Metering device state inspection method

A technology of measuring devices and inspection methods, applied in the direction of measuring devices, measuring electrical variables, instruments, etc., can solve problems such as low work efficiency, unsmooth inspection work, and inability to realize comprehensive inspection of the state of measuring devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

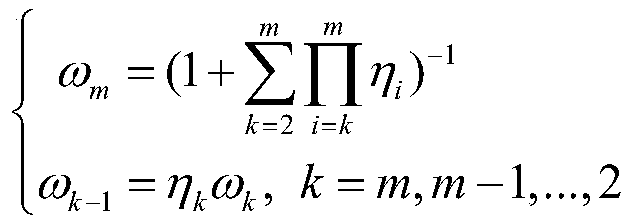

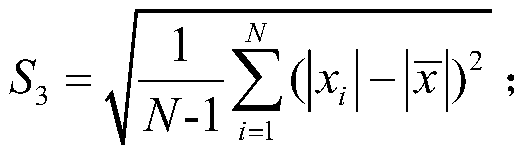

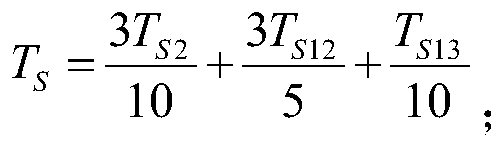

Method used

Image

Examples

Embodiment Construction

[0086] The measuring device state inspection method of the present invention comprises the following steps:

[0087] A. Collect the basic information data and on-site operation data of the metering device; the basic information data of the metering device can be obtained through the existing metering production scheduling platform (MDS), and the metering production scheduling platform (MDS) brings together the full performance of the metering device before delivery , after the arrival of the goods, sample comparison, random inspection, full inspection and other links to verify the error data, each supplier's bid winning batch, arrival batch, return batch information and failures in the operation link, collect the basic information of the metering device When collecting data, you only need to call the relevant data stored in the metering production scheduling platform; the on-site operation data of the metering device can be obtained through the existing power consumption inform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com