Definite-proportion discharging device and method for powdery and granular material

A technology for granular materials and unloading devices, applied in the direction of loading/unloading, transportation and packaging, conveyors, etc., can solve the problems of high time efficiency, high cost, troublesome operation, etc., and achieve the effect of simple and practical structure, flexible adjustment and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

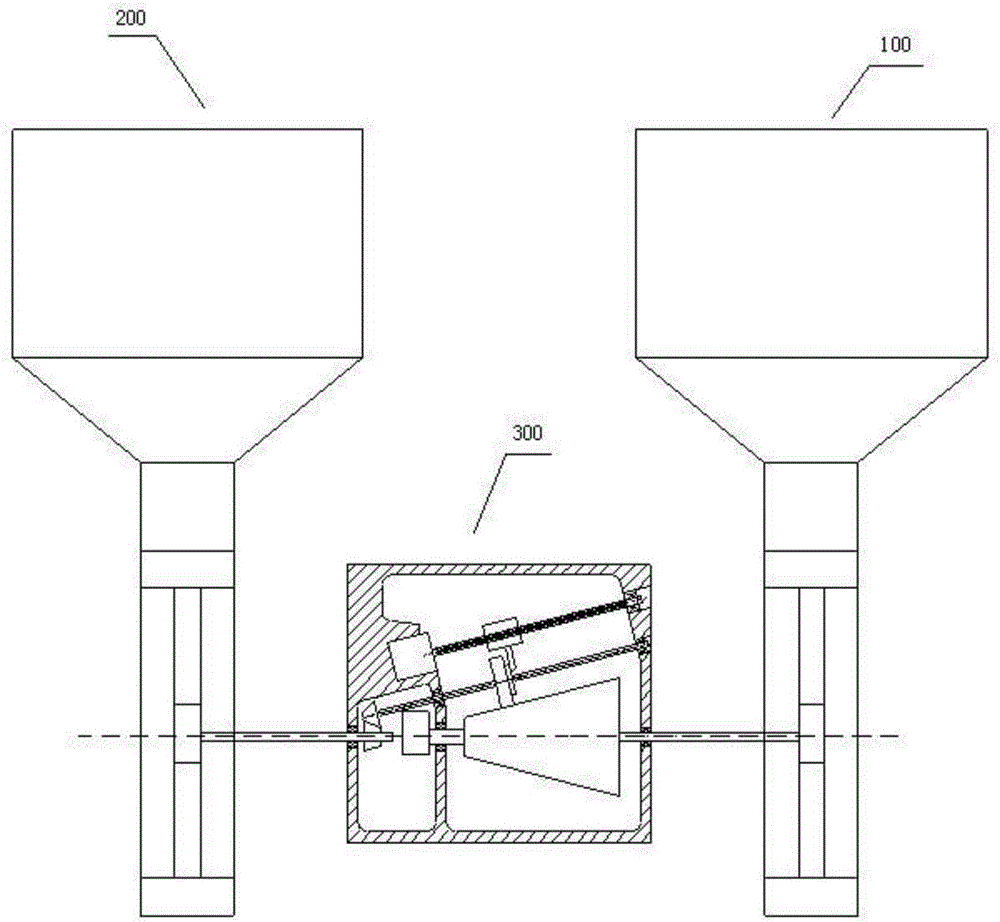

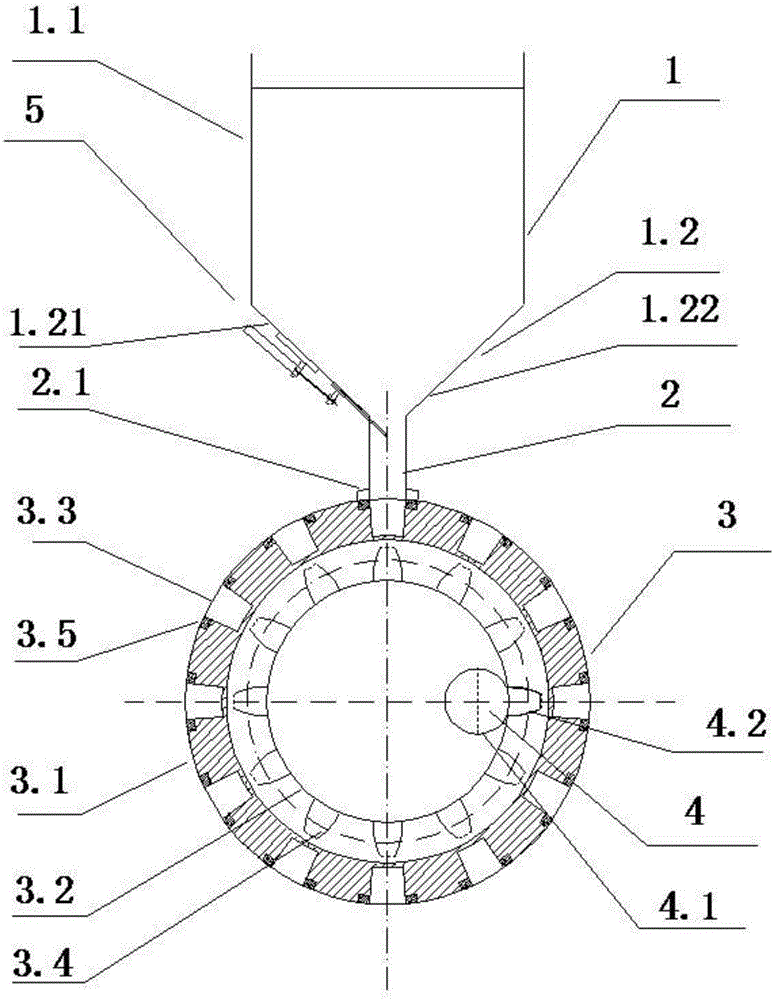

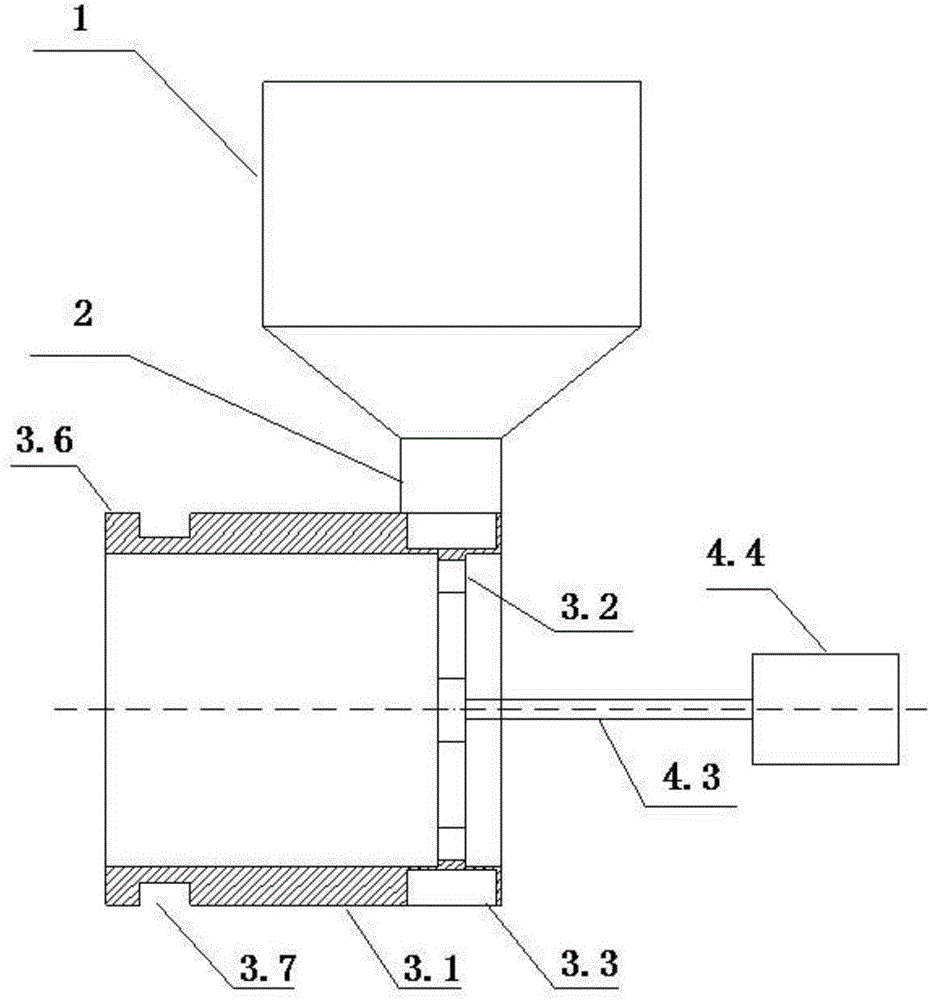

[0046]As shown in the figure, a fixed-ratio unloading device for powder and granular materials includes a quantitative intermittent conveying mechanism and a speed adjustment mechanism 300, and the quantitative intermittent conveying mechanism includes a first quantitative intermittent conveying mechanism 100 and a second quantitative intermittent conveying mechanism 200 , the speed adjustment mechanism is coupled between the first quantitative intermittent delivery mechanism 100 and the second quantitative intermittent delivery mechanism 200, so that the first quantitative intermittent delivery mechanism 100 and the second quantitative intermittent delivery mechanism 200 discharge in a fixed ratio the material being conveyed;

[0047] The quantitative intermittent conveying mechanism includes a hopper 1 and a rotating metering wheel 3. The hopper 1 includes a cross-section constant part 1.1 and a cross-section tapering part 1.2 integrated with its lower end. The top of the cro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com