Patents

Literature

91 results about "Granoblastic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

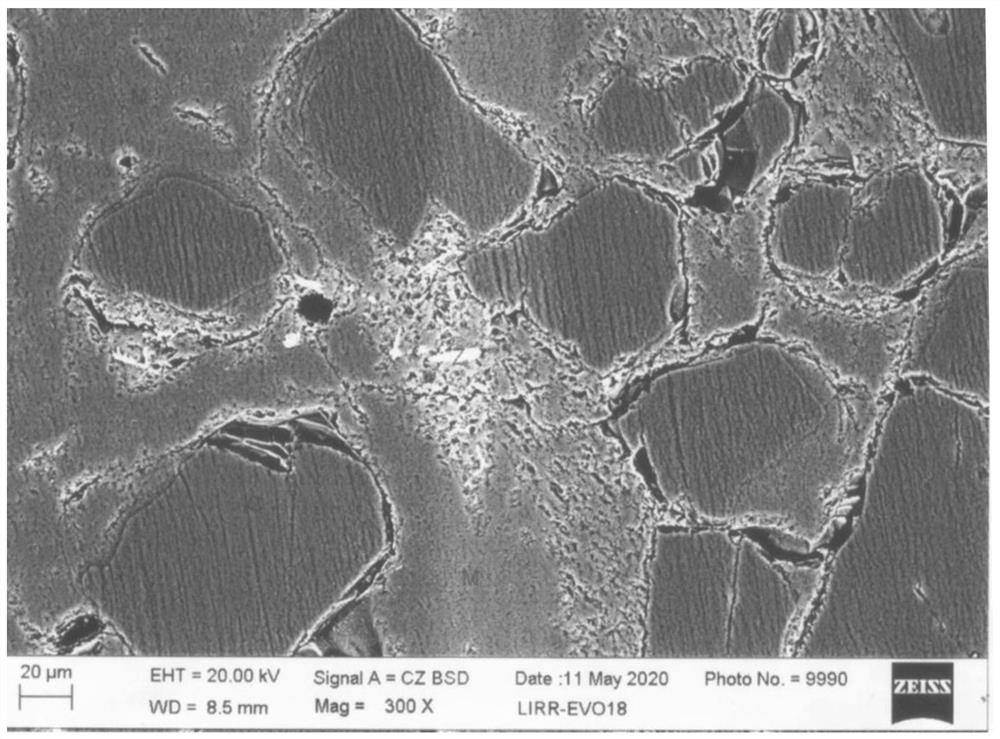

Granoblastic is an adjective describing an anhedral phaneritic equi-granular metamorphic rock texture. Granoblastic texture is typical of quartzite, marble and other non-foliated metamorphic rocks without porphyroblasts. Characteristics defining granoblastic texture include: grains visible to the unaided eye, sutured boundaries and approximately equidimensional grains. The grain boundaries intersect at 120° triple junctions under ideal conditions. Variation from the ideal results from stress produced foliation during crystallization resulting in schistose textures.

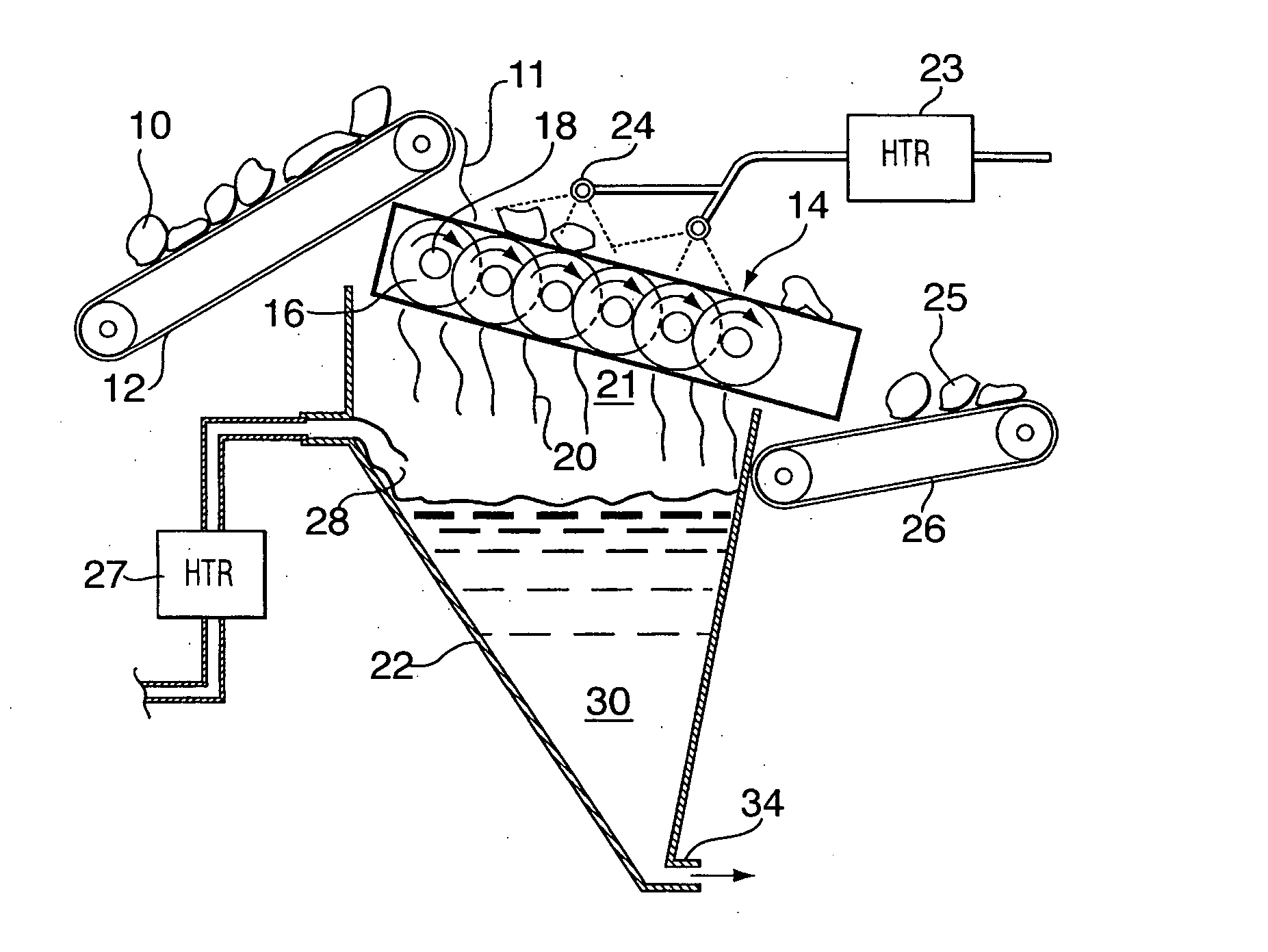

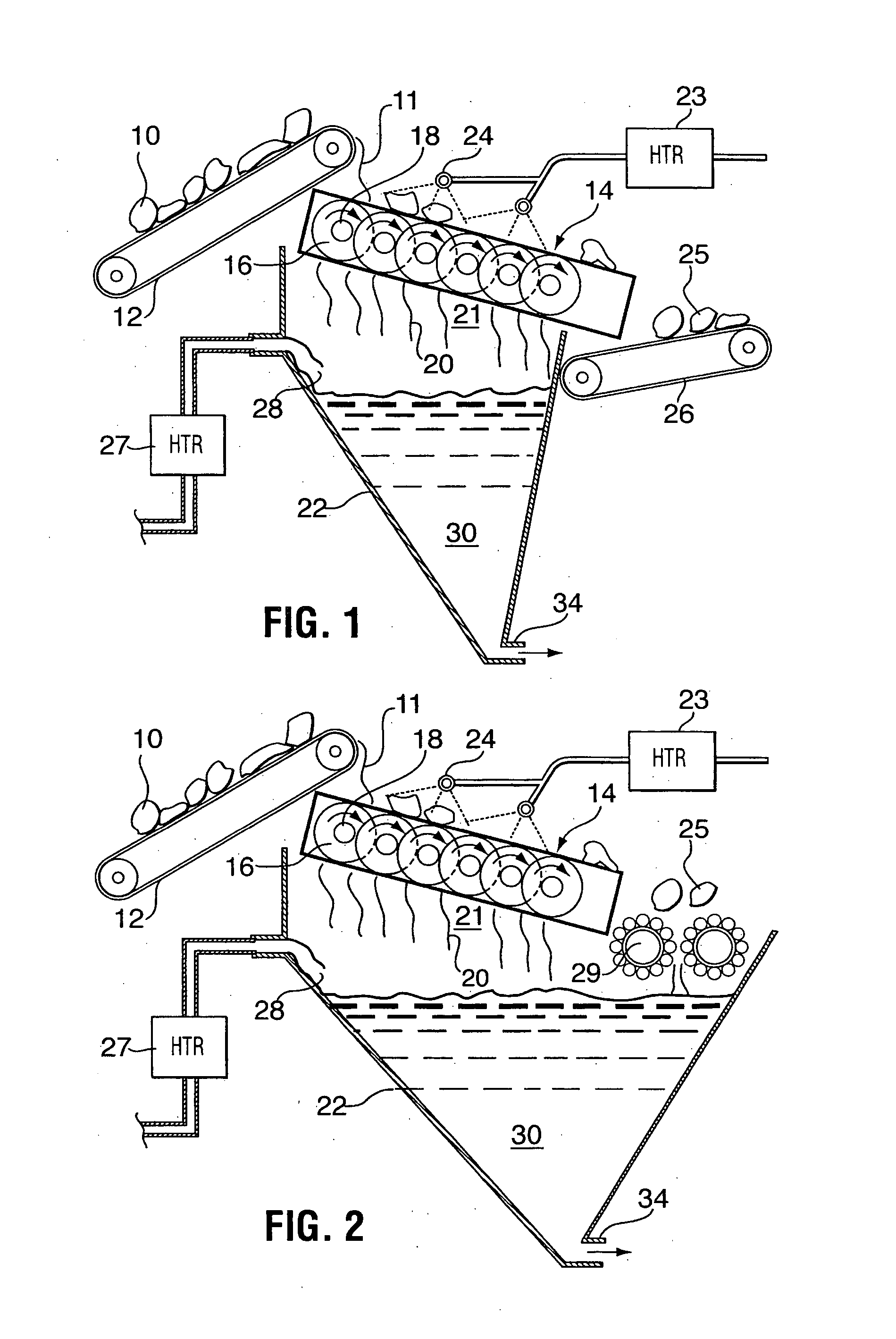

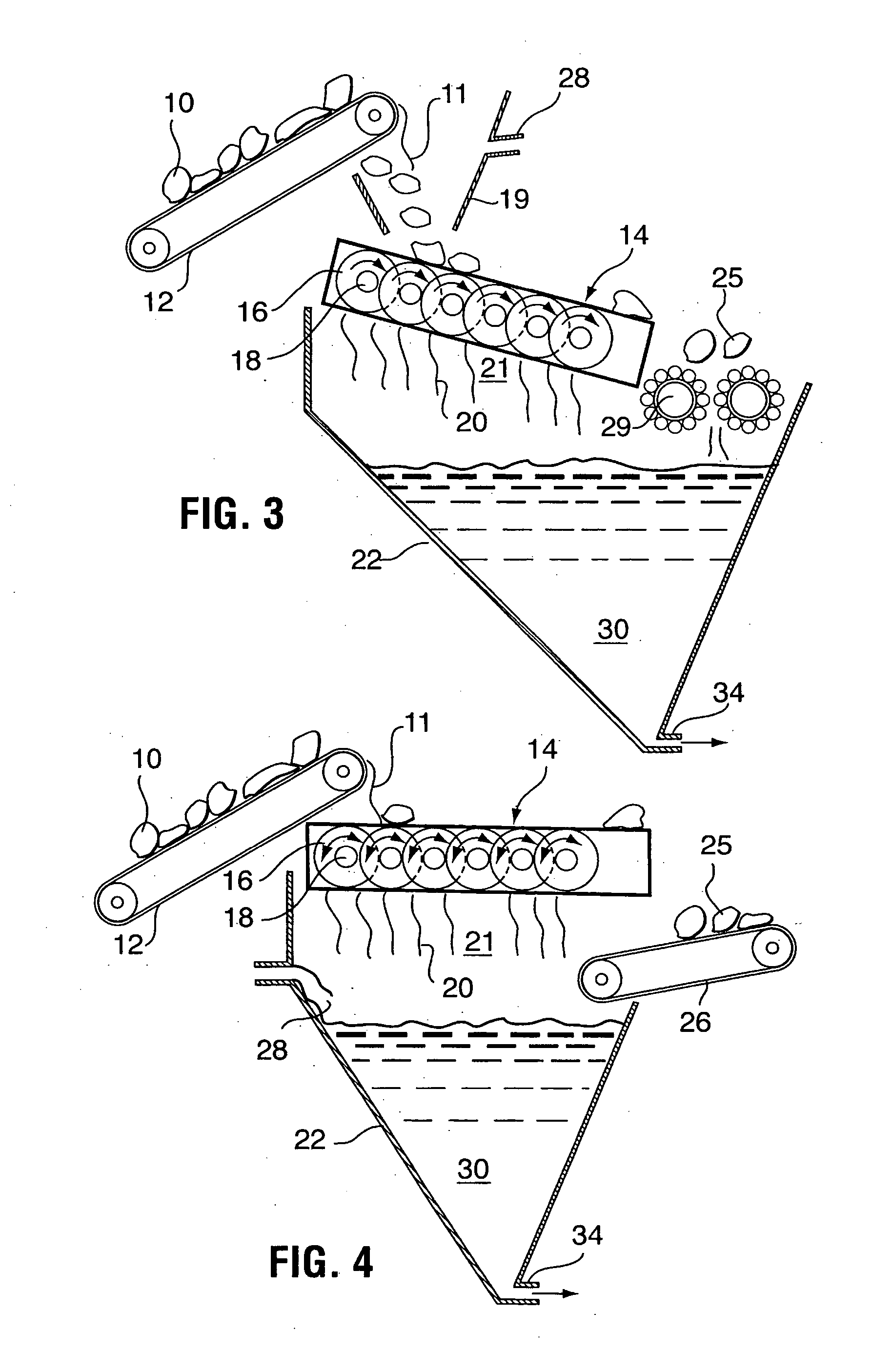

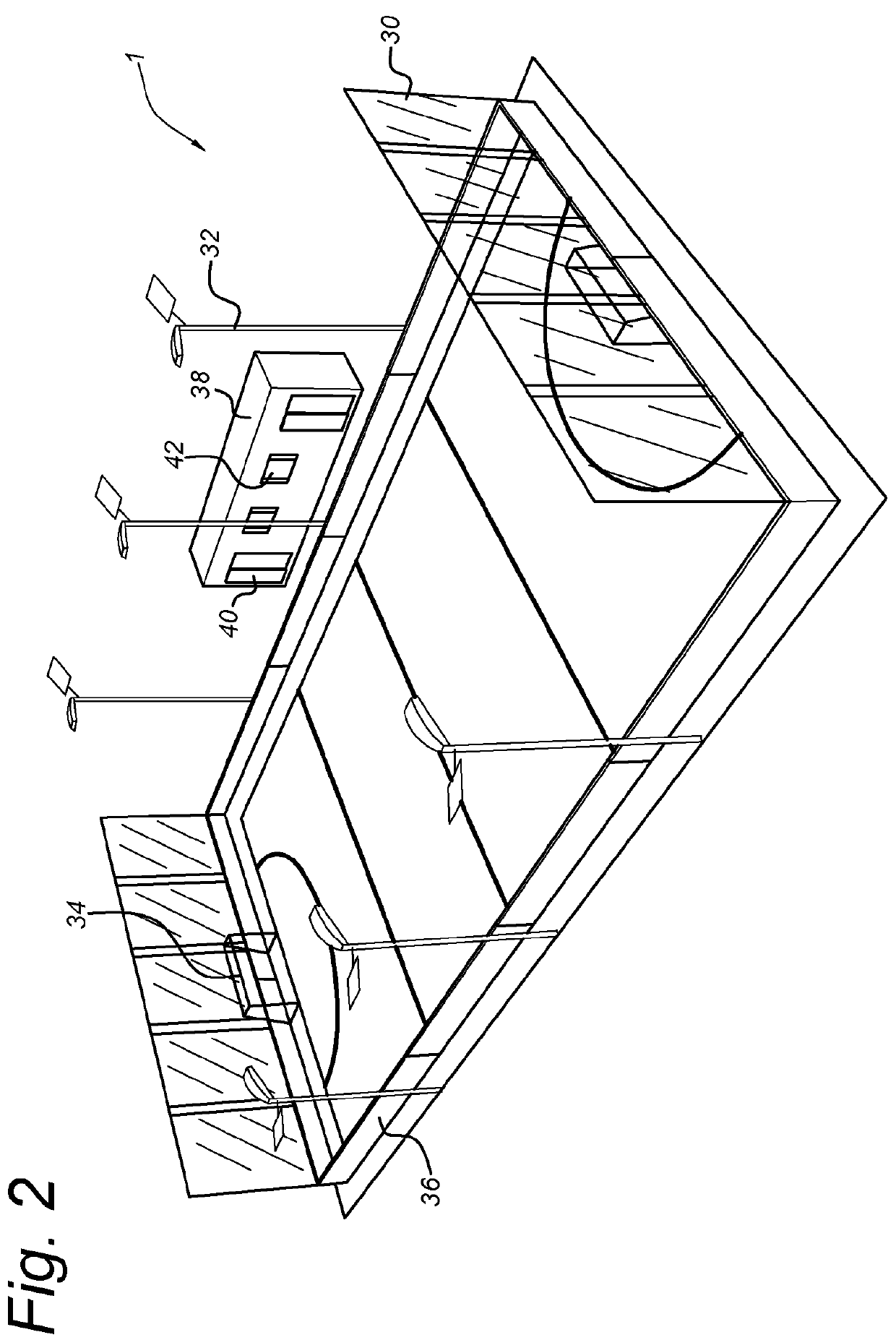

Sizing roller screen ore processing apparatus

Discloses a mined ore processing apparatus to process mined ores, such as oil sands ore, into granular material. An ore processor bed receives the ore to be processed. The ore processor bed has a frame supporting several rotating elements each separately driven to provide independent rotation rate and direction from the other. The ore processing bed is operable as a sizing device to decimate mined ore supply into granular material and separating it from rocks and other large lump mineral materials found in situ. The ore processing bed may be oriented to provide an upward inclination, which, when combined with alternating rotating element rotation directions, provides a crushing action to the ore material to crush larger rock. Alternately, a rock crusher is also provided to disintegrate oversized materials.

