Liftable conveying roller way device

A conveying roller table and lifting technology, which is applied in the direction of auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems affecting the height of the workshop and driving, the height difference between the front and rear of the equipment, and the height of the bending machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

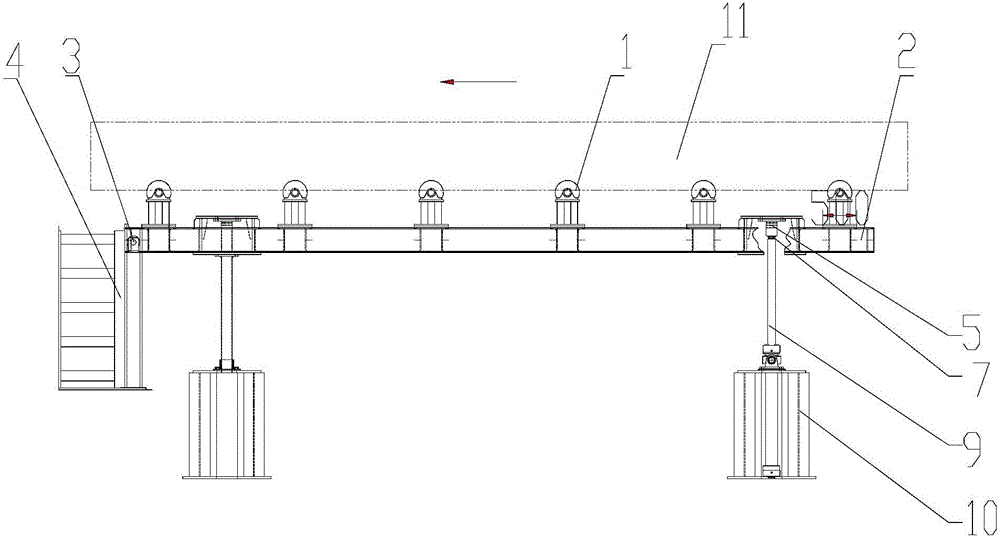

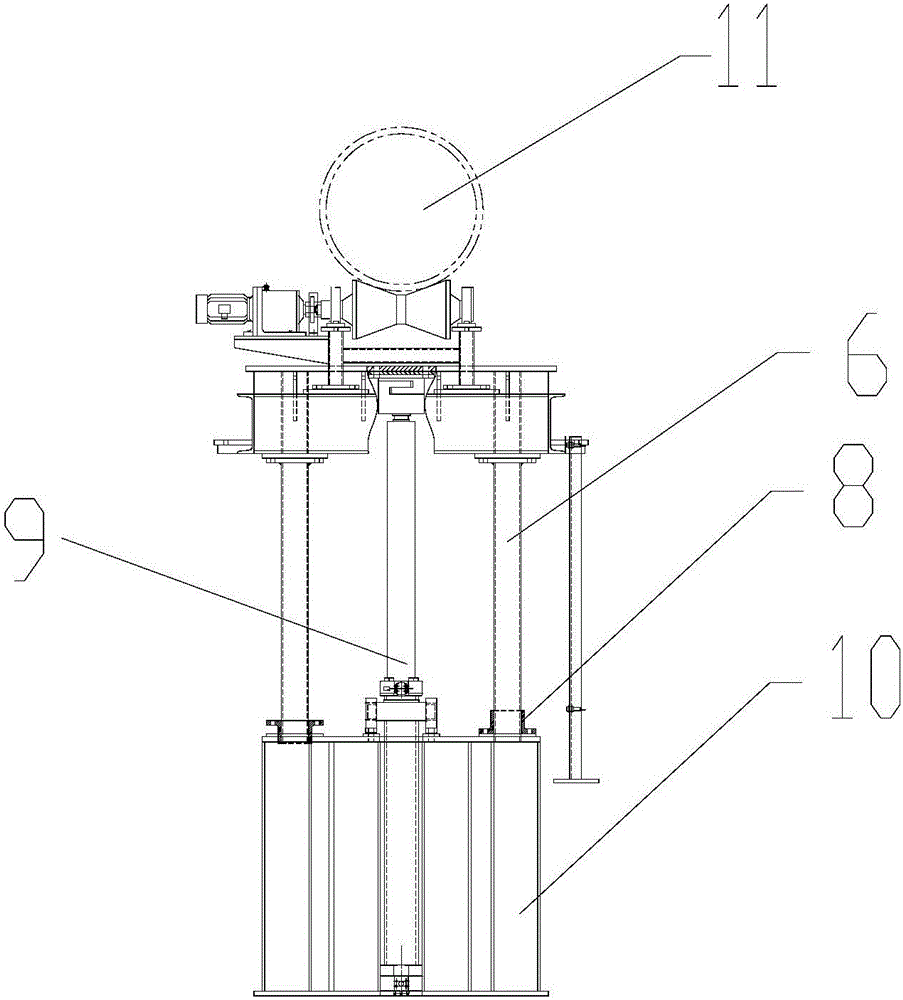

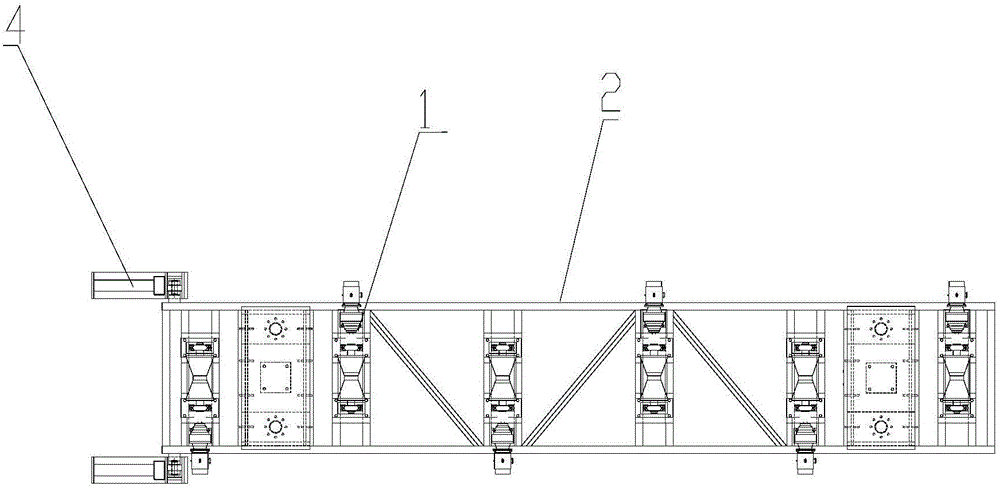

[0026] The liftable conveying roller table device in this embodiment includes a lifting frame 2 provided with a conveying roller table 1 arranged behind the bending machine in the forming area, a guide mechanism for controlling the lifting direction of the lifting frame 2, and driving the lifting frame to go up and down. The driving mechanism; the conveying roller table 1 is formed by several conveying rollers arranged at intervals above the lifting frame.

[0027] Wherein, the conveying rollers of the conveying roller table 1 are fixed on the lifting frame 2 through bolt spacing, so as to be integrated with the lifting frame 2, and the length of the conveying roller table 1 is at least the length of a steel pipe, that is, the conveying pipeline 1 can support at least one steel pipe 11 horizontally. The drive mechanism includes a lifting cylinder 9 fixed on the cylinder base 10 below the lifting frame, the output end of the lifting cylinder 9 is connected with the lower end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com