A safety release mechanism with locking and emergency fixed force

A fixed force and safe technology, applied in the direction of quick-acting fasteners, etc., can solve the problems of poor economy, complex structure, inconvenient operation, etc., and achieve the effects of high reliability, low cost and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

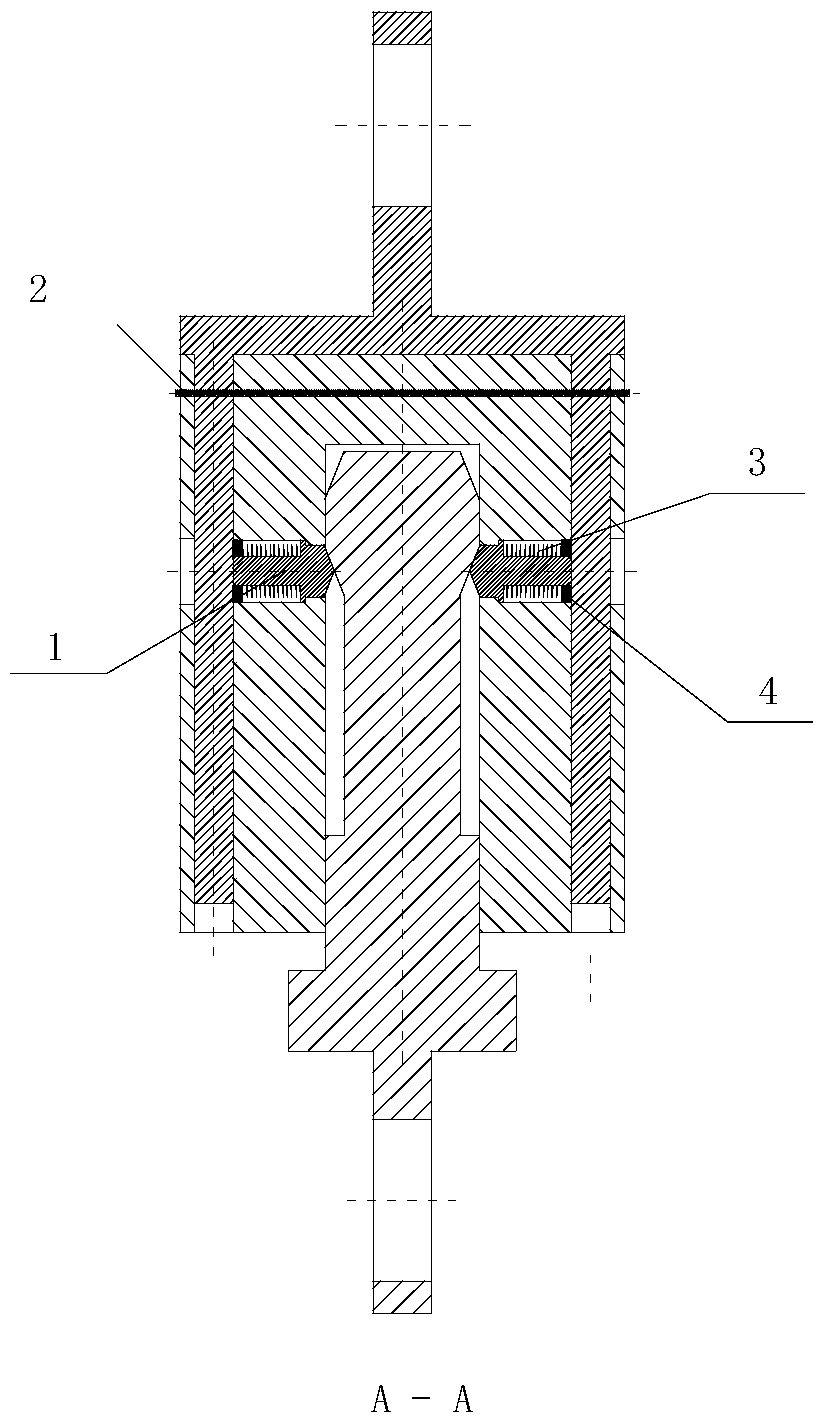

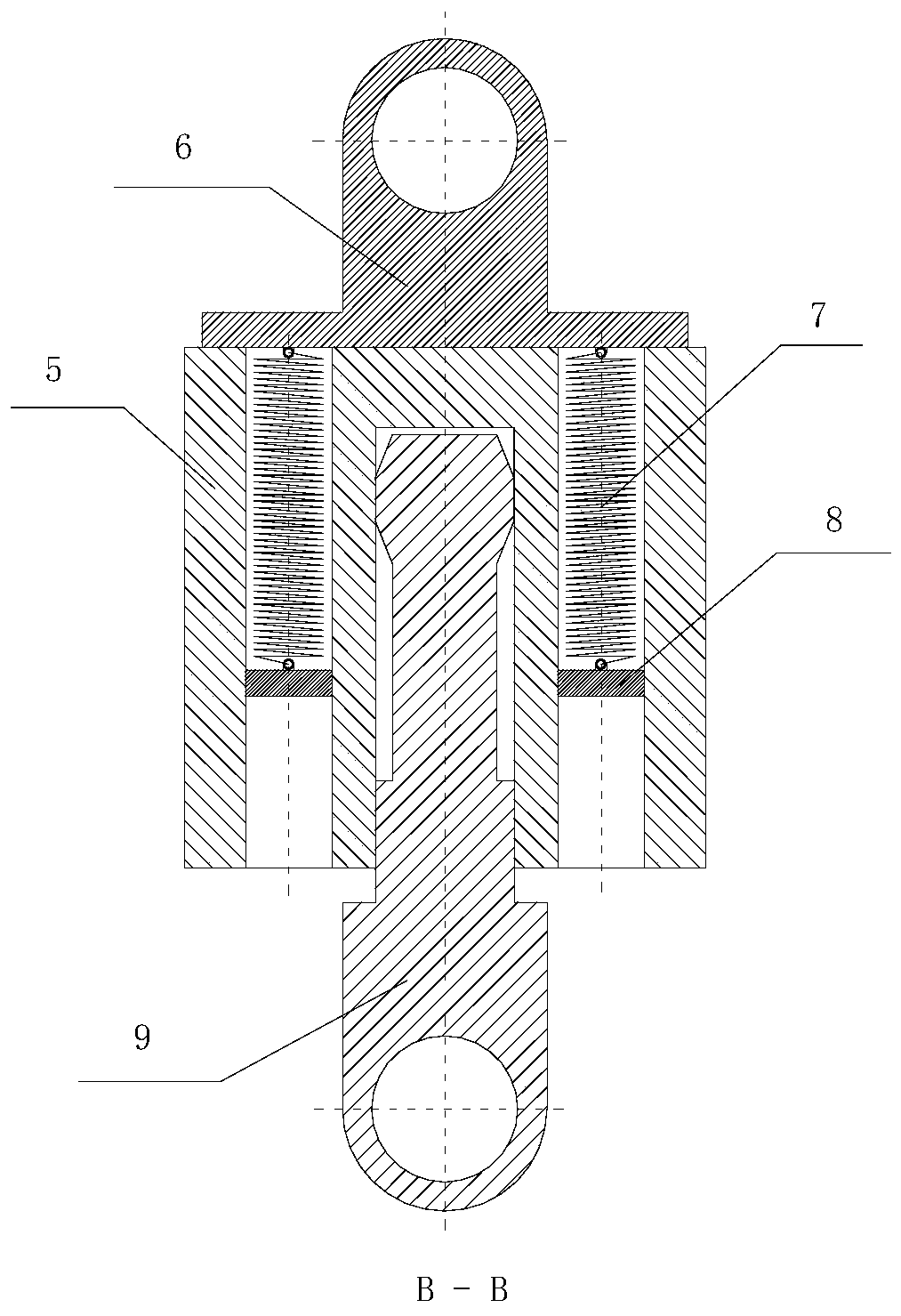

[0014] Below in conjunction with accompanying drawing, the present invention is described in further detail:

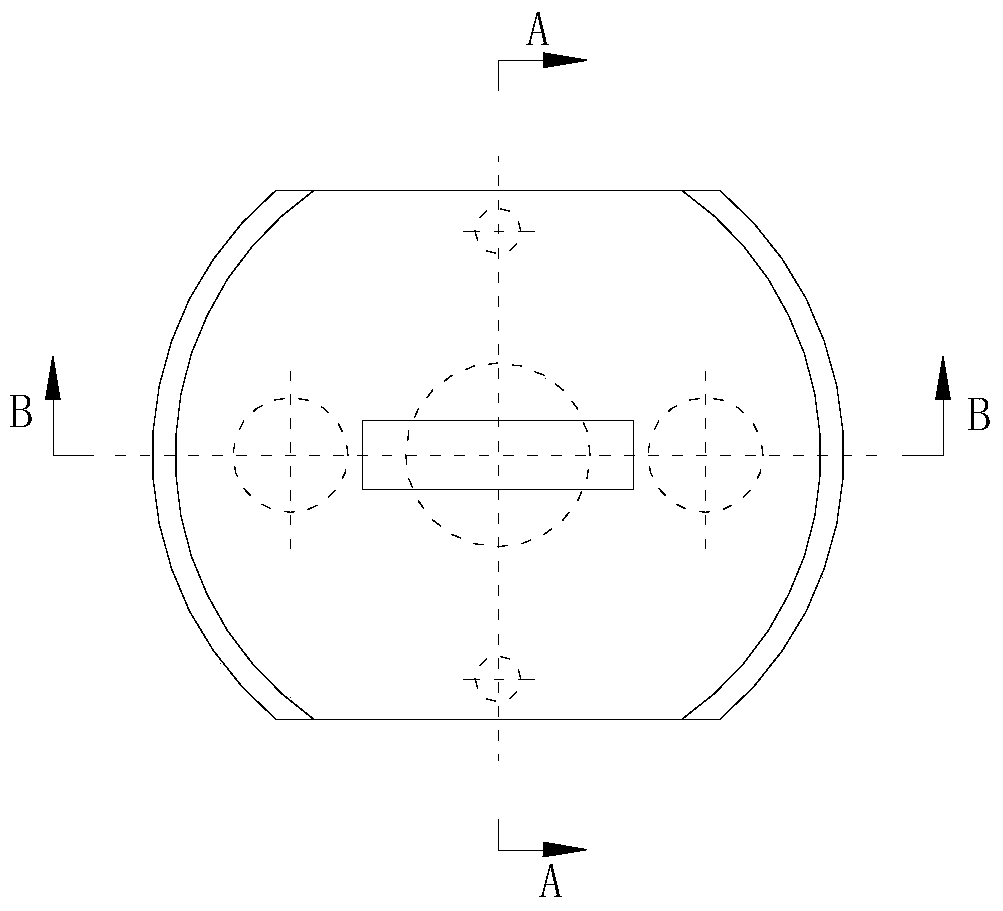

[0015] A safety release mechanism with locking and emergency fixed force, such as figure 1 , 2 , 3, including slider 1, locking pin 2, pressure spring 3, blocking cover 4, connecting piece 5, mounting seat 6, tension spring 7, constant force block 8, and separating piece 9;

[0016] Wherein, there are 5 circular holes upwards on the lower surface of the connector 5, and the 5 circular holes are distributed in a cross, wherein the central circular hole is a blind hole, and the remaining 4 holes are through holes; the top of the mounting seat 6 is a connecting part, and the mounting Two cantilever rods are symmetrically distributed front and back under the seat 6, and the cantilever rods extend into the front and rear 2 round holes of the connector 5, and two tension springs 7 are symmetrically arranged under the mounting seat 6, and each tension spring 7 lower end is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com