Owner:SUNCOR ENERGY INC

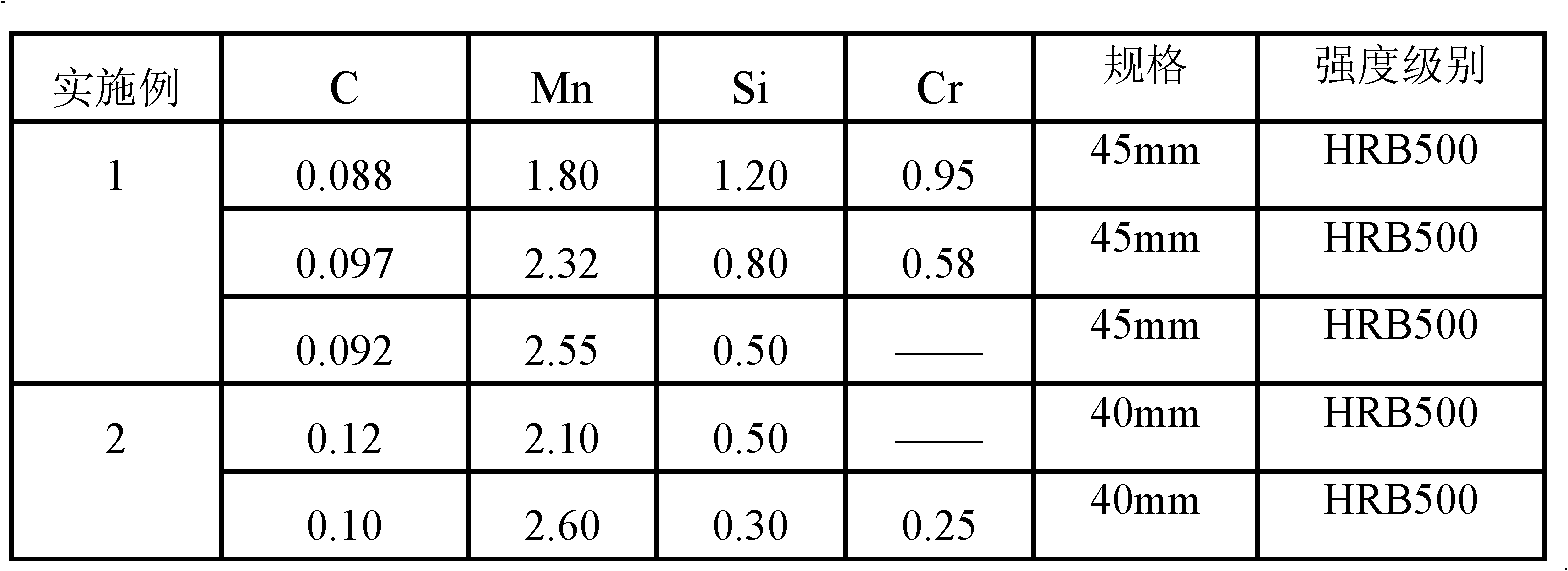

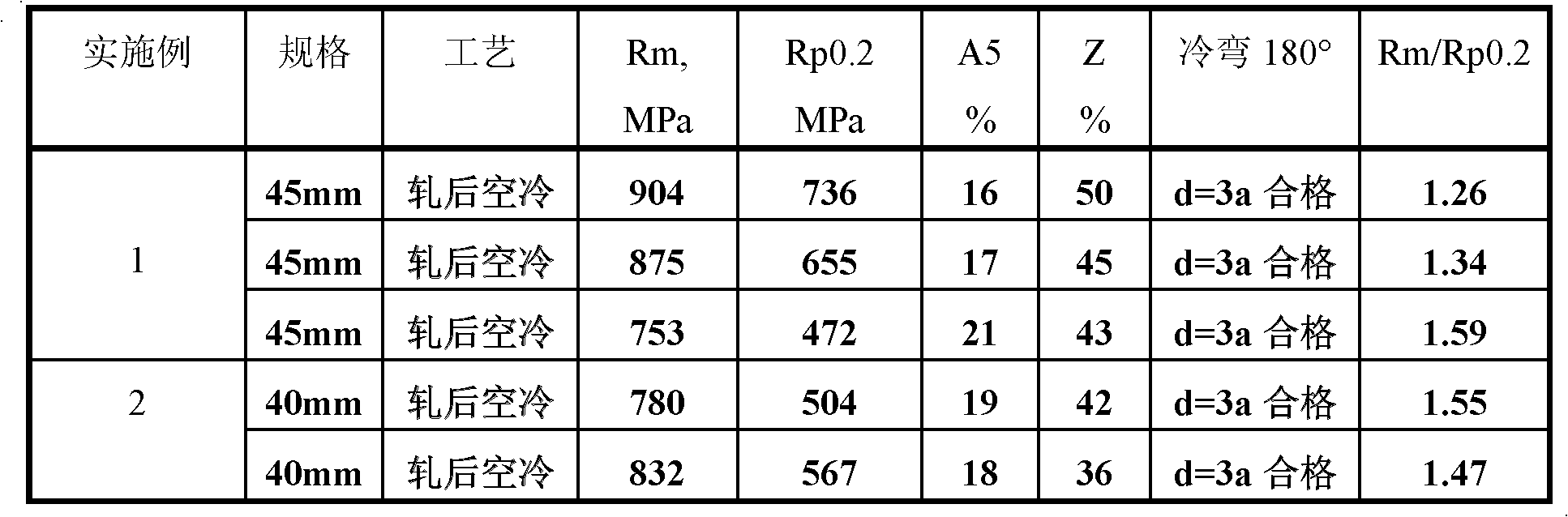

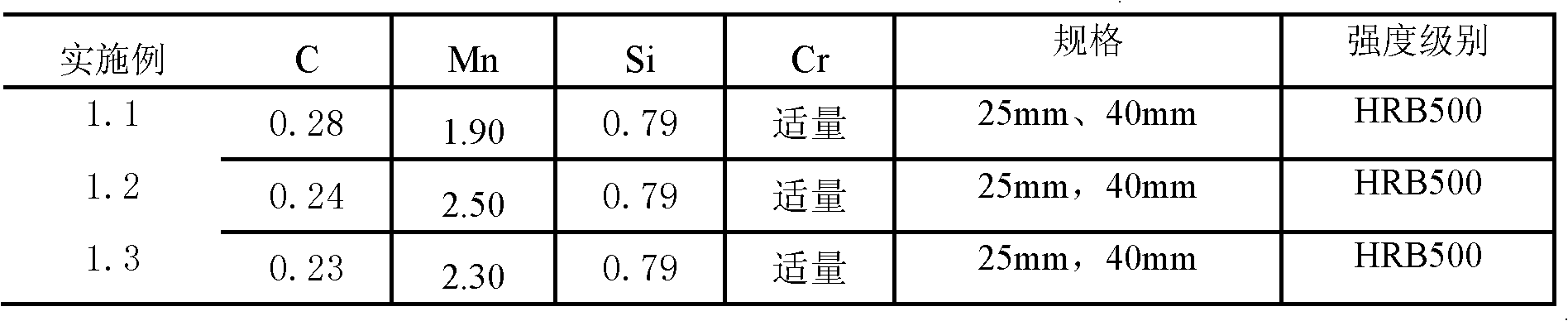

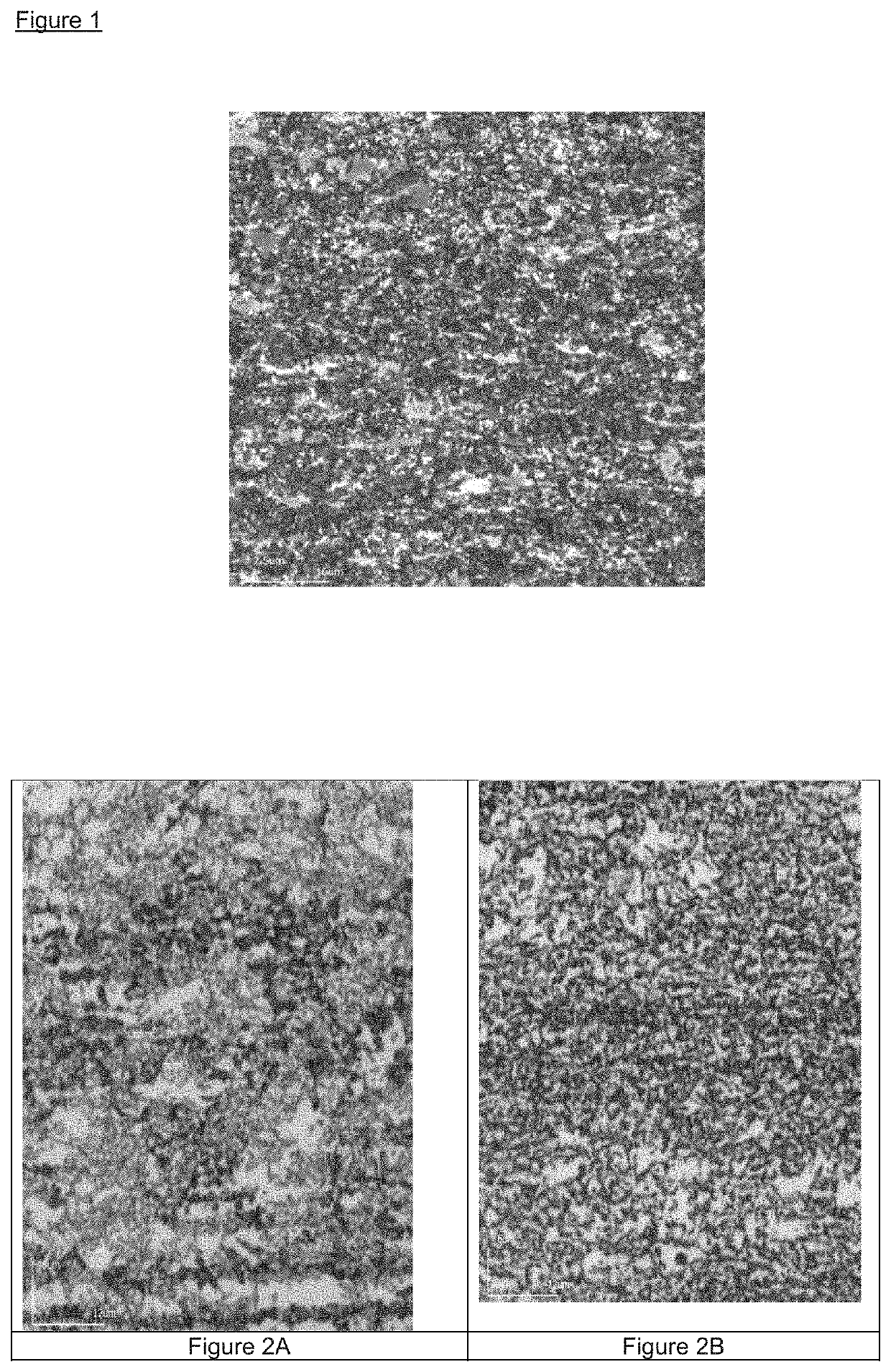

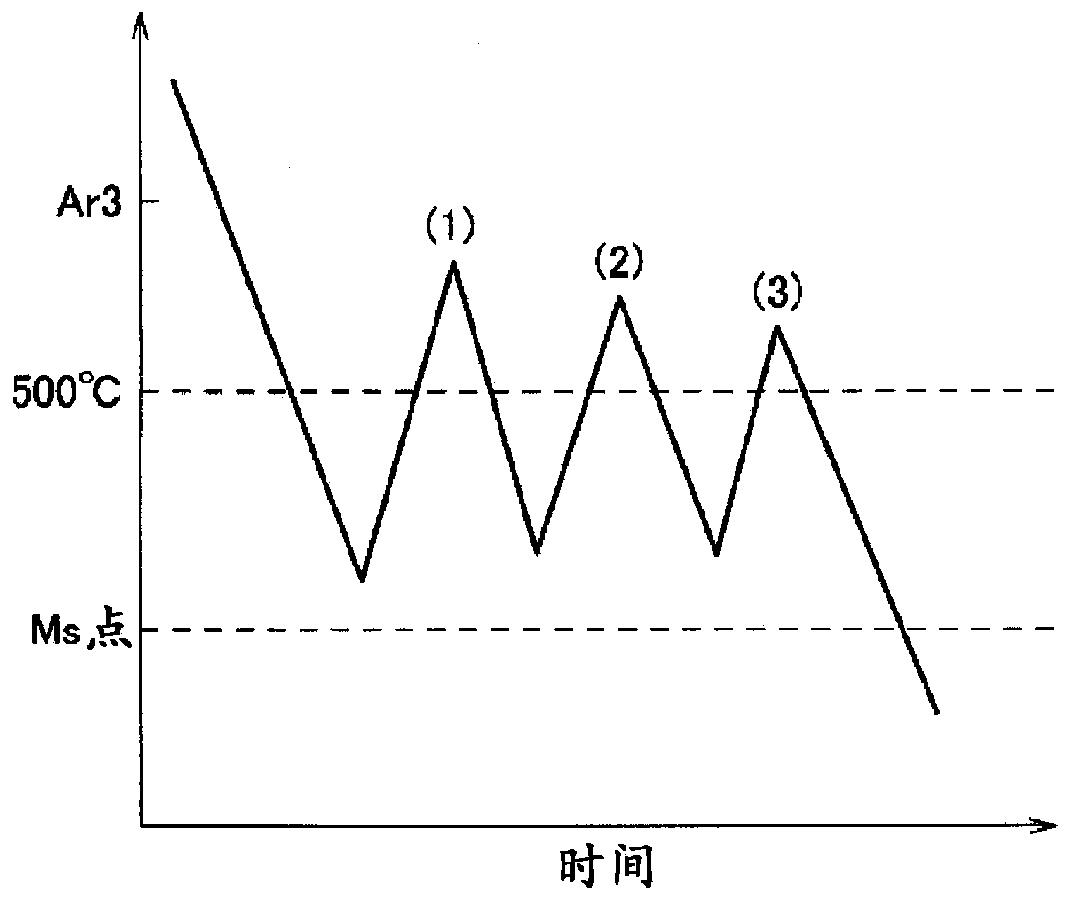

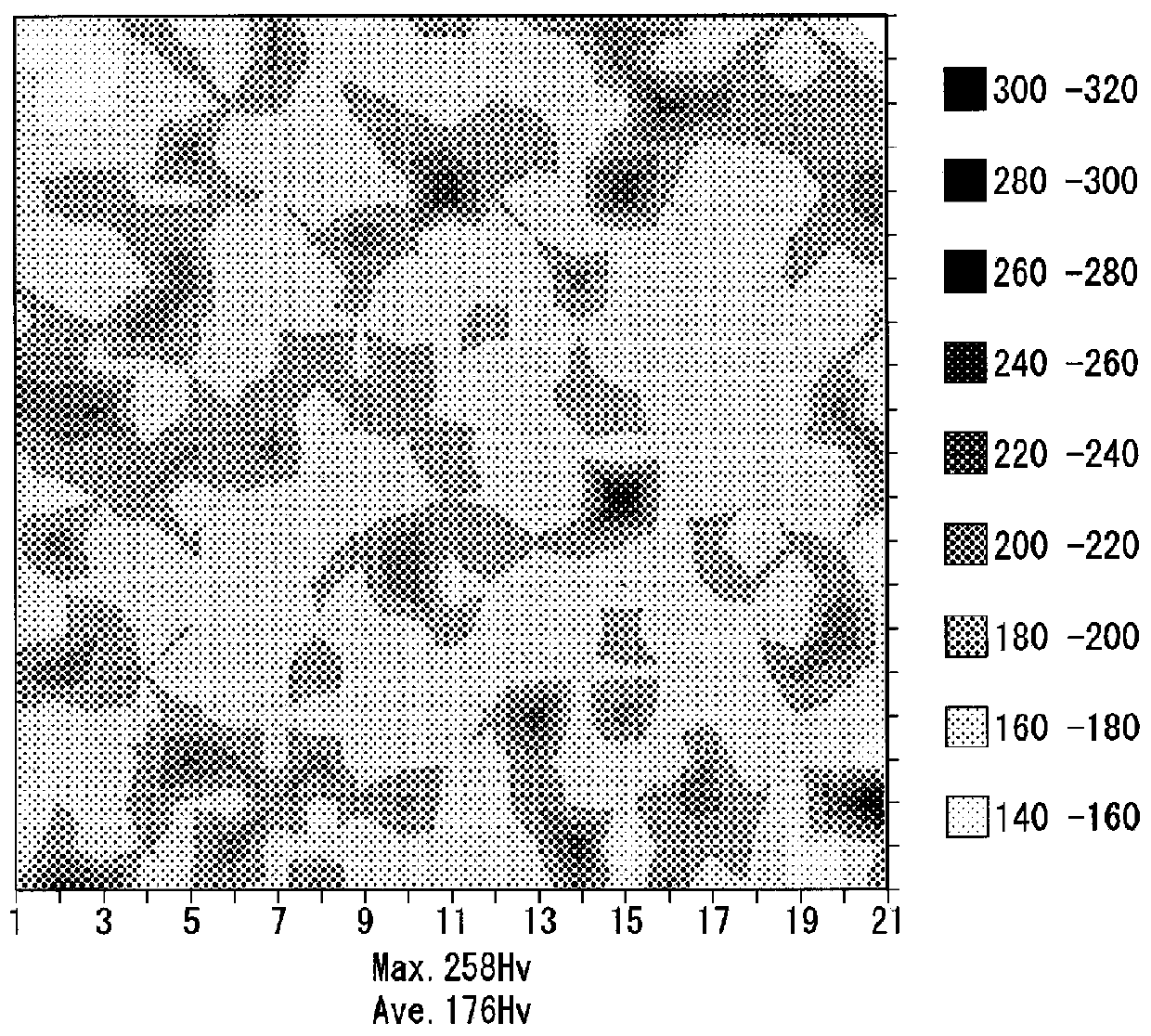

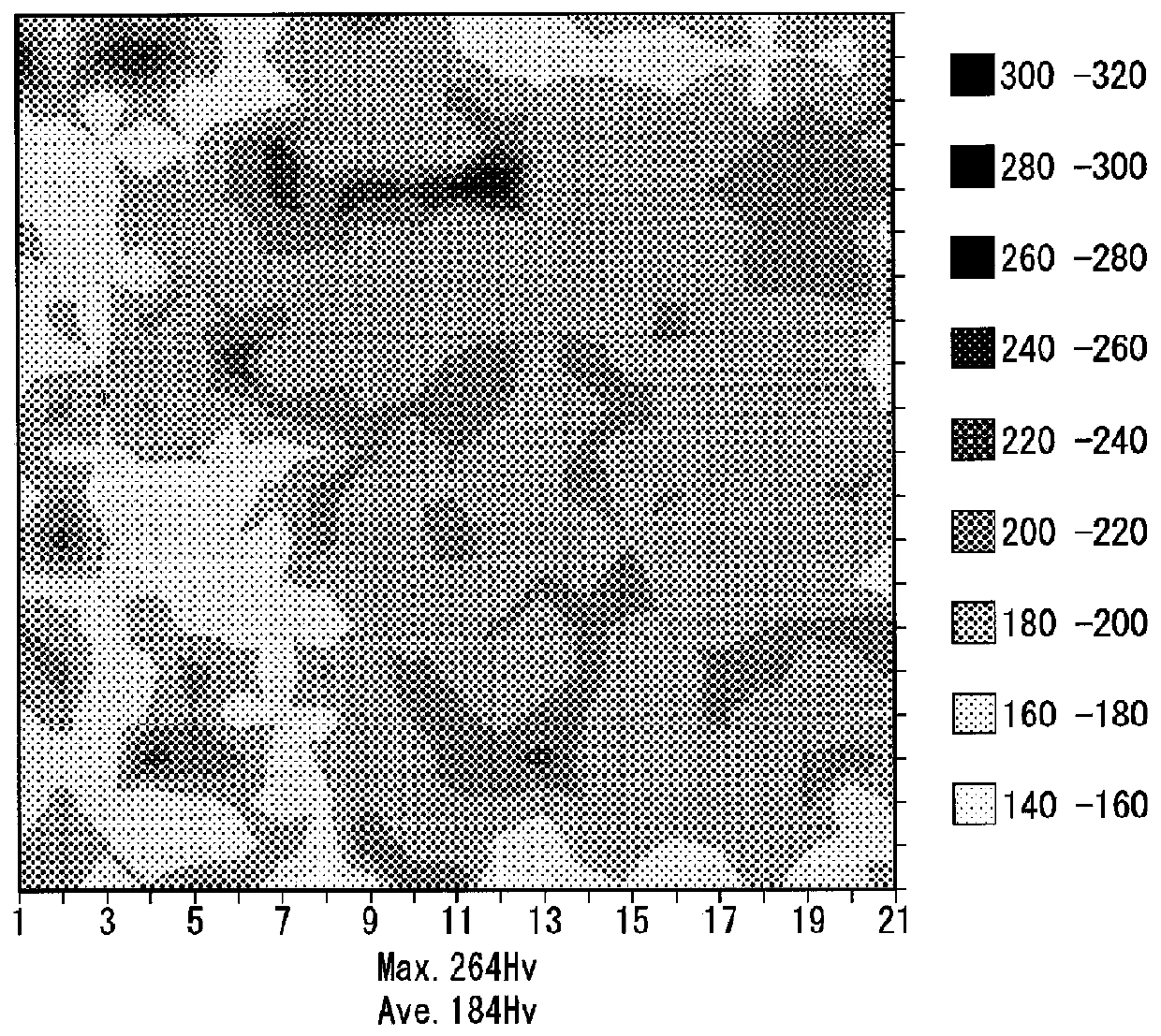

High-strength shock-resistance steel bars and production method thereof

The invention discloses high-strength shock-resistance steel bars and a production method thereof. The yield strength of the high-strength shock-resistance steel bars is 500 to 1200MPa, wherein alloy elements are not required to be added into the high-strength shock-resistance steel bars the yield strength of which is below 600MP, and the components in the steel by the weight percentages includes 0.08 to 0.35% of C, 1.8 to 3.2% of Mn, 0.2 to 1.5% of Si, 0 to 1.0% of Cr, 0 to 0.02% of P and 0 to 0.01% of S, and a small amount of micro-alloy elements of V, Nb and the like are added if necessary. The steel bars have the complex phase tissues in the types of grain boundary allotriomorphic ferrite / granular bainite, lower bainite / martensite and the like and can obtain good strength and toughness coordination by controlling the ratio, the morphology and the distribution of each phase. In addition, the steel bars have extremely strong yield ratio, and the tensile strength allowance of the high-strength shock-resistance steel bars is higher than that of the existing high-strength steel bars by 50%.

Owner:XI LIN IRON & STEEL GRP +1

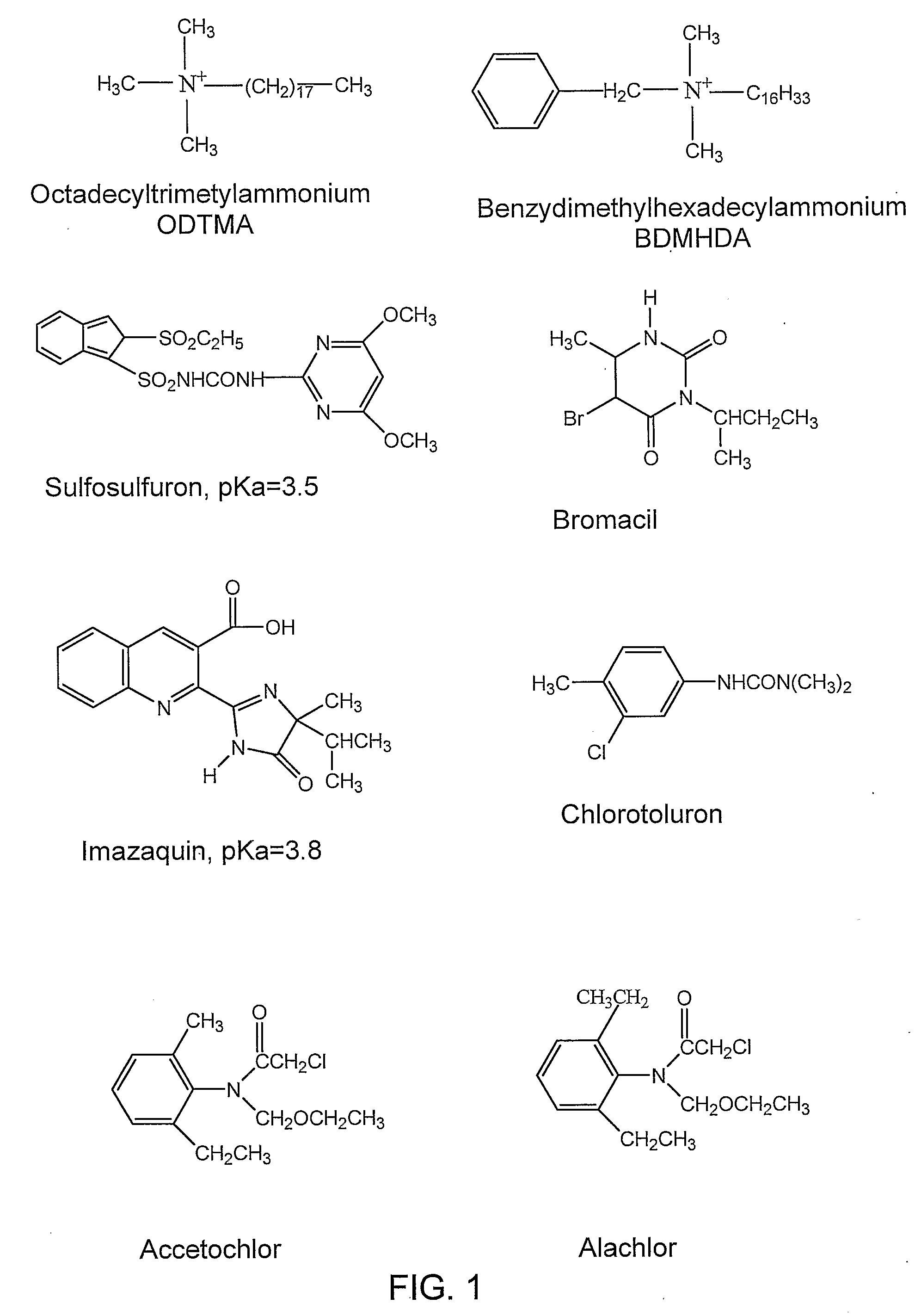

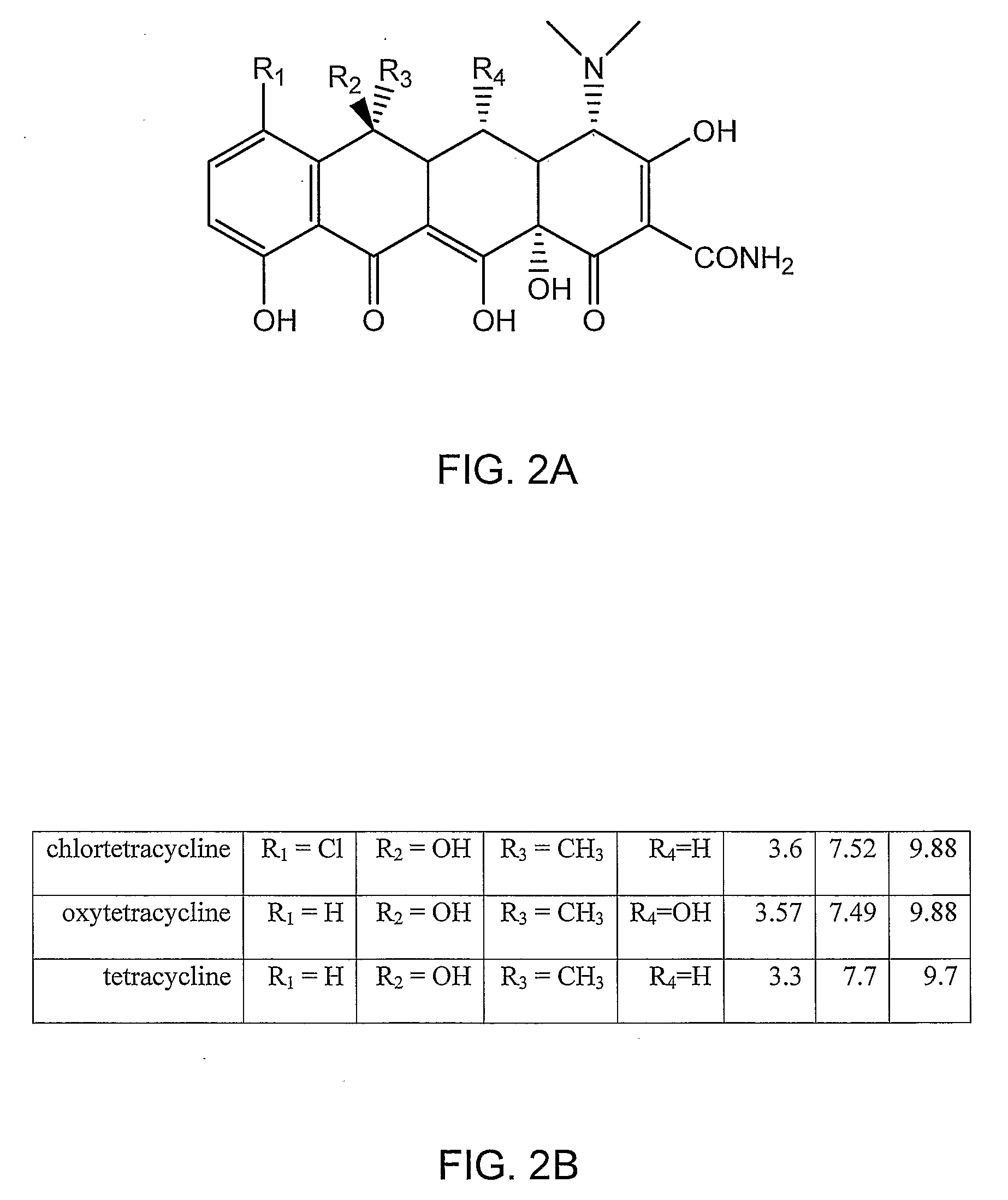

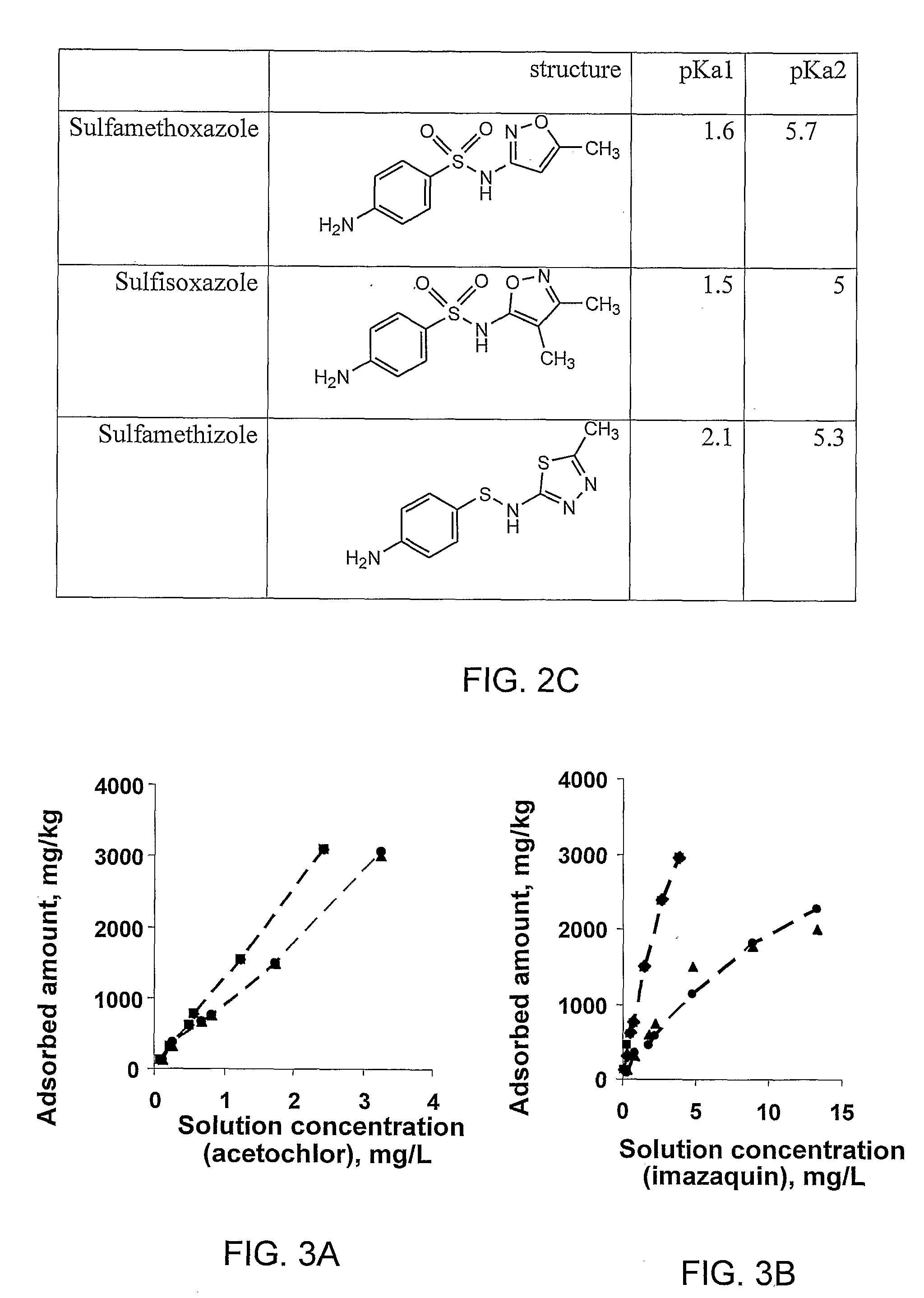

Removal Of Organic Pollutants From Contaminated Water

InactiveUS20090114599A1Improve adsorption capacityOther chemical processesWater contaminantsContaminated waterMicelle

