Cleaning device energy saving method

A cleaning device and technology for cleaning devices, which are used in household cleaning devices, cleaning equipment, washing machines/washing machines for tableware, etc., can solve the problems of energy waste, cost increase, labor cost, etc. The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

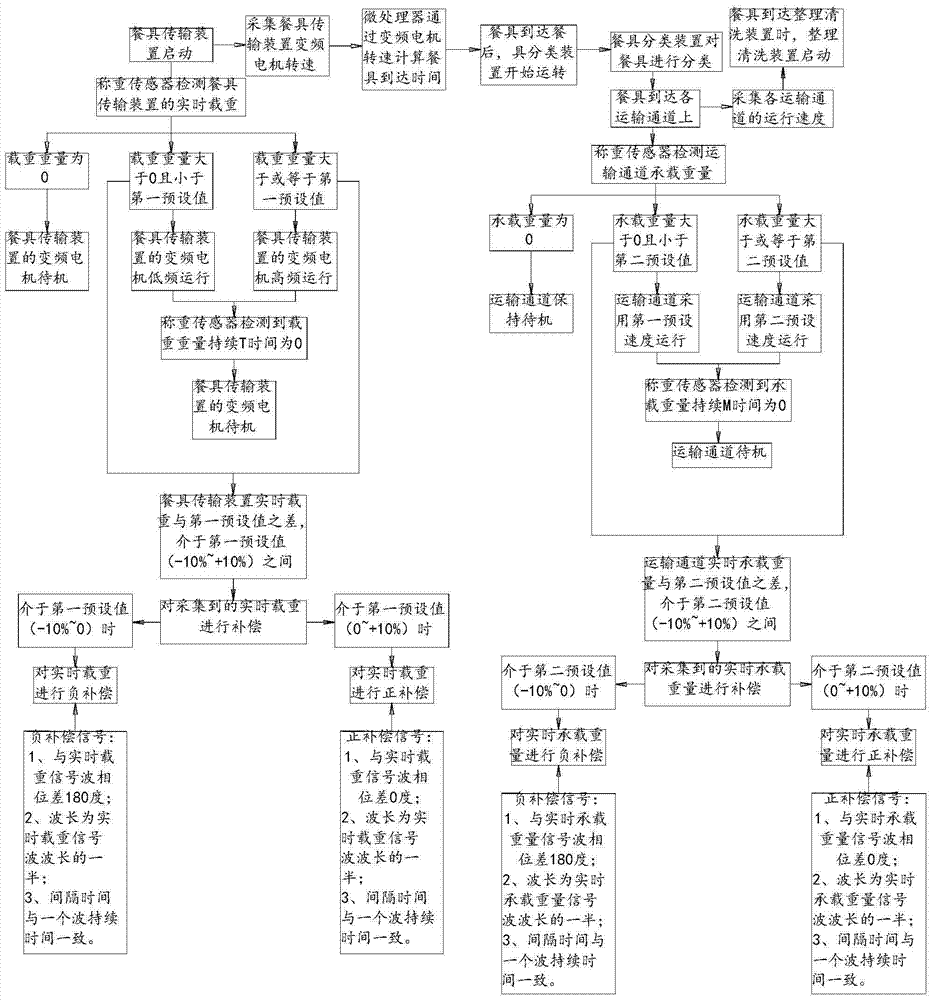

[0028] A cleaning device energy-saving method, comprising the following steps:

[0029] After the tableware transmission device is started, the load cell detects the real-time load on the tableware transmission device;

[0030] When the load weight detected by the load cell is 0, the variable frequency motor is in a standby state, and the tableware conveying device driven by the variable frequency motor remains in a stopped state;

[0031] When the load weight detected by the load cell is less than the first preset value and greater than 0, the variable frequency motor of the tableware conveying device operates at a low frequency;

[0032] When the load weight detected by the load cell is greater than or equal to the first preset value, the variable frequency motor of the tableware conveying device operates at high frequency;

[0033] When the variable frequency motor of the tableware conveying device is operated at low frequency or high frequency, when the load weight detect...

Embodiment 2

[0036] In order to further reduce energy consumption, save energy, and improve the degree of automation and intelligence of the equipment, on the basis of Embodiment 1, the following steps are further included: collecting the rotating speed of the variable frequency motor of the tableware conveying device, and transmitting the rotating speed to The microprocessor analyzes and processes, and the microprocessor calculates the time for the tableware to be transported to the tableware sorting device through the rotating speed of the variable frequency motor, and controls the operation of the tableware sorting device when the tableware arrives at the tableware sorting device. By calculating the rotation speed of the frequency conversion motor of the tableware transmission device, the time for the tableware to reach the tableware sorting device can be calculated. When the tableware arrives, the tableware sorting device will start to operate, which can maximize energy utilization effic...

Embodiment 3

[0038]Embodiment 3 may further include the following steps on the basis of Embodiment 1 or Embodiment 2: after being classified by the sorting device, different types of tableware are transported to the sorting and cleaning device via their respective transport channels, and each transport channel is equipped with There is a load cell for detecting the weight of the load on each transport channel. When the load detected on the transport channel is 0, the transport channel remains in standby mode. When the load detected on the transport channel is greater than 0 and less than the second When the preset value is set, the transport channel runs at the first preset speed. When the load capacity detected by the transport channel is greater than or equal to the second preset value, the transport channel runs at the second preset speed, and one of the transport channels uses In the running state of the first preset speed or the second preset speed, when the load weight detected by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com