High-reliability needle breakage detection device

A broken needle detection and reliability technology, which is applied in the fields of knitting, textiles and papermaking, to achieve high reliability and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in further detail below:

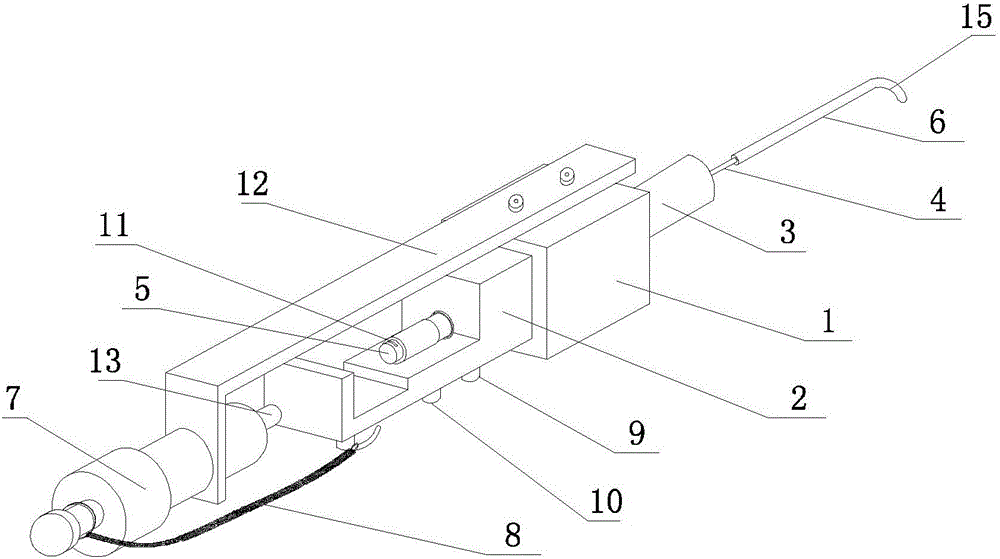

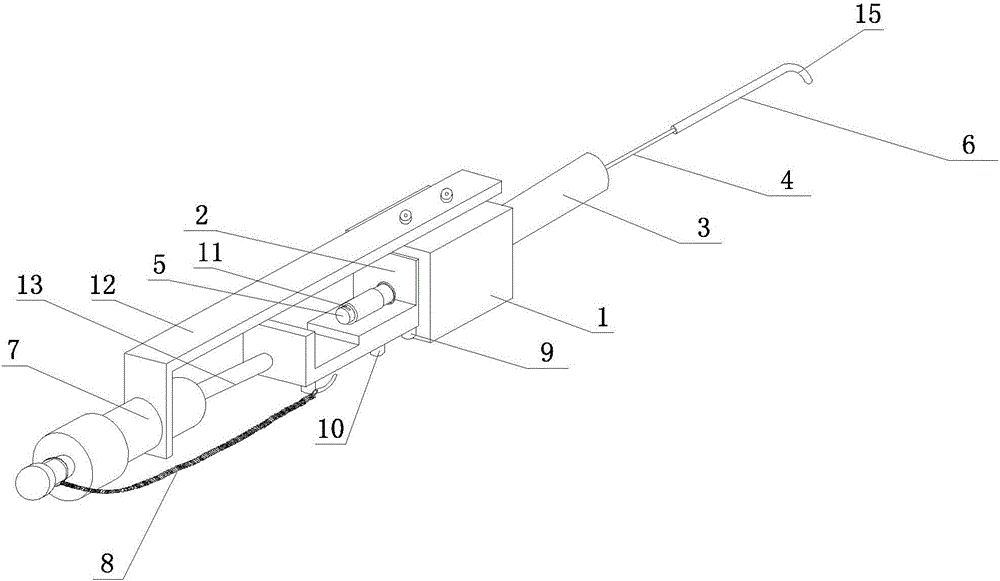

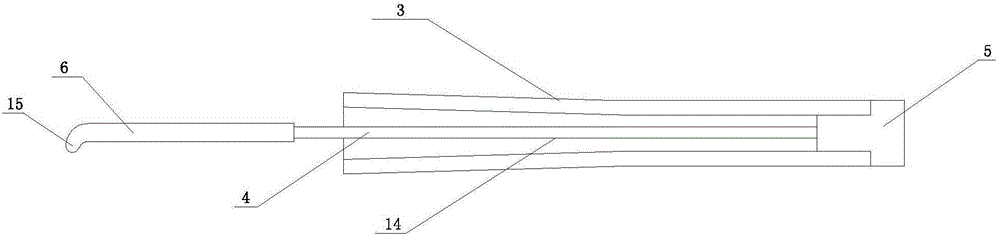

[0025] A high-reliability broken needle detection device of the present invention, such as figure 1 As shown, it includes a mounting base 1 fixedly connected to the hosiery machine. The mounting base 1 is slidably connected with a slider 2. The slider 2 is driven to slide by a driving device. A detection element is also provided on the slider 2. The detection element includes a conductive tube 3 and one end of which is inserted into the conductive tube 3 and the other end is suspended outside the conductive tube 3. The conductive rod 4 is provided with a first conductive part 14 that can be in contact with the conductive tube 3 when it swings. The conductive tube 3 is connected to the conductive tube 3. The sliders 2 are insulated, and the driving device, the conductive tube 3 and the first conductive part 14 are respectively electrically connected to the controller of the hosiery machine. The conductive rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com