There is provided a method or a system for purification of water from neutral and anionic organic contaminants using either a mixture of a complex of an organic cation adsorbed on clay as a micelle, and a granular material or a complex of an organic cation adsorbed on clay as a micelle. There is also provided a column accommodating the mixture of a complex of an organic cation adsorbed on clay as a micelle, and a granular material.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD

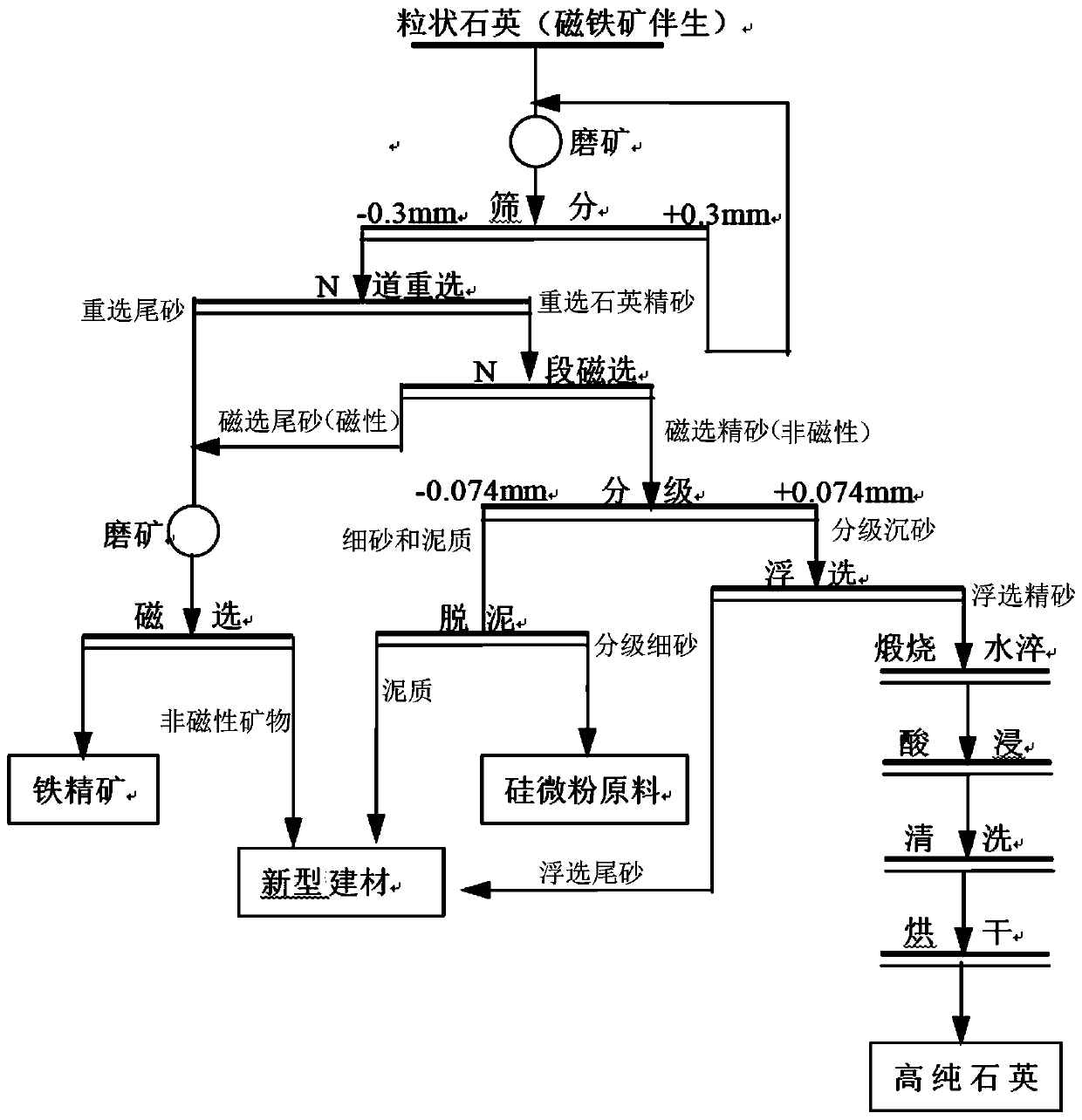

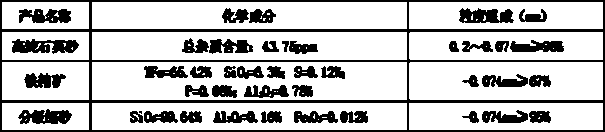

Method for preparing high-purity quartz sand iron ore concentrate from magnetite associated granular quartz

InactiveCN110976077AAchieve separationAvoid secondary pollutionSolid separationGravity separationMagnetic separation

The invention relates to a method for preparing high-purity quartz sand iron ore concentrate from magnetite associated granular quartz. The method comprises the following steps of, grinding and screening granular quartz, returning oversize products for regrinding, and carrying out gravity separation on undersize products to remove heavy minerals; carrying out medium magnetism and strong magnetismon the gravity separation fine sand to obtain magnetic minerals and non-magnetic quartz minerals; removing fine particles and mud of quartz through grading and desliming, taking graded fine sand as anelectrical and electronic grade silica micropowder raw material, and removing non-quartz particles of graded settled sand through flotation; carrying out "calcination, water quenching, acid leaching,cleaning and drying" on the flotation fine sand to obtain the high-purity quartz sand; carrying out ball milling and magnetic separation on gravity separation tailings and magnetic separation magnetic minerals to obtain high-grade iron ore concentrate; and using tailing mud and tailing sand generated in the ore dressing process as a novel building material raw material. According to the method, comprehensive utilization of resources can be achieved, and good economic, social and environment-friendly benefits are achieved.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD

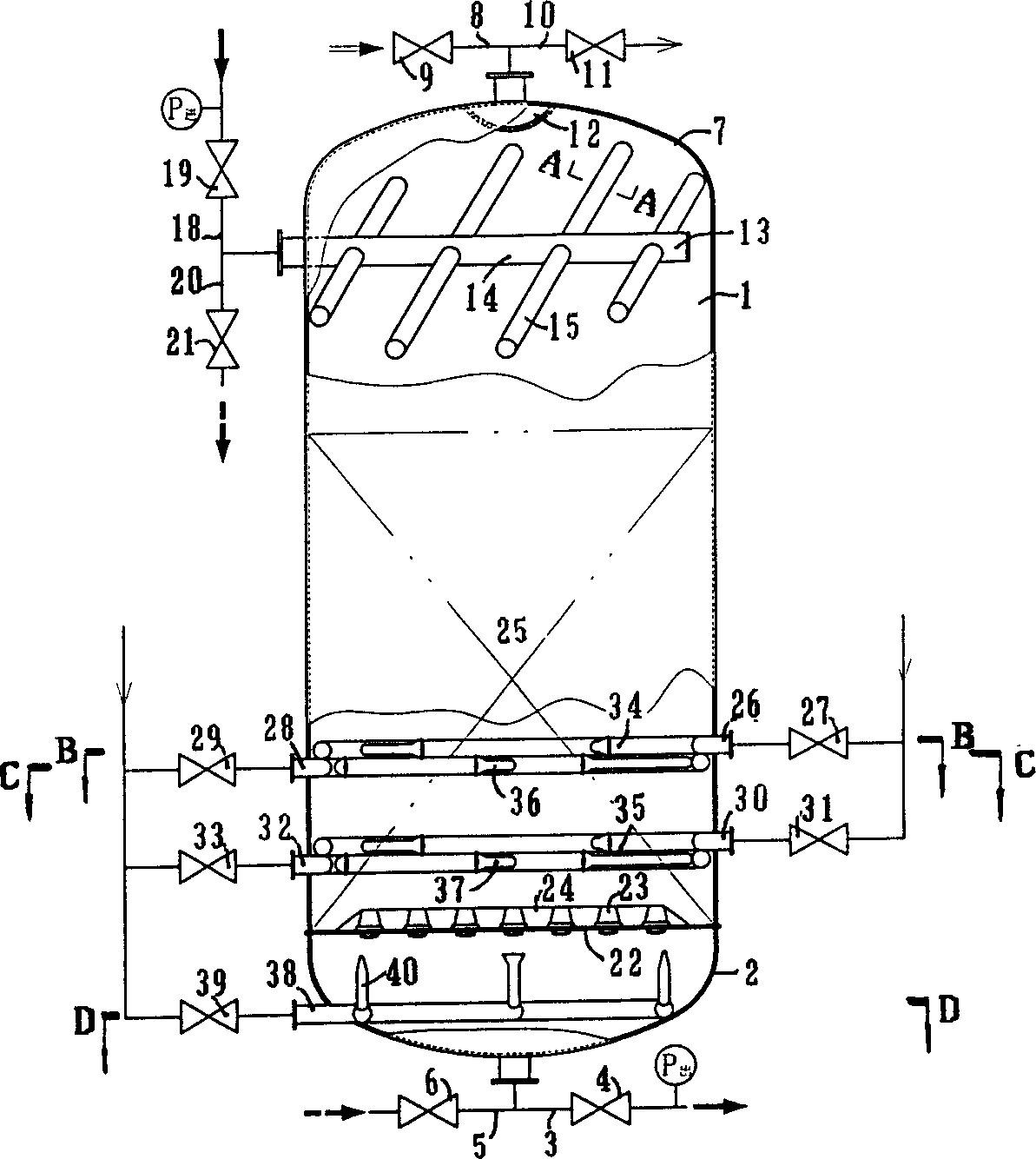

Multi-dimensional space filter material scrubbing method

InactiveCN1640523AImprove cleanlinessRestore filter capacityLoose filtering material filtersGravity filtersWater flowAnthracite

The invented multi-dimensional space filtering material scrubbing method relates to a method for treating waste water. Said method is characterized by that in the container filled up with filtering material said invention utilizes the scrubbing air flow formed from rotary pressure air flow in the filtering material and upward pressure air flow in the lower portion of filtering material, scrubbing water flow of upward pressure water flow or / and addition of promoting agent to scrub the filtering material. Said invention is applicable to fibre ball filtering material, and also is applicable to filtering materials of quartz sand, active carbon, anthracite coal, manganese sand, magnetite granules and ceramsite, etc.

Owner:杨静

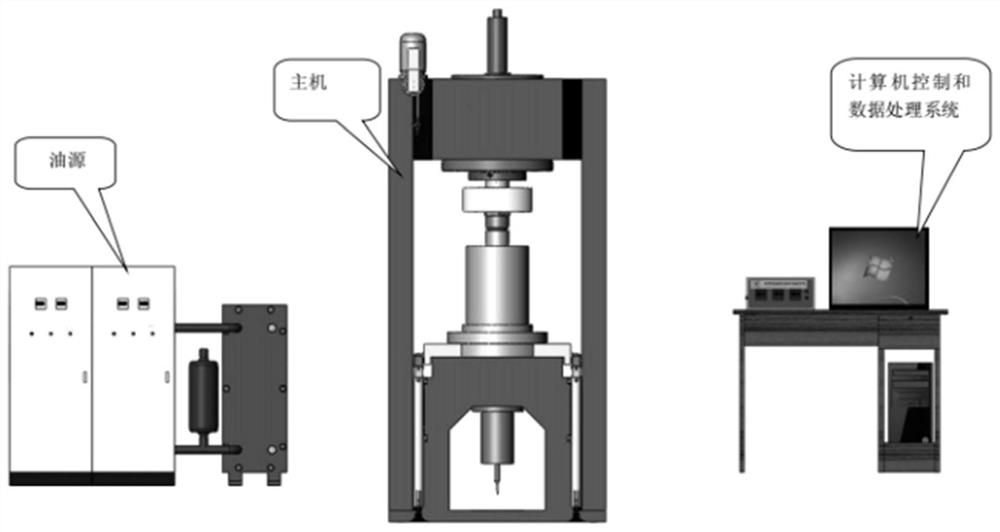

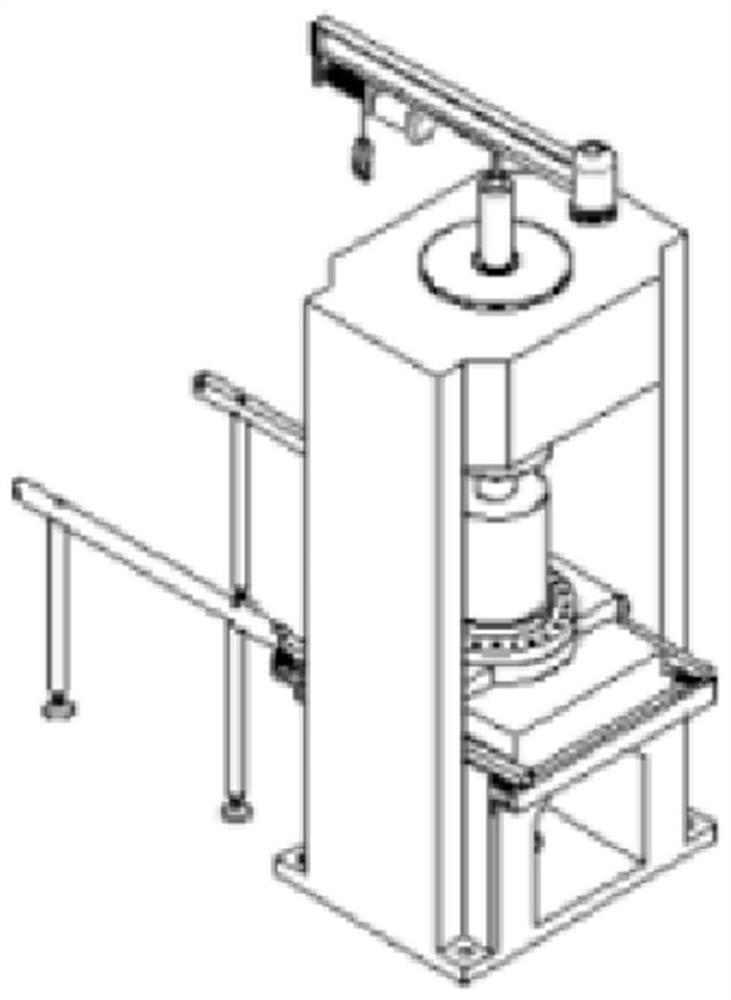

Laboratory three-dimensional dynamic rock crushing test system and method

ActiveCN112881188ASimple and fast operationLoading does not affect each otherMaterial strength using tensile/compressive forcesData processing systemServo actuator

The invention belongs to the technical field of laboratory mechanical rock breaking, and particularly relates to a laboratory three-dimensional dynamic rock breaking test system and method. The laboratory three-dimensional dynamic rock breaking test system comprises a host, a functional device, an electro-hydraulic servo axial loading system, a measurement control system, a computer control and data processing system and the like, and is reasonable in structure. The test system and method are simple and convenient to operate, can be used for simulating mechanical property test research of crushing of natural rocks, artificial concrete and granular compaction and consolidation test pieces under the condition of high stress of various dynamic loads such as impact and mechanical tunneling; according to the test system, a conventional mechanical experiment and a rock breaking experiment under the dynamic confining pressure condition can be achieved, and loading of an axial (3000KN) static pressure actuator and loading of an axial (25KN) servo actuator do not affect each other; the rock breaking direction in the experiment is downward, rock debris generated by rock breaking can automatically fall off, and the influence on stress, displacement and the like in the simulated rock breaking experiment is reduced; and real-time dynamic fracture positioning and damage parameters are obtained.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

