Core Holder

A core holder and core technology, used in instruments, scientific instruments, measuring devices, etc., can solve the problems of limiting the use pressure of the core holder, the inner diameter of the confining pressure kettle should not be too large, and it cannot work under high temperature conditions. , to achieve the effect of weakening interference, strong resistance to high temperature and high pressure, and good heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

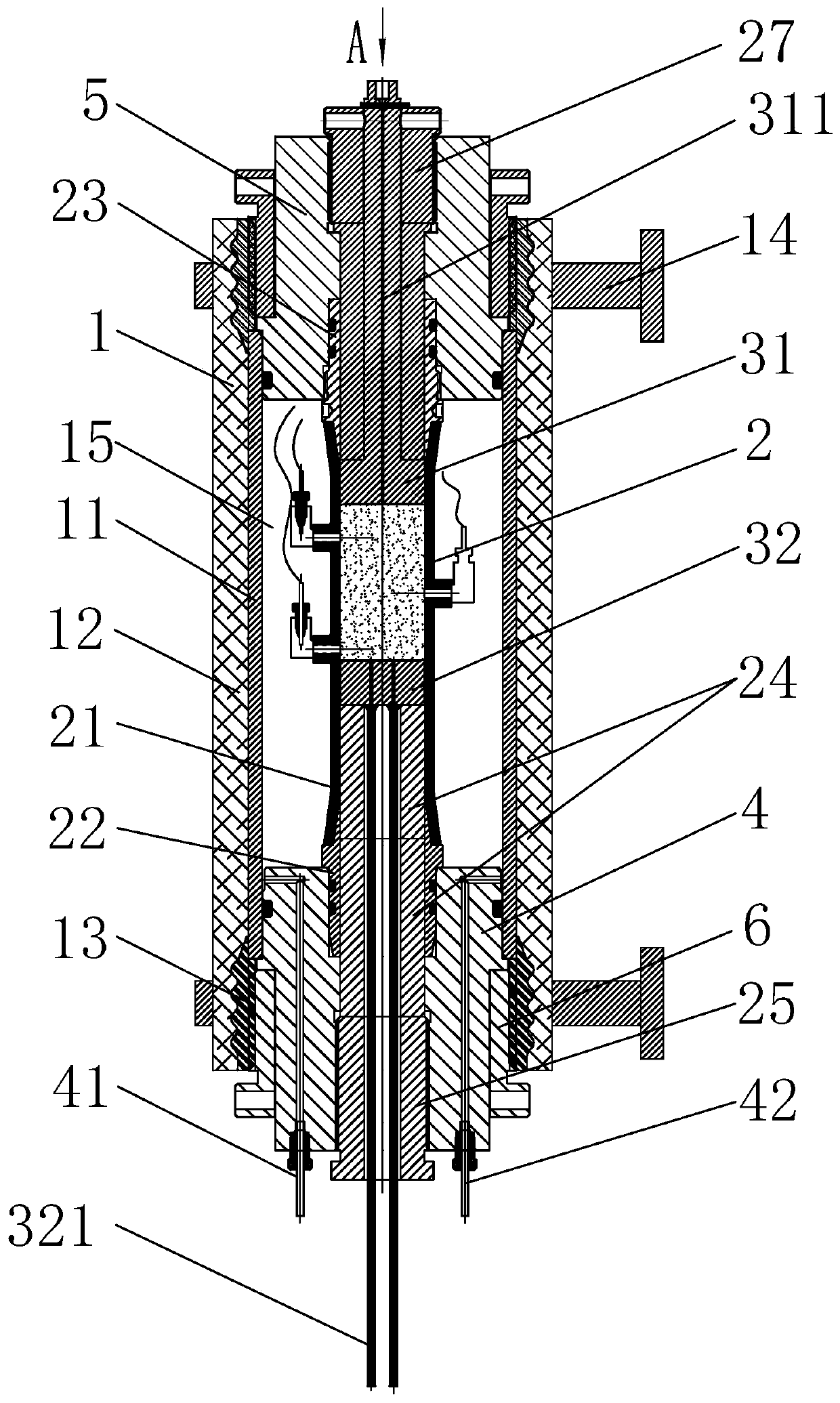

