Vehicle cabin assembly and vehicle with same

A vehicle and engine room technology, applied in the vehicle engine room assembly and the vehicle field with the vehicle engine room assembly, can solve problems such as unstable collision results, achieve the effects of optimizing collision performance, optimizing layout, and increasing energy absorption ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further illustrate the technical means and functions adopted by the present invention to achieve the intended invention purpose, the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

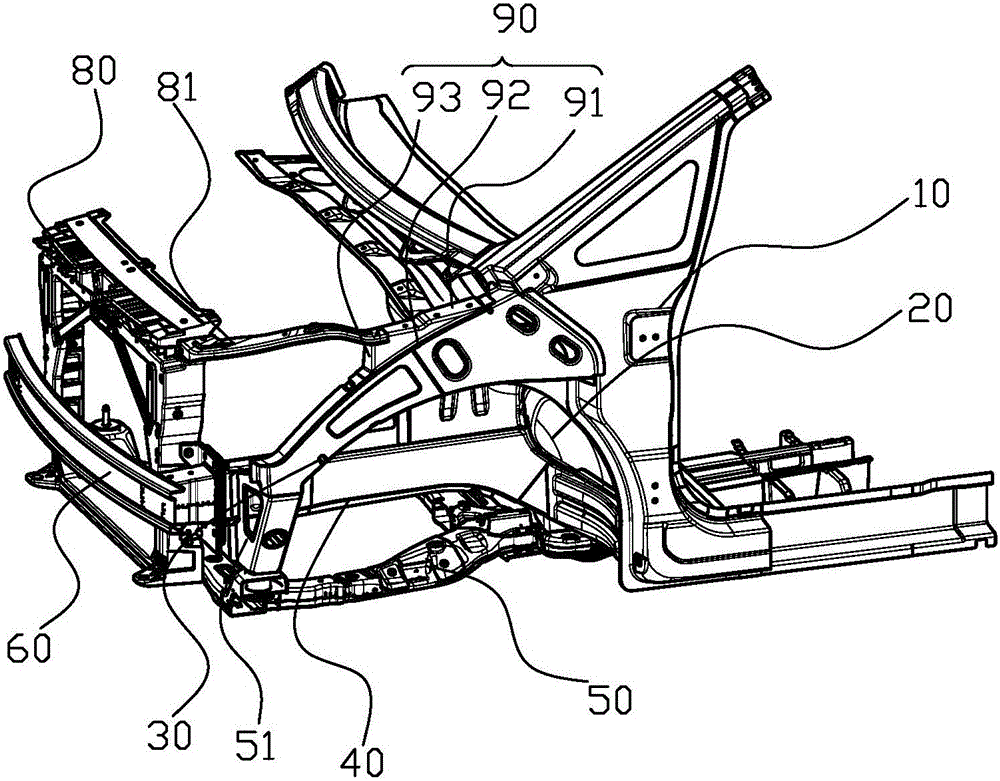

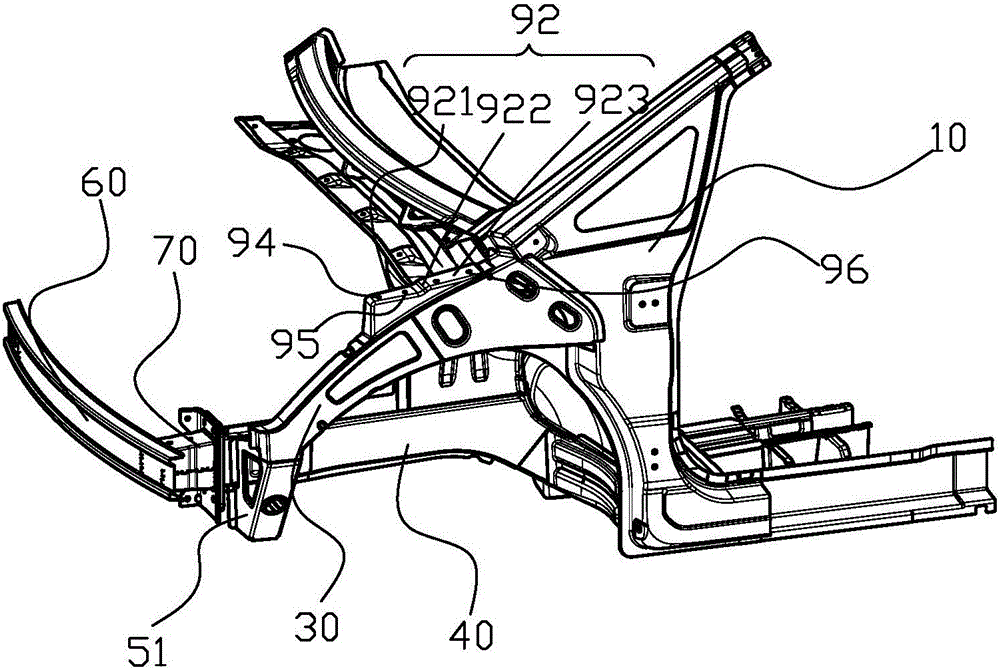

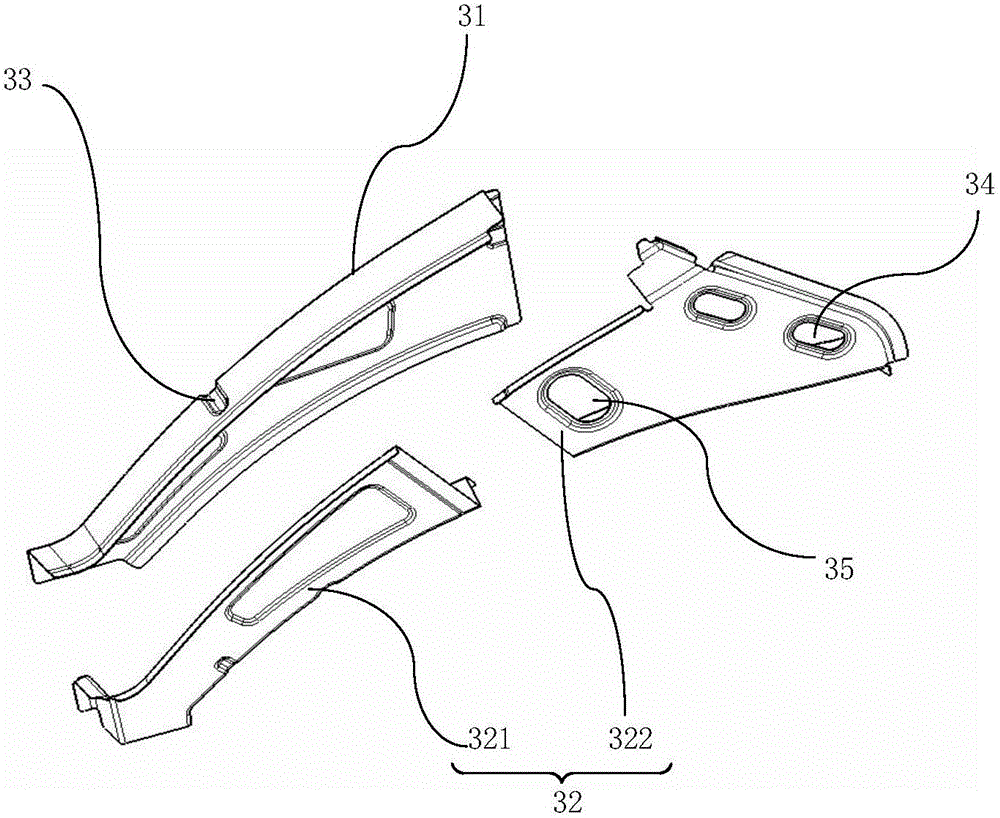

[0021] figure 1 It is a structural schematic diagram of the cabin assembly provided by the embodiment of the present invention, figure 2 for figure 1 Schematic diagram of the installation position of the mounting support in the middle, such as figure 1 and figure 2 As shown, the cabin assembly provided by the embodiment of the present invention includes an A-pillar 10, a dash panel 20, a roof rail 30, a main longitudinal beam 40, a front subframe 50, a subframe connecting plate 51, an anti-collision beam 60, a suction Energy box 70, front-end module 80, front-end module connecting plate 81 and installation support seat 90.

[0022] Wherein, the A-pillars 10 are located on both sides of the front o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com