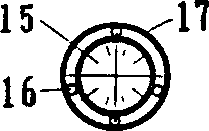

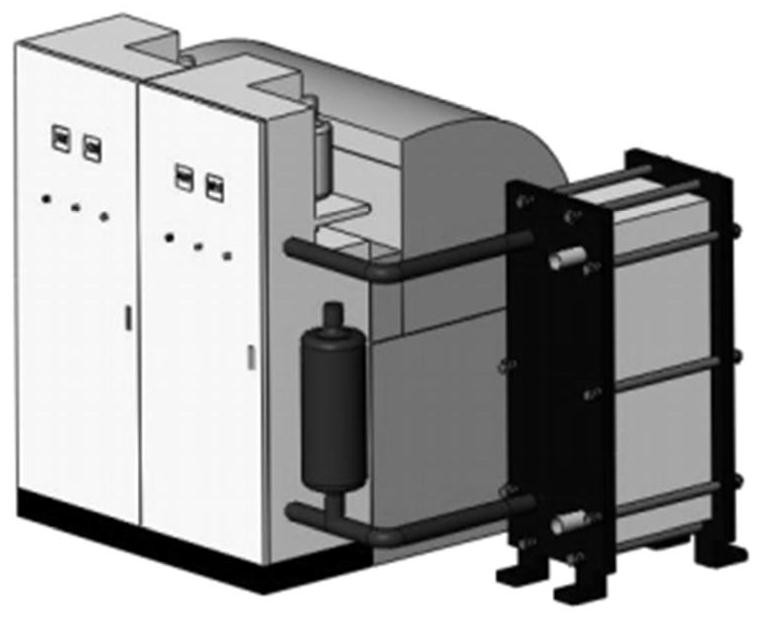

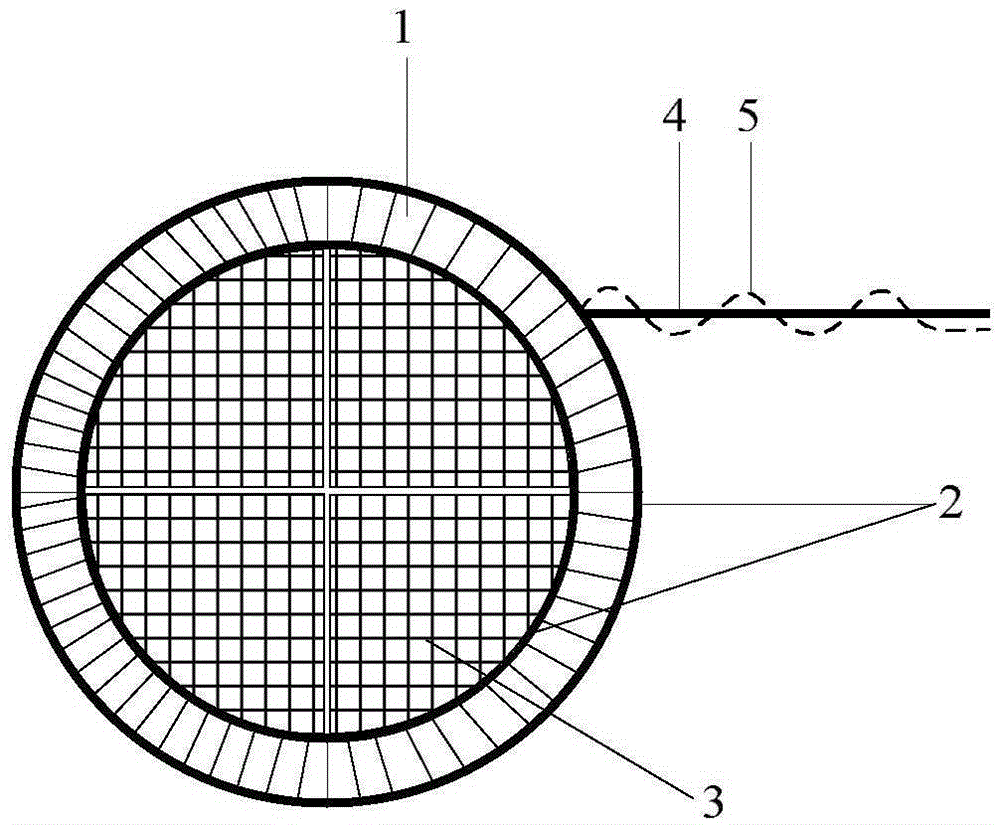

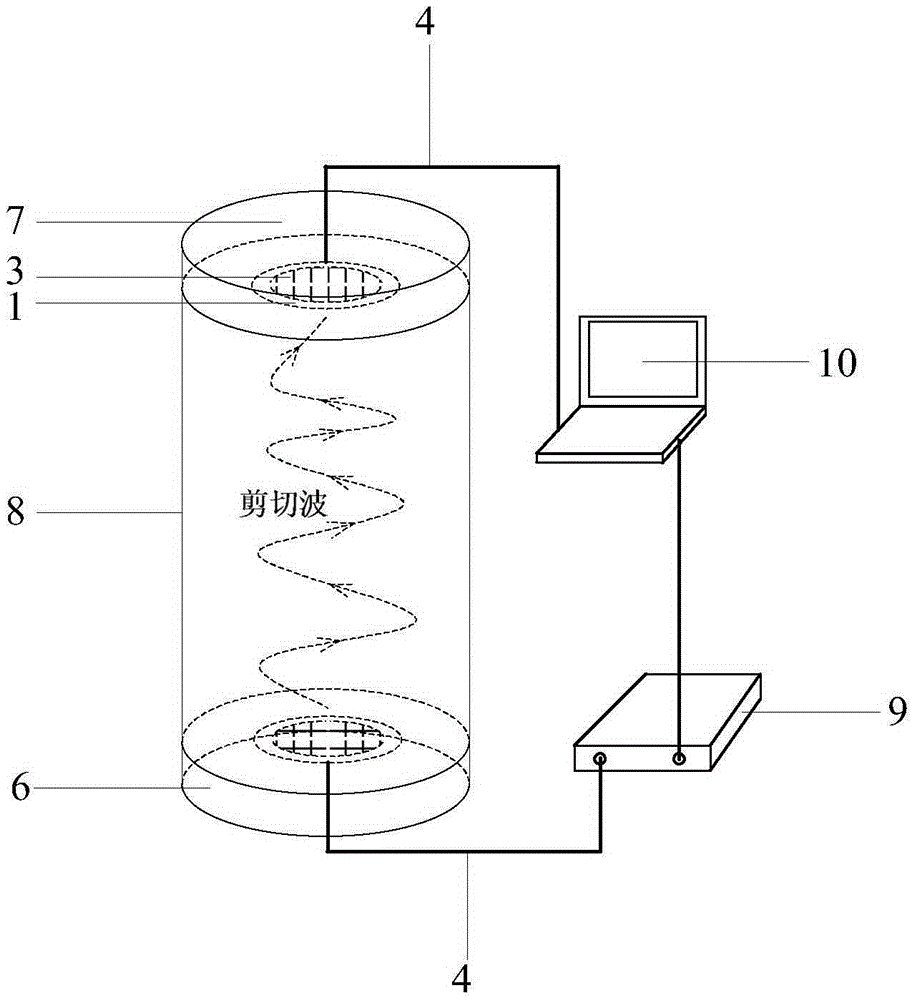

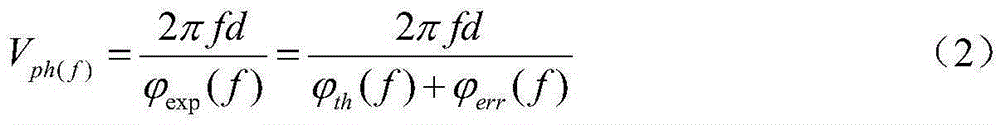

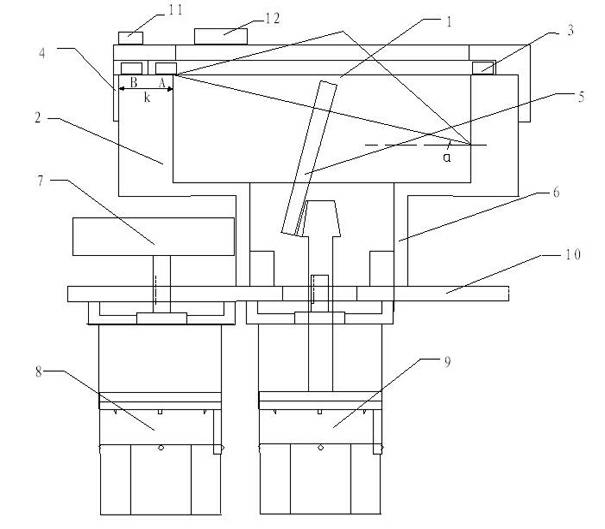

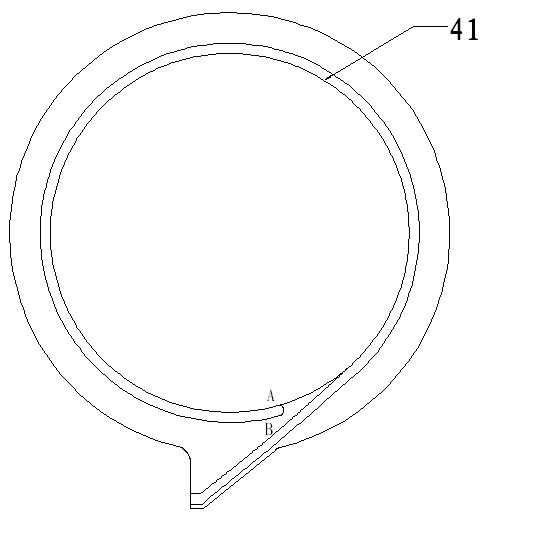

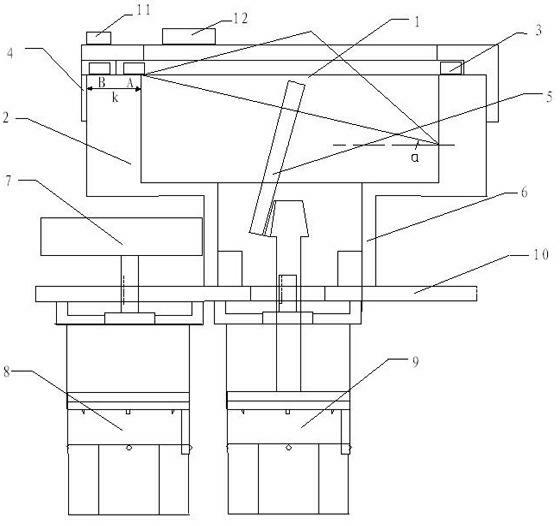

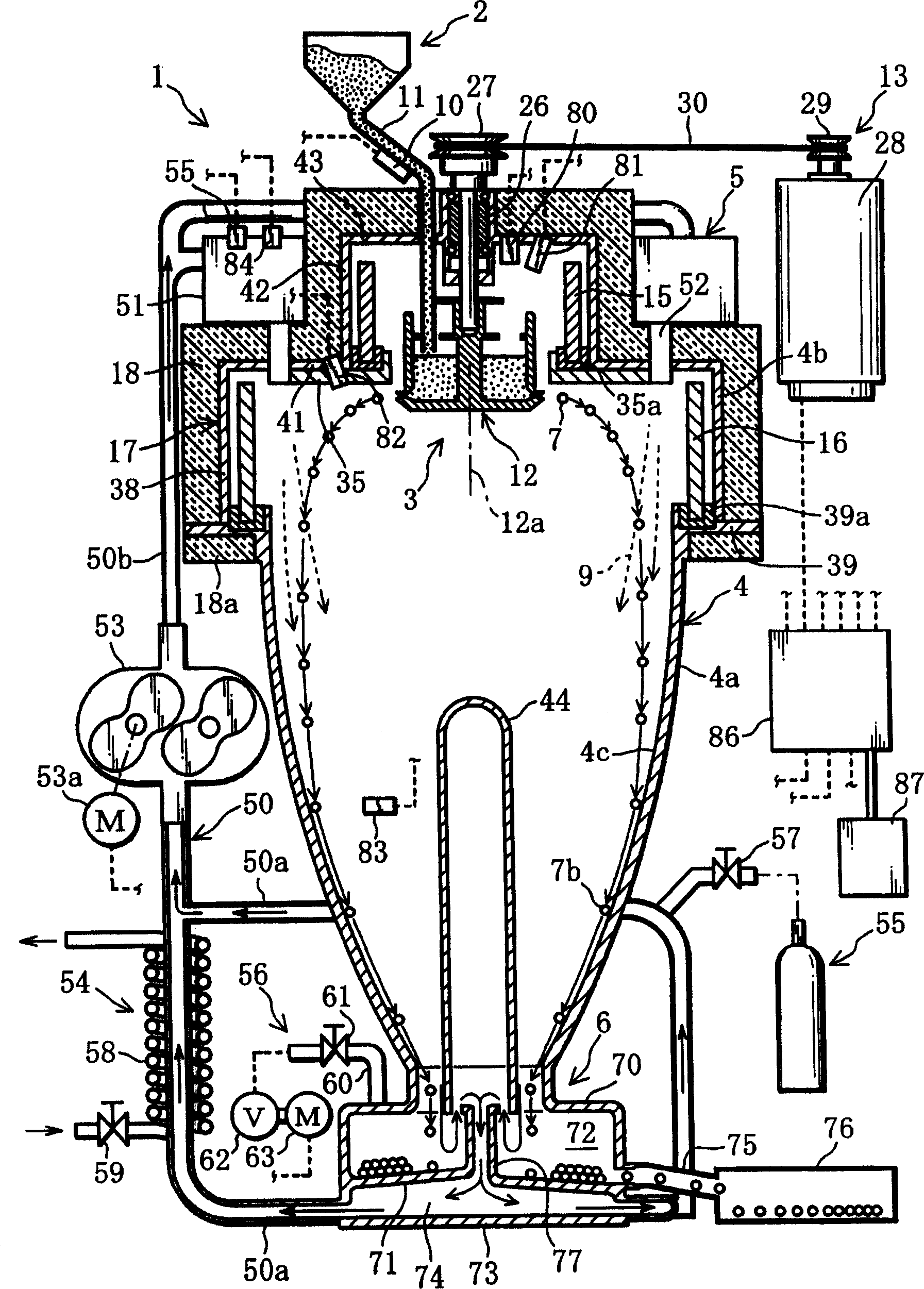

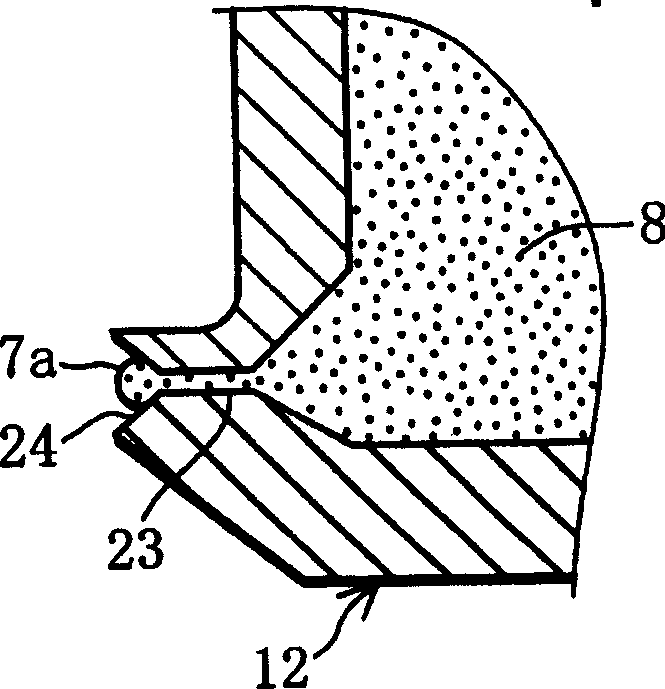

Piezoelectric ring excitation device for testing granular material shear wave velocity and indoor testing device

ActiveCN105388219AAccurate Shear Wave VelocityLarge variabilityAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic/sonic/infrasonic wave generationRadial deformationAtomic physics

The invention disclose a piezoelectric ring excitation device for testing the granular material shear wave velocity and an indoor testing device. The piezoelectric ring excitation device comprises a piezoelectric ring (1), the inner side wall and the outer side wall of the piezoelectric ring (1) are both coated with epoxy resin (2), the interior of the piezoelectric ring (1) is filled with permeable stones (3), and the piezoelectric ring (1) is connected with data transmission cables (4) and a grounding wire (5). When the granular material shear wave velocity is tested, a pair of the piezoelectric ring excitation devices are installed on a base (6) and a top cap (7) respectively and serve as a shear wave excitation element and a receiving element, a sample (8) is arranged between the base (6) and the top cap (7), the base (6) is connected with a power amplifier (9) through one data transmission cable (4) and connected to a computer (10), and the top cap (7) is directly connected to the computer (10) through the other transmission cable (4). The piezoelectric ring excitation device adopts a radial deformation transmission shear wave, high precision is achieved, and a good testing means is provided for evaluating engineering characteristics of rock and soil materials.

Owner:SOUTHEAST UNIV

Medium Material for Removing Phenol Contamination from Groundwater, Method of Producing the Same, and Use of the Same

A medium material for removing phenol contamination from groundwater, a method of producing the same, and use of the same id disclosed. In at least some embodiments, the medium material is a granular material which has an average particle diameter of 0.5-1.5 cm and is formed from a bacteria-entrapping solution, a manganese sand filter material, modified bentonite, and biochar at a mass ratio of 1:0.2-0.4:0.2-0.4:0.1-0.2 by a series of processes including strain culturing, catalysis, mixing, solidification, and the like. The medium material can remove phenol from groundwater, is a safe and environment-friendly material, has a long service life, and / or achieves waste treatment with waste.

Owner:CHINESE RES ACAD OF ENVIORNMENTAL SCI

High-speed rotating shaping device

InactiveCN102320464AAvoid cloggingHigh-speed sort shapingConveyor partsEngineeringMechanical engineering

The invention relates to a high-speed rotating shaping device, comprising a horizontal turntable, a conic body, an outer cover, a driving mechanism and a fixed bracket. The conic body is arranged above the horizontal turntable, a slant angle alpha is formed between the conic body and the horizontal plane, the highest point of bottom rotation of the conic body is as high as an upper edge of the horizontal turntable, and width of the upper edge of the horizontal turntable is k; the outer cover is arranged over the horizontal turntable and fixed through an external bracket, an inner side of the outer cover is provided with a rail, and the rail is butted with the upper edge of the horizontal turntable to form a granular material operation channel; an inlet of the rail is the highest point of the bottom rotation of the conic body; an outlet of the rail extends towards an external side of the upper edge of the horizontal turntable to form a rail spiral section, the conic body and the horizontal turntable are connected with the driving mechanism, and the driving mechanism is fixed on the fixed bracket. The high-speed rotating shaping device can sort and shape the flaky and granular materials at high speed, thereby greatly meeting the requirements on large-scale high-speed production of the flaky and granular materials in different sizes, and improving work efficiency.

