Apparatus for pulling core through ejecting block in small space

A narrow space, top block technology, applied in the field of top block core-pulling devices, can solve the problems of insufficient movement space, insufficient strength, and small thickness of the inclined top block, etc., to achieve low production cost, high production efficiency, and stable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following are examples of the present invention, and the practical use of the present invention is not limited to the examples.

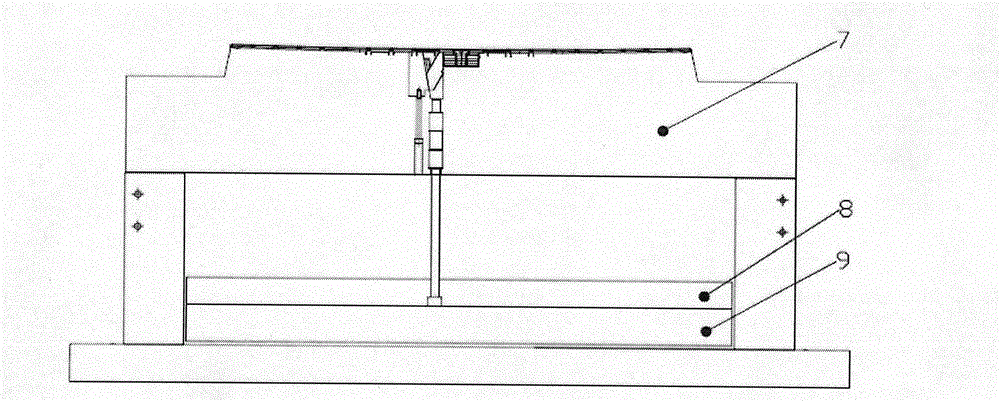

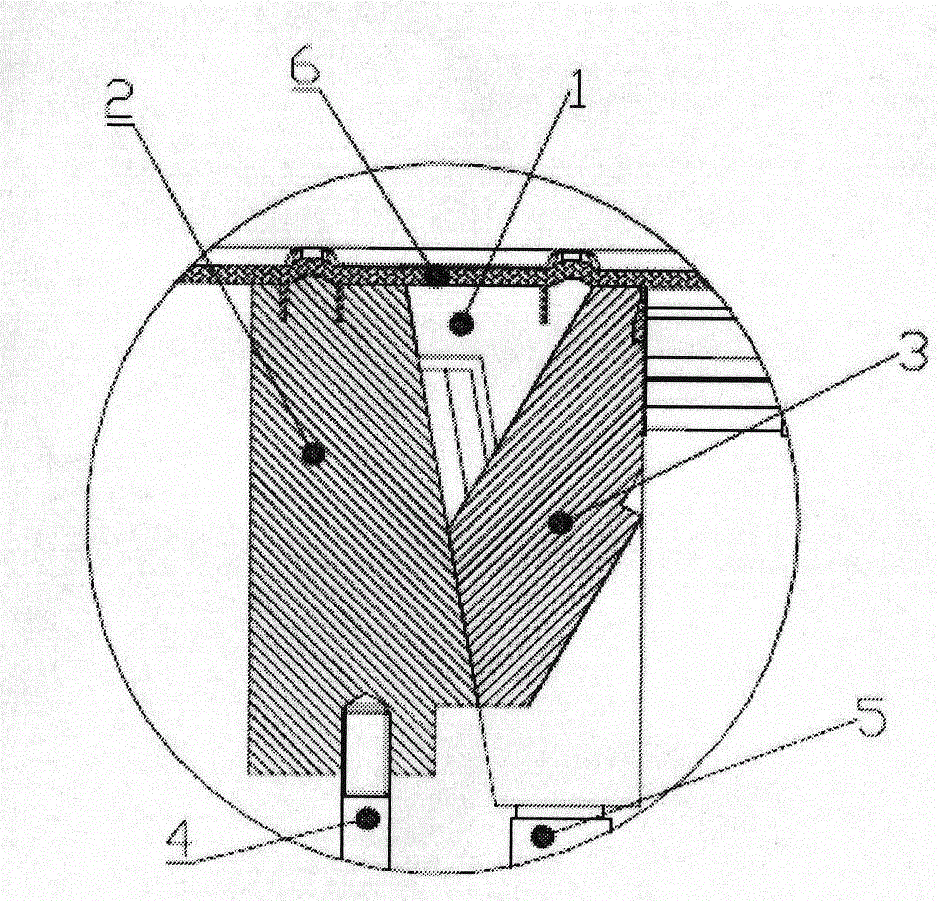

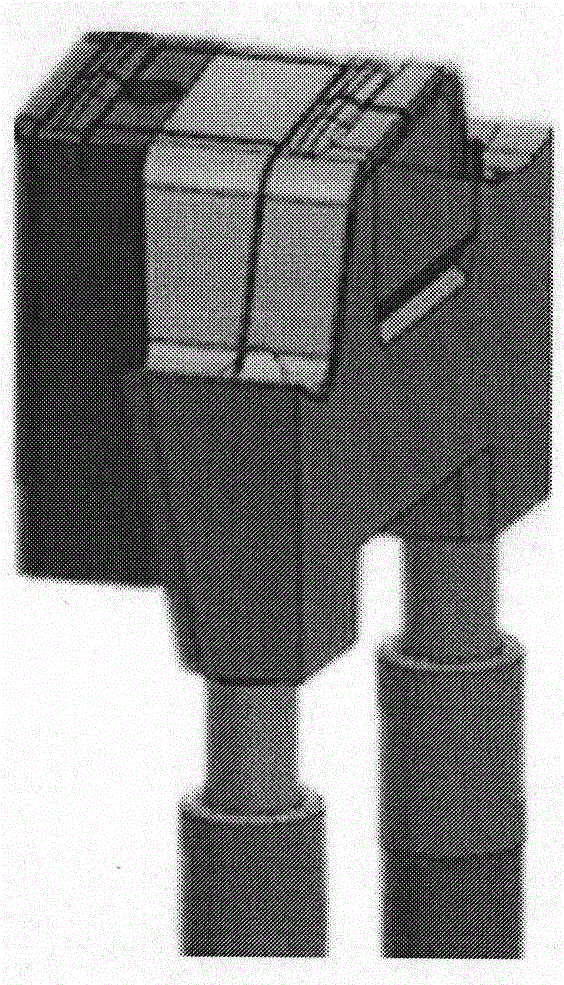

[0012] refer to figure 2 , image 3 , Figure 4 , Figure 5 , in this embodiment, the jacking block core-pulling device in a narrow space consists of a straight jacking block 1, a T-shaped fixed block 2, a T-shaped core-pulling block 3, a movable mold 7, an inner hexagon bolt 4, and a straight jacking block connecting rod 5 , Top plate 9, top plate fixing plate 8 form. in figure 2 The 2 in it is the product, the T-shaped fixed block 2 is fixed on the movable mold 7 by the inner hexagonal bolt, and the T-shaped core-pulling block 3 is engaged with the T-shaped fixed block 2. The straight jacking block 1 is connected with the straight jacking block connecting rod. When the top plate 9 and the top plate fixing plate 8 are ejected, when moving upward, the straight jacking block connecting rod 5 is driven to move upward, thereby driving t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com