A hook-type device with force locking and power failure separation

A locking lever and locking pin technology, applied in the field of separation, can solve the problems of poor economy, complex structure, inconvenient operation, etc., and achieve the effects of high reliability, reduced cost, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention is described in further detail:

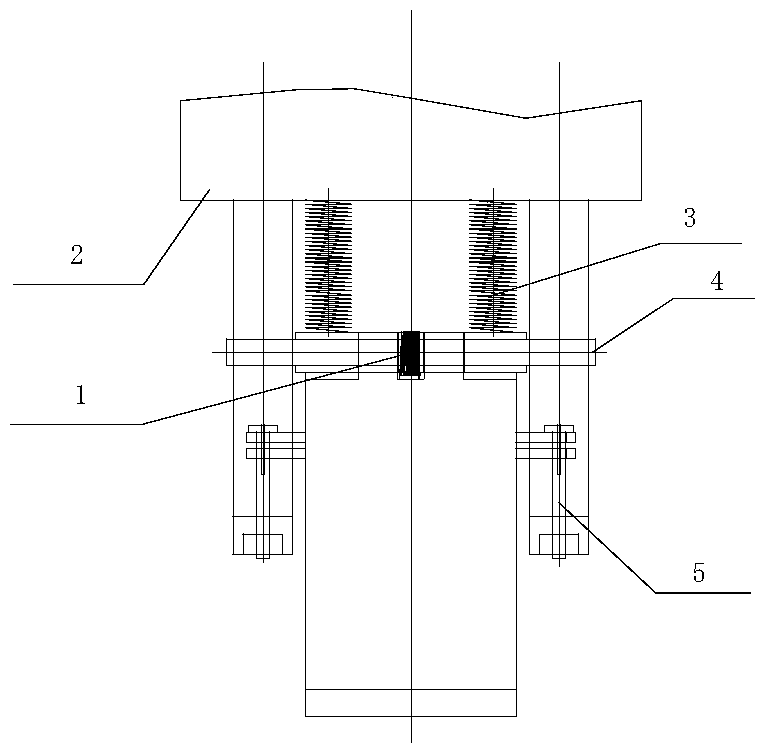

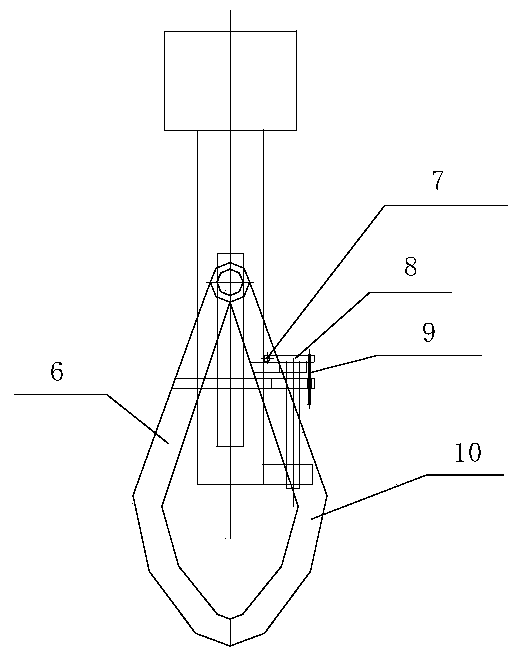

[0014] A hook-type device with force locking and power failure separation, such as figure 1 , 2 As shown, including large torsion spring 1, mounting base 2, 2 extension springs 3, sliding rod 4, 2 locking rods 5, left hook 6, 2 torsion springs 7, 2 baffles 8, 2 locking pins 9 , right hook 10;

[0015] Wherein, the mounting seat 2 is provided with two downward cantilever beams on the left and right sides, and each cantilever beam has a rectangular groove laterally, and the two ends of the sliding rod 4 respectively extend into the rectangular grooves of the two cantilever beams. Connected to the bottom of the mounting base 2, the other ends of the two extension springs 3 are connected to the sliding rod 4, the upper ends of the left hook 6 and the right hook 10 are hinged with the sliding rod 4, and the large torsion spring 1 is set in the middle of the sliding rod 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com