Owner:韩小应

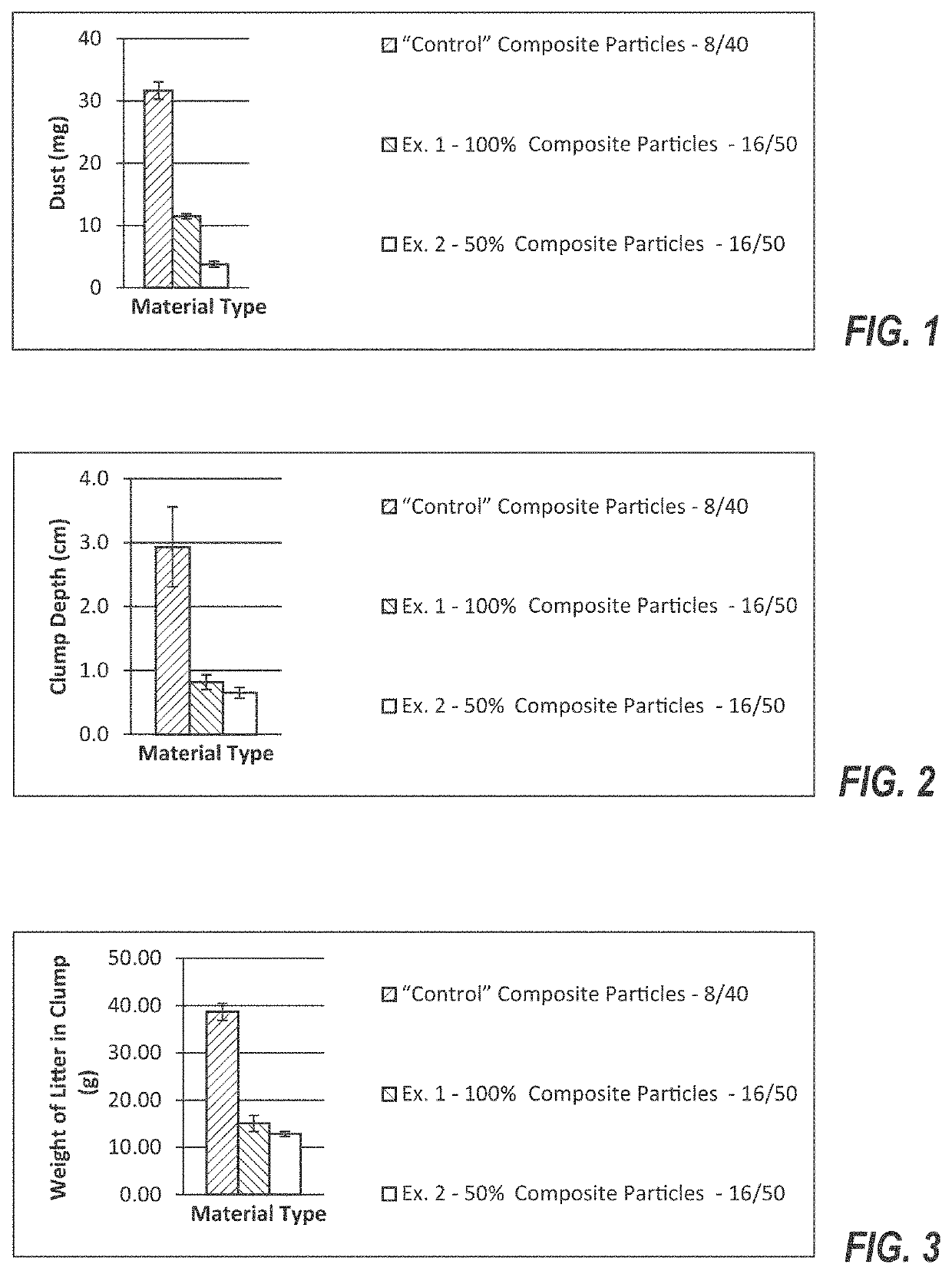

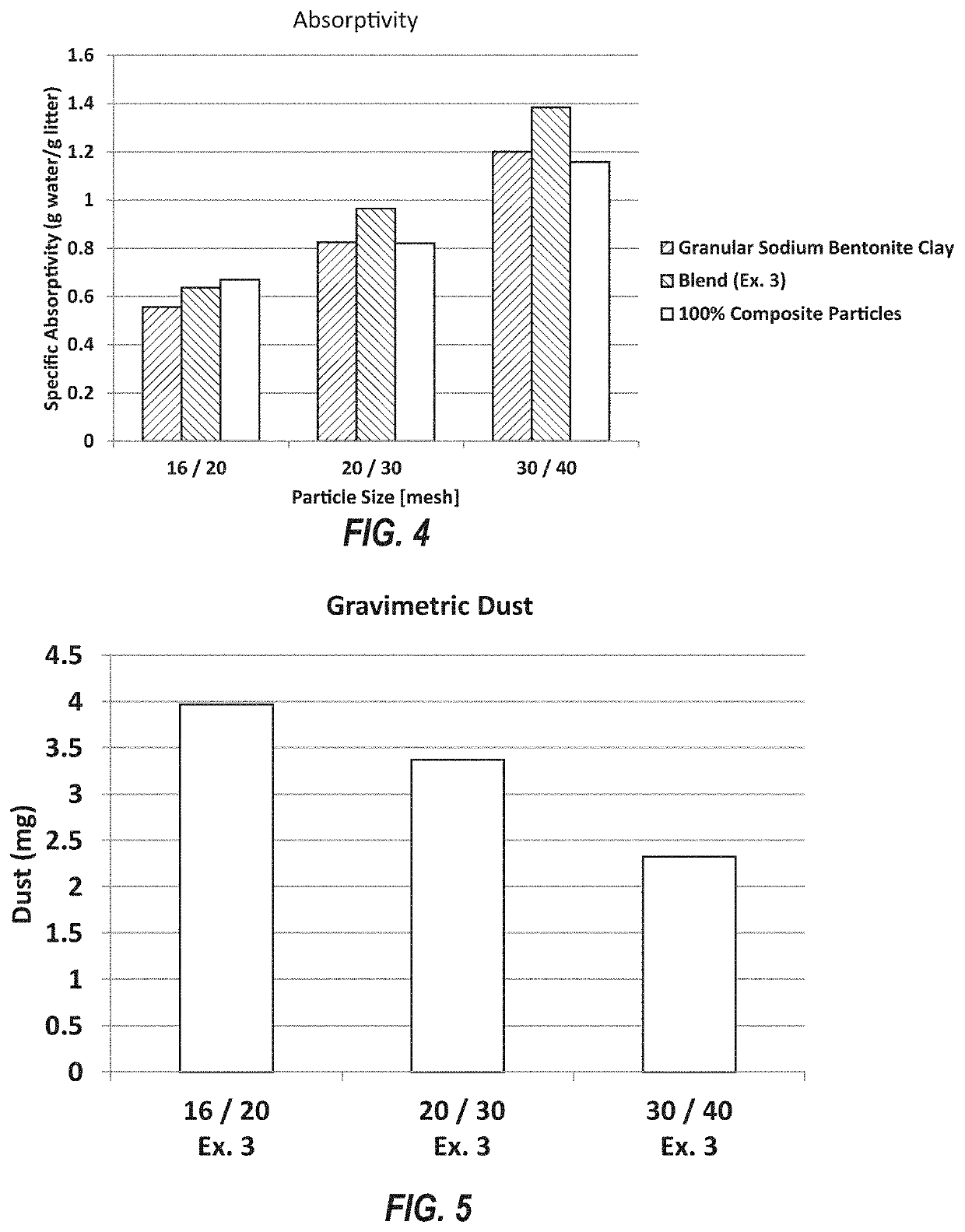

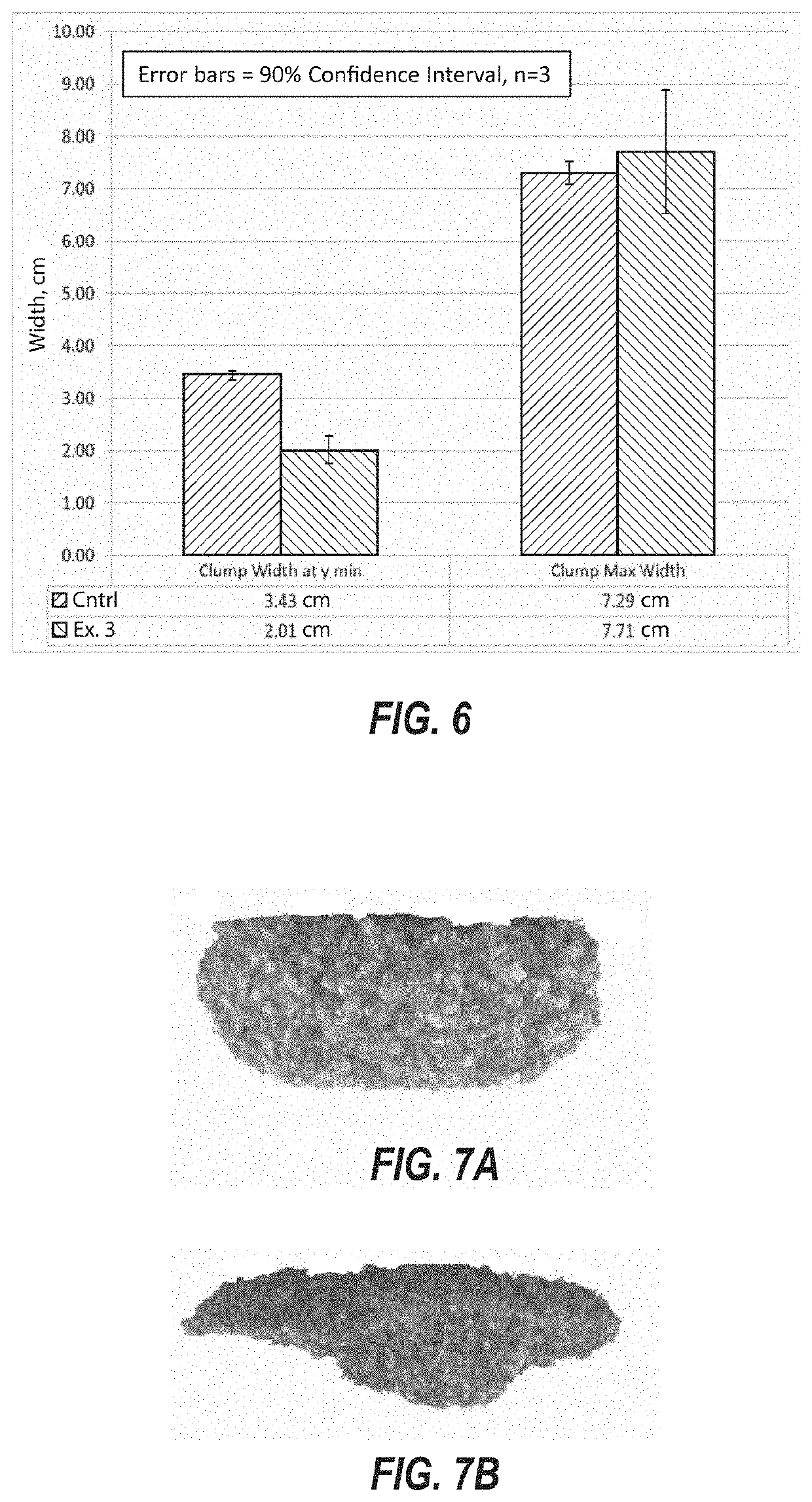

Clumping animal litter and method thereof

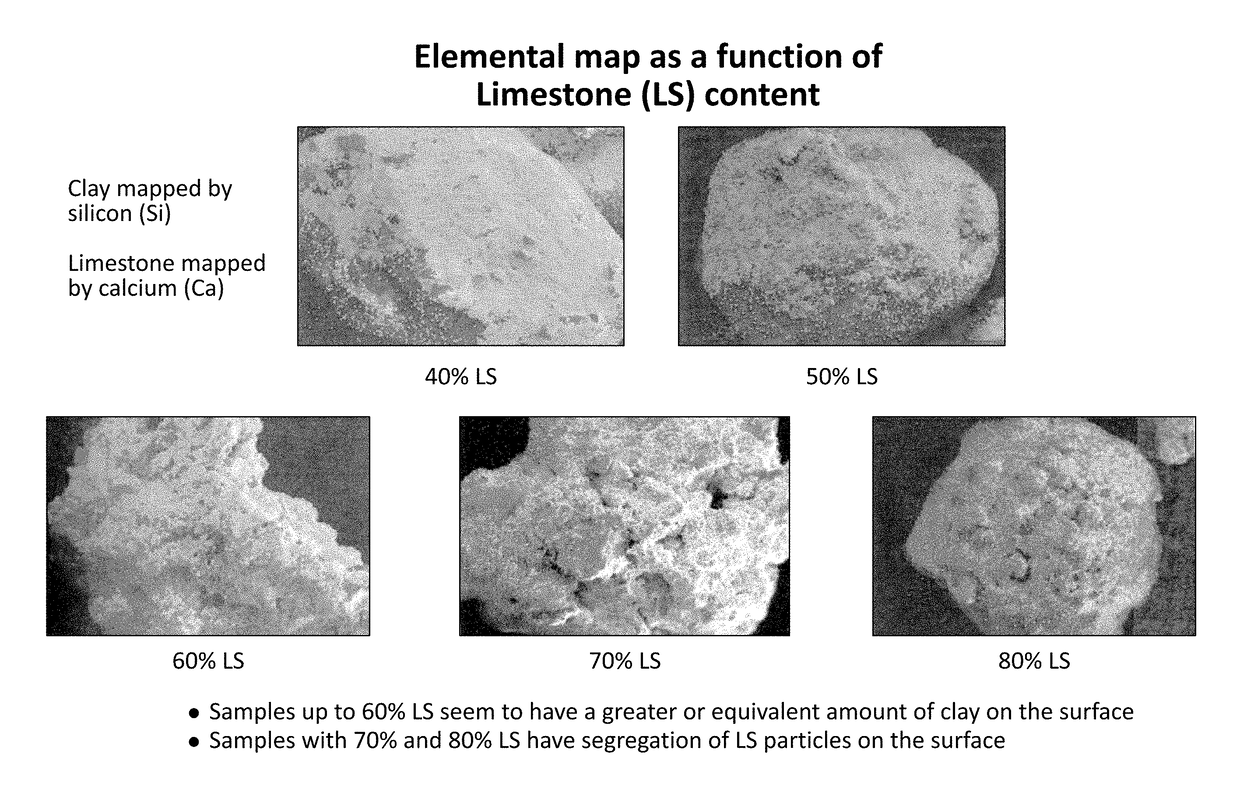

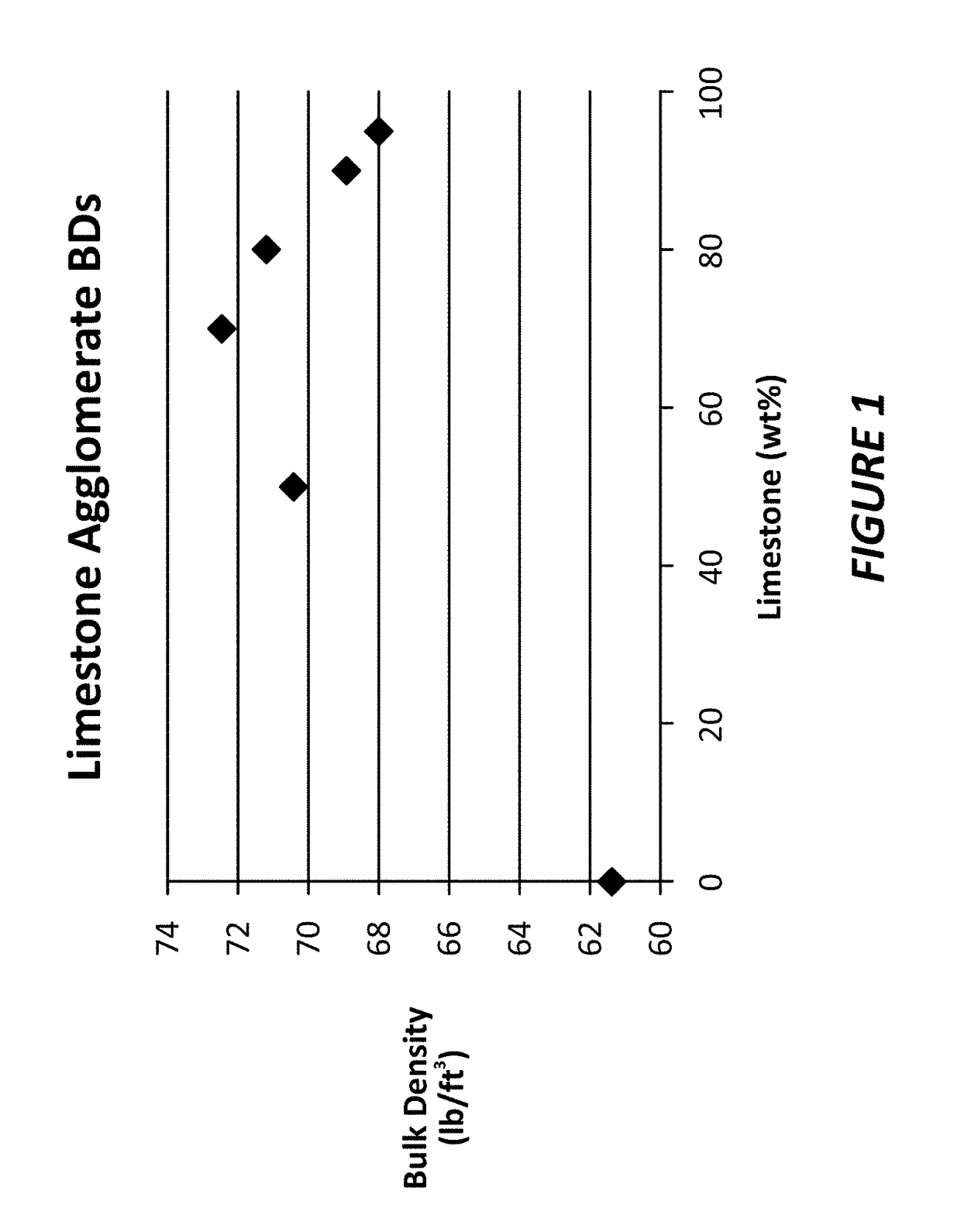

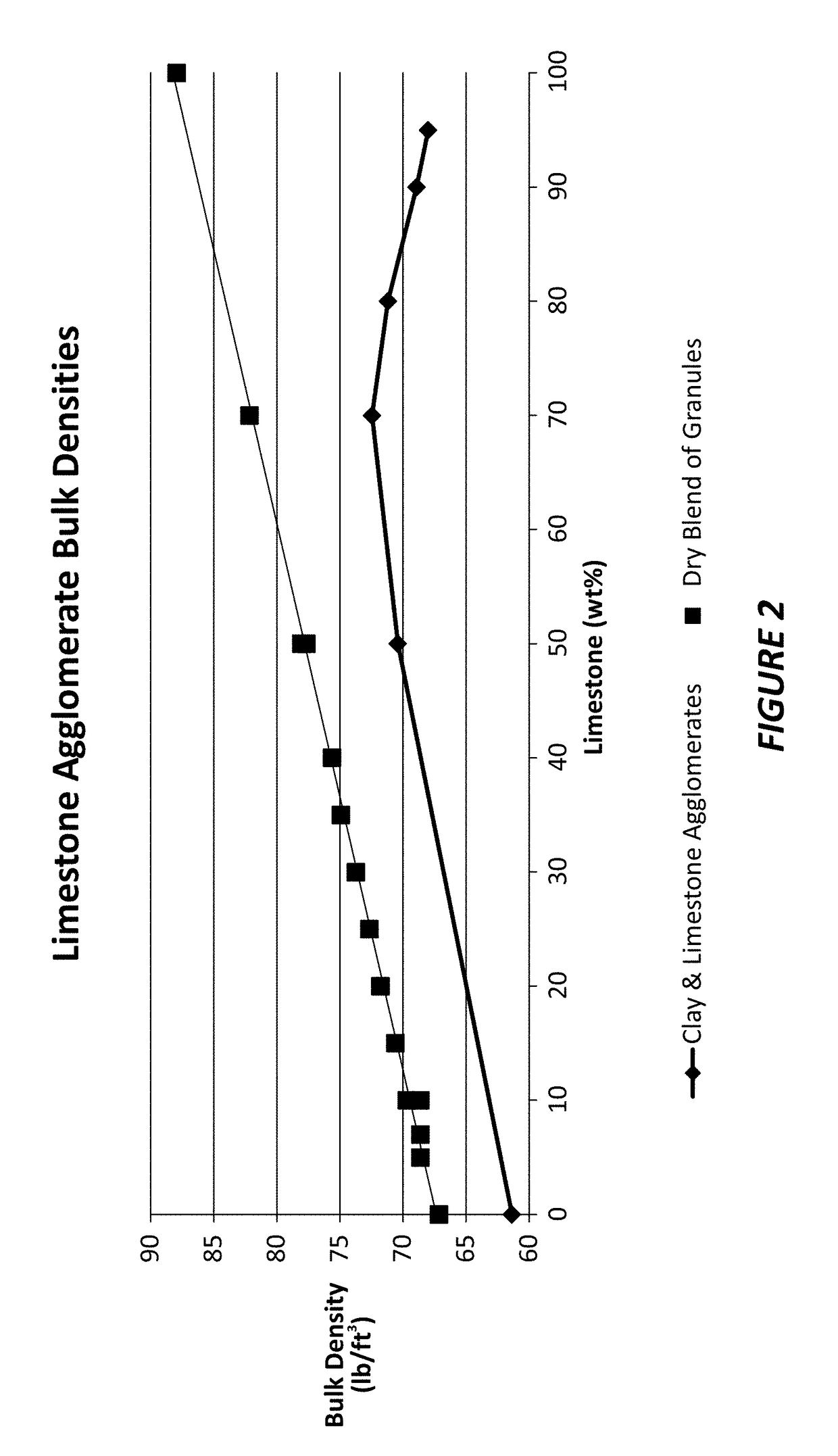

A clumpable animal litter comprises composite particles of filler materials, such as limestone and sand, and sodium bentonite. The filler materials have a lower bulk density as compared to a granular mixture of the same percentage of filler and sodium bentonite clay and contain up to eighty-five percent less clay.

Owner:THE CLOROX CO

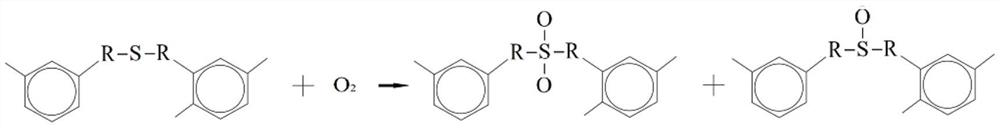

Coal tar modified durable sulfur concrete and preparation method thereof

InactiveCN111875323ASolve the land environmentSolve the pollution of the environmentSlagCrushed stone

The invention discloses coal tar modified durable sulfur concrete and a preparation method thereof. Each cubic meter of the coal tar modified durable sulfur concrete comprises the following componentsby mass: 1080 kg of industrial sulfur particles; 600 kg of granular crushed stone; 72 kg of fly ash; 41 kg of granulated blast furnace slag; 342 kg of quartz sand; 29 kg of waste ceramic fine aggregate; 24 kg of waste glass micro powder; 36kg of stone chip powder; 36kg of volcanic ash; 65 kg of rubber particles; and 30kg of glass fiber; wherein the mass of the modifier is 1-5% of the mass of theindustrial sulfur particles; the mass of the thickening agent is 0.1-0.5% of the total mass of the sulfur concrete; and the mass of the coupling agent is 0.3-2% of the mass of the industrial sulfur particles. According to the invention, the durability problem caused by material embrittlement and volume shrinkage due to sulfur solid-phase transformation is solved, the cost problem that the traditional sulfur concrete is generally high in price is solved, and the problems that wastes occupy land and pollute the natural environment are also solved.

Owner:INNER MONGOLIA UNIV OF TECH

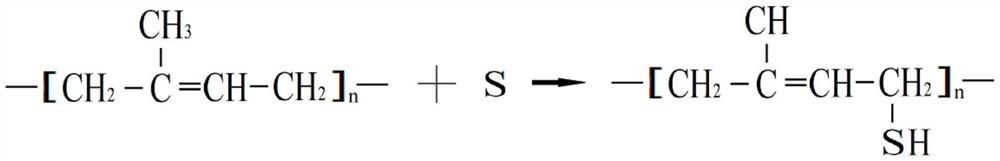

Dropping pipetype granular crystal manufacturing apparatus and granular crystal manufacturing method

InactiveCN1890409AProlong the fallIncrease the lengthAfter-treatment apparatusPolycrystalline material growthCrucibleManufactured apparatus

A dropping pipe type granular crystal manufacturing apparatus capable of manufacturing generally spherical crystal bodies by rapidly solidifying the granular droplets of an inorganic material by using the contact thereof with the inside wall surface of a dropping pipe as a solidifying trigger while jetting the droplets from the nozzles of a rotating crucible by a centrifugal force and allowing the droplets to fall freely inside the dropping pipe. The crucible is disposed at the upper end of the dropping pipe, stores the melted solution of the inorganic material, and is rotatable around the vertical axis thereof, and the plurality of small diameter nozzles formed radially from the vertical axis thereof are formed at the outer peripheral part of the crucible. The crucible is rotatingly driven by a rotatingly driving means, the crucibleand the inorganic material stored in the crucible are heated by a heating means, and cooling gas flow is formed in the dropping pipe by a gas flow formation means.

Owner:KYOSEMI CORP

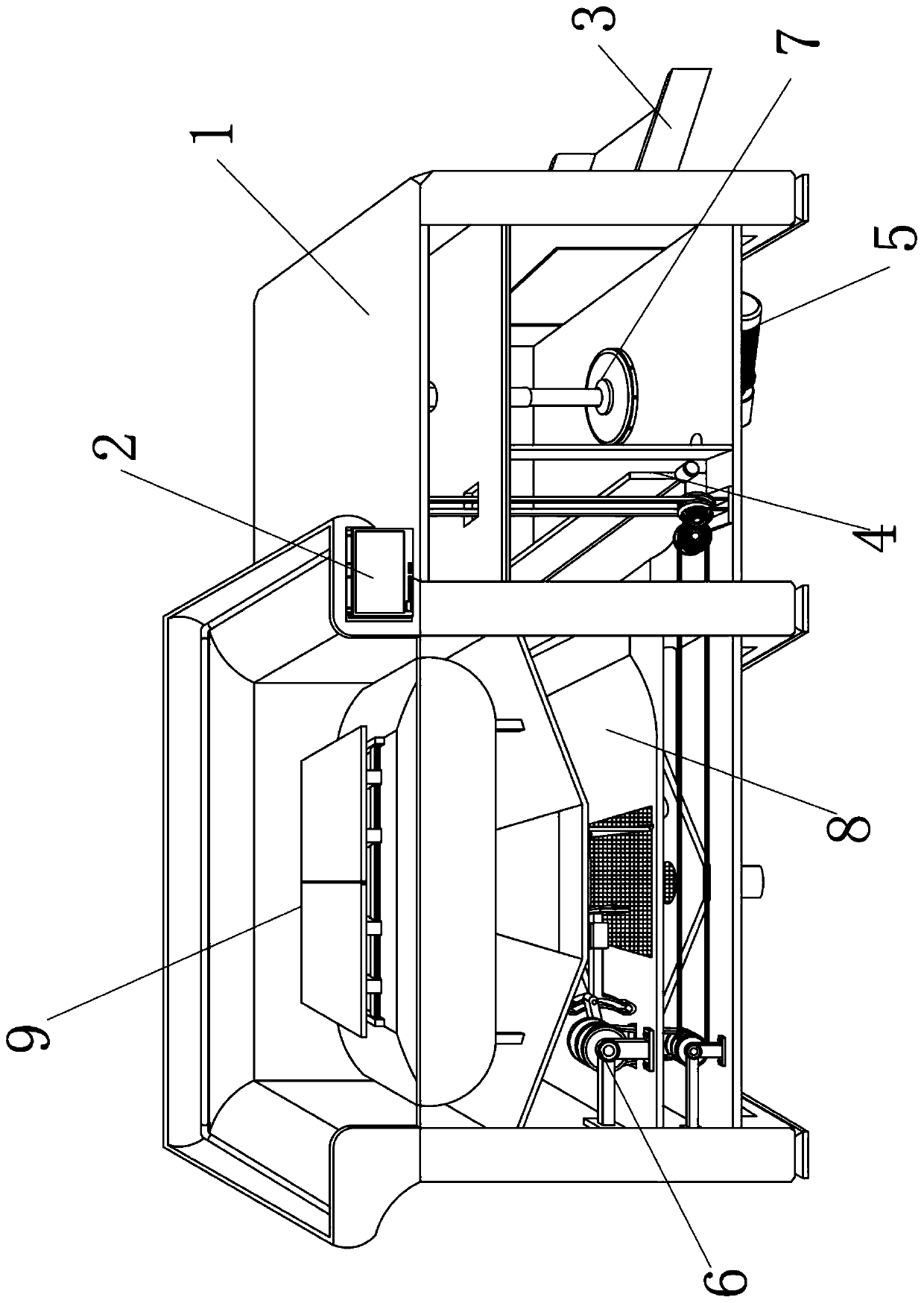

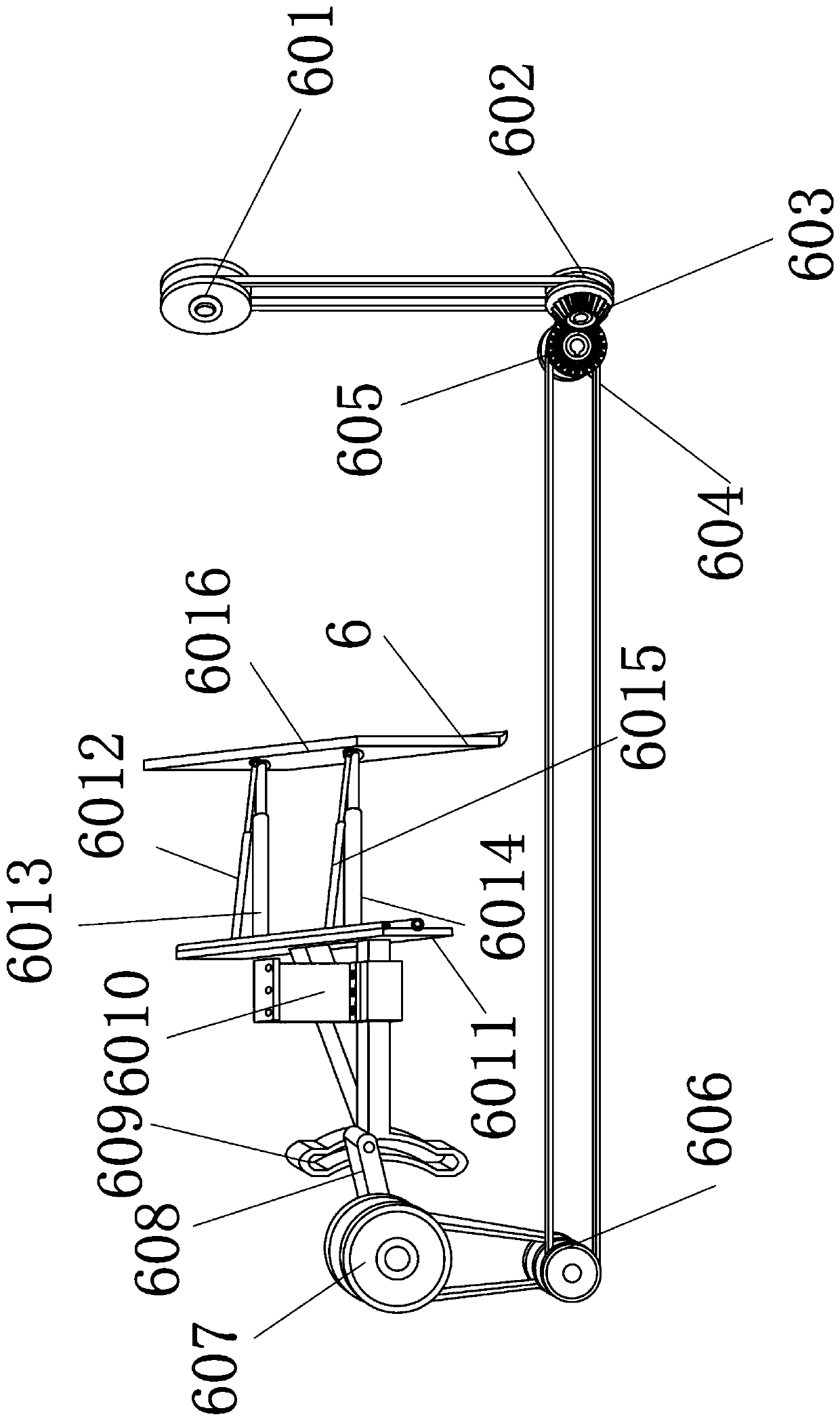

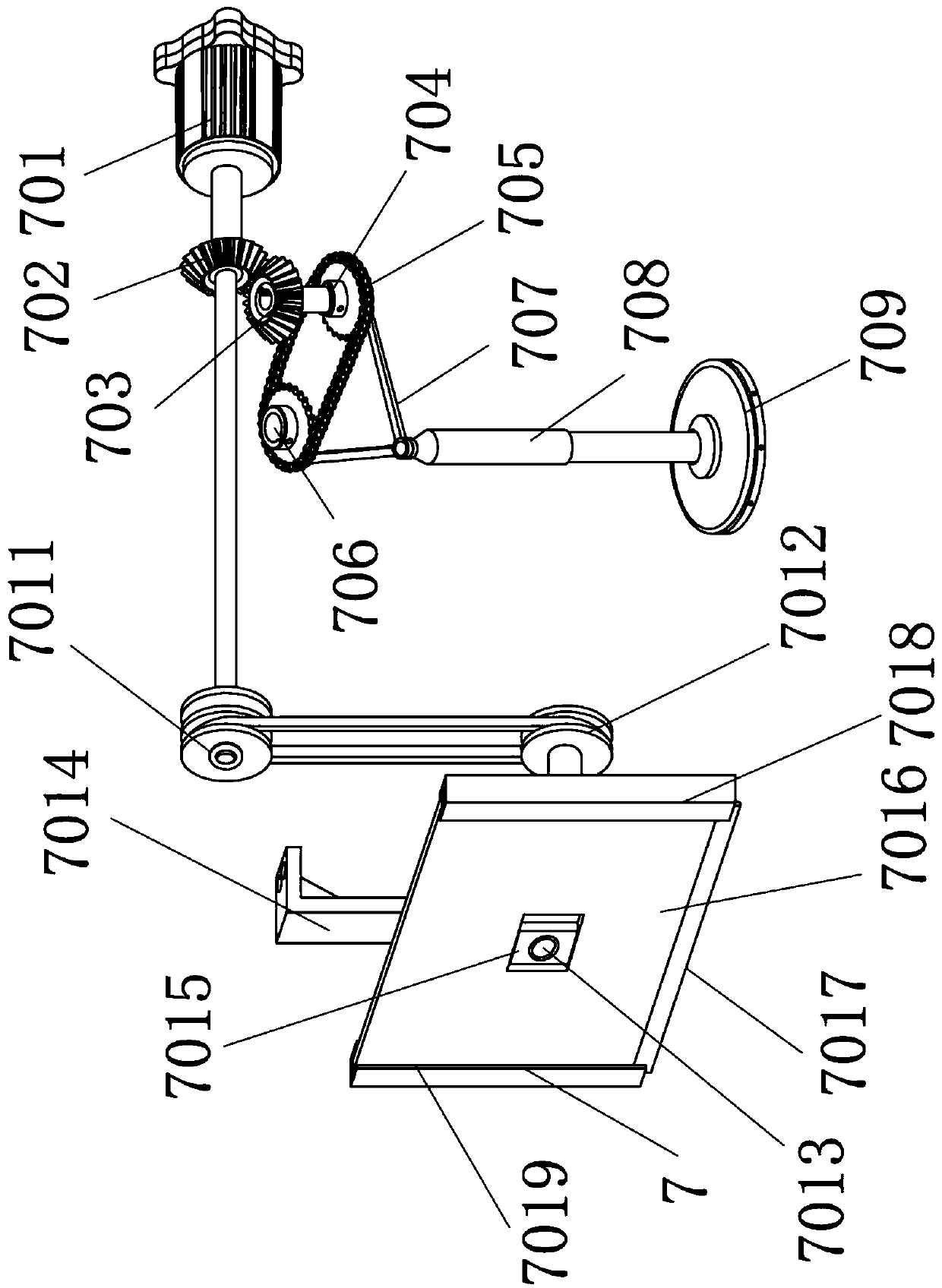

Environmentally-friendly recovery device of artificial quartz stones

The invention relates to production of artificial quartz stones, in particular to an environmentally-friendly recovery device of the artificial quartz stones. The invention aims to provide the environmentally-friendly recovery device of the artificial quartz stones. In order to achieve the above aim, the environmentally-friendly recovery device of the artificial quartz stones comprises an outer frame, a control screen, a discharging platform, a material blocking plate, a sludge pump, a waste pushing and moving mechanism, a rotary waste granulation mechanism, a multi-layer filter plate mechanism and a waterfall type circulation collecting processing platform; the discharging platform is arranged at the bottom of the right side of the outer frame; the material blocking plate is arranged on the middle right side of the inner bottom of the outer frame; and the sludge pump is arranged on the right side of the bottom end of the outer frame. The environmentally-friendly recovery device of theartificial quartz stones can collect waste and polishing slurry of artificial quartz plates and greatly increases the utilization rate of the waste; and the prepared ceramsite-shaped waste has the characteristics of waterproofness and high hardness, has low loss during grinding and can adapt to grinding of materials with different particle size.

Owner:牛月波

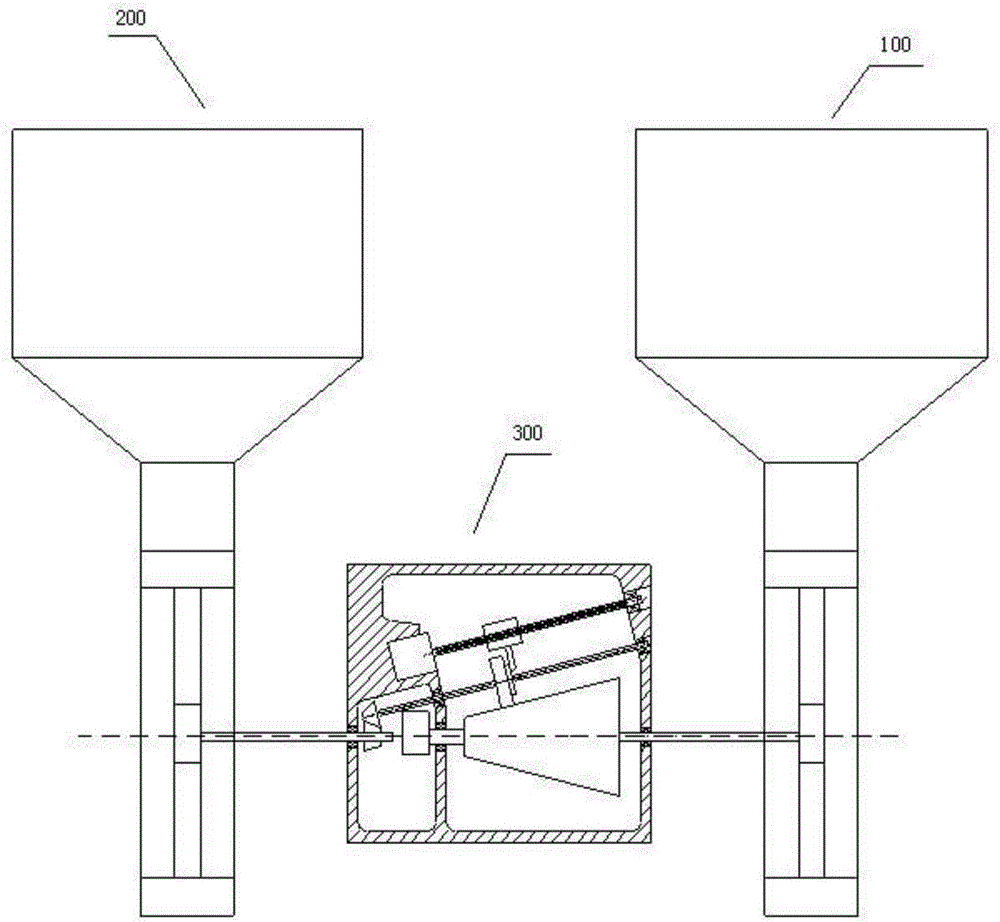

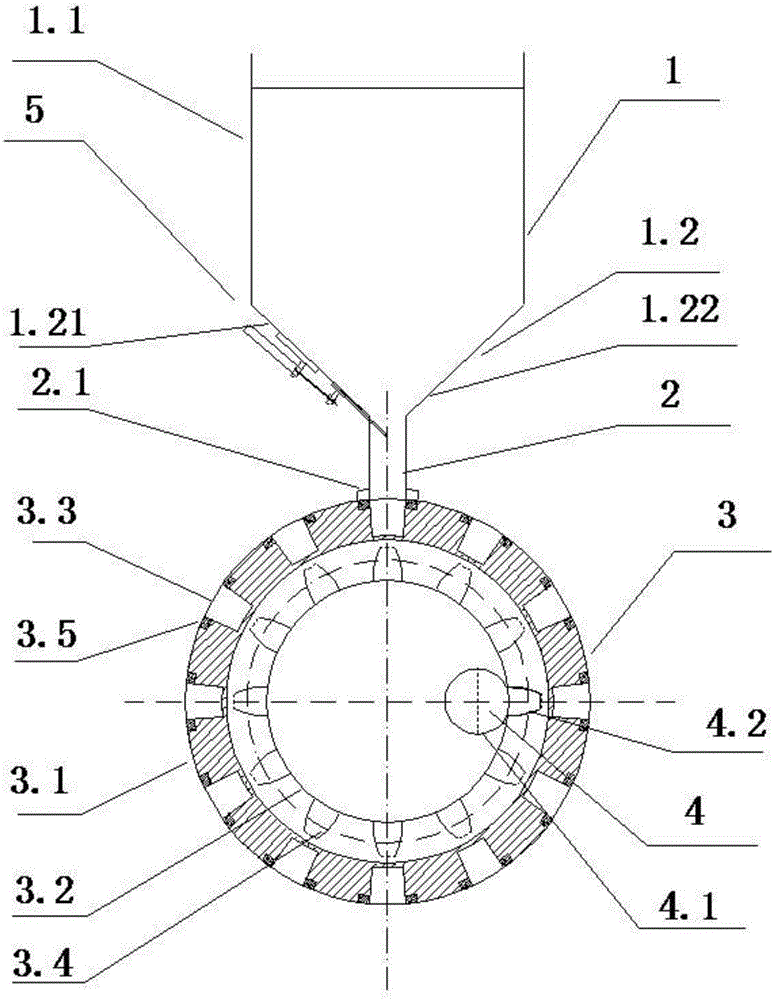

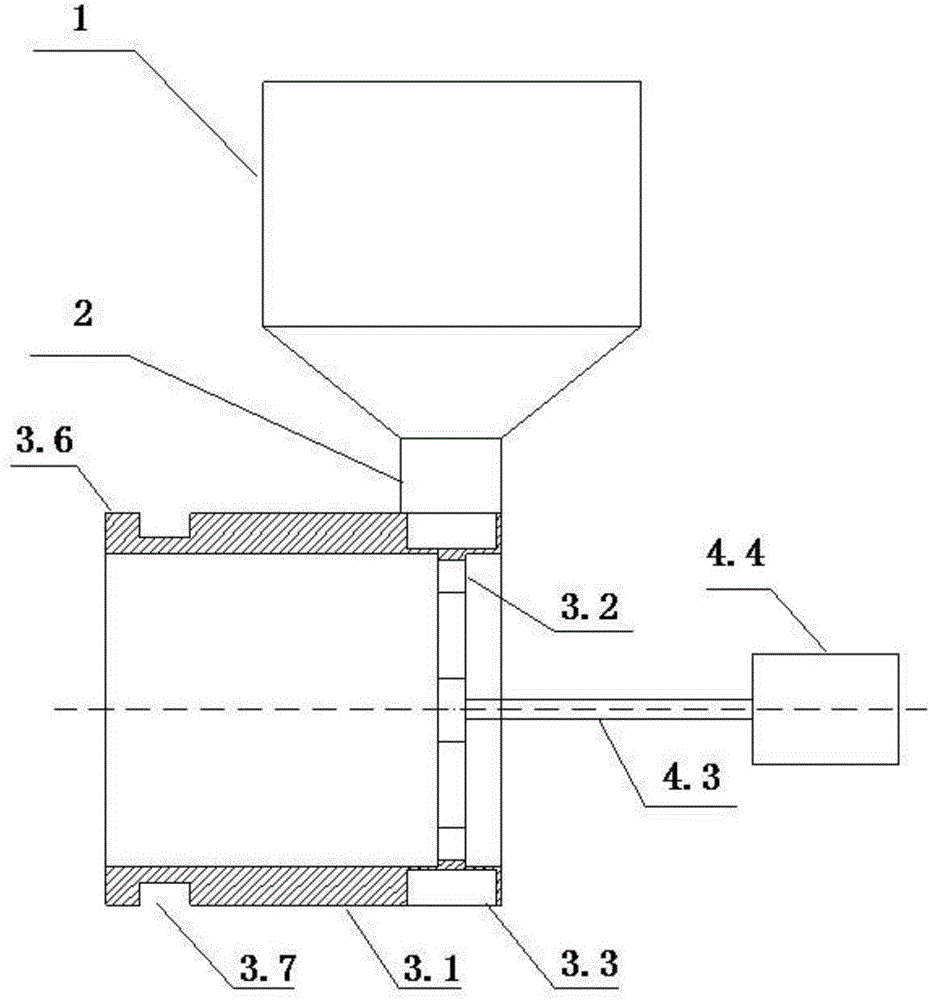

Definite-proportion discharging device and method for powdery and granular material