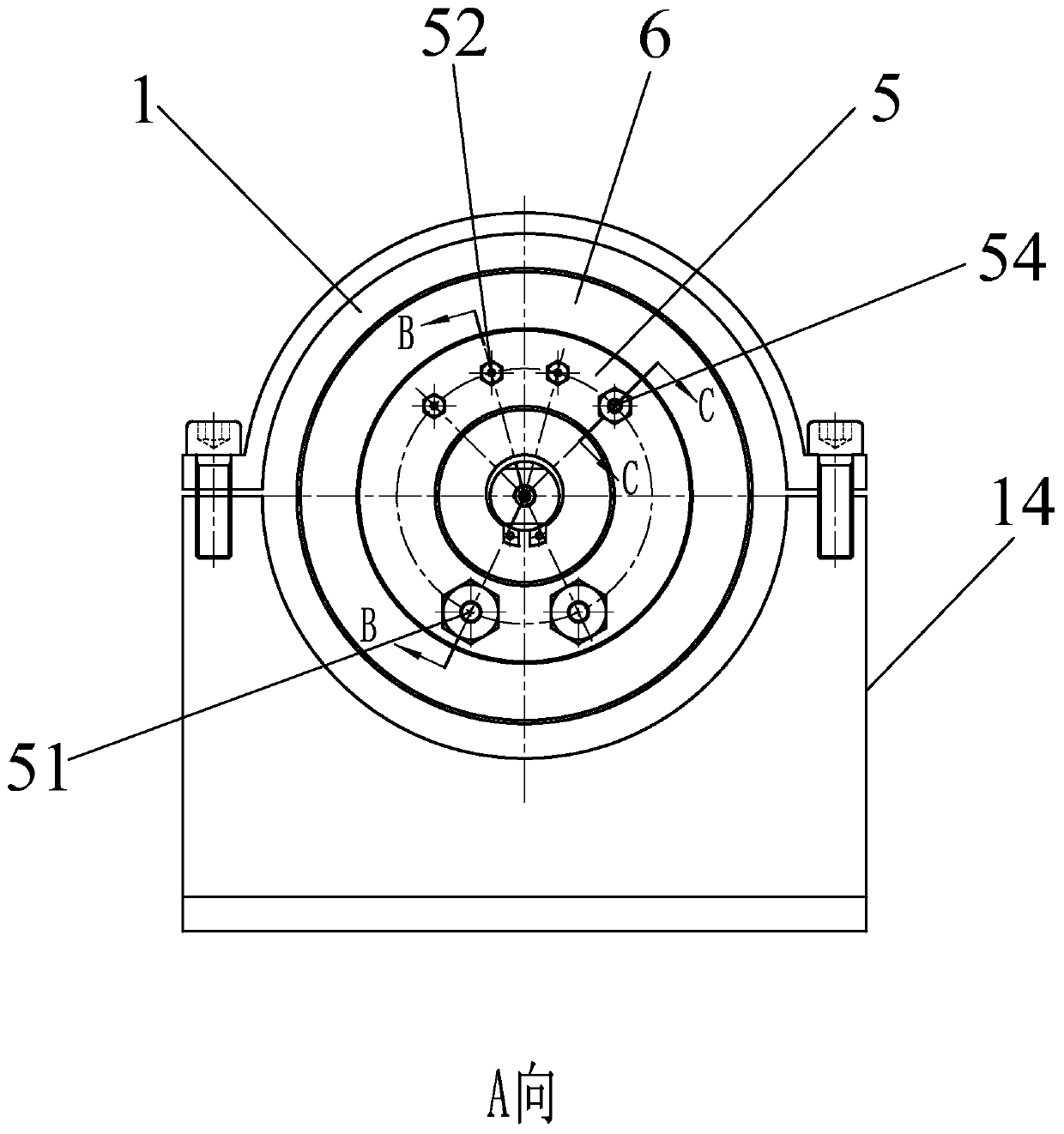

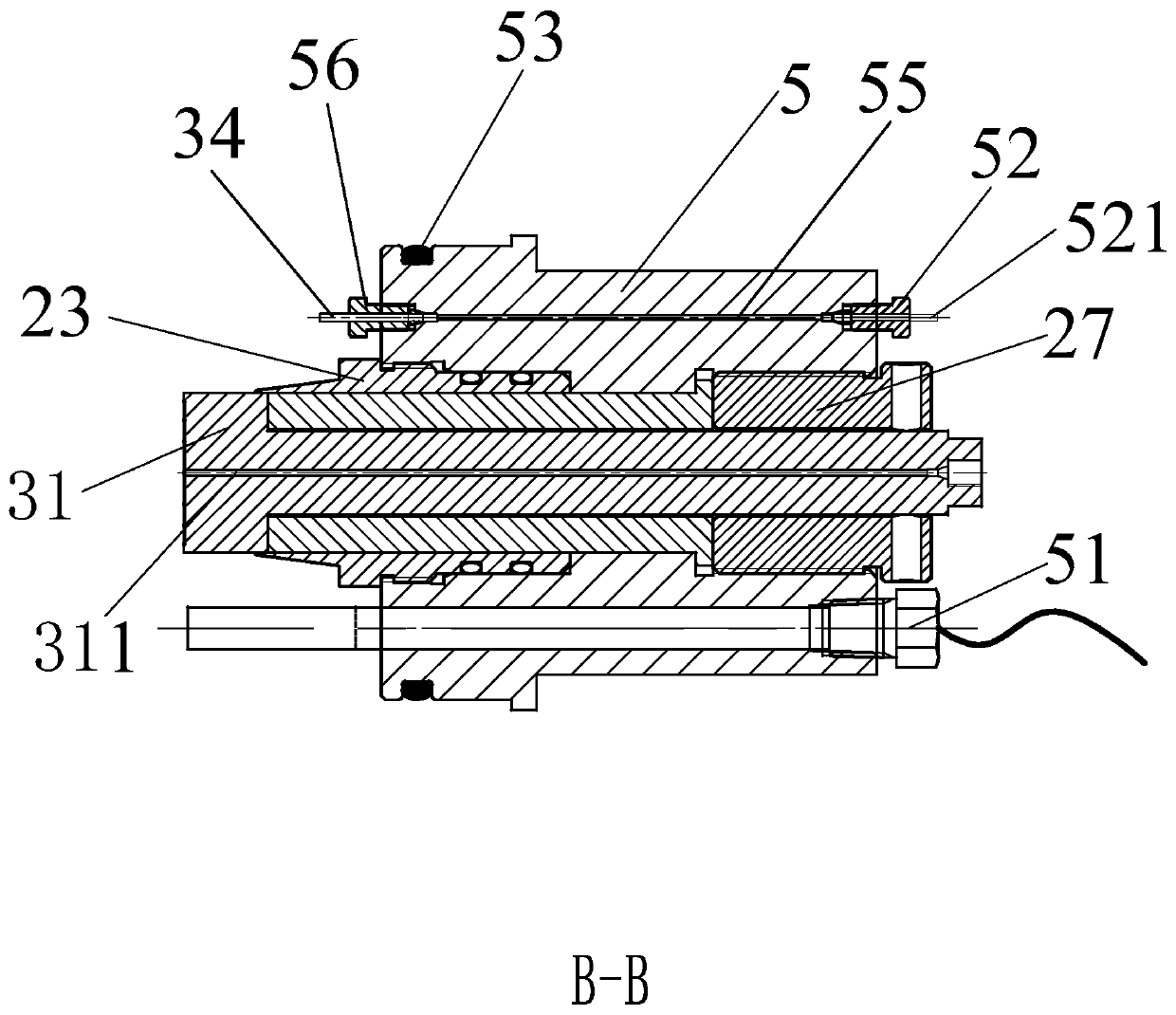

[0029] like figure 1 and Figure 4 As shown, the core holder of the present invention mainly includes a cylindrical confining pressure still body 1, and a support seat 14 fixedly supported on the outer wall of the confining pressure still body 1. The confining pressure still body 1 includes a shell 12, an inner lining 11 and a threaded Ring 13, the two ends of the confining pressure still body 1 are fixedly connected with the adjusting plug 4 and the positioning plug 5 respectively, the internal thread of the threaded ring 13 on the confining pressure still body 1 is connected with the external thread of the compression screw sleeve 6, and the compression screw The inner ring of the sleeve 6 is pressed and fixed to adjust the plug 4 and the positioning plug 5, and the adjusting plug 4 and the positioning plug 5 are respectively fixed on the two ends of the confining pressure still body 1.

[0030] The seal between the adjusting plug 4 and the positioning plug 5 and the confin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com