Method for installing sugarcane leaf peeling racks

An installation method and leaf stripping technology, which is applied to harvesters, agricultural machinery and implements, applications, etc., can solve problems such as difficult maintenance of sugarcane leaf stripping devices, and achieve the effects of reducing production costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with accompanying drawing:

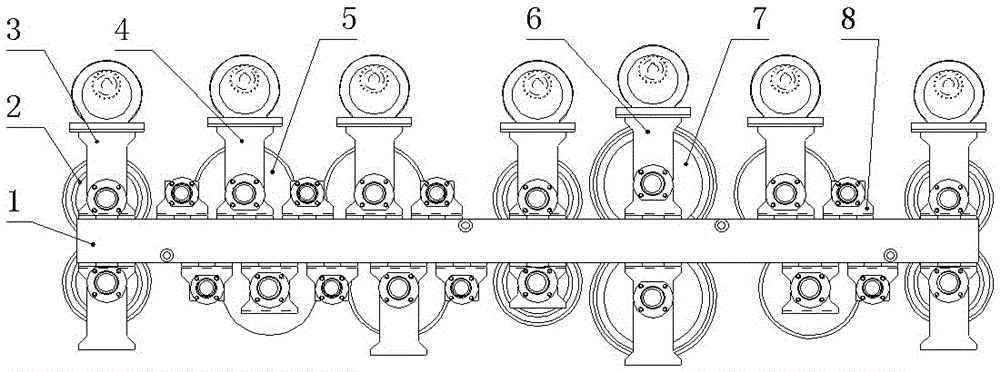

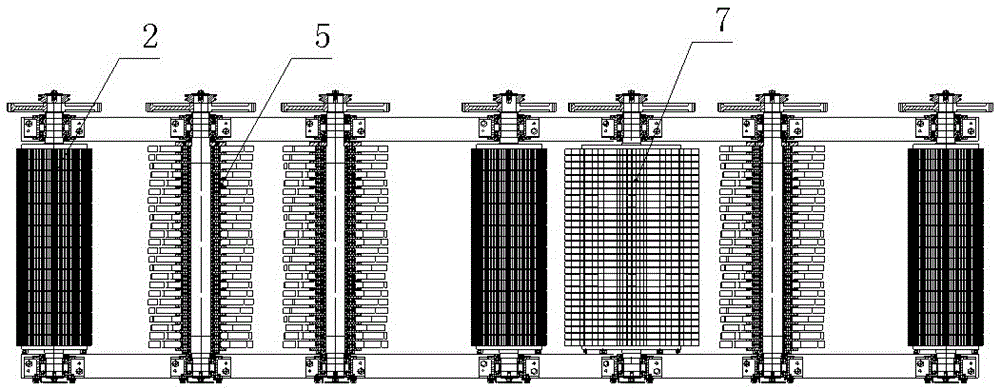

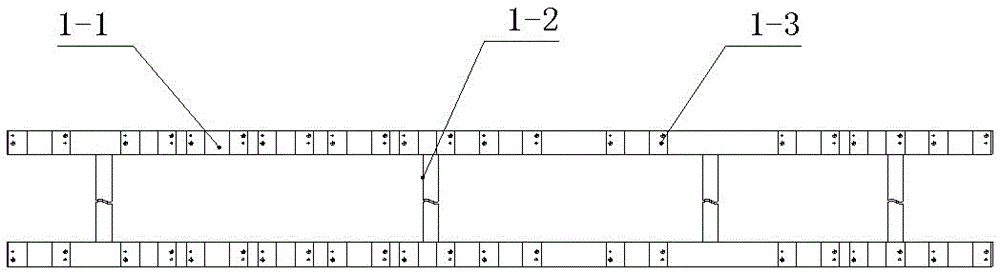

[0020] Such as figure 1 and figure 2 The shown sugarcane leaf stripping device includes leaf stripping rollers and conveying rollers, a frame body 1, frame body 1 has two longitudinal beams 1-1 and four beams welded between the two longitudinal beams 1-1 1-2, a plurality of pads 1-3 of equal height are provided on the top and bottom surfaces of each longitudinal beam 1-1; Leaf rollers and a plurality of conveying rollers, a plurality of leaf stripping rollers include a first-level leaf stripping roller 5 and a second-level leaf stripping roller 7; in this embodiment, three first-level leaf stripping rollers are arranged at intervals between the top and bottom surfaces of two longitudinal beams 1-1 Leaf stripping roller 5, a secondary leaf stripping roller 7 and three delivery rollers 2; a primary leaf stripping roller 5 on the top surface of the longitudinal be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com