Screw-mounted filter

A filter and screw technology, applied in the field of filters, can solve problems such as failure to eliminate the phenomenon of failure, and achieve the effects of increasing reliability and convenience, low manufacturing cost, and convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

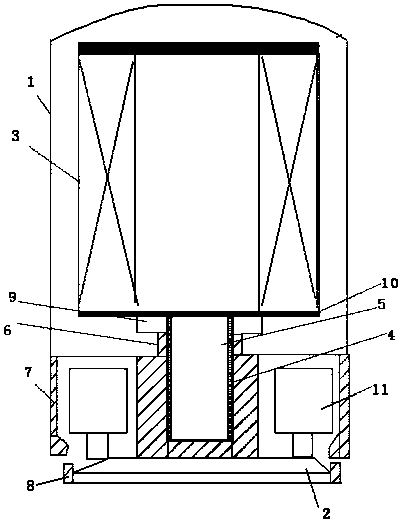

[0014] As shown in Fig. 1, a kind of filter that is installed in a spiral, comprises a filter housing 1 and a base 2 connected to the filter housing, the filter housing 1 is a cylinder, and the cavity of the filter housing 1 is provided with a filter element 3 , the center of the base 2 has an oil outlet 4, the oil outlet 4 is a cylindrical hole with internal threads, and the mouth of the oil outlet 4 is also provided with an annular boss 9 , the center of the lower end cover 10 of the filter element 3 is also provided with an annular cylinder 5 corresponding to the cylindrical hole, the cylinder 5 has an external thread matching the internal thread of the cylindrical hole, and the cylinder The body 5 is screwed into the cylindrical hole, an O-ring 6 is provided between the annular boss 9 and the filter element 3, and a threaded groove is provided around the base 2, and the threaded groove is connected with the filter housing 1 The threaded connecting plate 7 is connected, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com