All-direction cruising and photographing mechanism and wheel type pipeline detecting robot

A camera and axial motor technology, applied in the field of machinery, can solve the problems of affecting the monitoring effect, difficult to obtain monitoring pictures, unable to achieve omnidirectional shooting, etc., to achieve the effect of improving convenience and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

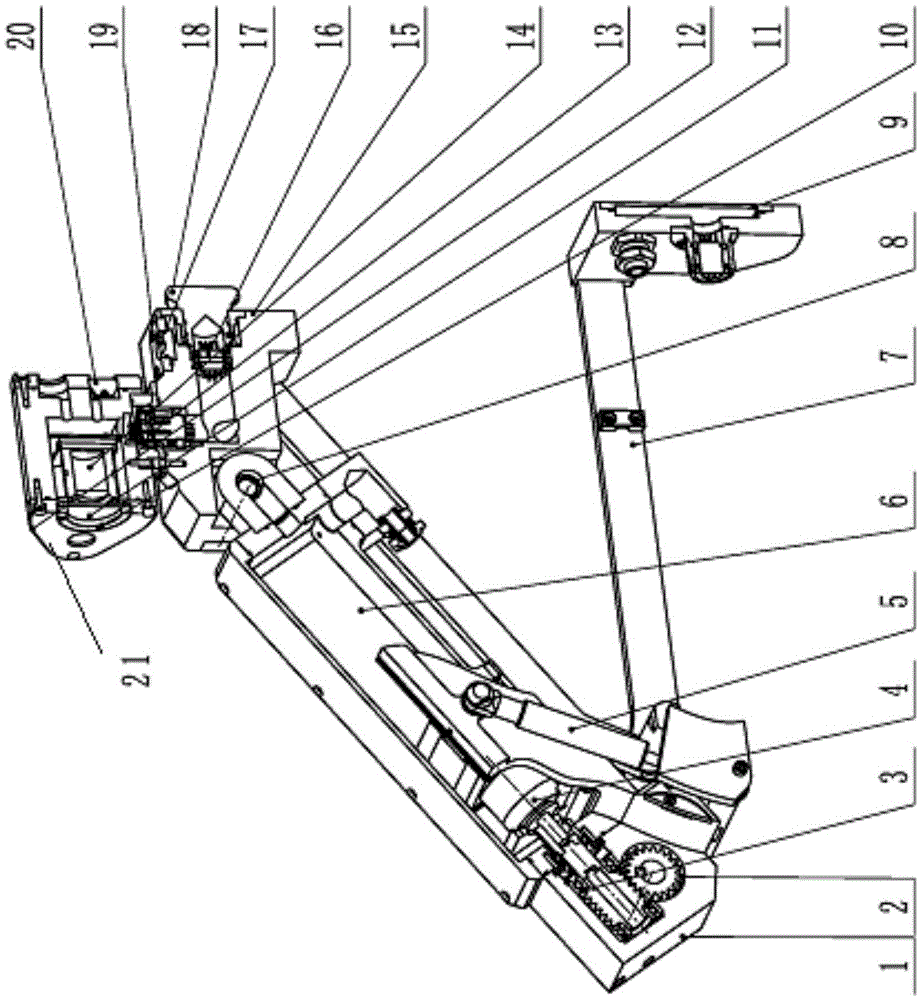

[0061] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0062] The invention provides an omnidirectional cruise shooting mechanism and a wheeled pipeline detection robot with good monitoring effect.

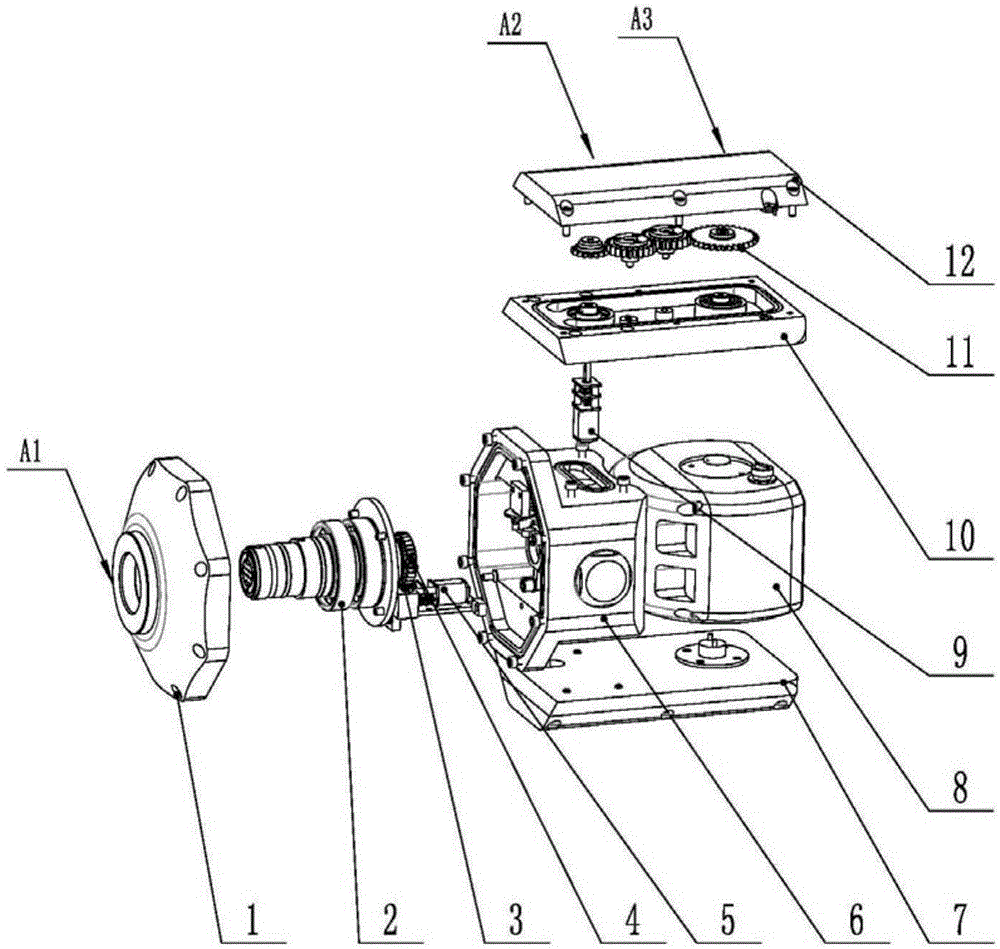

[0063] Such as figure 1 As shown, the embodiment of the present invention proposes an omnidirectional cruise shooting mechanism, including a bottom base 7, a camera main cabin 8 rotatably fixed on the base for accommodating the camera mechanism, and driving the camera The main compartment is a vertical motor 9 that rotates along a vertical axis relative to the base, and an axial motor 5 that is used to drive the camera mechanism to rotate along a horizontal axis in the main camera compartment 8;

[0064] Wherein, the bottom base 7 is provided with a rotating shaft extending vertically, and a fixed gear 11 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com