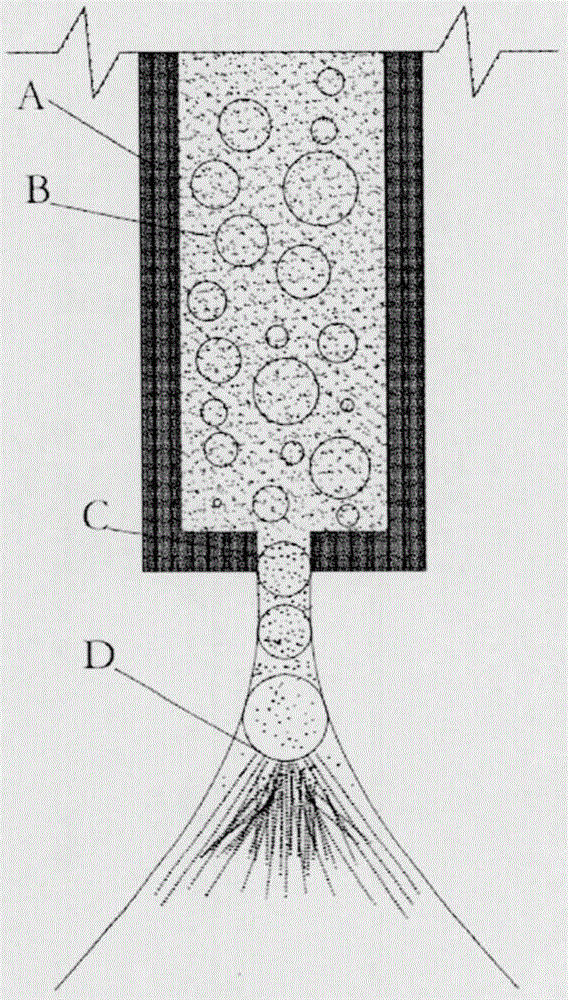

Bypass vortex-bubble atomizing type low-pressure fine-spray sprayer

A low-pressure water mist and sprinkler technology, which is used in fire rescue and other directions, can solve the problems of poor fire extinguishing effect of water mist sprinklers, complex structure of swirl core, and inability to fully utilize water flow energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

