Connecting devices for rail vehicles

A technology for connecting devices and rail vehicles, applied in the direction of brakes, etc., can solve problems such as reliability decline and mechanical anti-skid sensor resonance, and achieve the effect of eliminating noise, reducing assembly technology requirements, and eliminating obvious temperature rise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

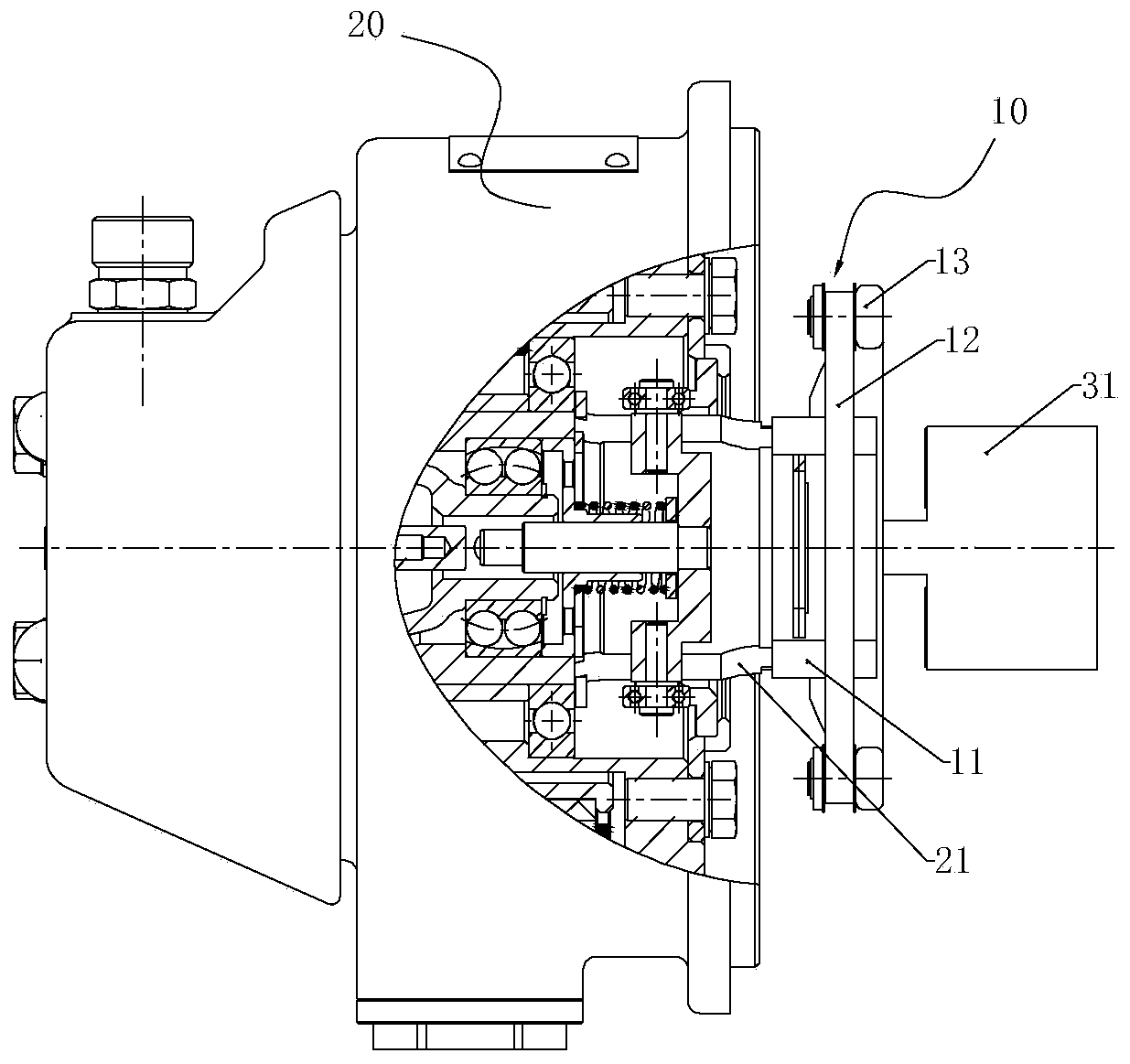

[0020] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

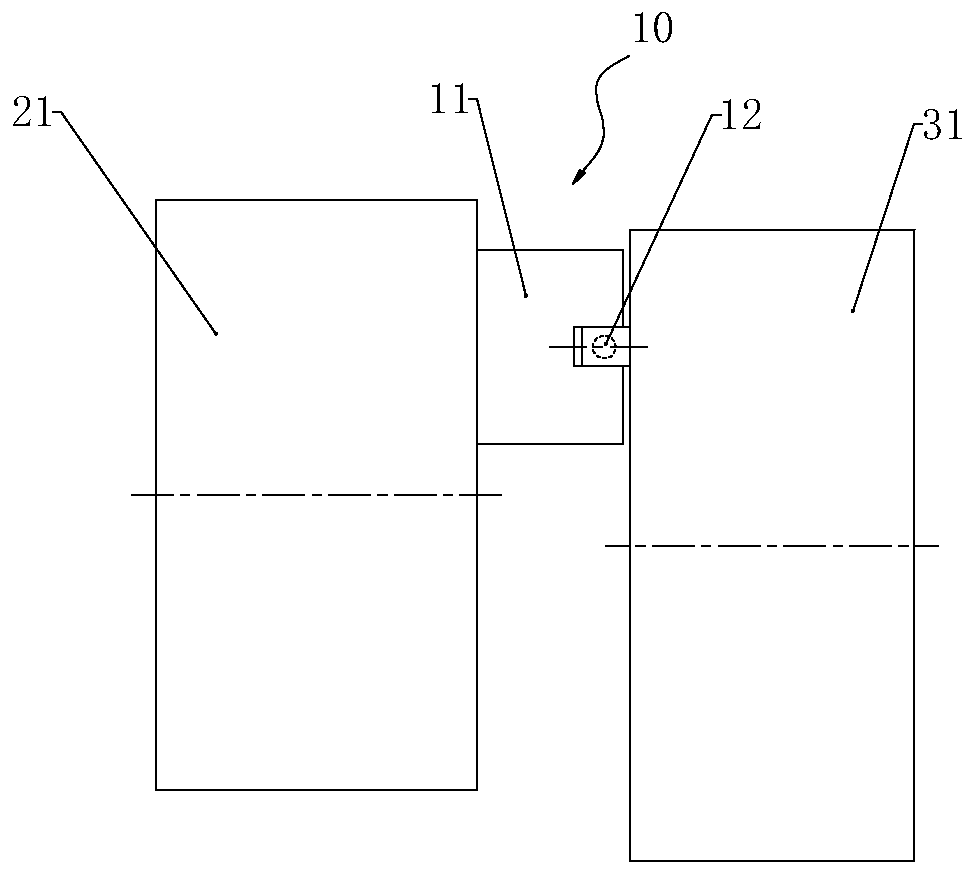

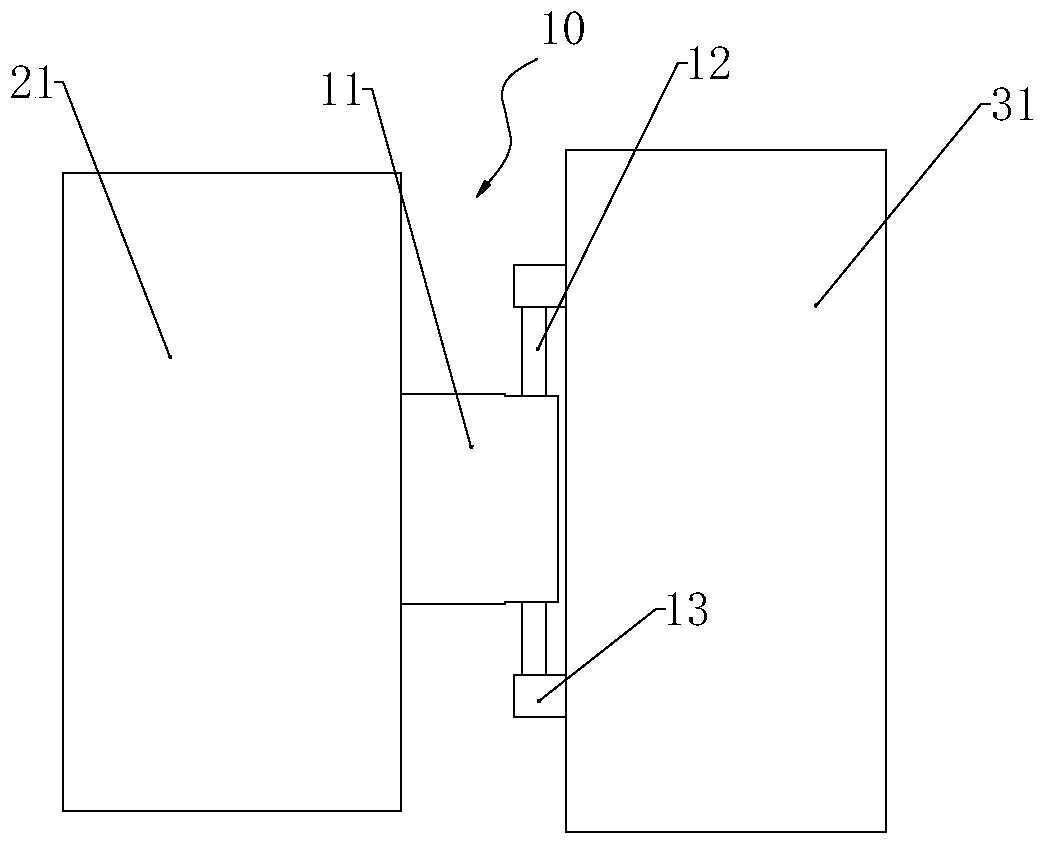

[0021] In order to eliminate or attenuate the resonance source of the transmission shaft of the mechanical anti-skid sensor, that is, to make the angular acceleration of the transmission shaft be zero or tend to zero, the present invention provides a connection device for rail vehicles, such as Figure 1a , Figure 1b and figure 2 As shown, the connecting device 10 is connected between the transmission shaft 21 of the mechanical anti-skid sensor 20 and the wheel axle 31 of the rail vehicle, and it includes a connecting block 11 and an elastic connecting body 12, and the connecting block 11 is slidably connected to the elastic connecting body 12 . The connecting block 11 is fixed on the connecting end of the transmission shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com