A Streamlined Box Girder Eddy Vibration Suppression Structure

A streamlined, vortex-vibration technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as the inability to effectively suppress vortex vibration, vortex-induced vibration, and propose a vibration-suppressing structure, so as to increase the comfort of use and reduce the amplitude of vortex vibration , to ensure the effect of structural safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

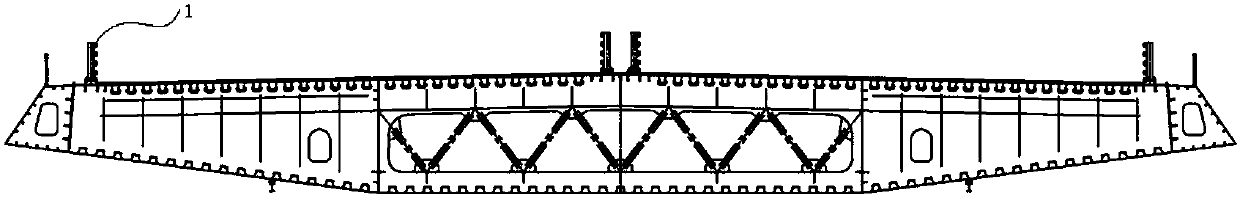

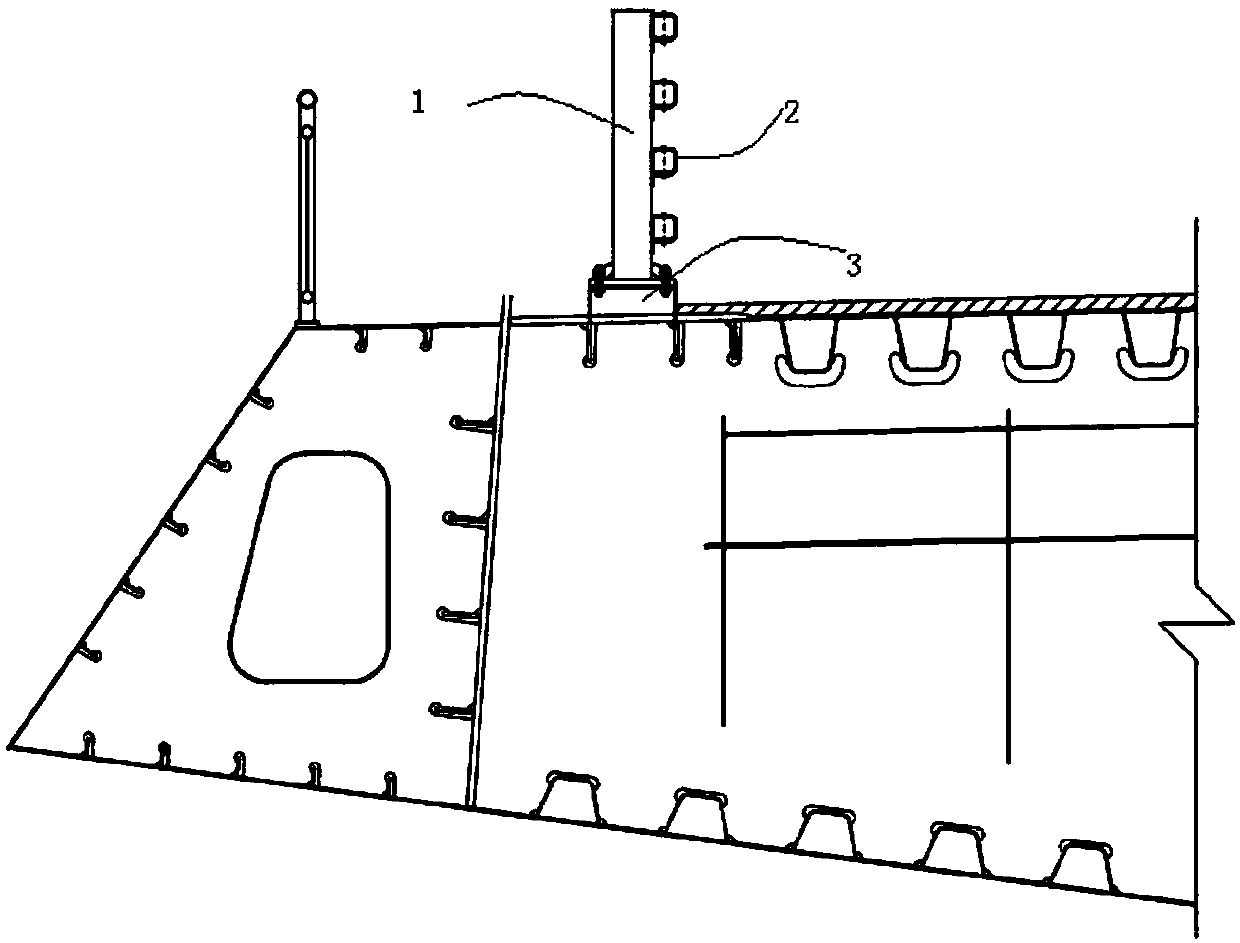

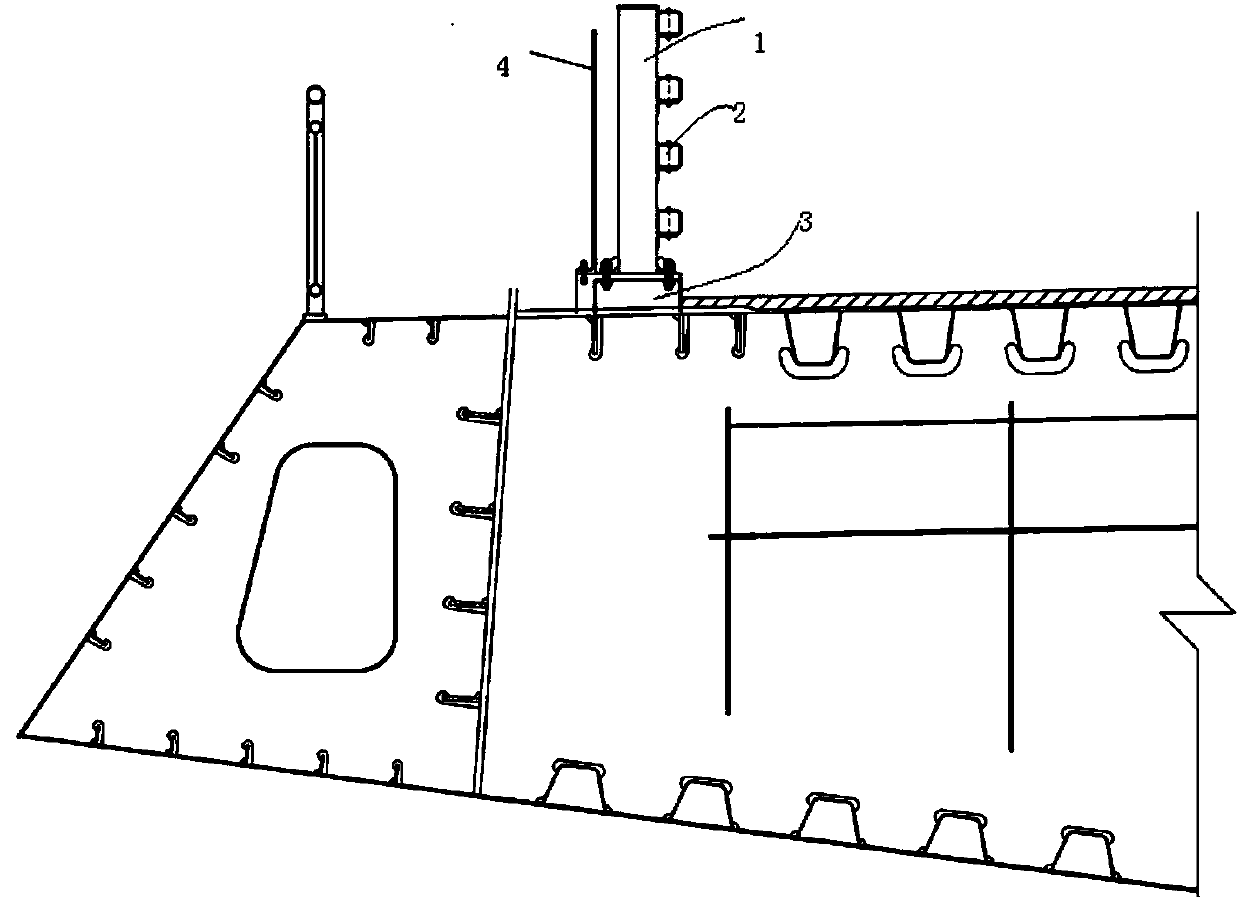

[0016] combine Figure 4a and Figure 4b as well as Figure 5a and Figure 5b It can be seen that a specific embodiment of the present invention is to suppress the vortex-induced vibration of the streamlined box girder of the long-span bridge by installing vortex vibration suppression plates along the span direction of the bridge at intervals between the anti-collision railing columns. In Fig. 4, 1 is the column of the anti-collision railing, 2 is the cross bar of the anti-collision railing, 3 is the support of the column of the anti-collision railing, and 4 is the vortex vibration suppression plate (referred to as the vibration suppression plate). The two ends of the vibration suppression plate are fixed on the support of the column of the anti-collision railing by bolts, and the distance between the vibration suppression plate and the column is 120-160 mm. H is the height of the column of the anti-collision railing, L is the distance between the columns of the anti-collis...

Embodiment 1

[0017] Example 1, B / L=3, D / H=1; H is 1420mm, L is 1500mm, D is 1420mm, B is 4500mm, and the distance between the damping plate and the column is 120mm.

Embodiment 2

[0018] Embodiment 2, B / L=4, D / H=0.5; All the other are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com