A sand mold self-positioning formwork

A self-positioning and template technology, applied in the field of sand casting, can solve problems such as unsatisfactory positioning effect, excessive positioning deviation of upper and lower molds, and poor positioning accuracy, so as to reduce the phenomenon of running out of fire, reduce the amount of wrong shapes, and have strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

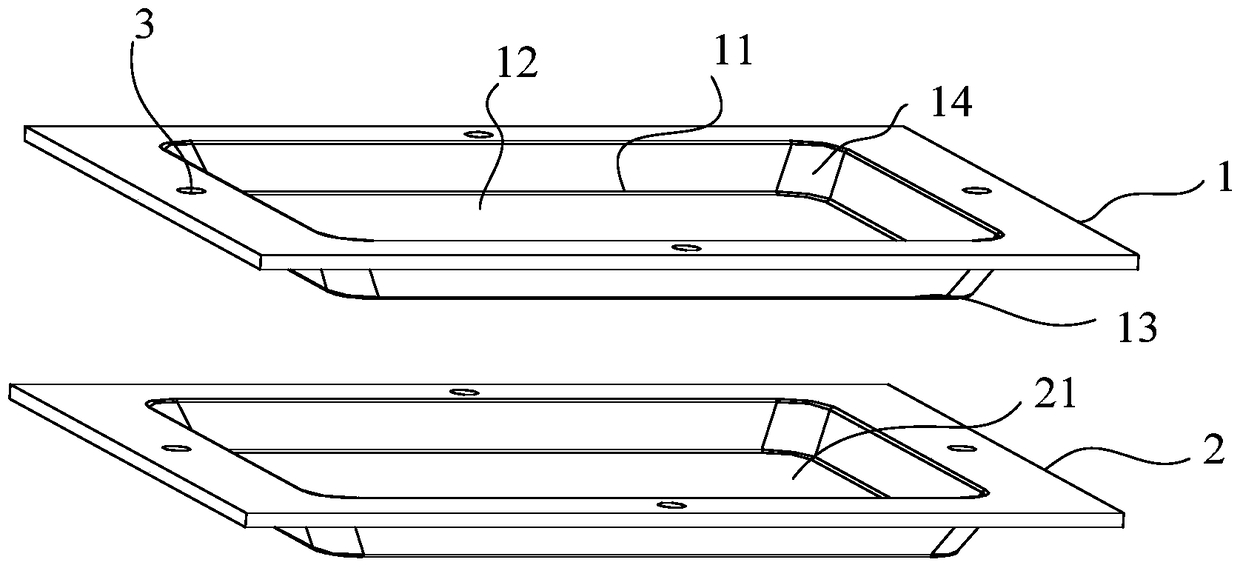

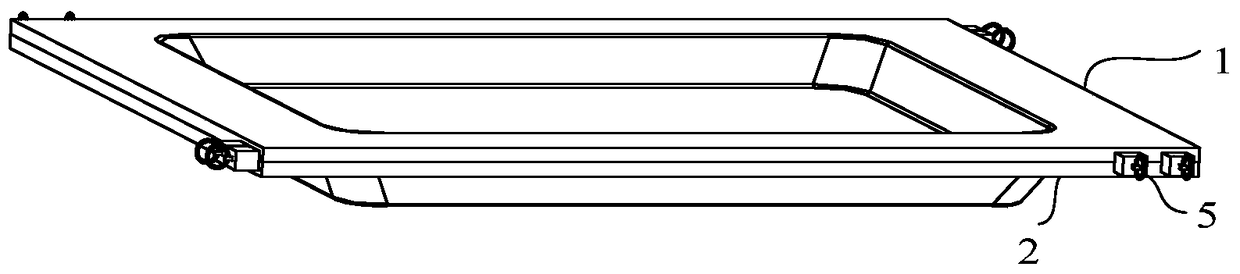

[0028] Example 1, such as figure 1 with figure 2 As shown, the present invention has designed a kind of self-positioning formwork of sand mold, comprises upper formwork 1 and lower formwork 2, and the middle part of one side of upper formwork 1 is provided with downward concave trapezoidal groove 12, and the middle part of the other side is provided with The downwardly protruding trapezoidal groove 13, the concave trapezoidal groove 12 and the convex trapezoidal groove 13 form the first trapezoidal groove, and the middle part of the lower template 2 is provided with a second trapezoidal groove 21 with the same structure as the first trapezoidal groove. The upper formwork 1 and the lower formwork 2 in the invention are the clamping positions realized by the structure of the trapezoidal