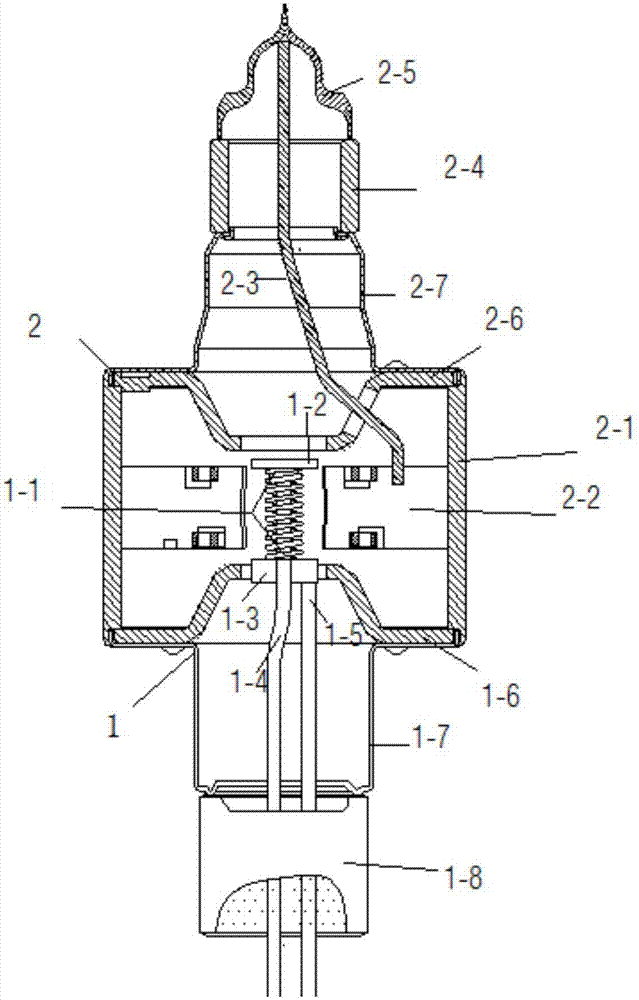

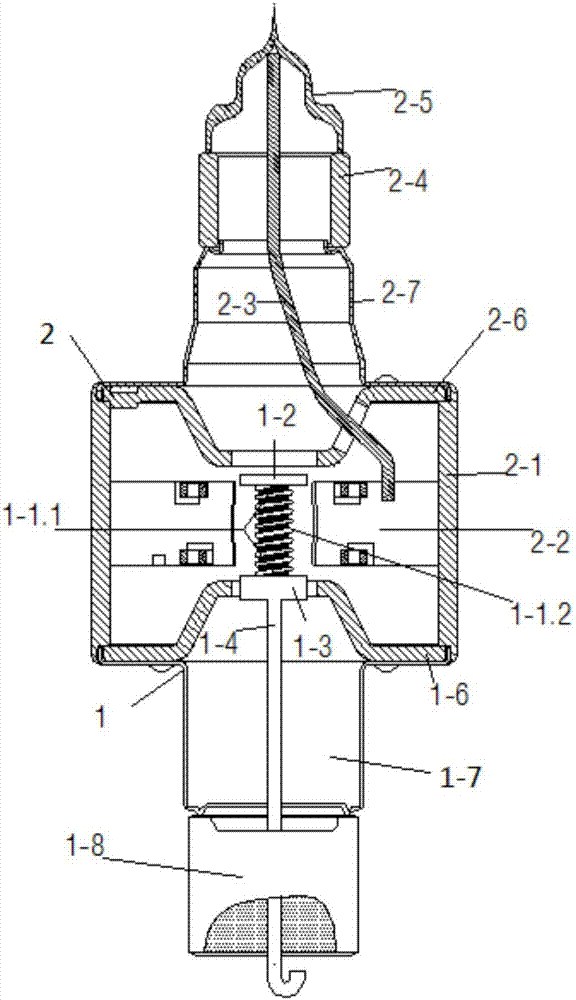

Magnetron using combined cold cathode head and production method of cold cathode body

A cold cathode and magnetron technology, applied in the direction of magnetron, transit time electron tube, etc., can solve the problems of magnetron vacuum degree drop, small emission current, high voltage ceramic deformation, etc., to achieve electromagnetic compatibility performance Good, single production process, high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

