Core shaft sleeve combination applied to roll type anti-fake bills

A mandrel and bill technology, applied in the field of mandrel set combination, can solve the problems of long processing mandrel cycle, affecting product delivery, troublesome mandrel storage, etc., and achieves the effects of low manufacturing cost, simple and compact structure, and easy use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

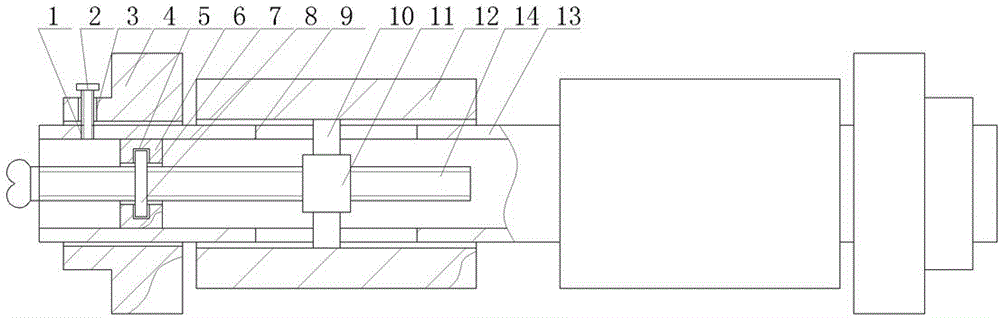

[0009] Mandrel set combination applied to roll-type anti-counterfeiting bills, such as figure 1 As shown, the fixed tube 13 is included, the fixed sleeve 4 is installed at the end of the fixed tube 13, and the mandrel 12 is installed in the middle of the fixed tube 13. The mandrel 12 is a tubular shell, and the fixed groove 9 is provided on the fixed tube 13. The connecting plate 10 is installed, the connecting plate 10 passes through the fixing groove 9, one side of the connecting plate 10 is connected with the mandrel 12, the other side of the connecting plate 10 is equipped with a fixing nut 11, and the inner side of the end of the fixing pipe 13 is installed with a fixing block 6, Offer the second through hole 7 on the fixed block 6, install the second bolt 14 in the second through hole 7, the screw mandrel of the second bolt 14 cooperates with the fixed nut 11, offer the annular groove 5 on the fixed block 6, the annular groove 5 is positioned at the first On the side cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com