Defect detection method and device

A defect detection and defect technology, which is applied in the direction of optical test defects/defects, etc., can solve problems such as hidden worries at the human management level, quality variation, and loss of quality, and achieve the effect of improving accuracy and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The features of the present invention are described in detail in the following embodiments, the content of which is sufficient to enable any person skilled in the art to understand the technical content of the present invention and implement it accordingly, and according to the contents, claims and drawings disclosed in this specification, anyone skilled in the art A skilled person can easily understand the related objects of the present invention. The following examples are to further describe the viewpoints of the present invention in detail, but not to limit the scope of the present invention in any way.

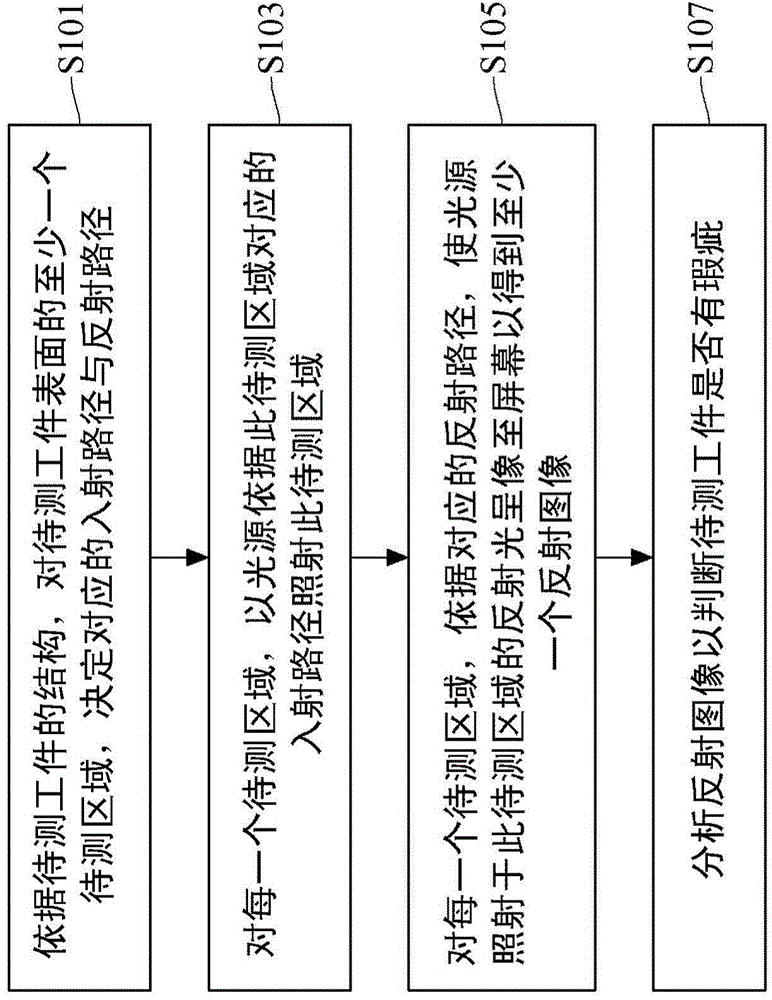

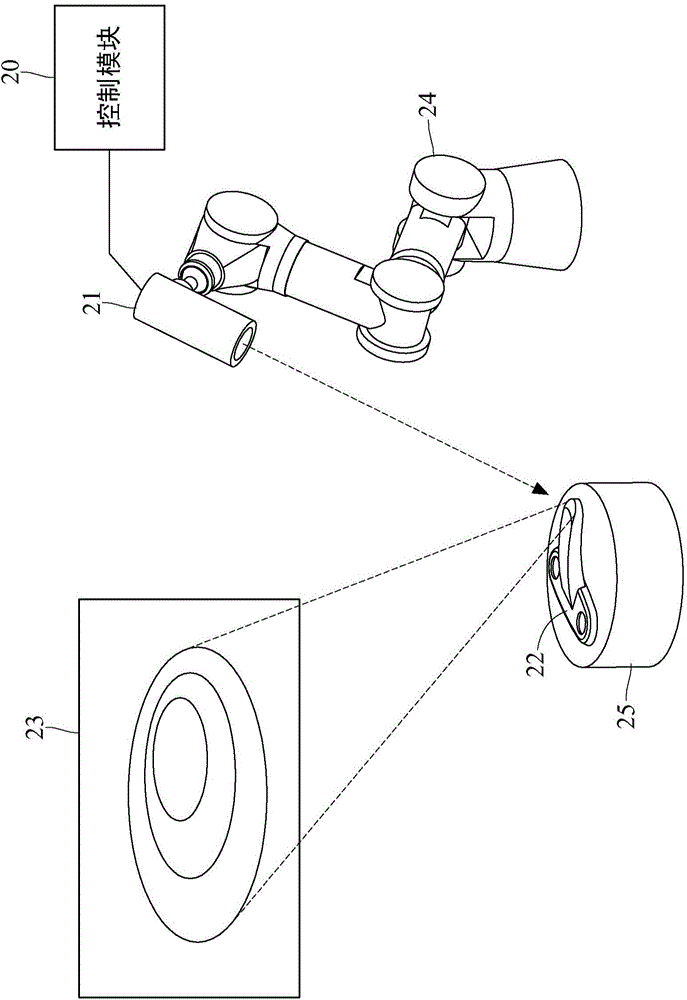

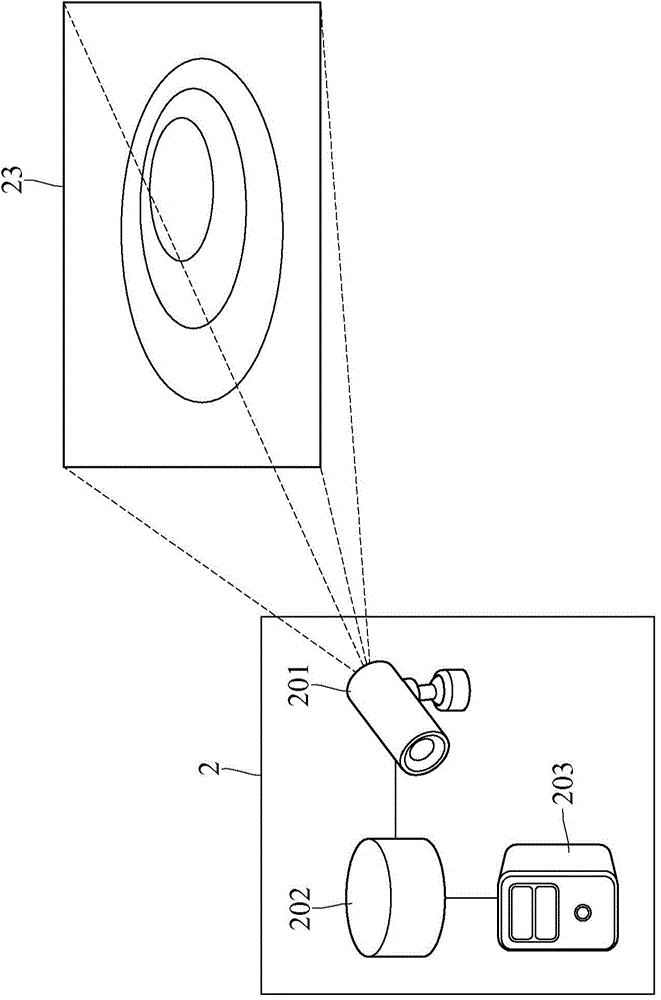

[0044] Please refer to figure 1 , figure 1 It is a flowchart of a defect detection method according to an embodiment of the present invention. Such as figure 1 As shown, the defect detection method of the present invention is based on the following steps: First, in step S101, according to the structure of the workpiece to be tested, the corresponding incident pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com