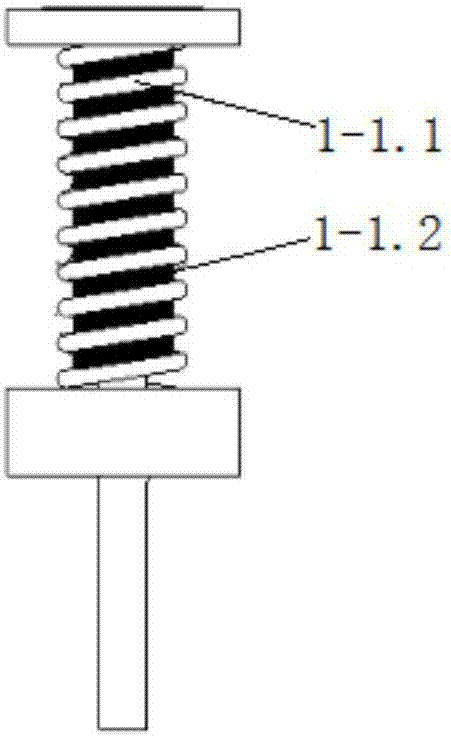

[0021] Embodiment 1: make the electron emitter with graphene, the cold cathode body that metal Cu powder, Zn powder are made bonding material, and adopt the magnetron of the combined type cold cathode head of this cold cathode body as example; Its cold cathode The production method of the body is:

[0022] Steps 1 and 2. Preparation and ball milling: Weigh 2 g of graphene with a thickness of 1-10 nm, 26.6 g of Cu powder with a particle size (Fisher particle size) of 30 μm, and 11.4 g of Zn powder; cm, the height is 5.5cm in the miniature ball mill (tank), the ball mill is mixed for 120 minutes to obtain the mixture; the power of the ball mill is 150W, and the diameters of the balls in the ball mill are φ1.4cm, φ0.9cm, φ0.7cm and the ratio is 2:8 Add 36g at a ratio of 2 (the ratio of ball to material is about 7:8);

[0023] Step 3. Compression molding: placing the gained mixture in a mold cavity with a diameter of φ2.9mm, and pressing it under a pressure of 40MPa into a cylind...

Embodiment 2

[0027] Embodiment 2: the present embodiment uses carbon nanotubes as the electron emitter, metal Cu powder, Zn powder, aluminum powder as the cold cathode body of the binding material, and the magnetic control of the combined cold cathode head that adopts the cold cathode body tube as an example; the production method of its cold cathode body is:

[0028] Steps 1 and 2. Material preparation and ball milling: Weigh 2g of carbon nanotubes with a length of 5um-10um and a diameter of φ30nm-50nm, 28g of Cu powder with a particle size of 30μm, 12g of Zn powder, and 99.9% industrially pure aluminum powder 8g; place parameter together in the miniature ball mill (tank) identical with embodiment 1, ball mill 120 minutes, get compound;

[0029] Step 3. Compression molding: placing the gained mixture in a mold cavity with a diameter of φ2.8mm, and pressing it under a pressure of 40MPa into a cylindrical body of (diameter × height) φ2.8mm × 10mm;

[0030] Step 4. Sintering: put each compa...

Embodiment 3

[0033] Embodiment 3: the present embodiment uses carbon nanotube and graphene mixture as electron emitter, makes the cold cathode body of binding material with metal Cu powder, Zn powder and aluminum powder, and adopts the combined cold cathode body of this cold cathode body Take the magnetron of the cathode head as an example; the production method of the cold cathode body is:

[0034] Steps 1 and 2. Material preparation and ball milling: Weigh 1.25g of carbon nanotubes with a length of 5um-10um and a diameter of φ30nm-50nm, 1.25g of graphene with a thickness of 1-10nm, and Cu powder with a particle size of 30μm , Zn powder, each 15g of aluminum powder of industrial purity 99.9%; Place parameter together in the miniature ball mill identical with embodiment 1, ball mill mixes 120 minutes, gets compound;

[0035] Step 3. Compression molding: placing the gained mixture in a mold cavity with a diameter of φ2.8mm, and pressing it under a pressure of 40MPa into a cylindrical body o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com