A pallet control method in high-speed wire production

A control method and high-speed wire rod technology, applied in the field of wire rod production technology, can solve the problems affecting the roll quality, inaccuracy, random acceleration of pallets, etc., to avoid the problem of random acceleration of pallets, reliable descending speed, and improved product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention is described below in conjunction with accompanying drawing:

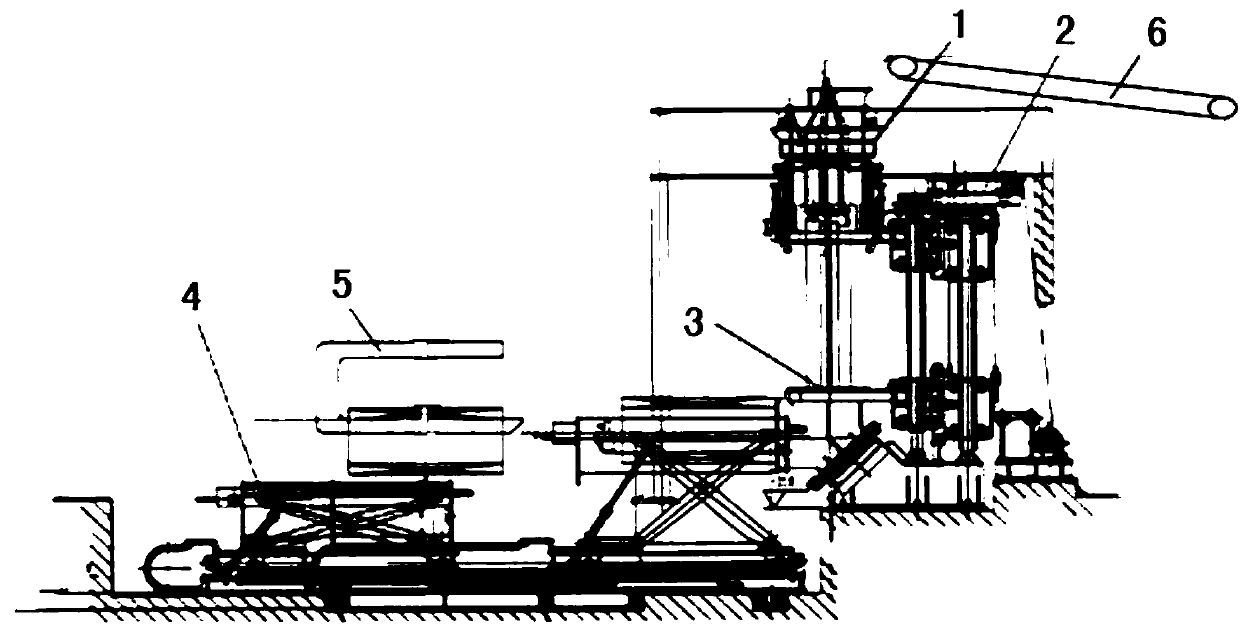

[0019] In order to facilitate the understanding of the control method of the present invention, a schematic diagram of the equipment site for the coiling station of the high-speed wire production line is provided as follows: figure 1 As shown, the main equipment includes reel collection drum 1, supporting plate 2, double-armed mandrel 3, coil unloading trolley 4, C-shaped hook 5, SM roller table 6, and the finished rolls are delivered by unloading trolley 4 and C-shaped roller after the roll collection is completed. Hook 5 is carried away and enters packing process.