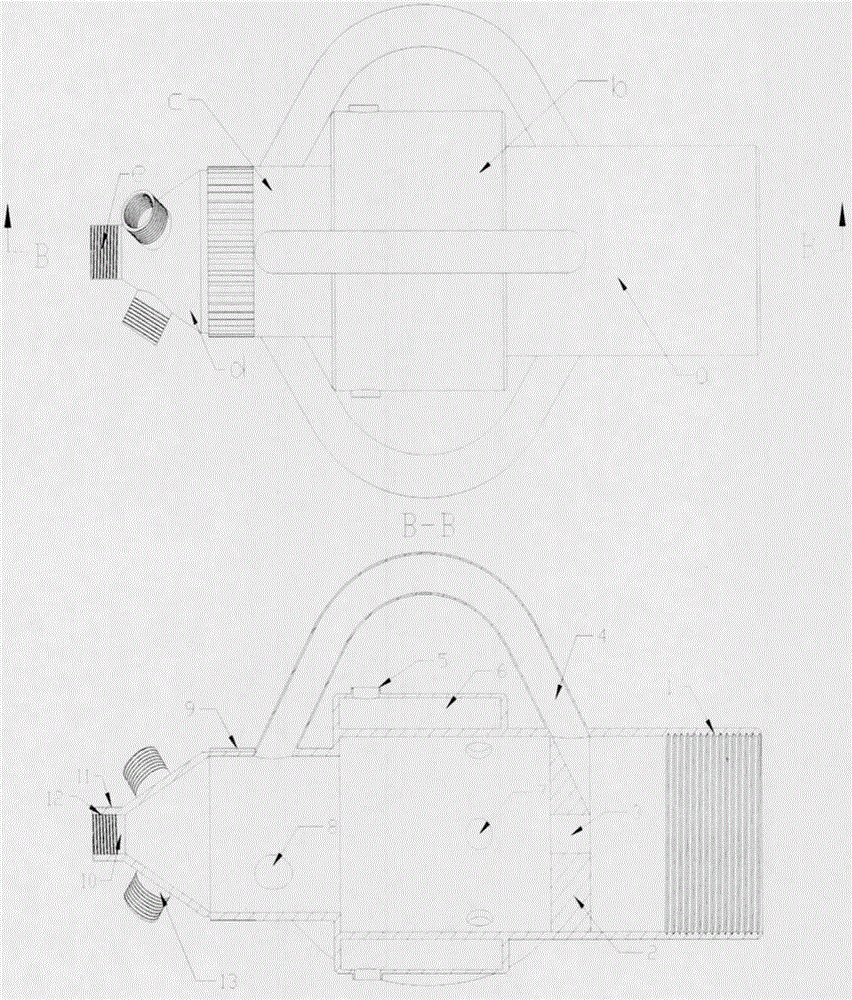

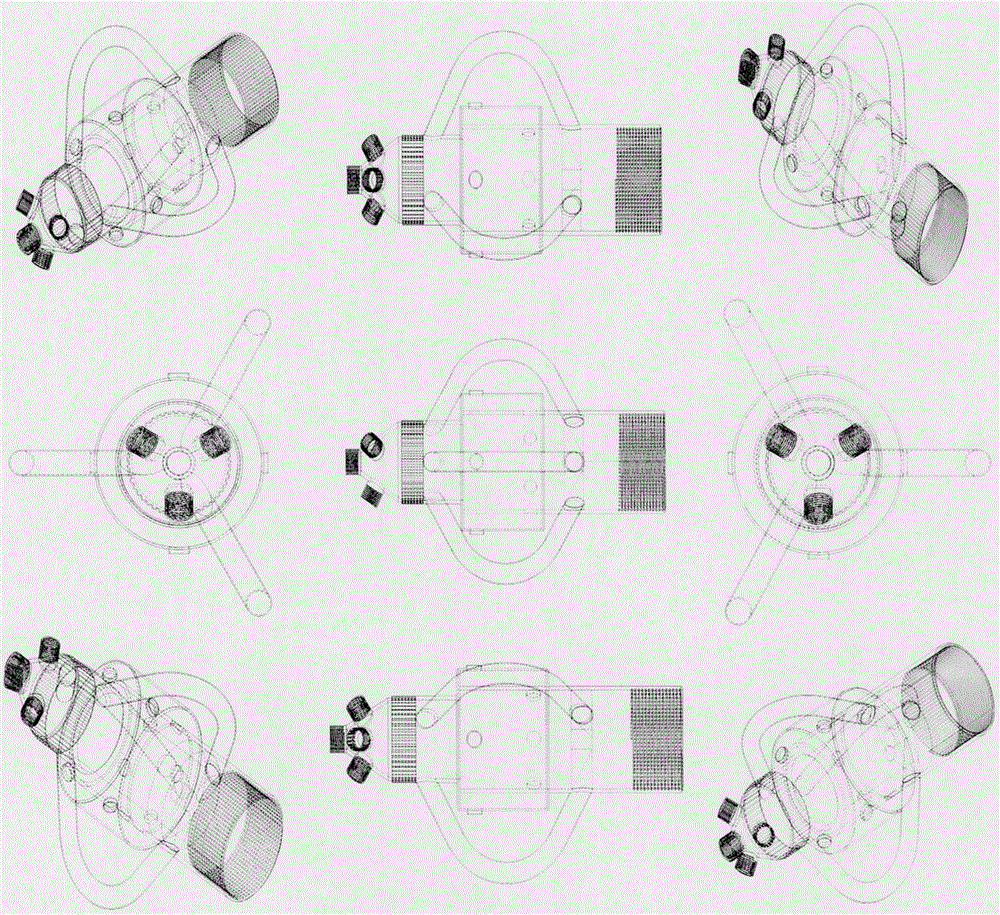

[0040] The fire-fighting water comes from the fire-fighting water pipeline, and enters the inflow section a through filters and other equipment. Pass through the bypass pipe 4 to bypass the gas injection section and reach the swirl mixing section c.

[0041] The main flow enters the gas injection section, and the atomizing gas (usually N 2 ) enters the atomizer body cavity 6 through the airway connected to the outer gas injection pipe connection hole 5, and then enters the main flow through the inner gas injection hole 7 for mixing, wherein there are 4 outer gas injection holes, which are evenly distributed on the circumference and located close to the swirl section; the inner gas injection holes There are 6, evenly distributed on the circumference, and the position is close to the incoming flow section.

[0042]The main flow flowing out of the gas injection section is fully mixed with the three bypass water flows in the swirl section c, where the main flow is also mixed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com