A fast transfer device and method with adjustable landing point based on rotary form

A transfer device and drop-point technology, applied in the directions of transportation and packaging, conveyor objects, conveyors, etc., can solve the problems of inability to transfer long-distance, affect the production cycle, affect the production cost, etc., and reduce the logistics operation cost and work efficiency. High and easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

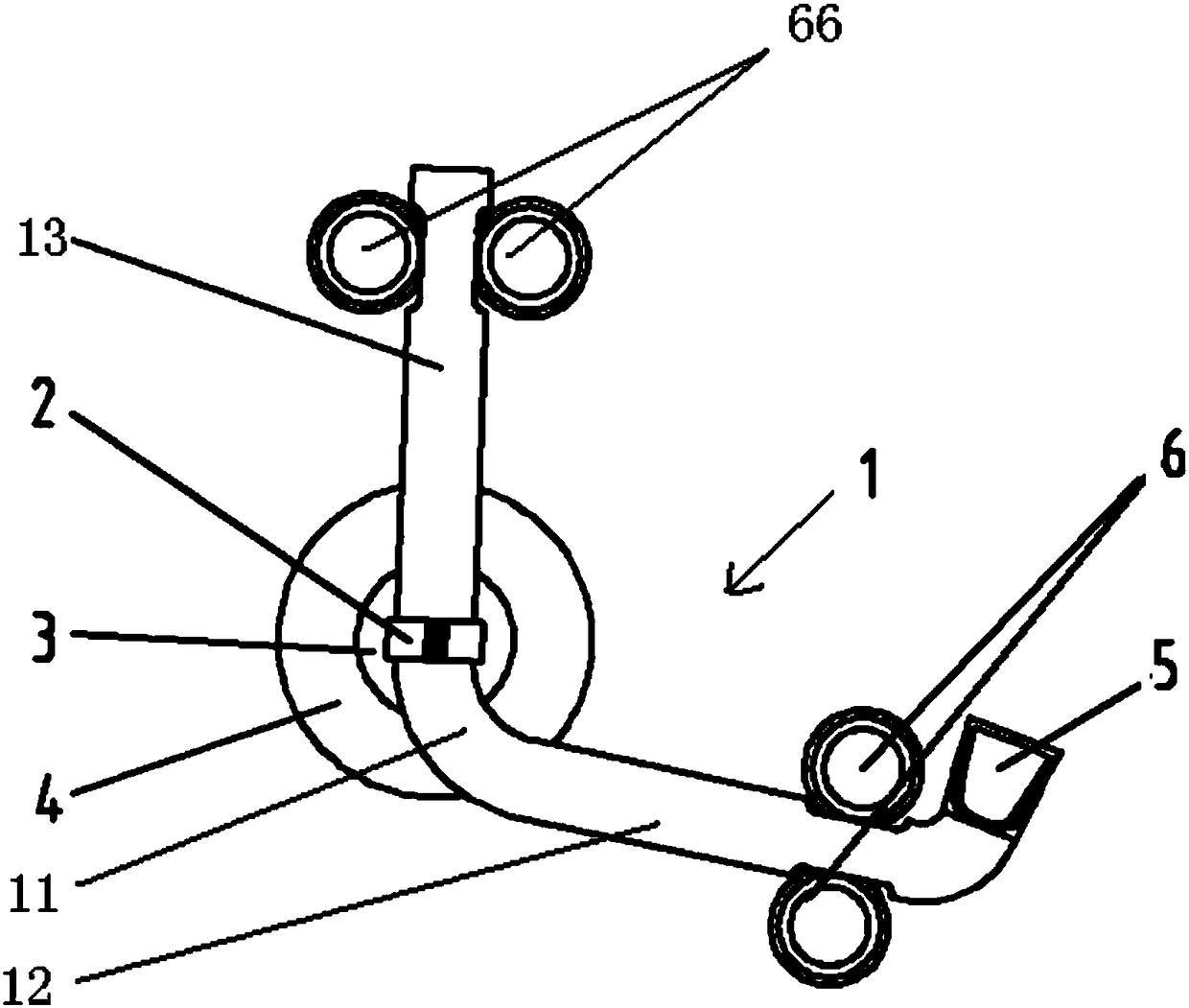

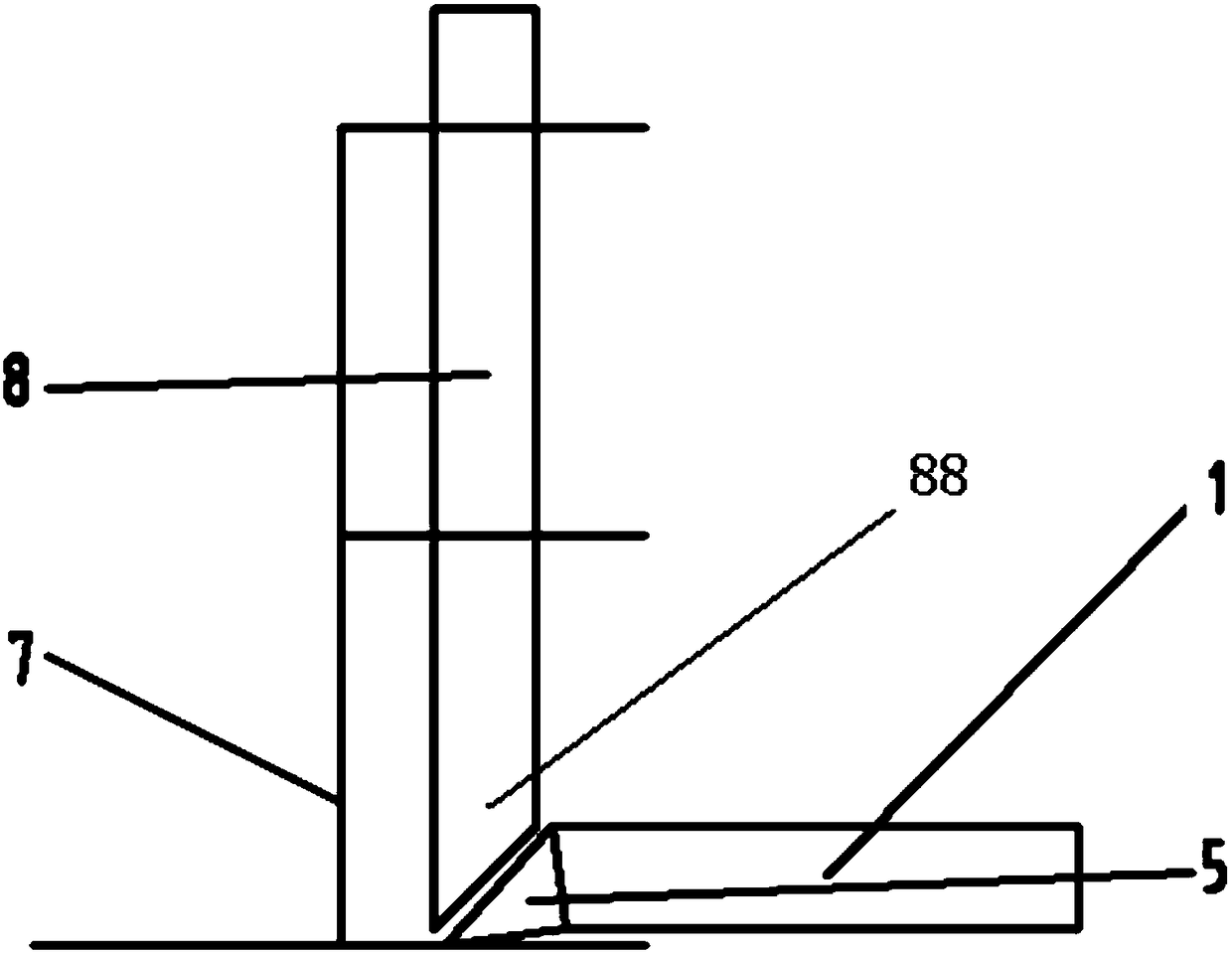

[0031] Such as Figure 1 to Figure 4 Shown. The invention discloses a rapid transfer device with adjustable drop point based on a rotary form, which includes a curved transfer channel 1, a driving mechanism that provides rotational power to the curved transfer channel 1, and a cargo supply mechanism that provides goods to the curved transfer channel 1;

