Automatic locating perpendicular steering rail transfer steel mold trolley

A vertical steering and automatic positioning technology, applied in the shaft lining, tunnel lining, underground chamber, etc., can solve the problems of difficult manual compensation, turning failure, difficult control, etc., and achieve the effect of high safety and reliable track change steering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

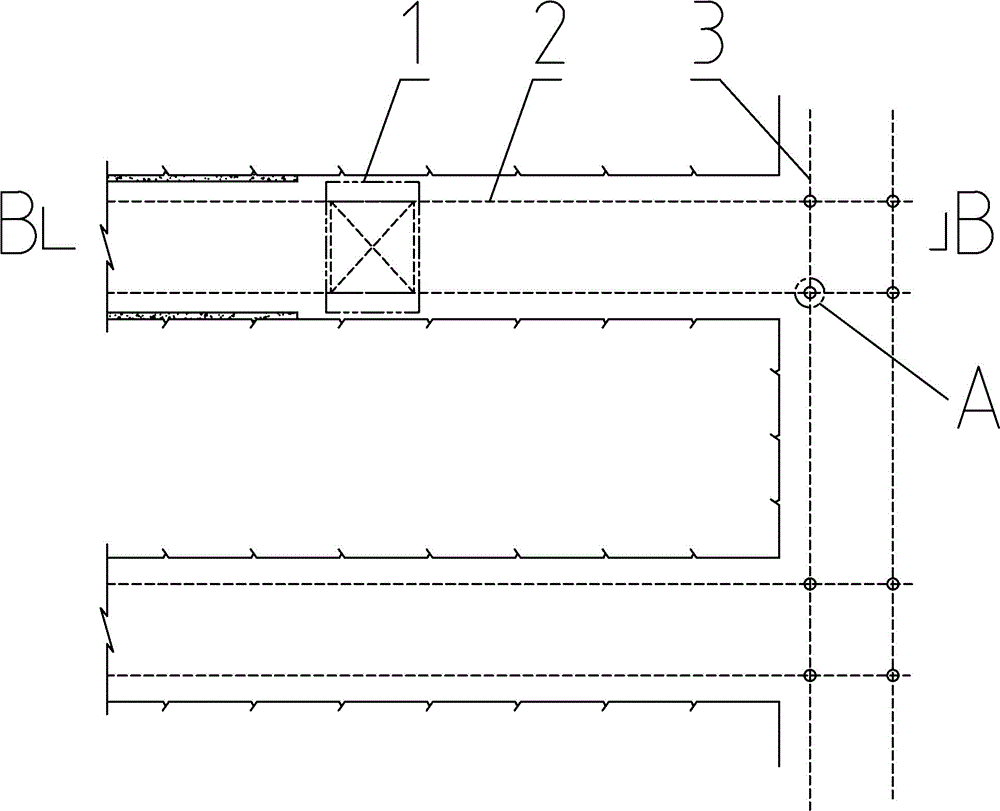

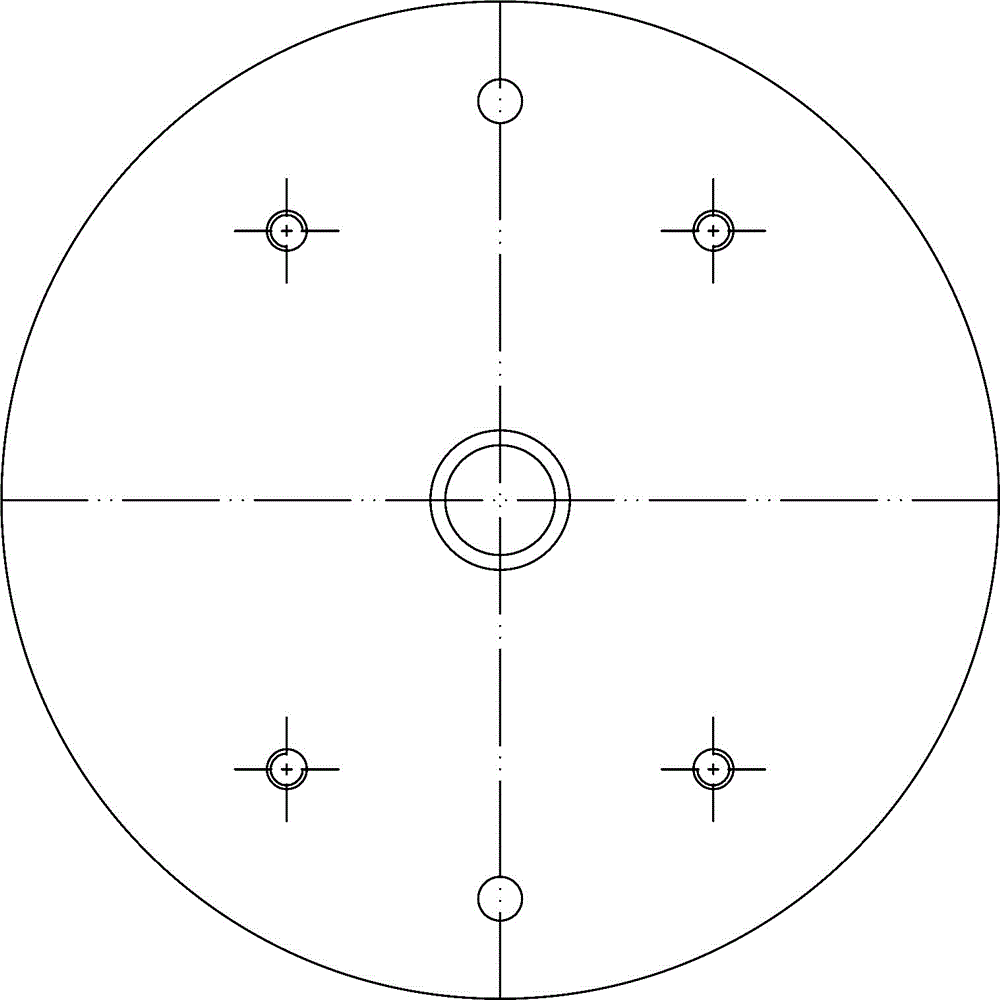

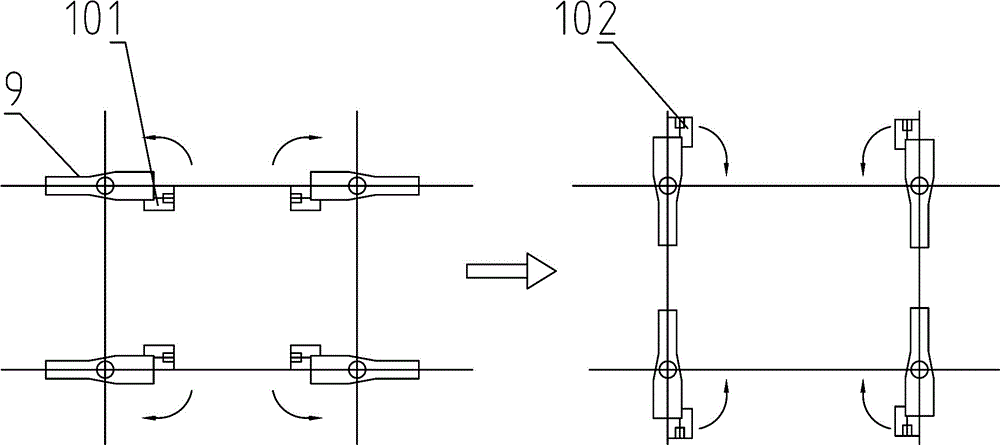

[0032] Such as Figure 1~3 Among them, a steel mold trolley with automatic positioning, vertical steering and track change. The bottom of steel mold trolley 1 is provided with a walking wheel set 9 that can rotate along a vertical shaft 91. The horizontal track 3 and the longitudinal track 2 are arranged in a "well" shape. A rail transfer device is provided at the staggered position of the transverse track 3 and the longitudinal track 2;

[0033] There are four walking wheel sets 9, the transverse spacing between the walking wheel sets 9 corresponds to the longitudinal track 2, and the longitudinal spacing between the walking wheel sets 9 corresponds to the transverse track 3; what needs to be explained, adopts the structure of the present invention , the spacing between the longitudinal track 2 and the transverse track 3 can be different, to adapt to the structure of the steel formwork trolley 1, without having to set the walking wheel set in a square layout in order to coope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com