A plough share refiner

A refiner and plowshare technology, applied in the direction of mixers, mixer accessories, mixers with rotating agitation devices, etc., can solve the long mixing time of coulter type mixing equipment and the inability of ribbon type mixing equipment to meet the requirements of refining and mixing, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, the present invention will be more clearly and completely described with reference to a preferred embodiment and in conjunction with the accompanying drawings.

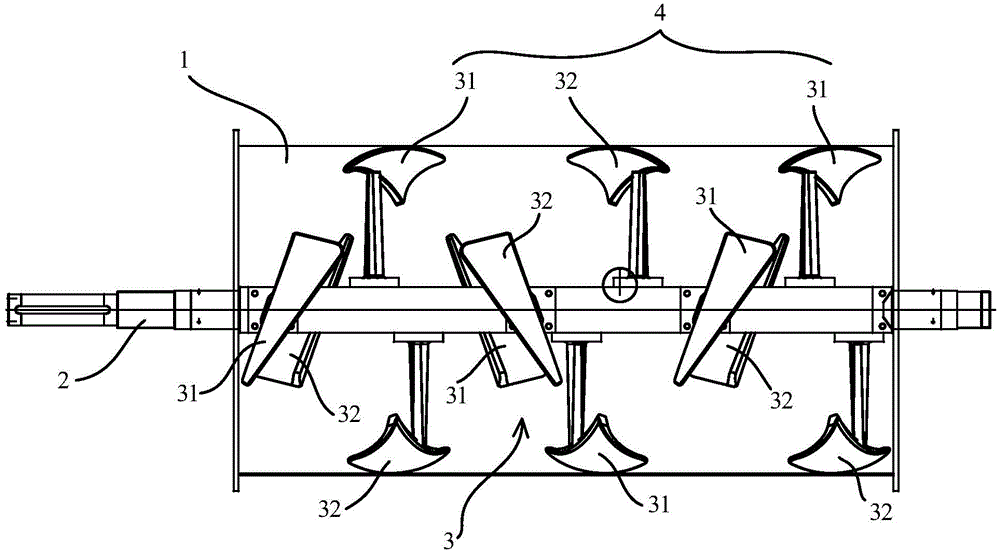

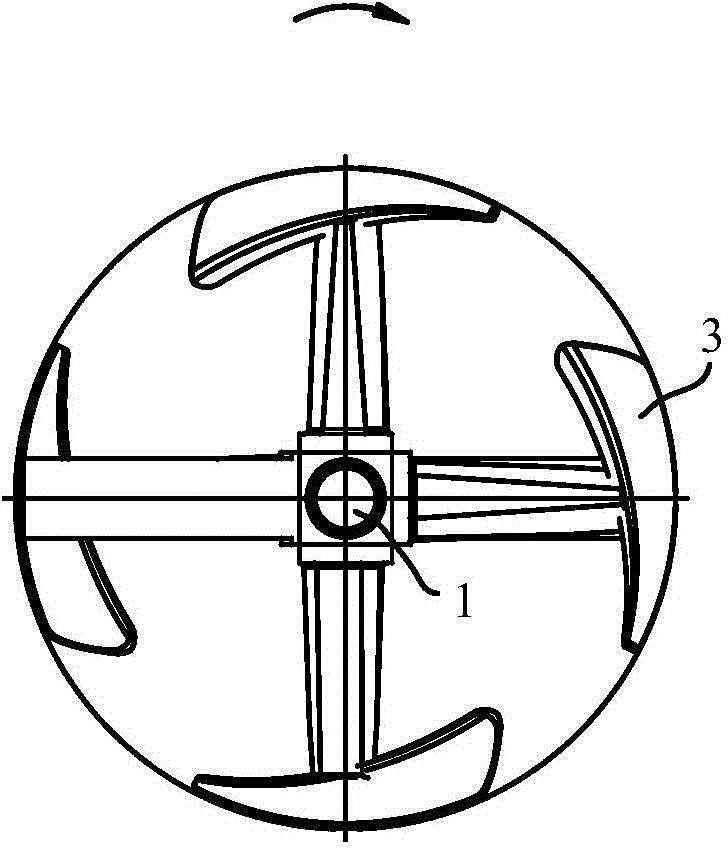

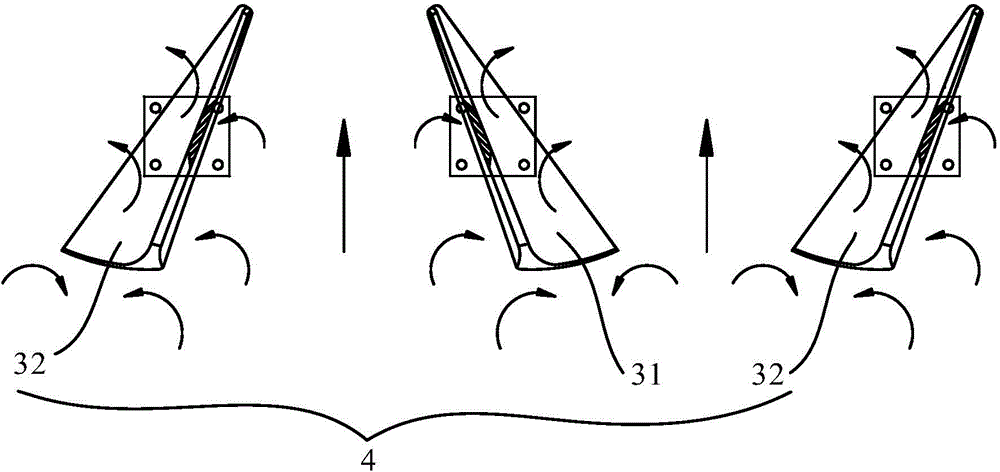

[0037] like figure 1 As shown, a plowshare refiner includes a cylinder 1, a main shaft 2 passing through the center of the cylinder, and a plurality of plowshares 3 arranged on the main shaft. The plowshares are divided into two types: a first plowshare 31 and a The second ploughshares 32; the first ploughshares are inclined to one direction of the axis of the main shaft, and the second ploughshares are inclined to the other direction of the axis of the main shaft; a group of ploughshares 4 are arranged on at least one orientation of the circumferential direction of the main shaft , the first ploughshares and the second ploughshares in the group of ploughshares are arranged in sequence to form a form of alternately arranged opposite and opposite to each other.

[0038] like figure 2 shown, when ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com