The invention provides a definite-proportion discharging device and method for a powdery and granular material. The definite-proportion discharging device for the powdery and granular material comprises quantitative intermittent conveying mechanisms and a speed adjusting mechanism (300); the quantitative intermittent conveying mechanisms comprise the first quantitative intermittent conveying mechanism (100) and the second quantitative intermittent conveying mechanism (200); and the speed adjusting mechanism is coupled between the first quantitative intermittent conveying mechanism (100) and the second quantitative intermittent conveying mechanism (200) so that the first quantitative intermittent conveying mechanism (100) and the second quantitative intermittent conveying mechanism (200) can discharge the conveyed material at a certain proportion. According to the definite-proportion discharging device and method for the powdery and granular material, the discharging speed ratio of the first quantitative intermittent conveying mechanism and the second quantitative intermittent conveying mechanism is accurately controlled and adjusted, the discharging speed ratio is the per-second filling amount ratio of filling counting grooves, and the discharging amount can be precisely controlled.

Owner:江苏天洁环保装备有限公司

High strength steel sheet having excellent formability and a method of manufacturing the steel sheet

ActiveUS11466335B2Increase weightSimple structureHot-dipping/immersion processesFurnace typesManganeseImpurity

Owner:ARCELORMITTAL INVESTIGACION Y DESARROLLO SL

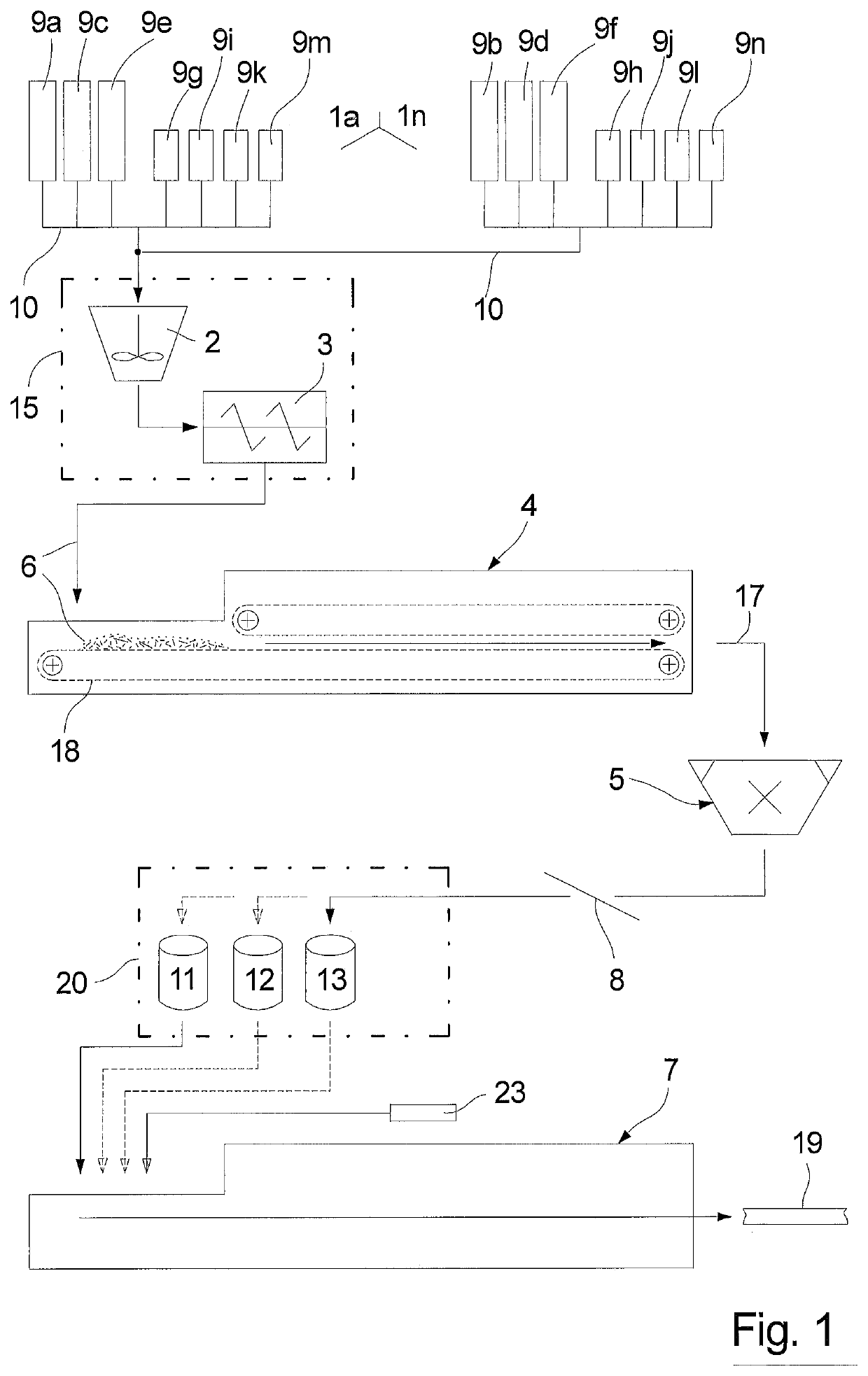

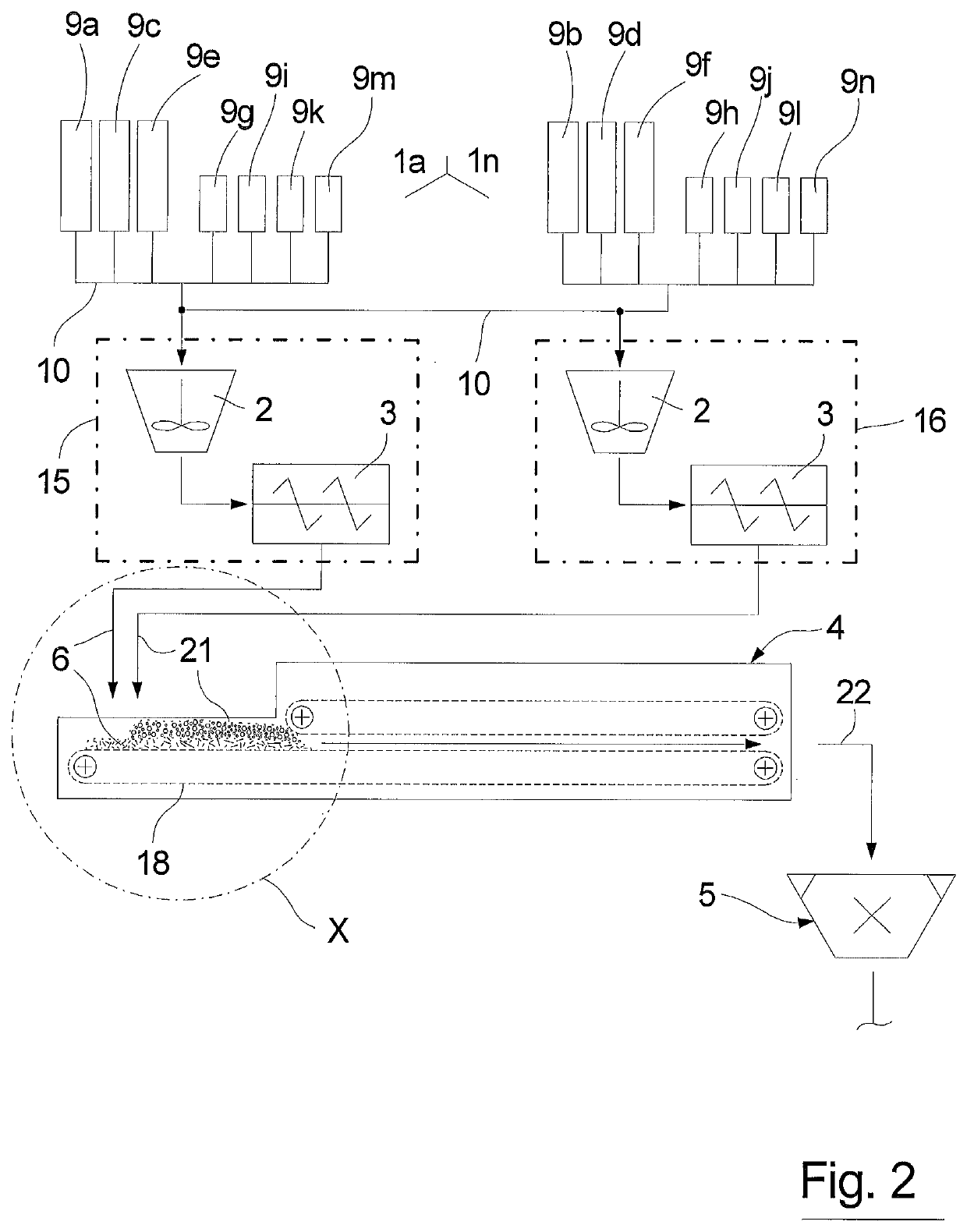

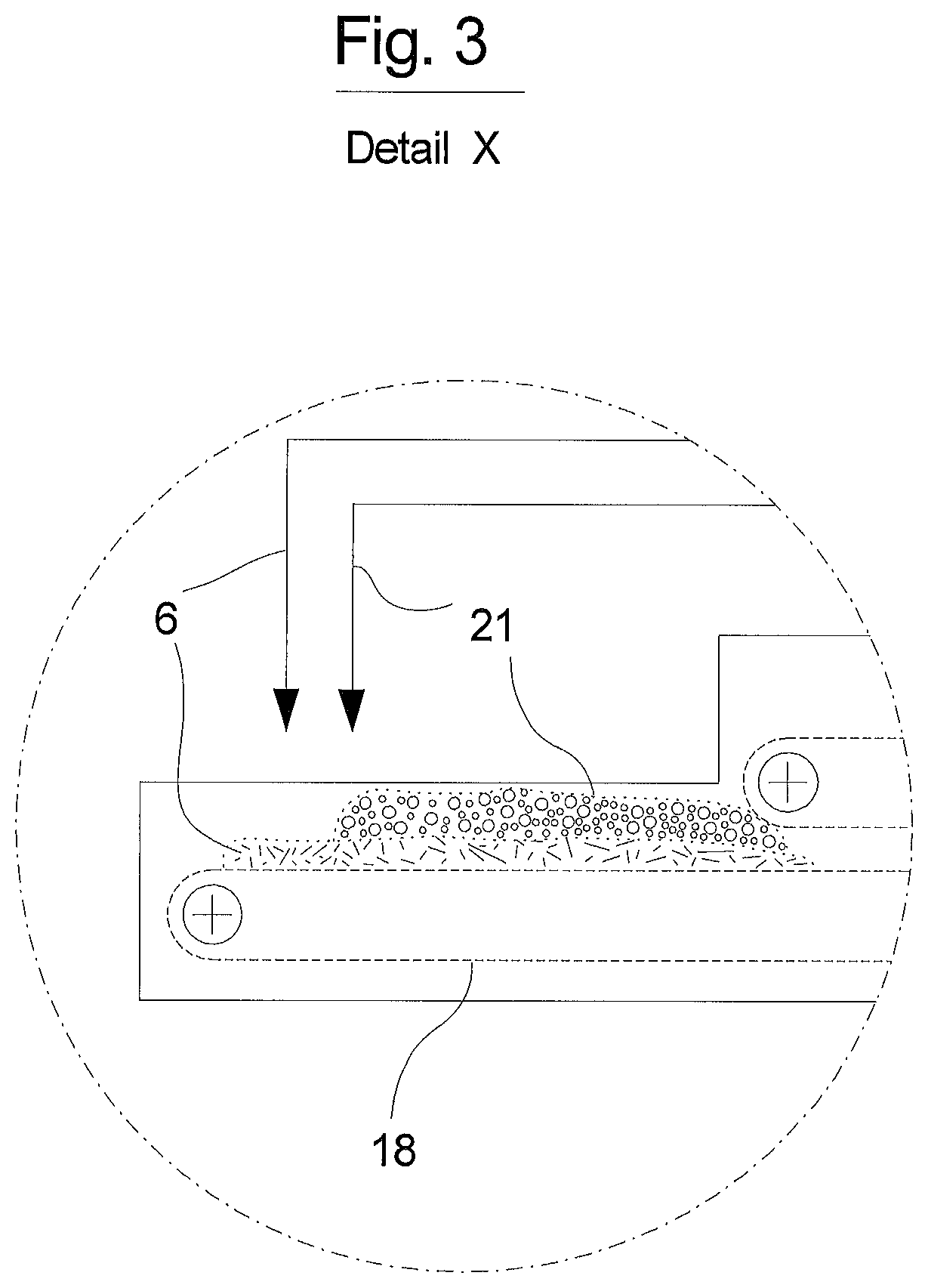

Method and device for producing a thermoplastic granulate material

In the production of thermoplastic granulate material, after mixing the starting materials, it is common in the state of the art for these materials to be kneaded and compressed in extruders, with subsequent granulation. According to the invention, no extruder is used, rather the starting materials for the thermoplastic granulate material are supplied directly to a double belt press after the mixing. Subsequently, the generated web-type to sheet-type body is processed into a granulate material by means of grinding, or is used as a web-type, sheet-type, strip-type or film-type intermediate product for the production of a further intermediate product or end products.

Owner:IPCO GERMANY GMBH

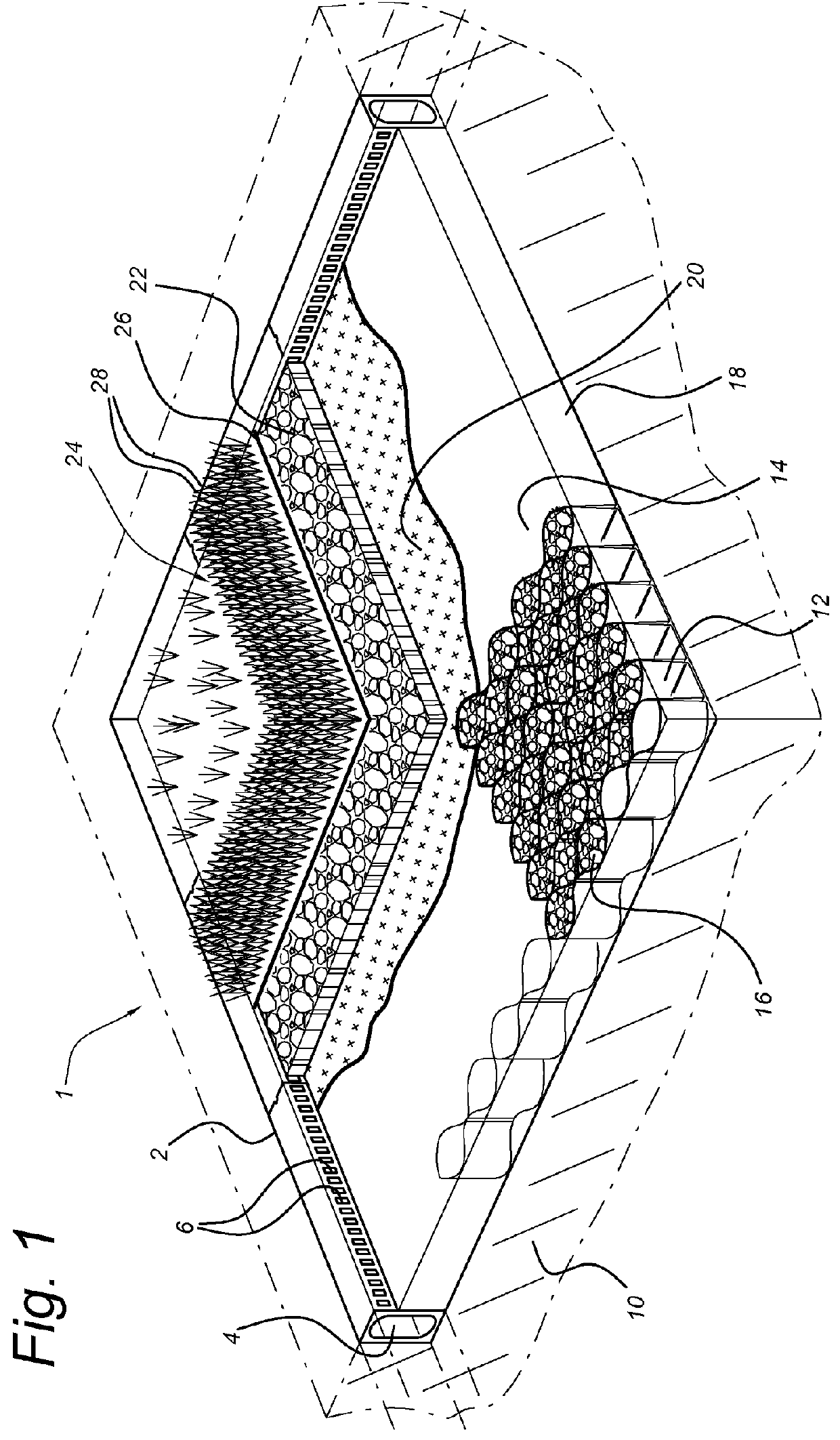

Modular Structure For Installing An Artificial Playing Field

A modular structure for installing an artificial playing field comprising: a stabilising layer forming a plurality of compartments for receiving a granular infill; a separation layer for location over the stabilising layer to retain the infill; a water distributing layer; and an artificial turf layer. The claimed construction allows a stable base layer to be formed using virtually any locally available granular material such as earth, gravel, lava, rock and the like. The compartments ensure that the granular material is held in place and cannot be displaced due to loading or washed away due to rain or flooding.

