Roller washing machine with cover plate storage structure

A drum washing machine and storage structure technology, which is applied to other washing machines, washing devices, textiles and papermaking, etc. It can solve the problems of pinching the user's fingers, easily blowing the cover, and shaking the cover, so as to prevent random activities, The effect of preventing accidental injury and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

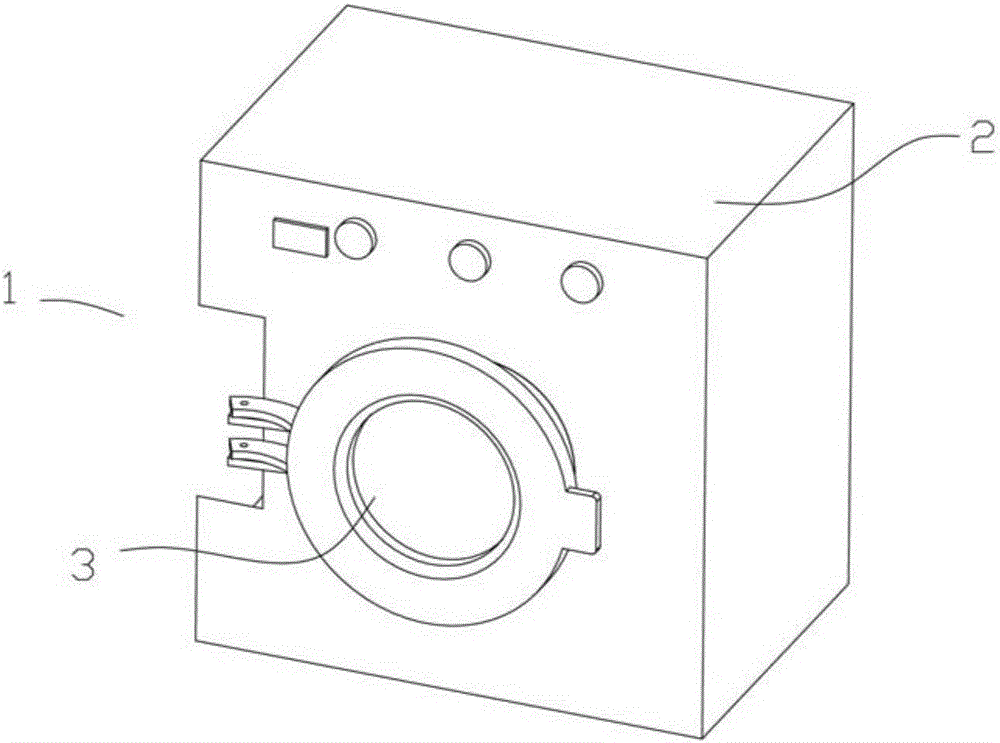

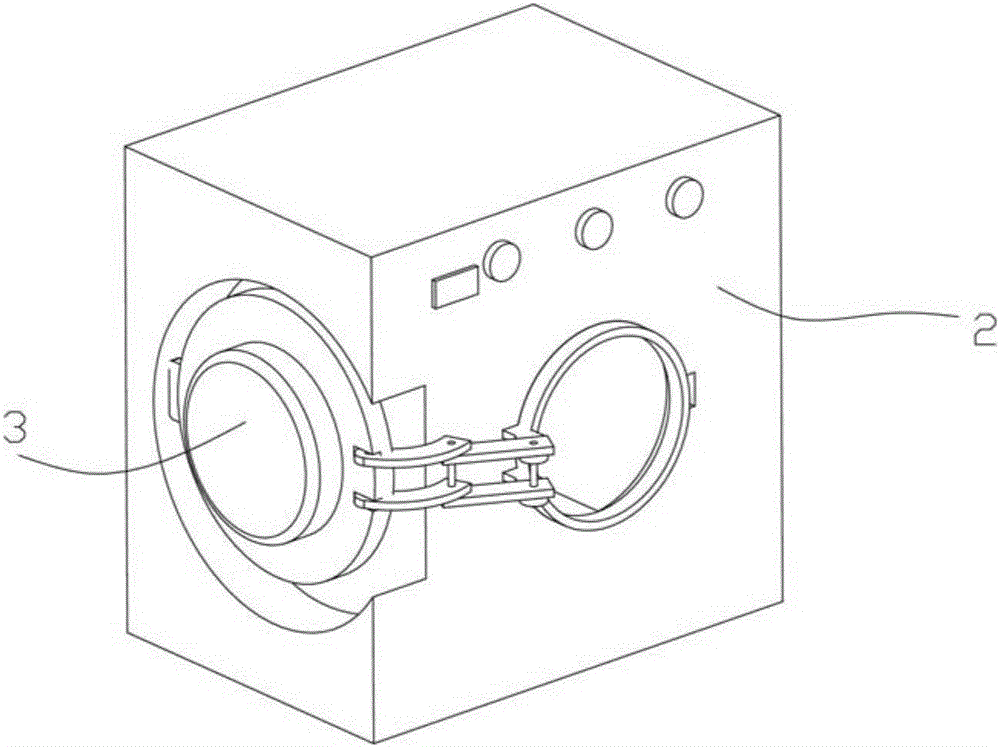

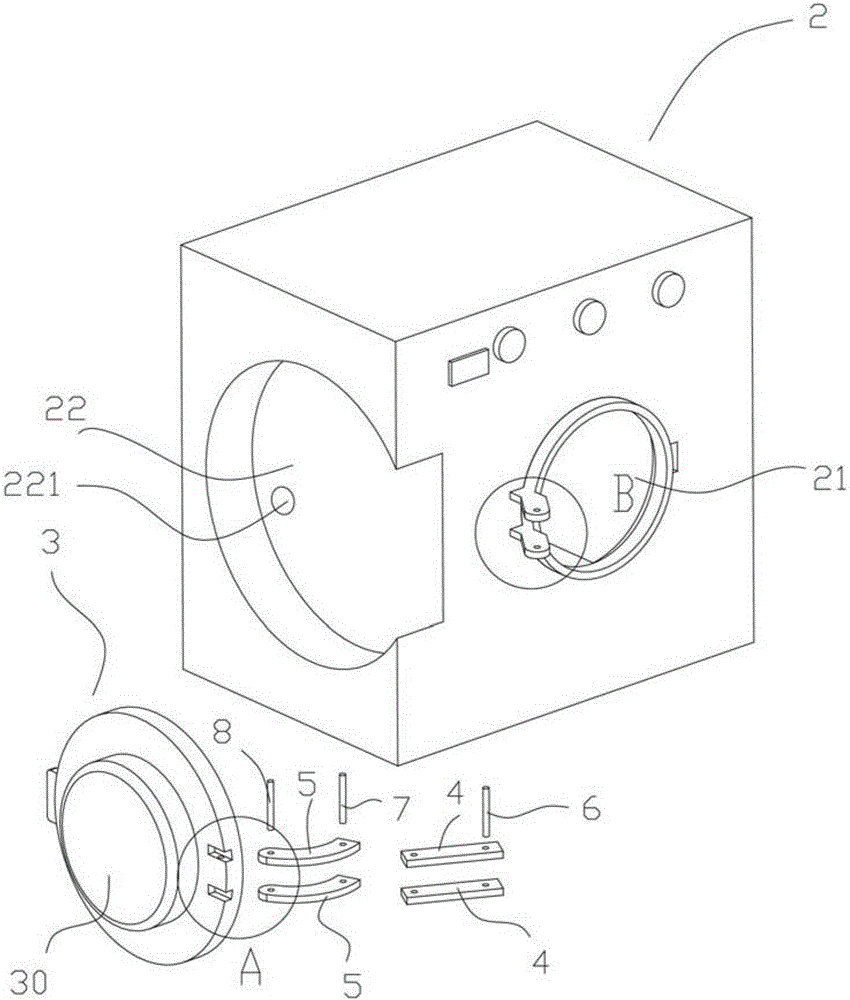

[0034] Such as Figure 1 to Figure 3 As shown, the drum washing machine 1 with a cover plate storage structure includes a casing 2 and a rotatable cover plate 3, an inwardly recessed storage groove 22 is provided on the side of the casing 2, and the cover plate 3 can be It is stored in this storage groove 22 .

[0035] The front portion of the casing 2 is provided with a clothes opening 21, and one side of the clothes opening 21 is provided with a pair of first connecting hinges 23, and the first connecting hinges 23 pass through a pair of second connecting hinges 4 and a pair of third connecting hinges. The connecting hinge 5 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com