groove respectively. The upper and lower formworks cannot move left and right, forward and backward, but can only move up and down; The middle part is provided with an upwardly convex upper bag...

Embodiment 2

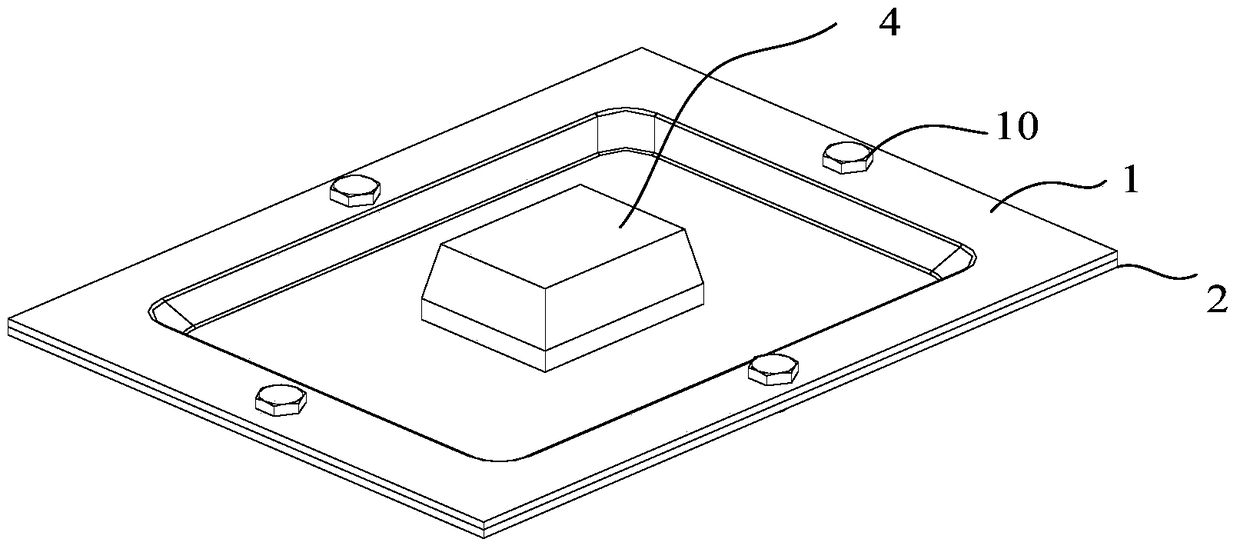

[0030] Embodiment 2, in order to make the positioning of the present invention more accurate and more practical, such as figure 2 As shown, the shape of the upper template 1 is a cuboid, and the first bolt holes 3 are arranged on the outside of the first trapezoidal groove 11 on the upper template 1 of the cuboid shape, and the first bolt holes 3 are at least 4. The lower template 2 The second bolt hole 3 that cooperates with the upper formwork 1 is also provided on the top. Like the present invention, trapezoidal grooves have been designed on the upper and lower formworks, so that the upper and lower formworks cannot move back and forth, left and right, respectively. The first bolt hole 3 and the second bolt hole 3 are provided, and the fixing bolts used to connect the upper and lower templates are arranged in the two bolt holes 3. The number of bolt holes 3 is at least 4, and its function is to fix the connection The upper and lower templates cannot move up and down. Second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com