[0032] The middle part of the curved transport channel 1 is a smoothly transitioned bend section 11, with the bend section 11 as a boundary, it is divided into a front section tube body 12 and a rear section tube body 13; the end of the front section tube body 12 is provided with an elbow Incoming port 5, the tail of the rear pipe body 13 is the outgoing port;

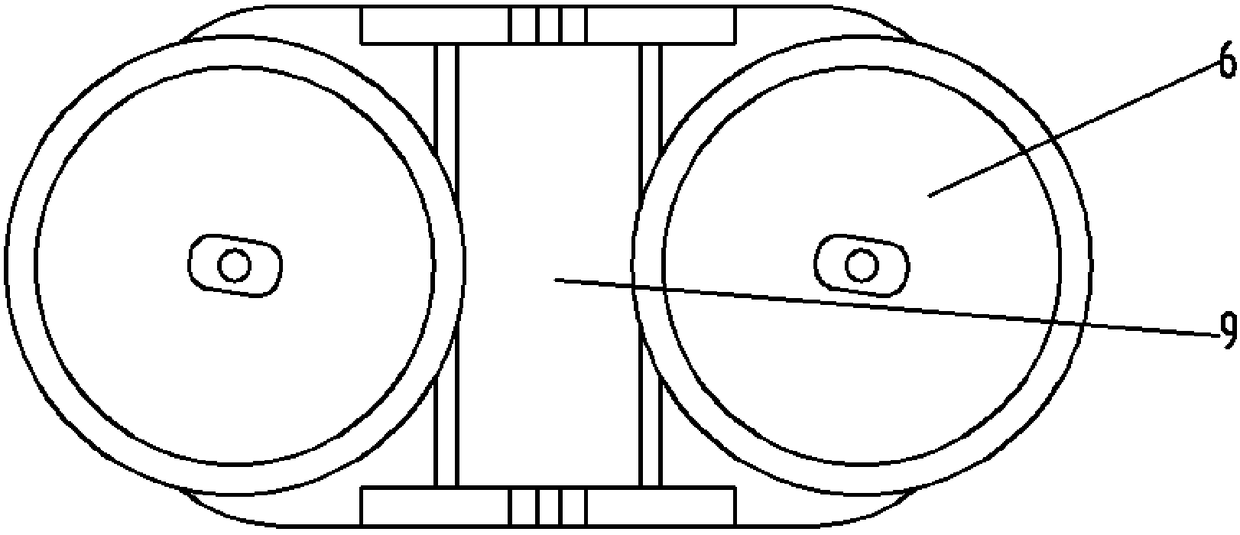

[0033] The front tube body 12 is provided with a first friction wheel set 6 symmetrically on both sides of the lower tube body near the elbow inlet 5, and two symmetrical wheels are provided on both sides of the tube body corresponding to the first friction wheel set 6 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com