Coal storage bunker external air cannon platform construction vehicle

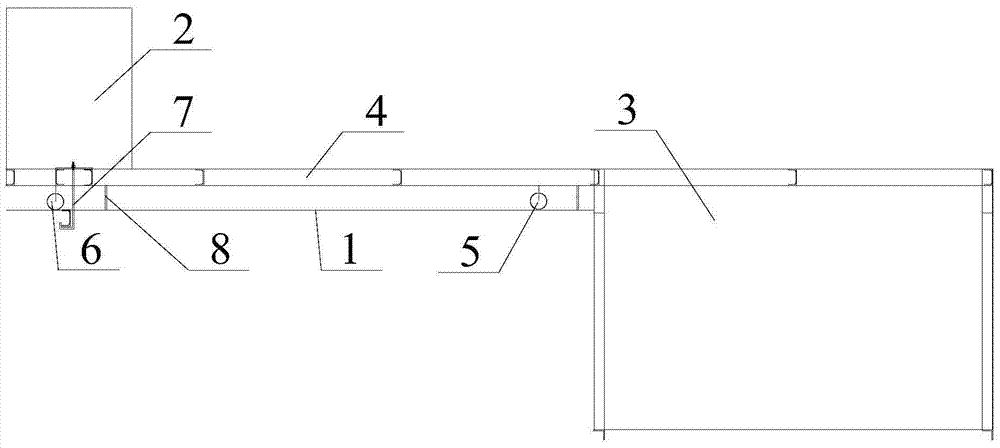

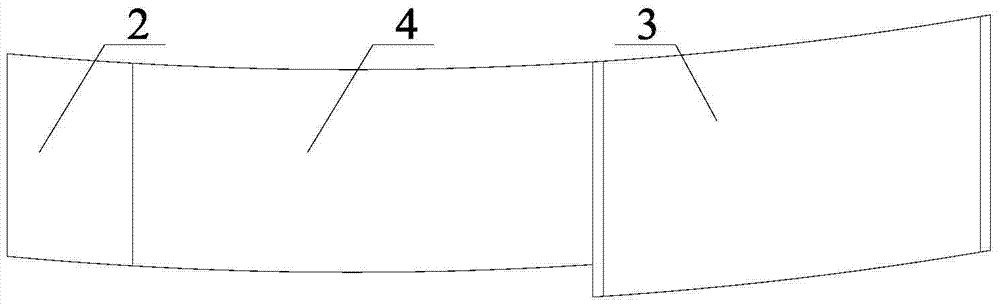

A coal storage bunker and air cannon technology is applied in the field of construction vehicles with an air cannon platform outside the coal storage bunker, which can solve the problems of high labor intensity, low construction efficiency, and low work efficiency, so as to reduce labor intensity and save repeated dismantling installation and improve construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

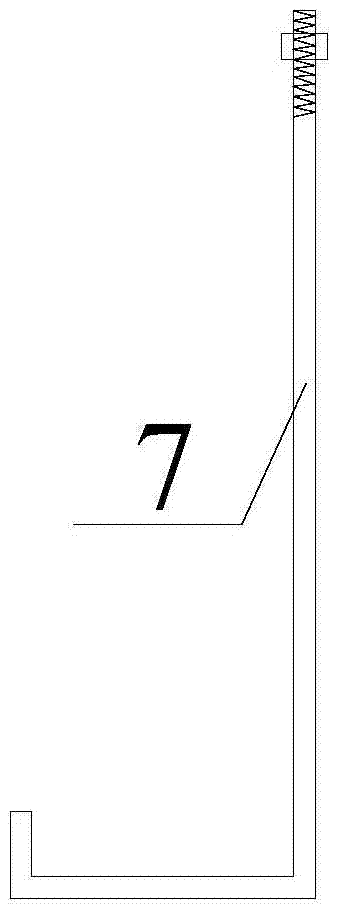

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1. To install the 22-meter warehouse air cannon platform, a total of 58 platform supports need to be installed, and the platform board is 69 meters long and 1.4 meters wide:

[0023] Using the method of building a full house of scaffolding, you need to rent 3,500 meters of steel pipes (DN40) and 2,000 sets of fasteners, and the rental fee is 140 yuan per day; it takes 7 days for 3 people to set up the scaffolding, and 3 days for dismantling; then install the air cannon platform and brackets, 2 people need 5 days. It will take a total of 15 days to complete the construction of the platform. The rental fee for renting steel pipe fasteners is 2,100 yuan, and the labor cost (200 yuan per person per day) will cost 8,000 yuan, totaling 10,100 yuan.

[0024] Using the hanging basket construction method, it is necessary to shift the hanging basket 12 times (6-meter hanging basket), and each hanging basket can install a platform of 6 meters (including the platform sup...

Embodiment 2

[0026] Embodiment 2, installation of the 25-meter warehouse air cannon platform: adopting the scaffolding method requires a construction period of 18 days and a cost of 12,500 yuan; using a hanging basket construction requires a construction period of 16 days and a cost of 10,500 yuan; using the construction vehicle of the invention requires a construction period 11 days, the cost is 4860 yuan.

Embodiment 3

[0027] Embodiment 3, install the 35-meter storehouse air cannon platform: adopt the scaffolding method, need construction period 22 days, cost 15000 yuan; adopt hanging basket construction, need construction period 21 days, cost 14000 yuan; adopt the construction vehicle construction of this invention, need construction period 13 days, the cost is 5660 yuan.

[0028] In summary, the installation process of the entire air cannon platform can be completed at one time by using the present invention, the amount of disassembly and assembly is small, and the process of repeated disassembly and assembly is omitted, the labor intensity is greatly reduced, time and effort are saved, and the construction efficiency is improved , saving construction cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com