Owner:TEN CATE THIOLON

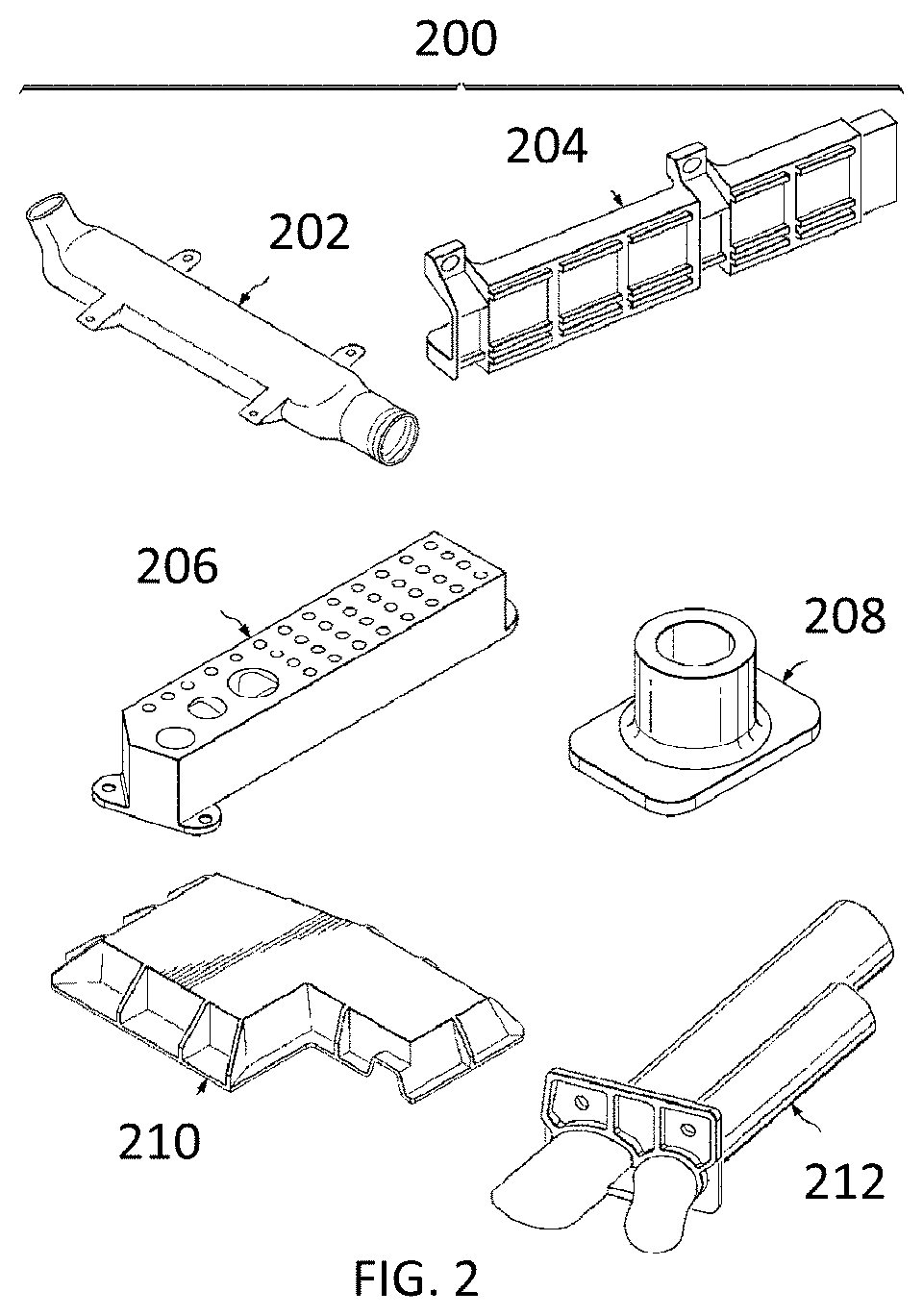

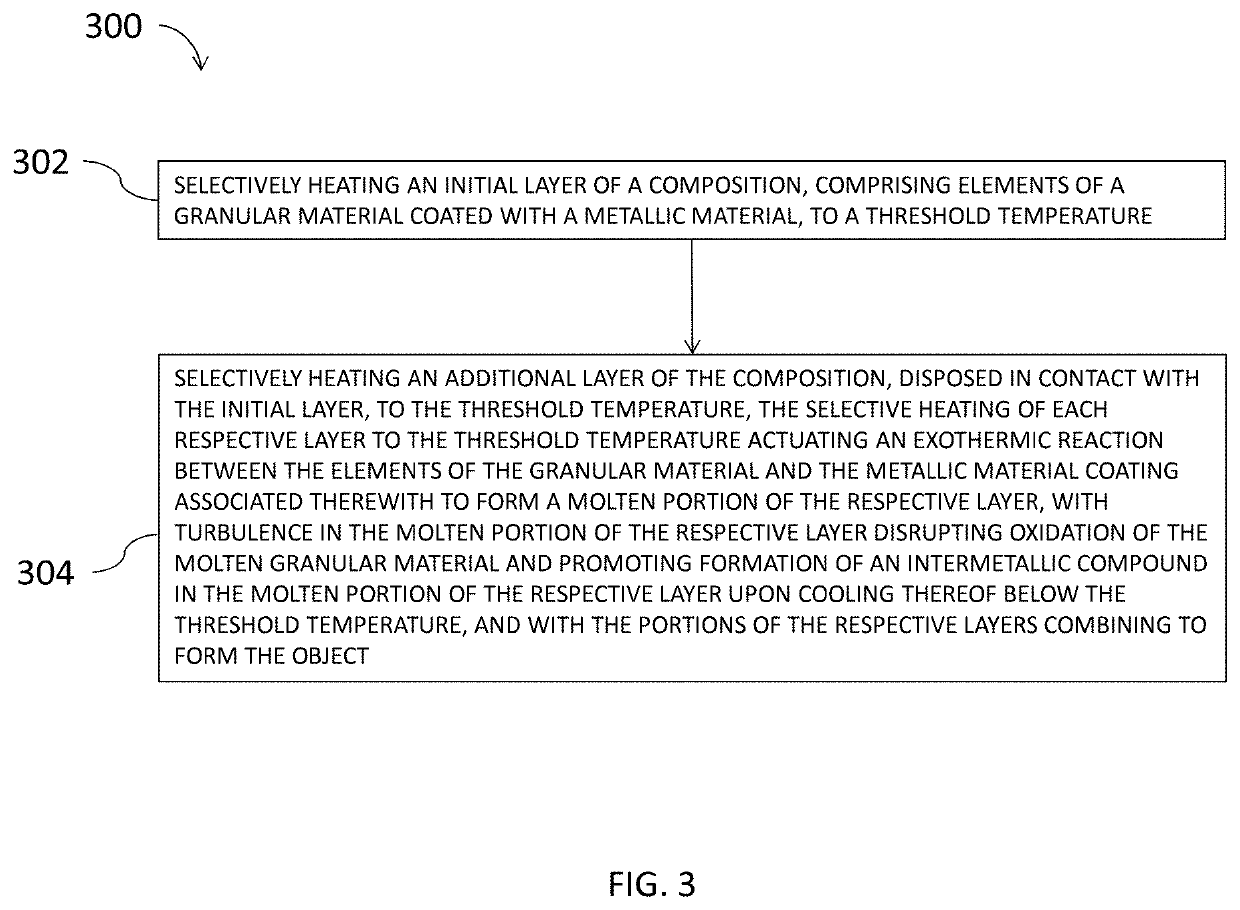

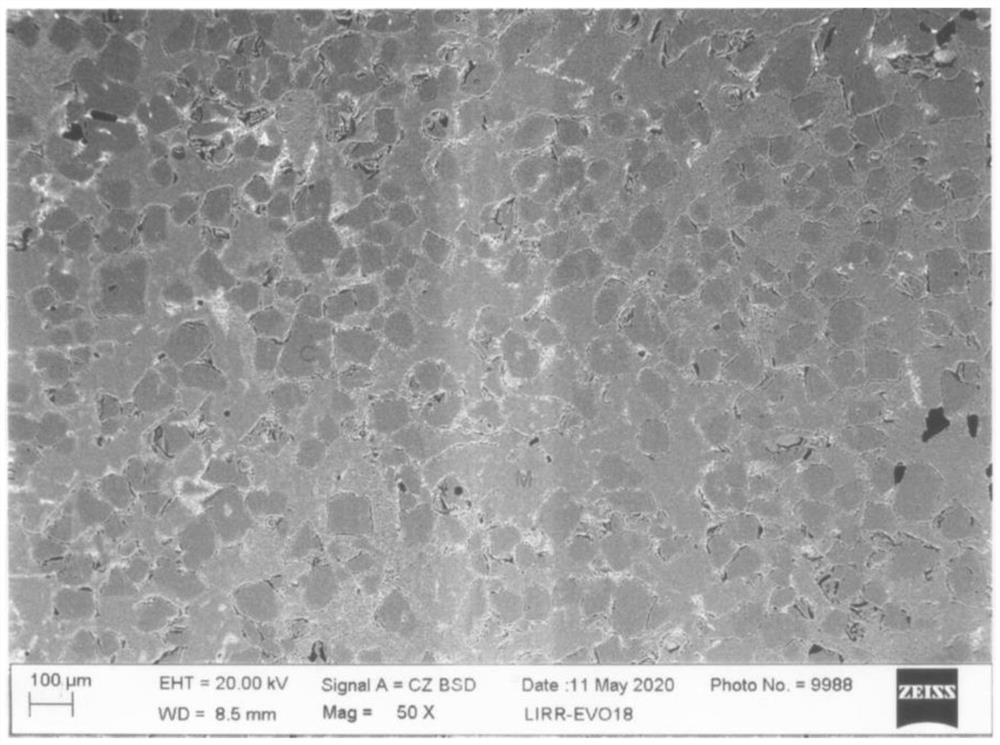

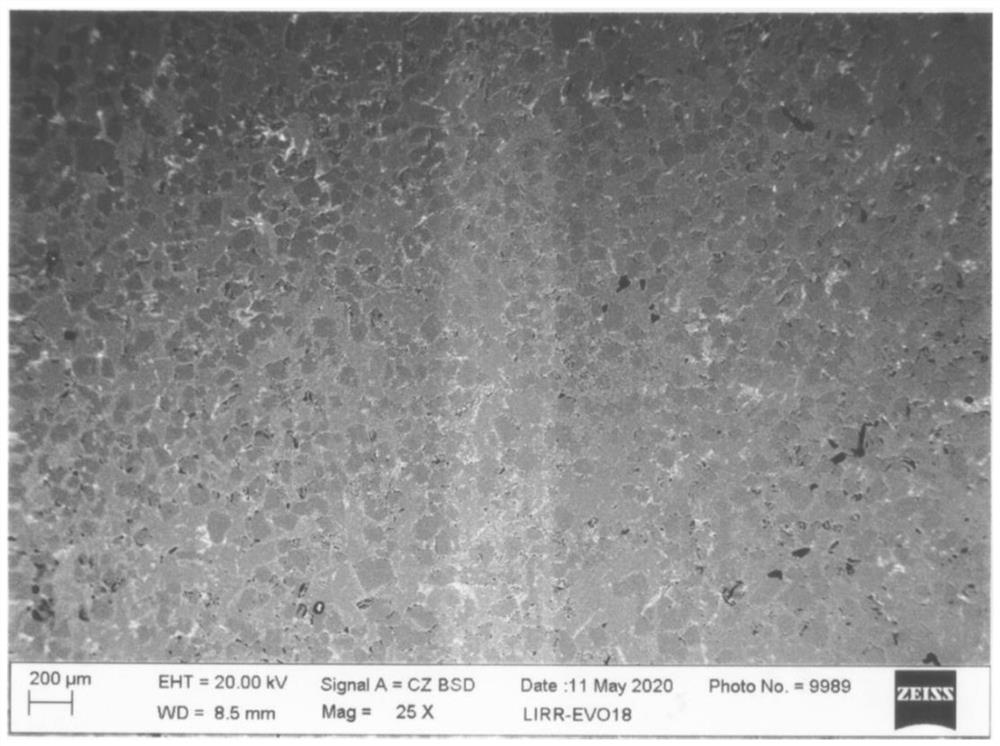

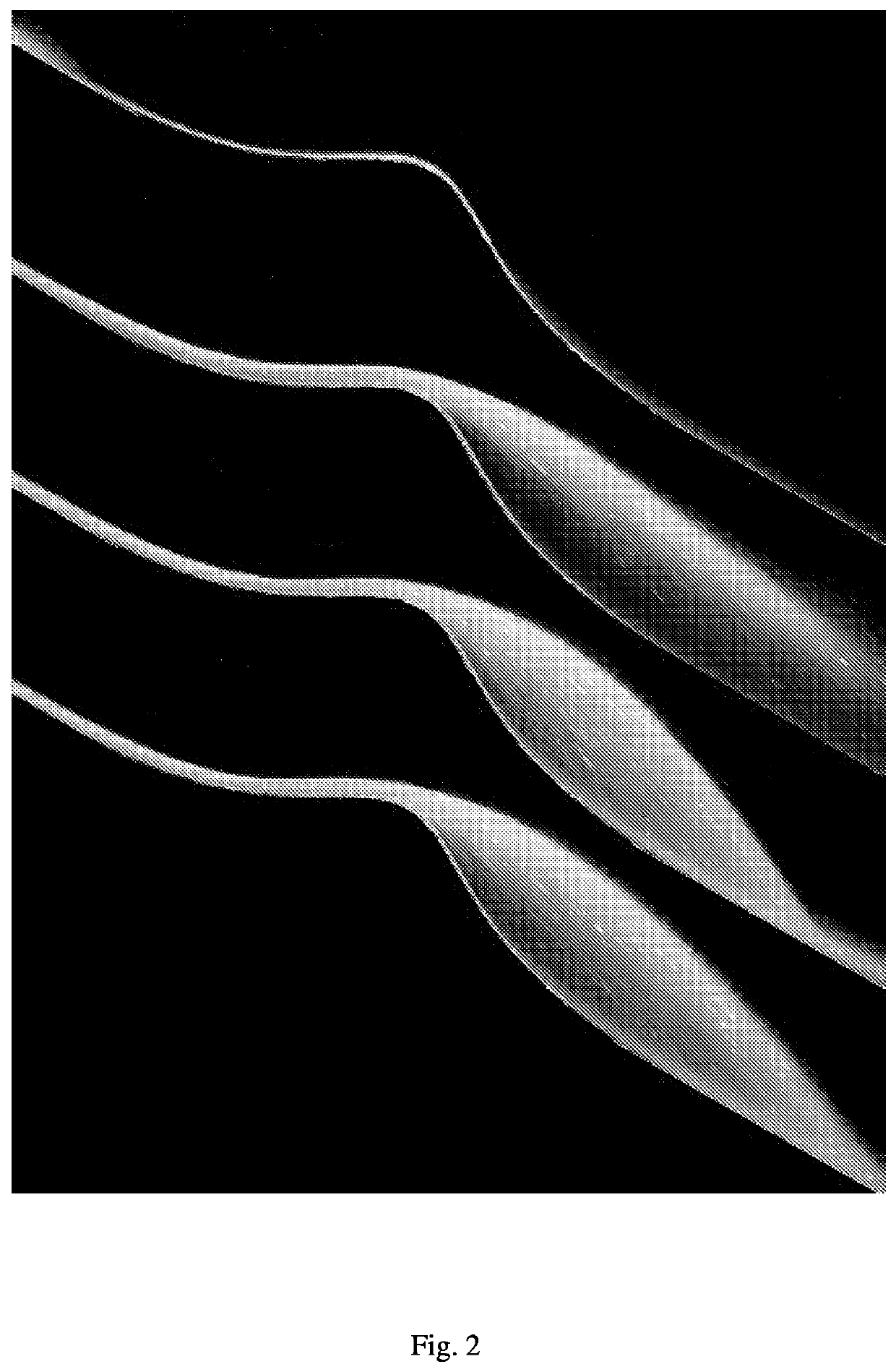

Method of manufacturing an object from granular material coated with a metallic material and a related article of manufacture

ActiveUS11045905B2Transportation and packagingVacuum evaporation coatingMetallic materialsGranoblastic

Owner:THE BOEING CO

Steel tube and steel sheet

ActiveCN111094610AExcellent resistance to HICFurnace typesWelding apparatusChemical compositionMetallurgy

This steel tube has: a base material part that comprises a tubular steel sheet; and a weld part that is provided at a joint part of the steel sheet and extends in the longitudinal direction of the steel sheet. The steel sheet has a prescribed chemical composition. The steel sheet satisfies ESSP=1.5 to 3.0 and Ceq=0.20 to 0.50. The metal structure of a surface layer part that goes to a depth of 1.0mm from the surface of the base material part is, by total area ratio, more than 80% granular bainite, acicular ferrite, tempered bainite, and / or tempered martensite. The surface layer part of the base material part has a maximum hardness Hvmax of at least 250 Hv and a yield ratio of at least 85%.

Owner:NIPPON STEEL CORP

Granular compositions and process for producing the same

InactiveCN1258977CImprove granulation effectBiocideAnimal repellantsProcess engineeringBULK ACTIVE INGREDIENT

A granulation composition having the granulation properties improved without being affected by the content, type or nature of a pesticidal active ingredient, and a process for its production, are provided. <??>A granular composition which comprises a pesticidal active ingredient and a highly pure quartz powder as essential components and which is obtained by an extrusion granulation method. A process for producing the granular composition, which comprises blending a pesticidal active ingredient and a highly pure quartz powder as essential components, and granulation by an extrusion granulation method. As compared with conventional ones, the granulation properties can be improved without being affected by the content, type and nature of the pesticidal active ingredient or the prescribed grain diameter of the granular composition.

Owner:KUMIAI CHEM IND CO LTD

Method for determining whether a rock is capable of functioning as an oil reservoir

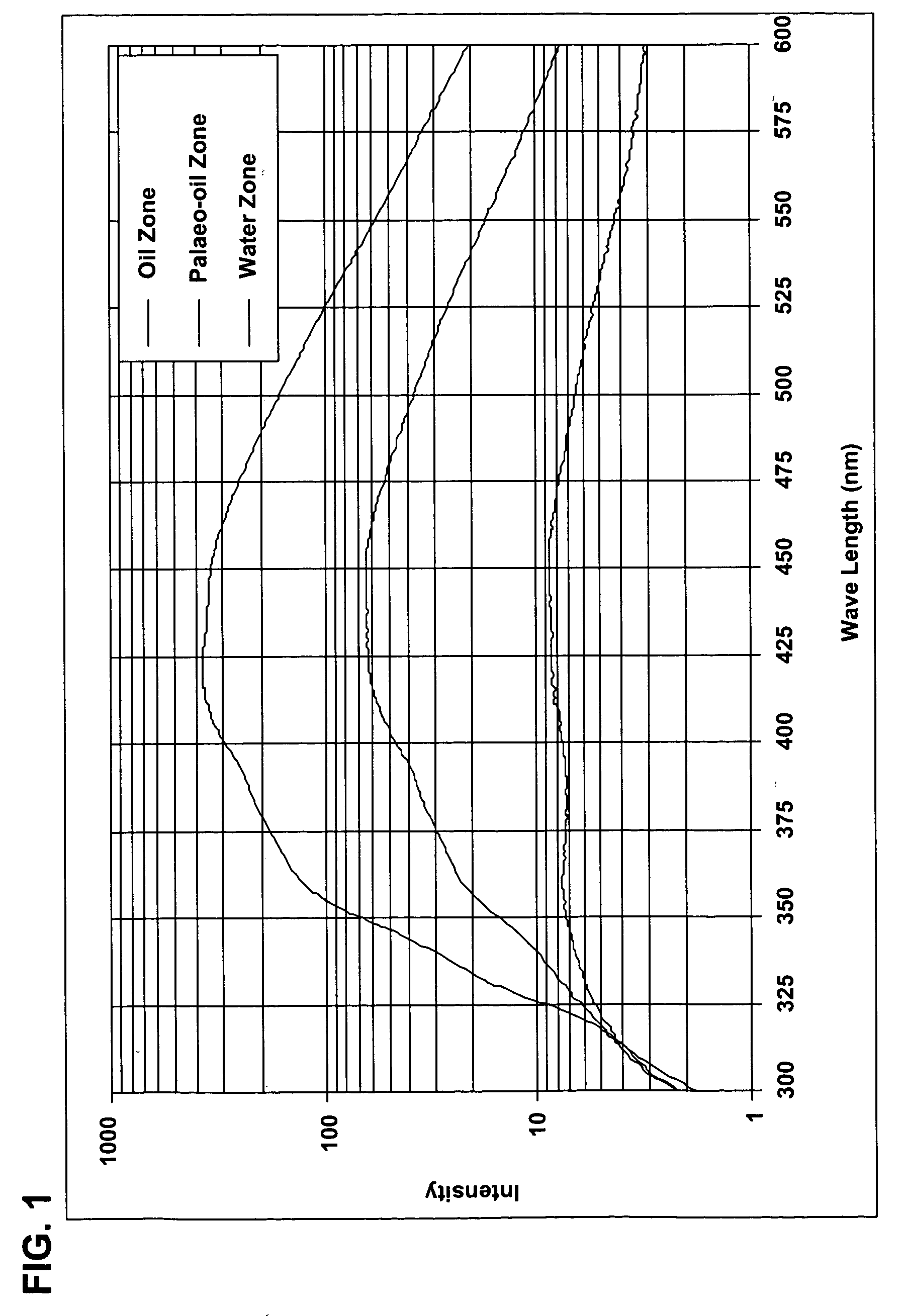

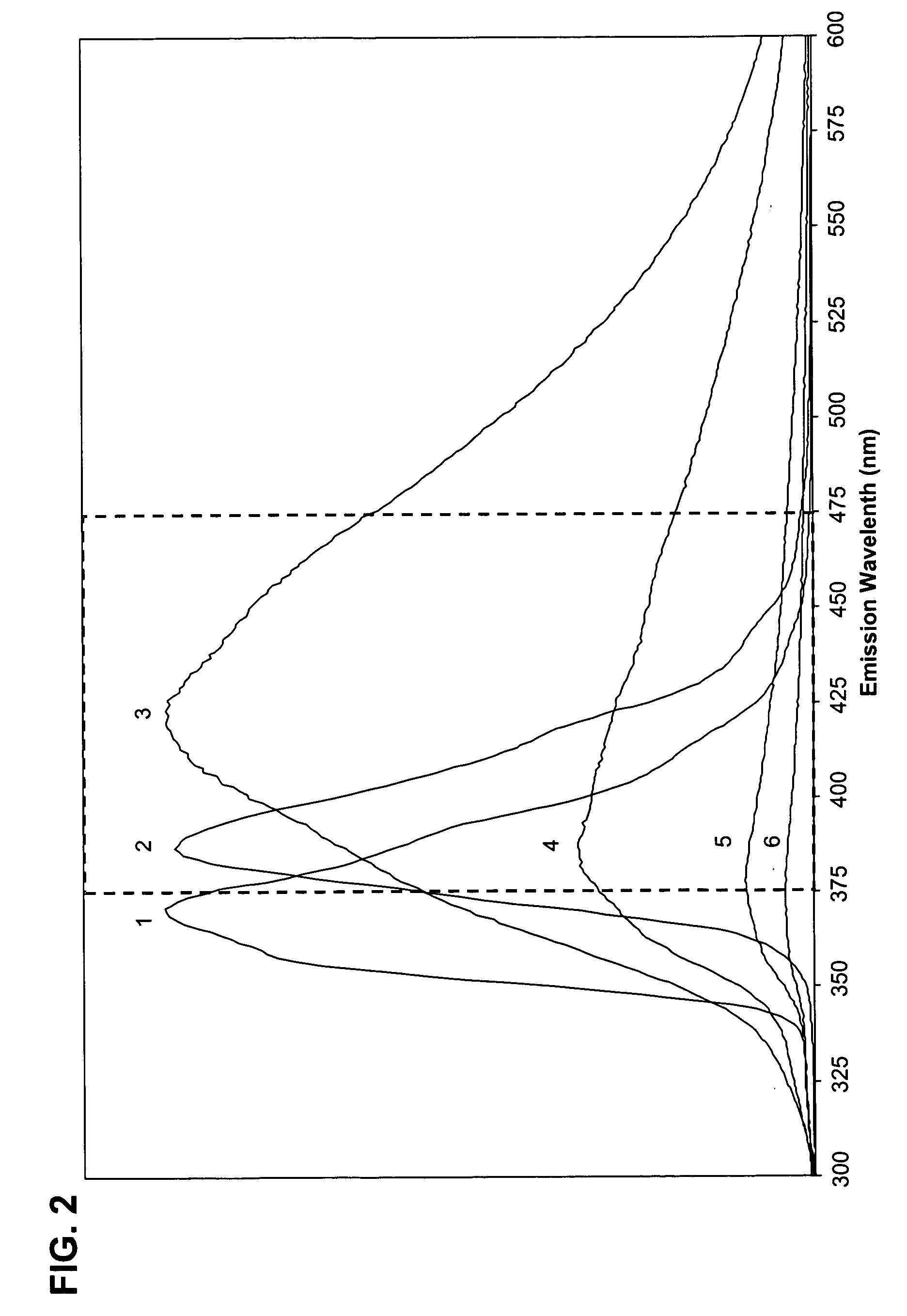

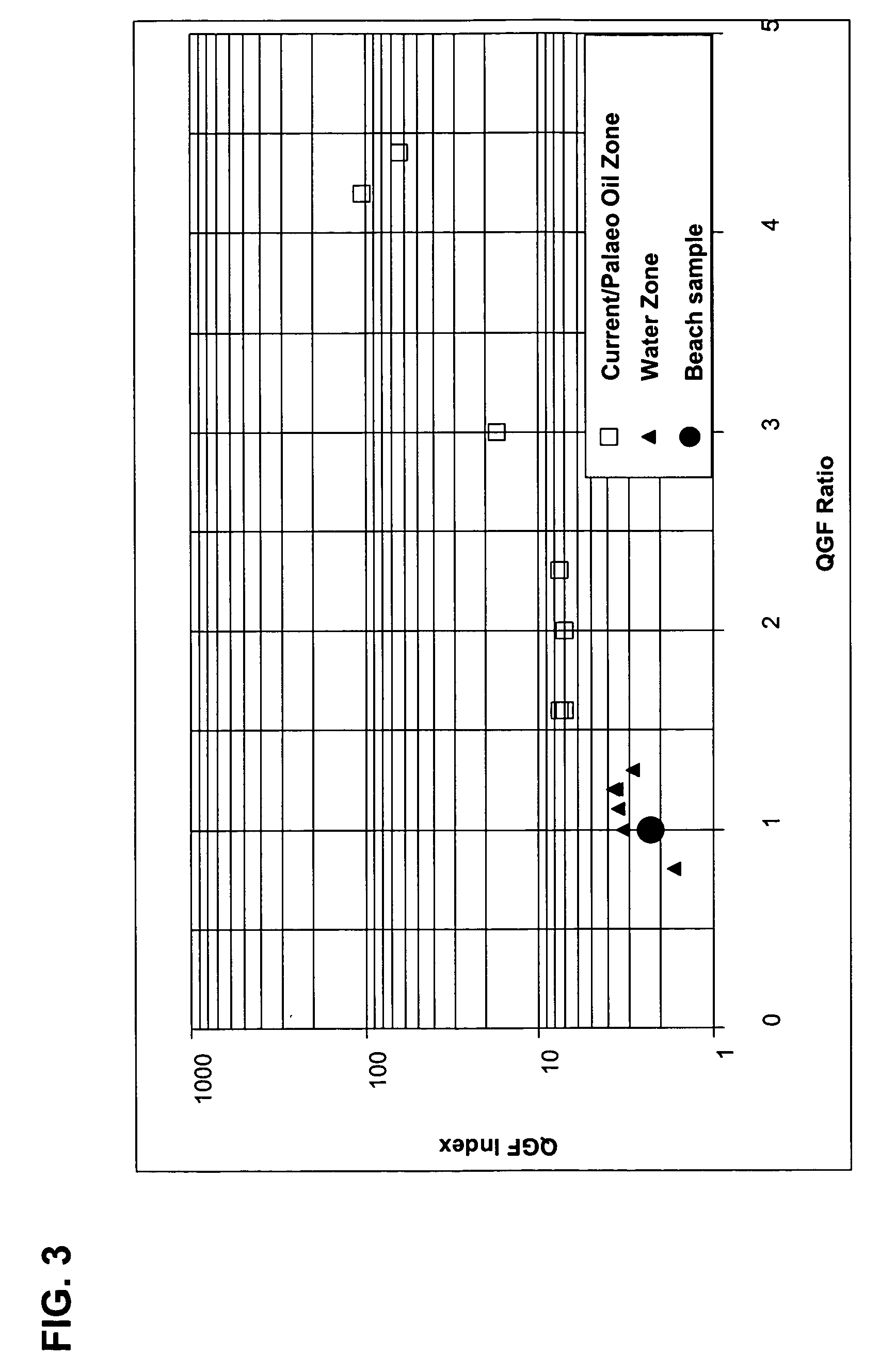

InactiveUS7173242B2Less pollutionFluorescence/phosphorescenceX/gamma/cosmic radiation measurmentFluorescencePhysical chemistry

A method is defined for determining whether a rock is capable of functioning as an oil reservoir has had or presently contains oil. The method includes the steps of: -cleaning a sample of the rock in a manner such that at least some of any adsorbed oil on the rock will remain and any oil inclusions within the rock remain intact; -irradiating the cleaned sample with fluorescence inducing electromagnetic (typically UV) radiation and measuring emitted (typically UV and visible) radiation from the sample; and-comparing the emitted radiation measurement against a similarly determined measurement from a rock sample of a known oil-producing reservoir, to determine whether or not the rock has had or presently contains oil. In a variation of the above method, the sample of the rock is cleaned step-wise in a manner that removes other than adsorbed oil on the rock, with a final cleaning step including contacting the sample with a solvent into which some adsorbed oil may be extracted. The solvent extract can then be analysed for oil (typically by irradiating the solvent with fluorescence inducing electromagnetic (typically UV) radiation) and the analysed oil then compared against a similarly derived and analysed oil from a rock sample of a known oil reservoir to determine whether or not the rock has had or presently contains oil. Typically the rock is granular and typically the cleaning step involves disaggregating the rock into single grains, prior to cleaning.

