Sealing connection structure and connector using same

A connection structure and connector technology, applied in the direction of the base/shell, etc., can solve the problems of connection failure and inability to seal well, and achieve the effect of high connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

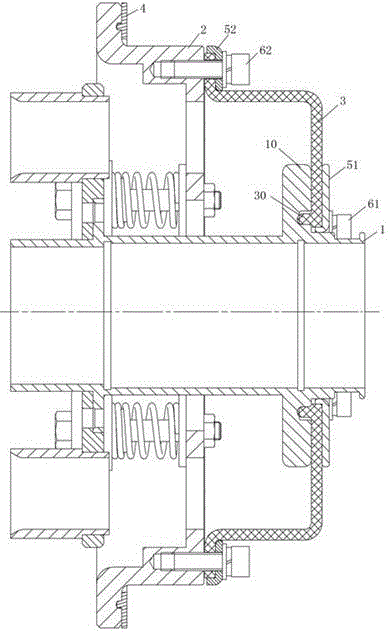

[0014] Embodiment 1 of the connector of the present invention: as figure 1 As shown, it includes an inner shell 1 and an outer shell 2 whose axis extends left and right. The left end of the outer shell is provided with an outer flange for fixed connection with the fixed plate, and a gasket 4 is provided between the outer flange and the fixed plate. The inner shell 1. The floating connection is inside the outer shell 2. There is a floating gap between the inner shell 1 and the outer shell 2 for the inner shell to float radially. The connector also includes a seal for sealing the floating gap between the inner shell and the outer shell. The connection structure, the sealing connection structure includes a fixed base and a flexible sealing sleeve 3, the fixed base is provided with a sealing connection surface for connecting the flexible sealing sleeve, the flexible sealing sleeve is connected to the sealing connection surface through a connecting piece and an annular pressure plat...

Embodiment 2

[0021] Embodiment 2 of the connector of the present invention: the difference from Embodiment 1 is that the connector only includes an outer sealing connection structure, and the inner edge of the flexible sealing sleeve is directly bonded to the inner housing.

Embodiment 3

[0022] Embodiment 3 of the connector of the present invention: the difference from Embodiment 1 is that the connector only includes an inner sealing connection structure, and the outer edge of the flexible sealing sleeve is directly bonded to the outer shell.

[0023]Embodiment 4 of the connector of the present invention: the difference from Embodiment 1 is that the connector only includes an outer sealing connection structure, and the inner edge of the flexible sealing sleeve is crimped to the inner housing through the flange provided on the inner housing superior.

[0024] Embodiment 5 of the connector of the present invention: the difference from Embodiment 1 is that the inner and outer concave-convex structures are mutually matched convex and concave structures that are evenly distributed in the circumferential direction, and the sealing connection surface of the outer shell and the flexible sealing sleeve. rise and groove.

[0025] Embodiment 6 of the connector of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com