Method for improving measurement precision of air quality detection equipment by segmentation optimal calibration

A technology for air quality detection and measurement accuracy, which is applied in the direction of measuring devices, particle suspension analysis, suspension and porous material analysis, etc., which can solve the problems of separate calibration, low precision and large error of air quality smart device sensors, and achieve high accuracy Improving, convenient and quick application, and reducing the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

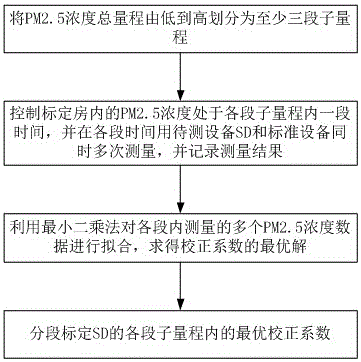

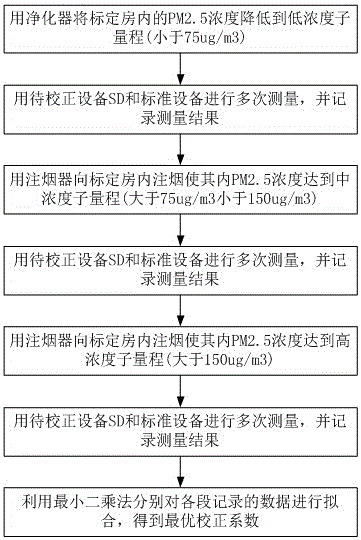

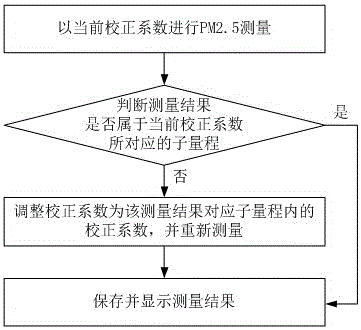

[0032] Such as Figure 1 to Figure 2 As shown, the method of segmented optimal calibration to improve the measurement accuracy of air quality detection equipment is mainly aimed at the correction method adopted by the existing air quality detection equipment, which causes the mechanical error and drift error of the original sensor to make the whole equipment The detection accuracy is low and the error is large.

[0033] Its specific implementation includes the following steps:

[0034] (S10) Divide the PM2.5 concentration total range of the air quality detection equipment SD to be corrected into at least three sub-ranges from low to high; wherein the molecular range is divided according to the multiple point value of the PM2.5 concentration standard, such as the current domestic PM2 The standard of .5 concentration is 75ug / m 3 , the total range can be divided into less than 75ug / m 3 Low concentration sub-range, between 75ug / m 3 -150ug / m 3 Medium concentration range betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com