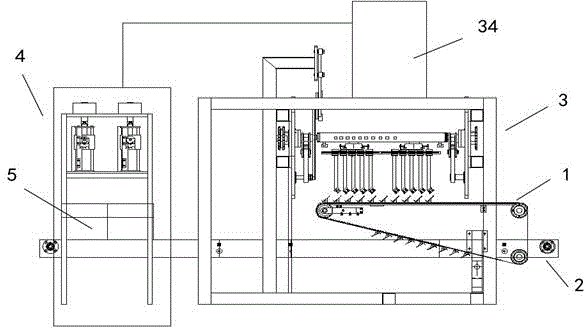

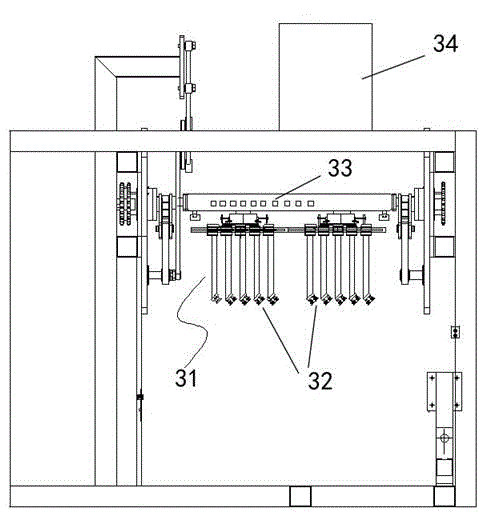

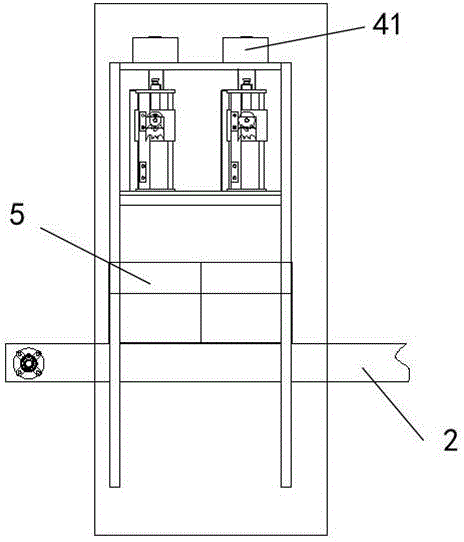

[0021] A product boxing system for a processing line, comprising a product feeding conveyor belt 1, a box body feeding conveyor belt 2 and a boxing device 3, the boxing system also includes a bag replenishing device 4, along the box body feeding direction, The box feeding conveyor belt 2 passes through the boxing device 3 and the bag filling device 4 successively; Vacuum sensor 33 and counting control module 34, vacuum sensor 33 detects the surface vacuum degree when each vacuum negative pressure sucker 32 grabs, and detection signal is transmitted on the counting control module 34, and counting control module 34 is connected bag replenishing device 4, replenishes The bag device 4 includes a storage box 41, a bag-filling suction cup 42 and a cylinder 43. The storage box 41 is located at the top of the bag-filling device 4 and is provided with an opening. The product placed in advance is stored inside the storage box 41. The cylinder 43 is connected with the bag refilling sucti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com