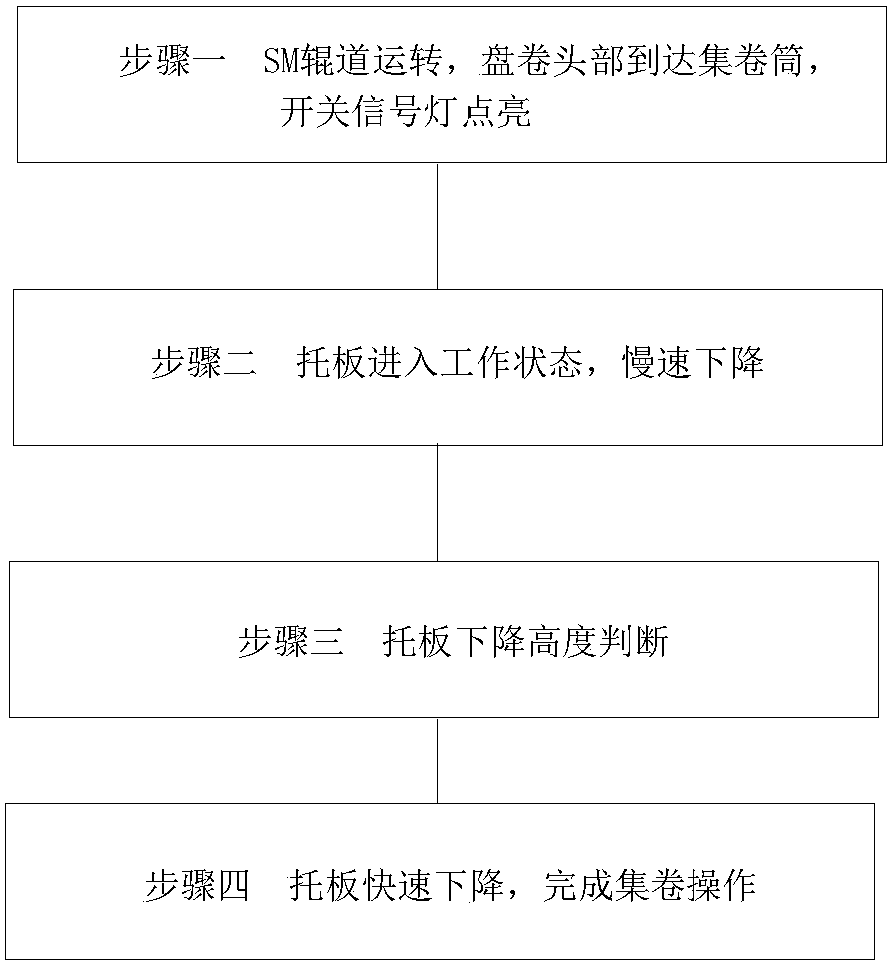

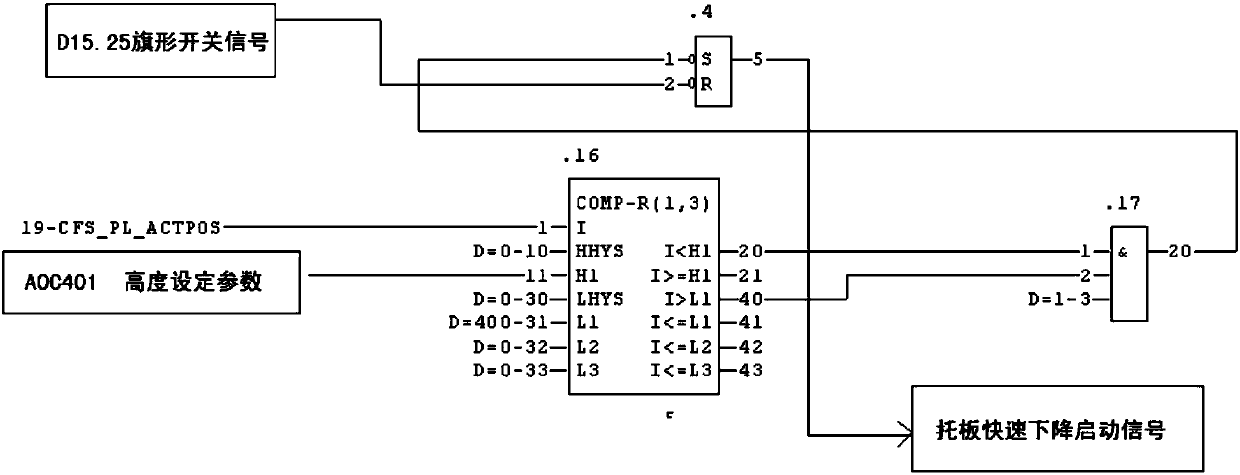

[0020] Such as figure 2 As shown, a pallet control method in high-speed wire rod production, the method is:

[0021] Step 1 The SM roller table is running, the coil head reaches the collection drum, and the detection switch is lit;

[0022] Step 2: The pallet enters the working state and desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com