Mandibular oral cavity model with mandibular nerve canal and injection molding method

An oral model and injection molding technology, applied in teaching models, instruments, educational appliances, etc., can solve the problems of long dimensional stability, low production efficiency, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to be able to understand the technical content of the present invention more clearly, the following embodiments are specifically described in detail, the purpose of which is only to better understand the content of the present invention and not to limit the protection scope of the present invention.

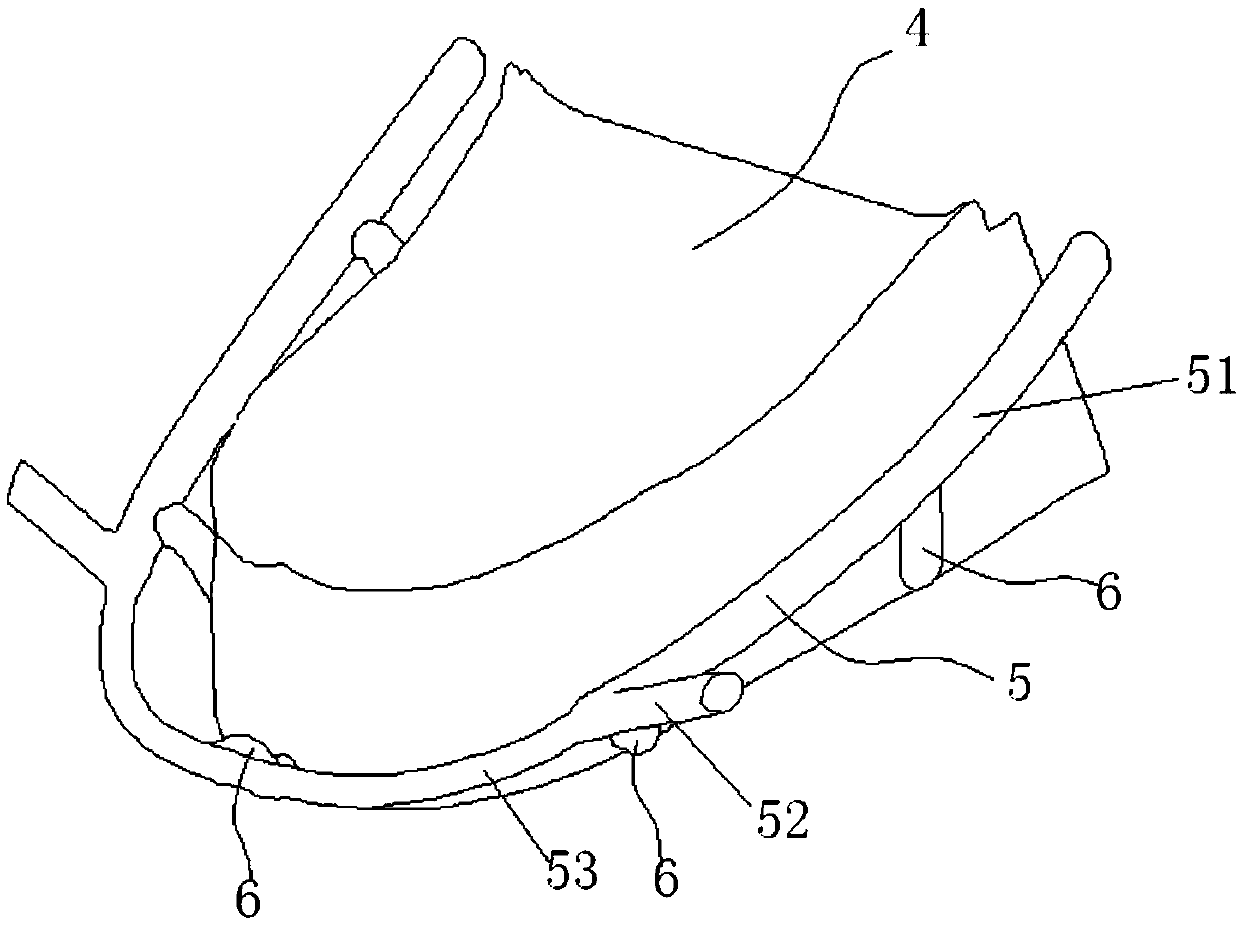

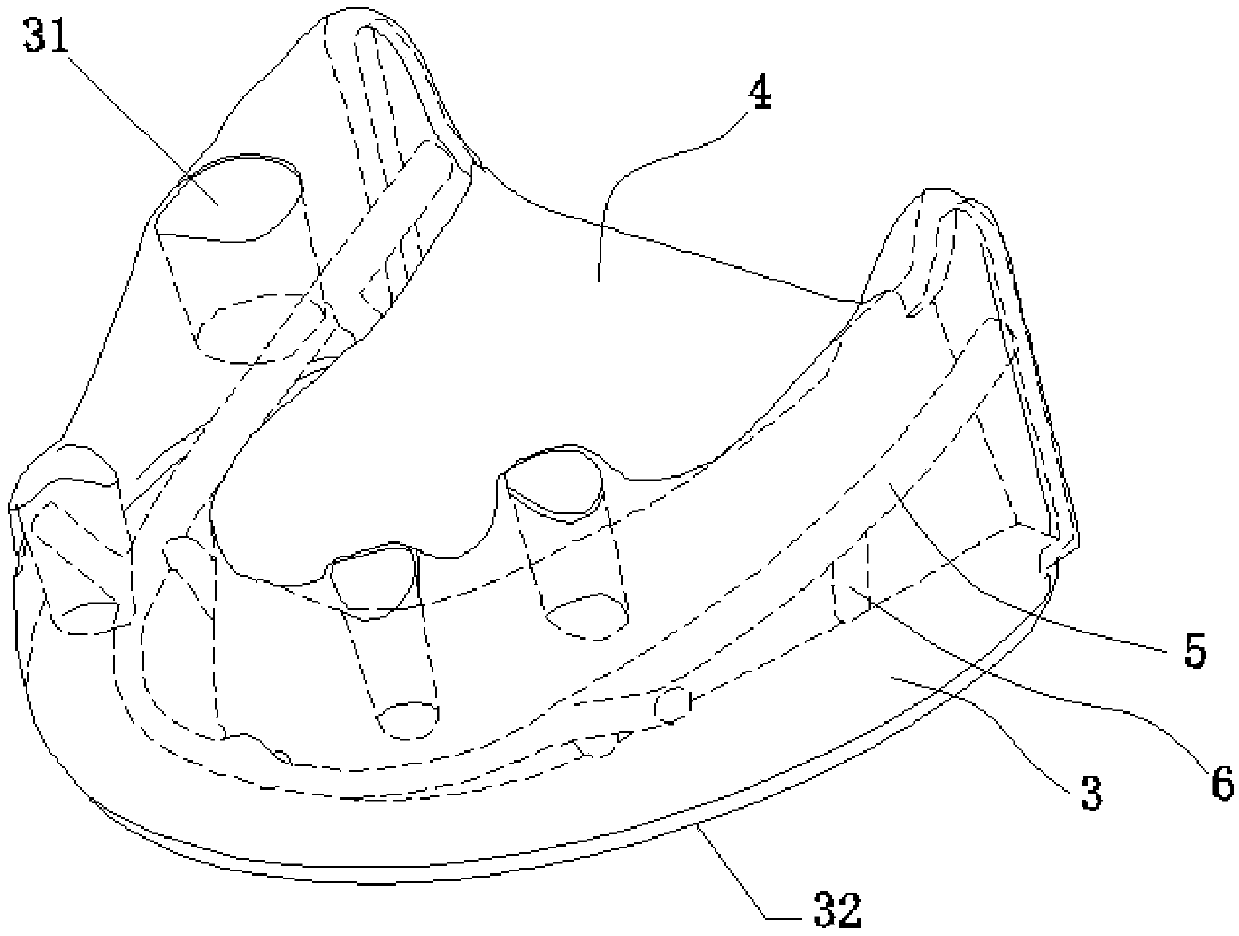

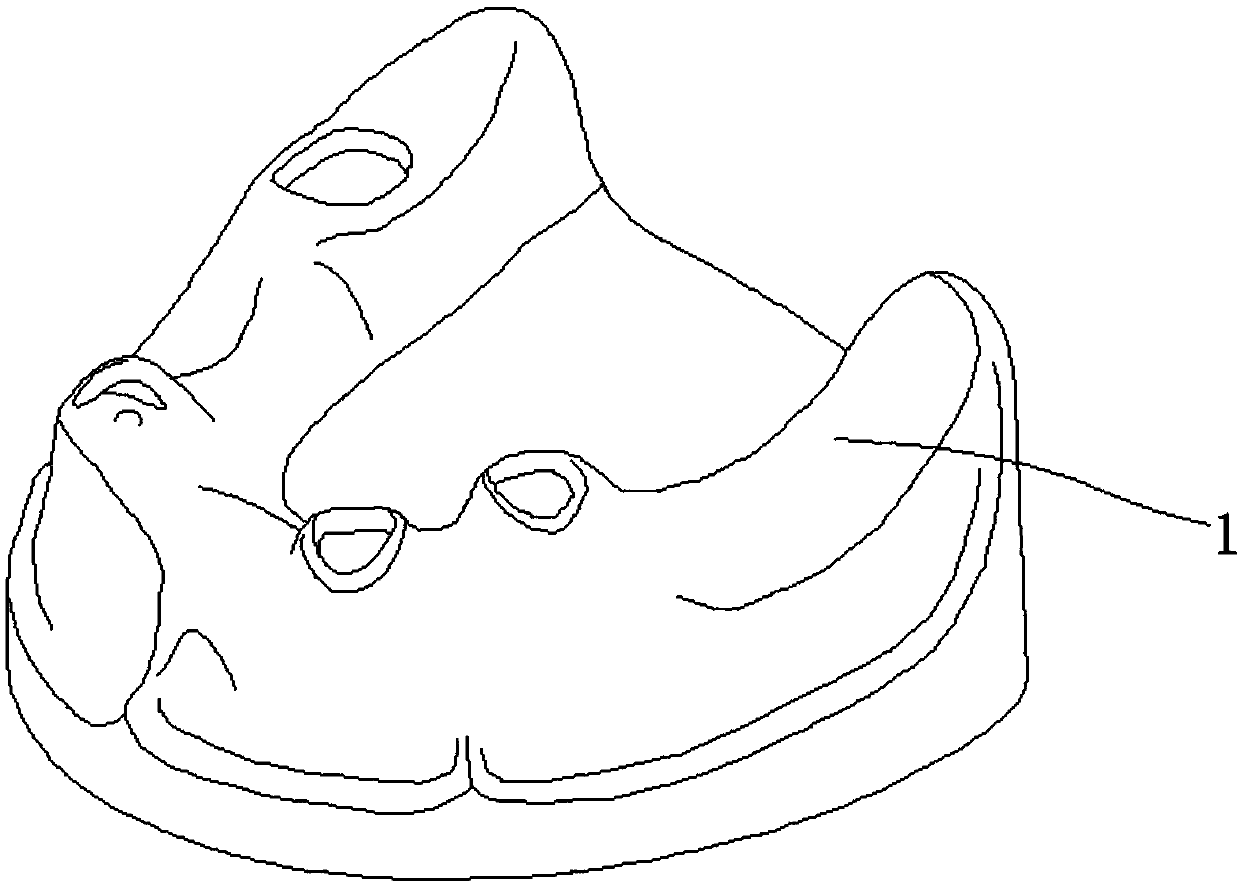

[0034] Such as Figure 4 , Figure 5 with Image 6 As shown, a mandibular oral cavity model with a mandibular neural tube includes soft tissue 1, a number of teeth 2, a mandible 3, a floor of the tongue 4 and a mandibular neural tube 5, the mandibular neural tube surrounds the front side of the tongue base and The left and right sides are fixedly connected to the bottom of the tongue through a number of connecting reinforcing ribs 6, and the bottom of the tongue, the mandibular nerve tube and the connecting reinforcing ribs are integrally injected into a tongue base part through a tongue injection mold; The mandible is wrapped around the anterior and left and right s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com