A busbar processing and bending system

A busbar and bending machine technology, applied in metal processing, metal processing equipment, forming tools, etc., can solve the problems of reducing work efficiency and achieve the effects of improving efficiency, reliable bending angle, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

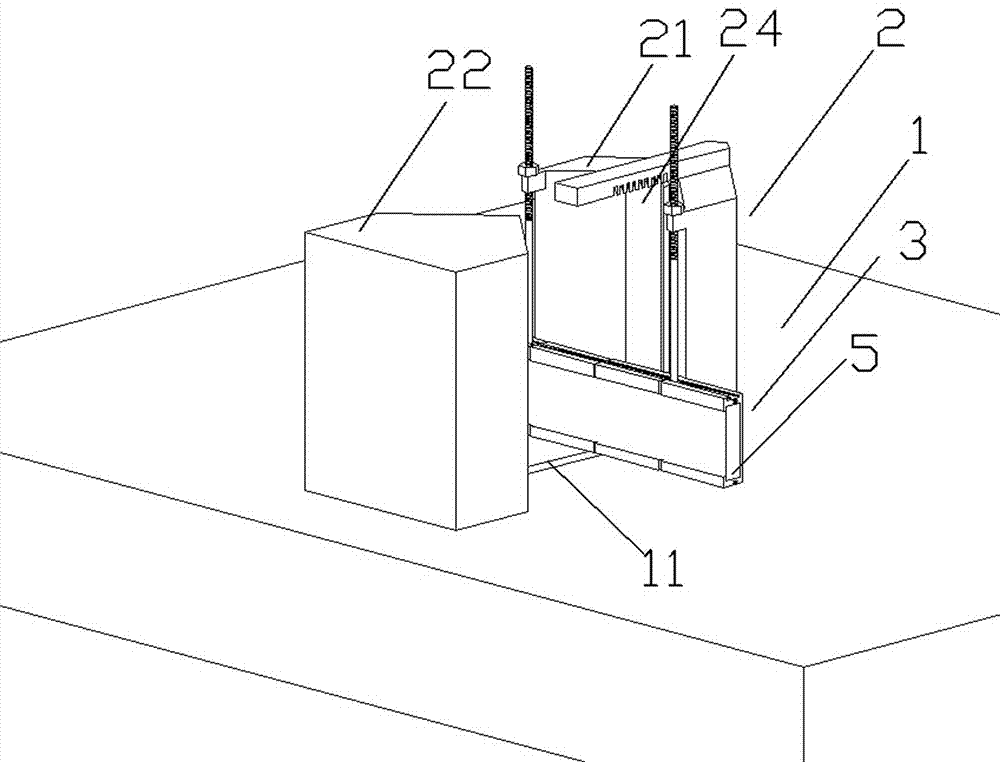

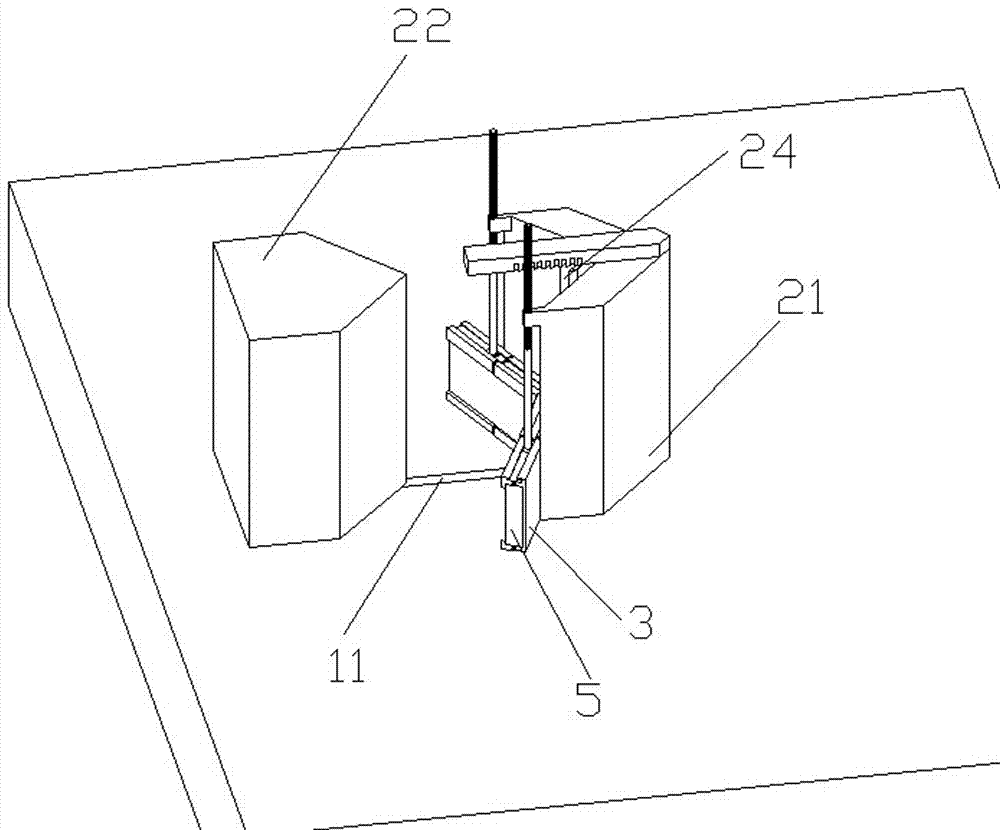

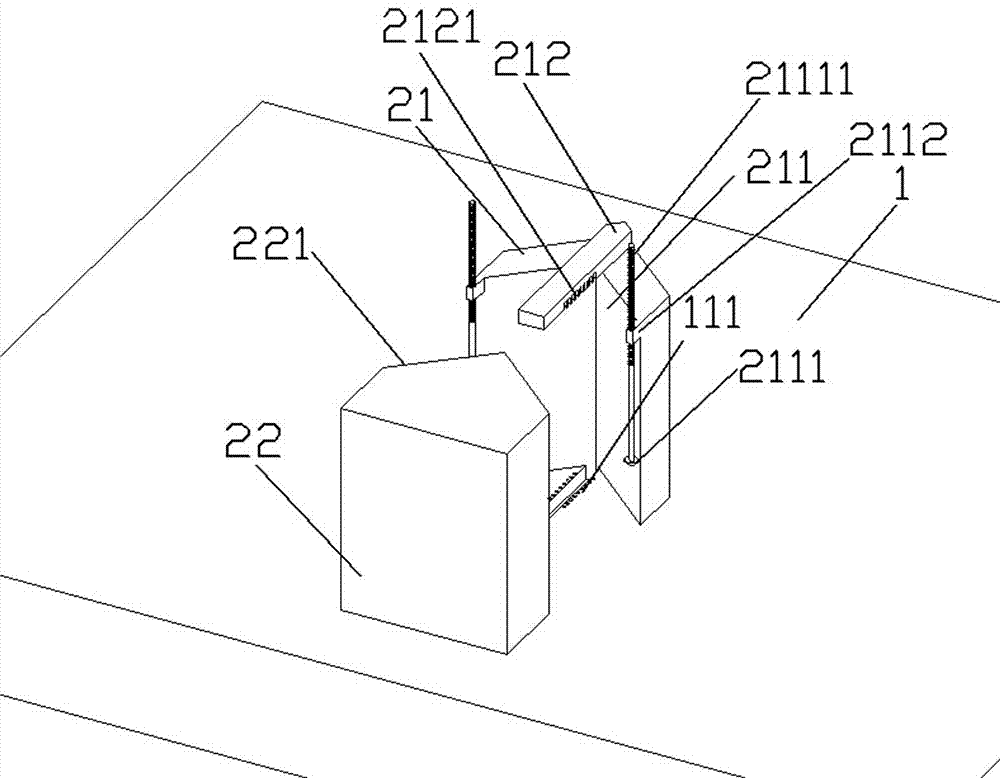

[0031] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings. A busbar processing and bending system includes a busbar processing bending machine 2 and a busbar processing splint 3 arranged on a workbench 1 . The busbar processing bending machine 2 includes a die 21 and a punch 22 . The die 21 is fixed on the workbench 1 and has an inclined concave surface 211 arranged symmetrically about the axis; the punch 22 has an inclined convex surface 221 arranged symmetrically about the axis, and the punch 22 can approach or move away from the die 21 along the axis.

[0032] The busbar processing splint 3 includes a splint main body 31 formed by rotating and splicing a plurality of sub-clamps 4 . The sub-splint 4 includes a sub-splint main body 41, L-shaped upper and lower stoppers (411, 412) symmetrically arranged on the upper and lower ends of the sub-splint main body, and a sub-splint groove 413 formed between the upper a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com