Installation method of large stern roller bearing blocks of anchor handling tug supply (AHTS) vessel for ocean engineering platform

A marine engineering and engineering platform technology, applied in ship parts, ship construction, ship design, etc., can solve the problems of cumbersome centering operations, high labor intensity, and low efficiency, and achieve improved centering accuracy, high angle accuracy, and enhanced reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

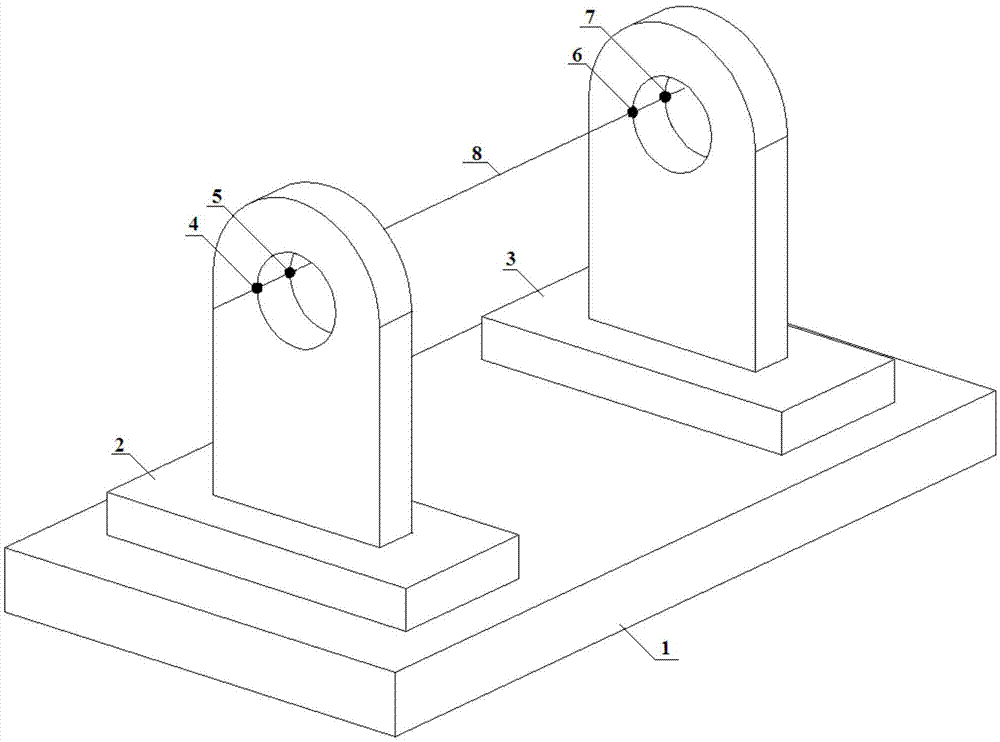

[0026] The embodiment of the present application provides a method for installing the large-scale stern roller bearing seat of a three-purpose workboat on a foreign engineering platform, so as to solve the problem of cumbersome centering operation, high labor intensity, long period, low efficiency and high cost of large-scale bearing seat adjustment in the prior art technical problems.

[0027] In order to solve the above technical problems, the general idea of the technical solution provided by the embodiment of the present application is as follows:

[0028] A method for installing a large-scale stern roller bearing seat of a three-purpose workboat on an ocean engineering platform, comprising:

[0029] Place a pair of bearing seats on a standard plate, and set a pair of standard centering points in the two shaft holes of the pair of bearing seats, that is, set the first standard centering point and the second standard centering point in sequence point, the third standard ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com