Owner:COMMONWEALTH SCI & IND RES ORG

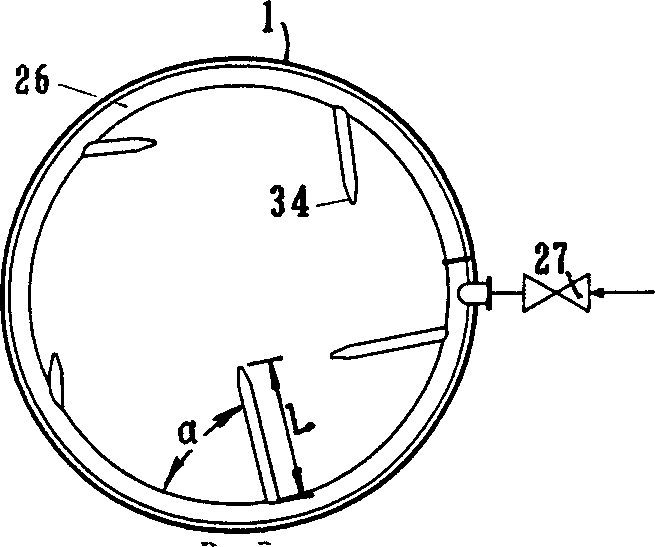

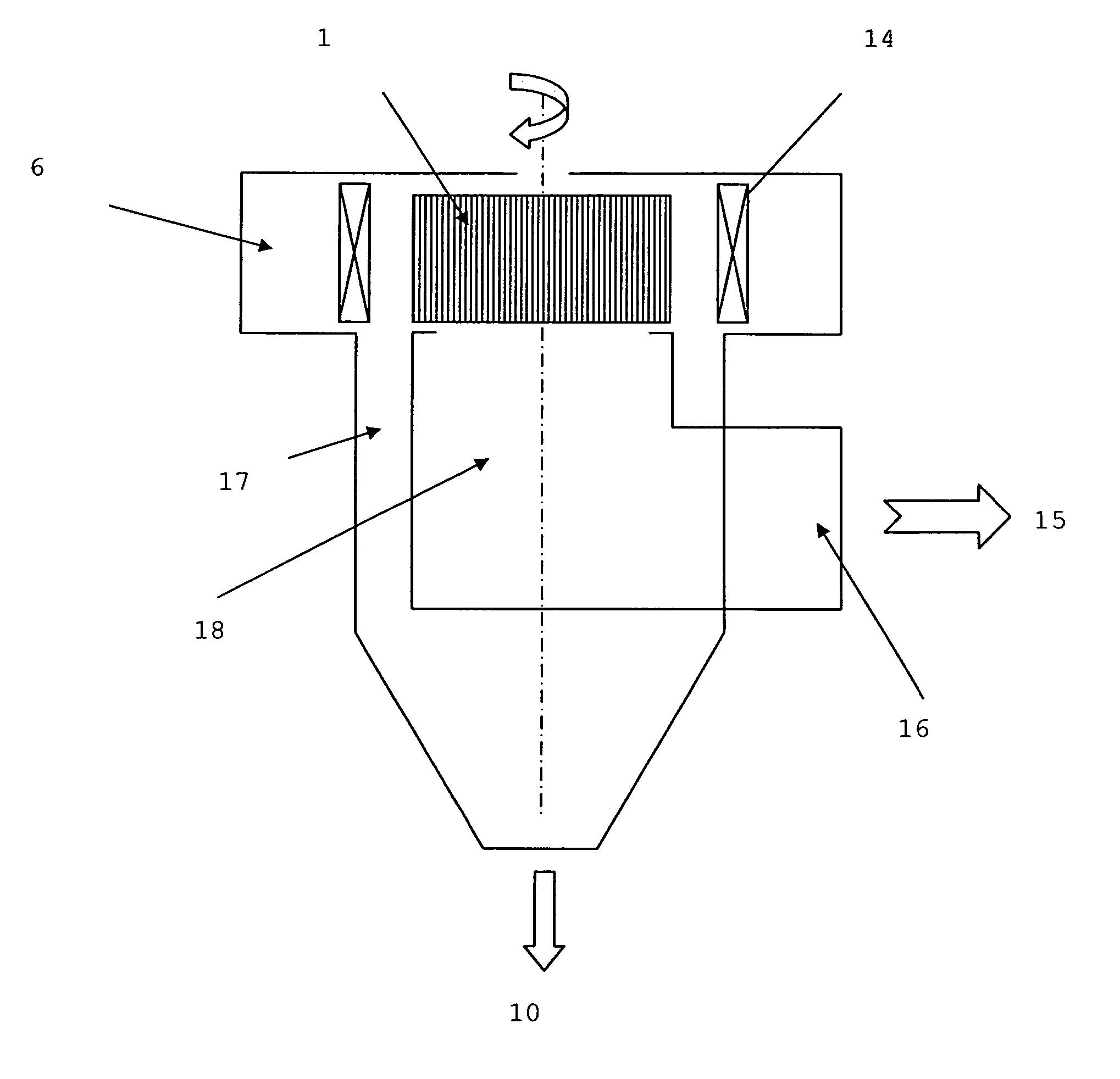

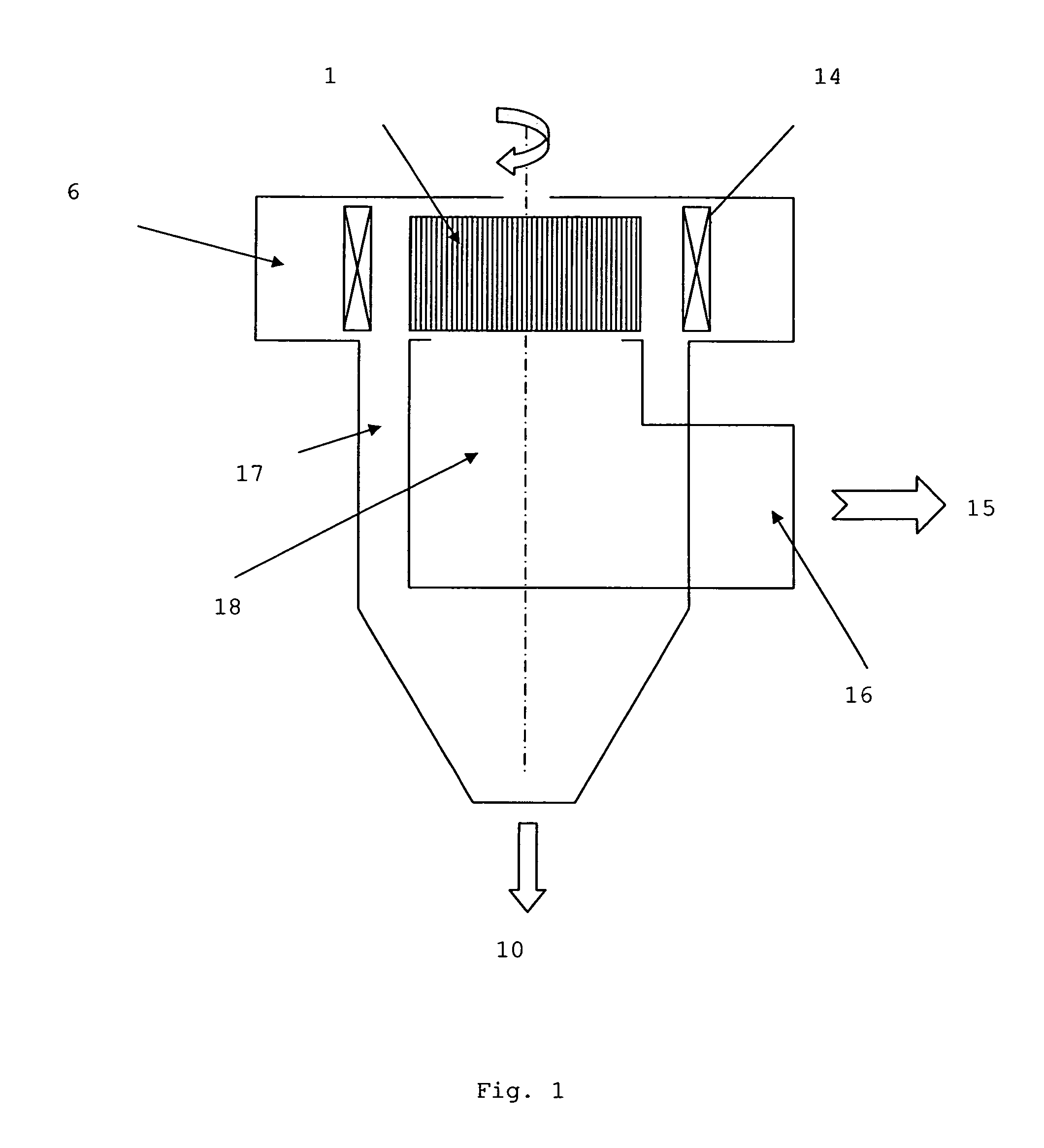

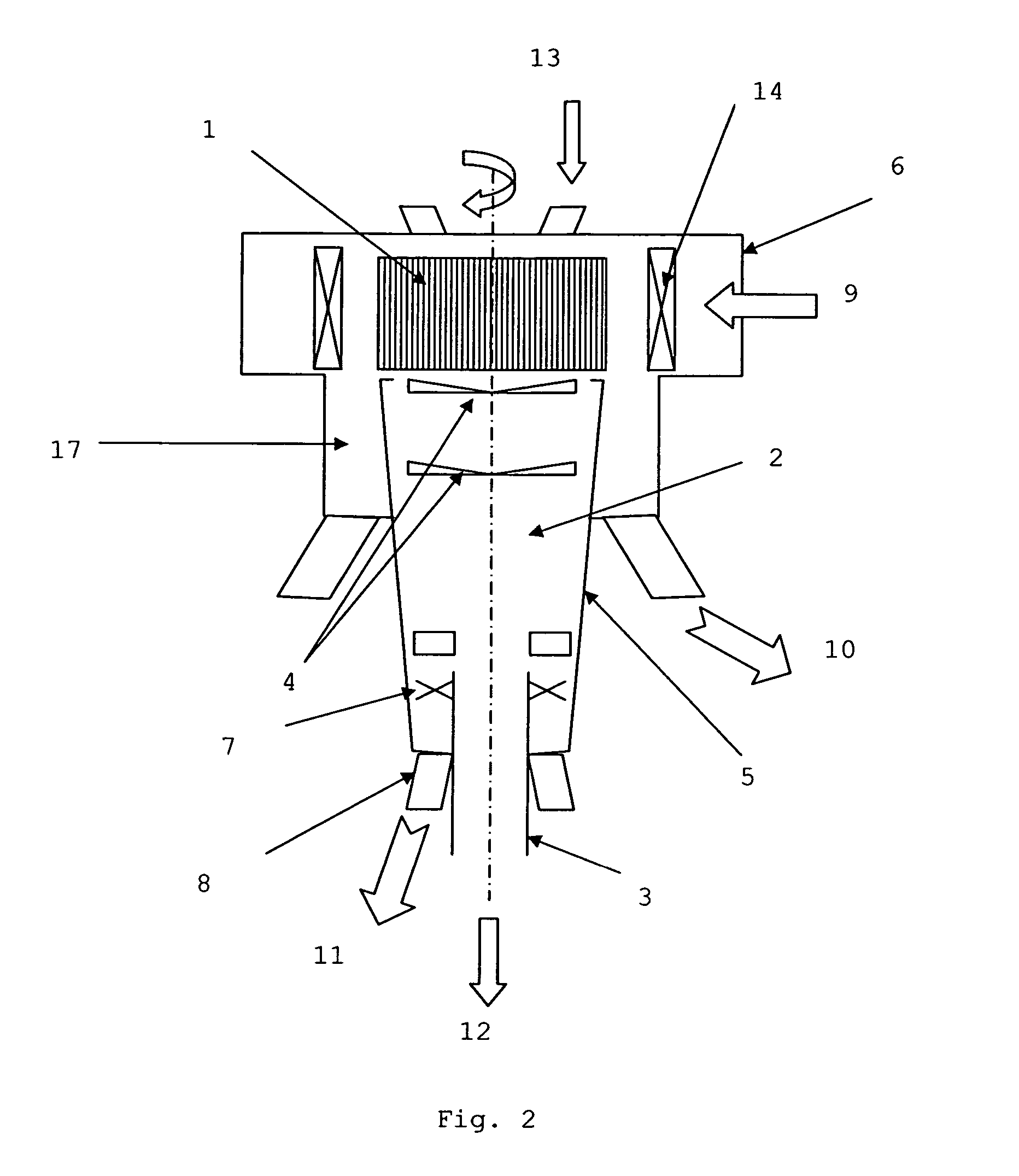

Classifier for granular material

ActiveUS20070163925A1Minimize turbulenceReversed direction vortexGas current separationStructural engineeringProcess engineering

The present invention relates to a dynamic air classifier for the separation of granular and powdery materials into fractions of different grain sizes comprising a rotary cage, wherein: said classifier also comprises a recovery chamber for fine materials with a outlet bottom, said chamber being defined by a casing; said recovery chamber is coaxially arranged in the protrusion of the rotary cage so as to be able to use the vortex created by the rotary cage for cycloning said material; said recovery chamber comprises openings in the casing allowing the passage of the centrifuged material towards ducts for collecting the material located outside the chamber.

Owner:MAGOTTEAUX INT SA

Steel sheet

ActiveUS10895002B2High strengthHigh elongationHot-dipping/immersion processesFurnace typesChemical compositionPearlite

A steel sheet includes a predetermined chemical composition and a metal structure represented by, in area fraction, ferrite: 30% to 50%, granular bainite: 5% to 20%, martensite: 30% to 55%, bainite: less than 35%, and retained austenite and pearlite: 10% or less in total. Preferably, of the steel sheet, a tensile strength is 1180 MPa or more, elongation is 10% or more, and a hole expansion value is 20% or more. Further preferably, a VDA bending angle in the case where a thickness is set to t (mm) is “7.69t2−38.4t+109” or more.

Owner:NIPPON STEEL CORP

Refractory material for surface layer of precision casting wax mold

The invention discloses a refractory material for a surface layer of a precision casting wax mold. The material is prepared uniformly mixing, by mass, 75-85% of industrial aluminum oxide, 11-18% of vein quartz and 3-6% of zircon sand, smelting at 2100-2300 DEG C by adopting a three-phase star-shaped electric arc furnace, crushing and grinding. Due to reasonable design and proportioning, the main crystal phases comprise approximately granular corundum and mullite which is continuously distributed; the size of the corundum crystals is about 30-120 microns; besides the two main crystalline phases, a small amount of glass phase and a small amount of zirconium oxide are also included. Demolding is easy, adhesion is avoided, sand burning is little, and the finish degree of a precision casting product is guaranteed. The specific gravity is 3.10 g / cm<3>; the thermal conductivity is high, and the linear expansion coefficient is small and is 5*10<-6>; and deformation, cracks and cracking of theformwork are reduced.

Owner:梅河口市德成耐火材料有限公司

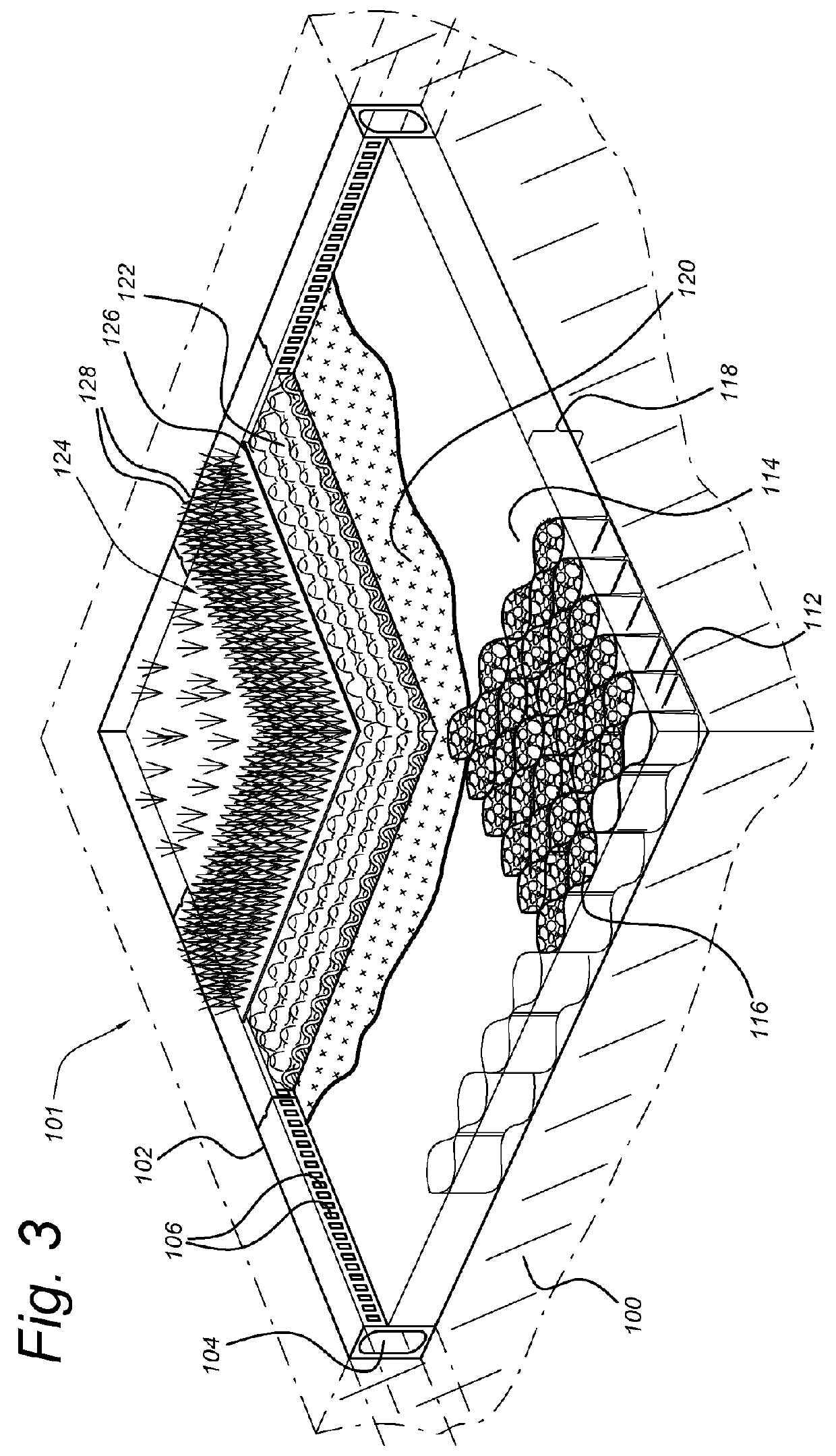

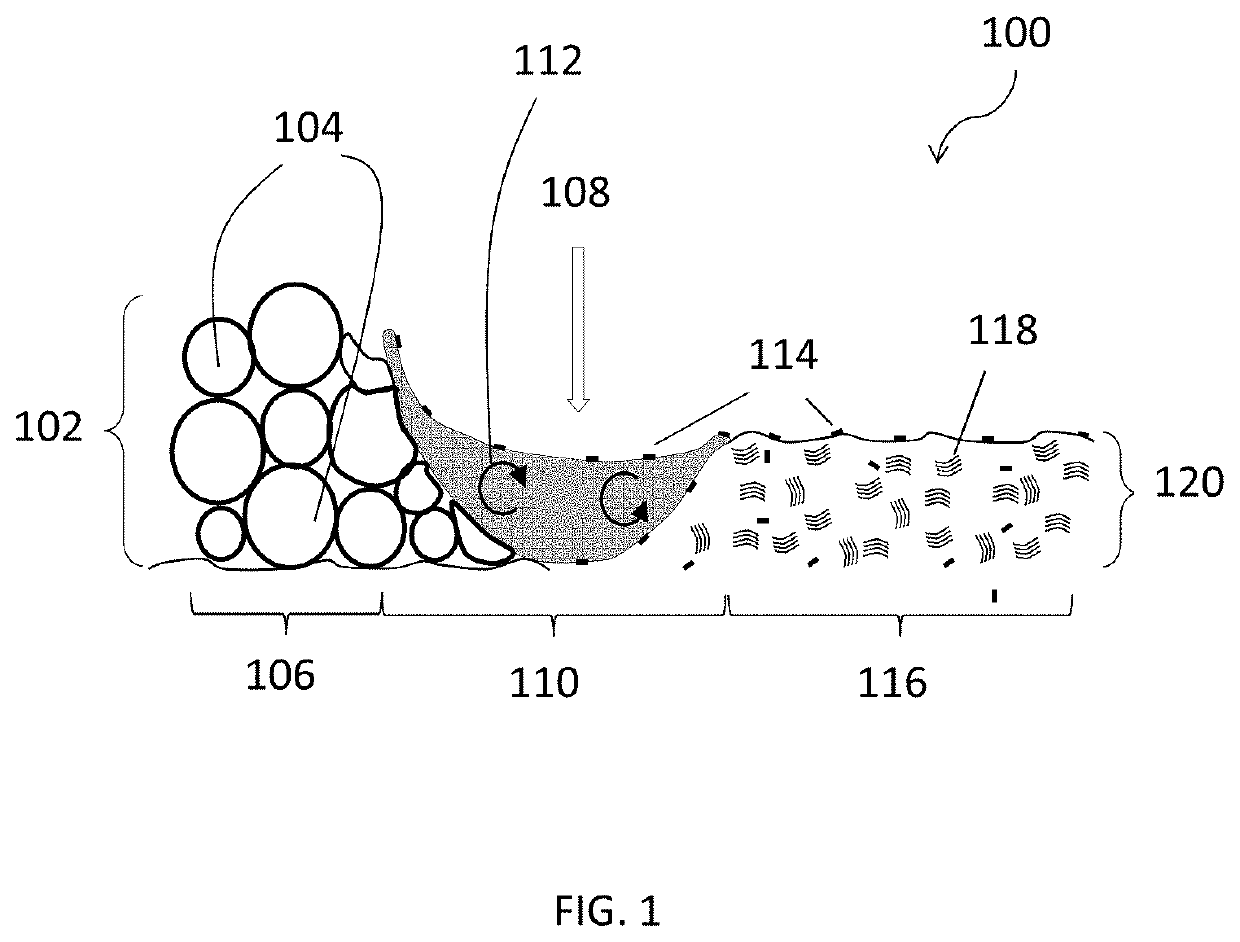

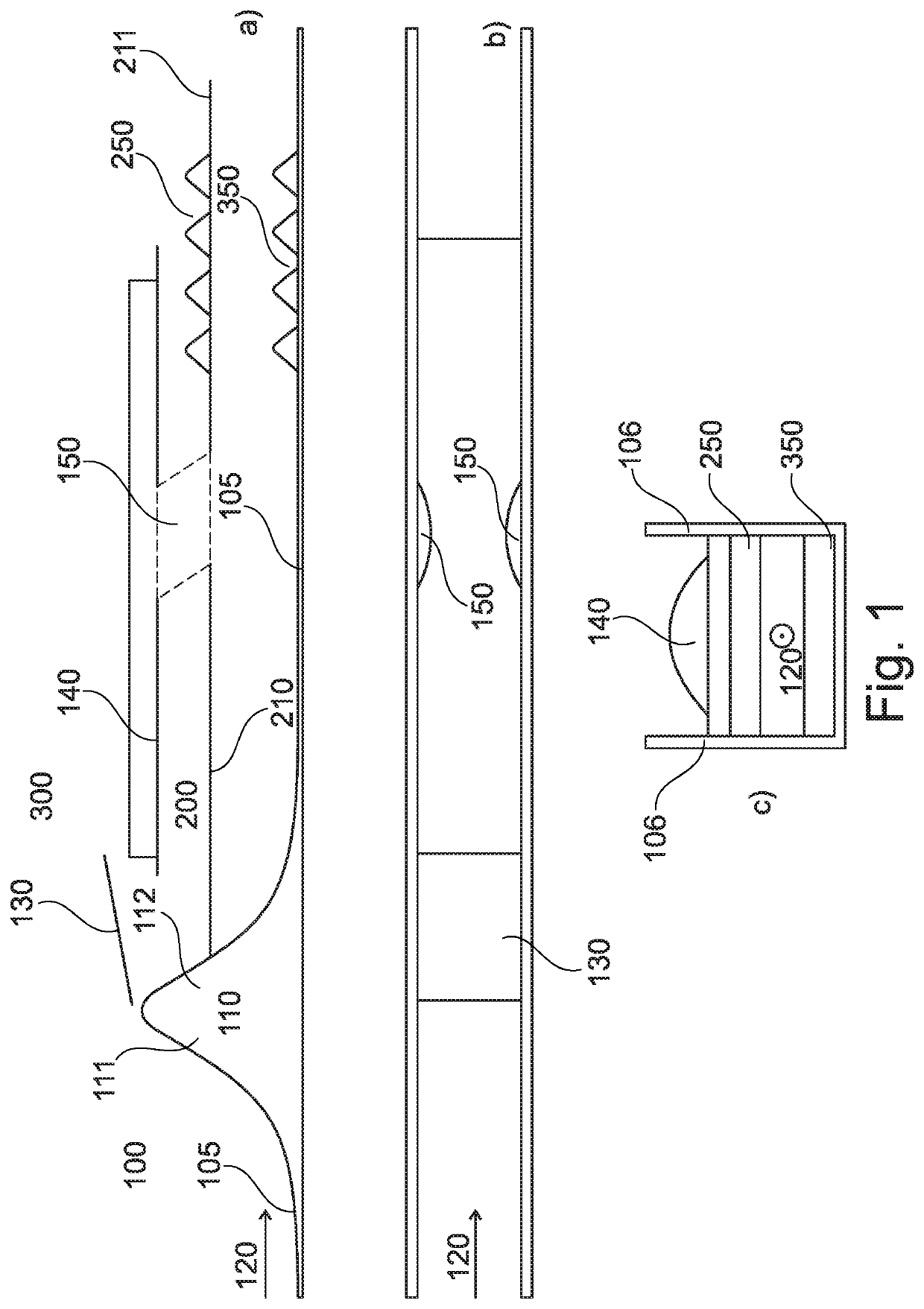

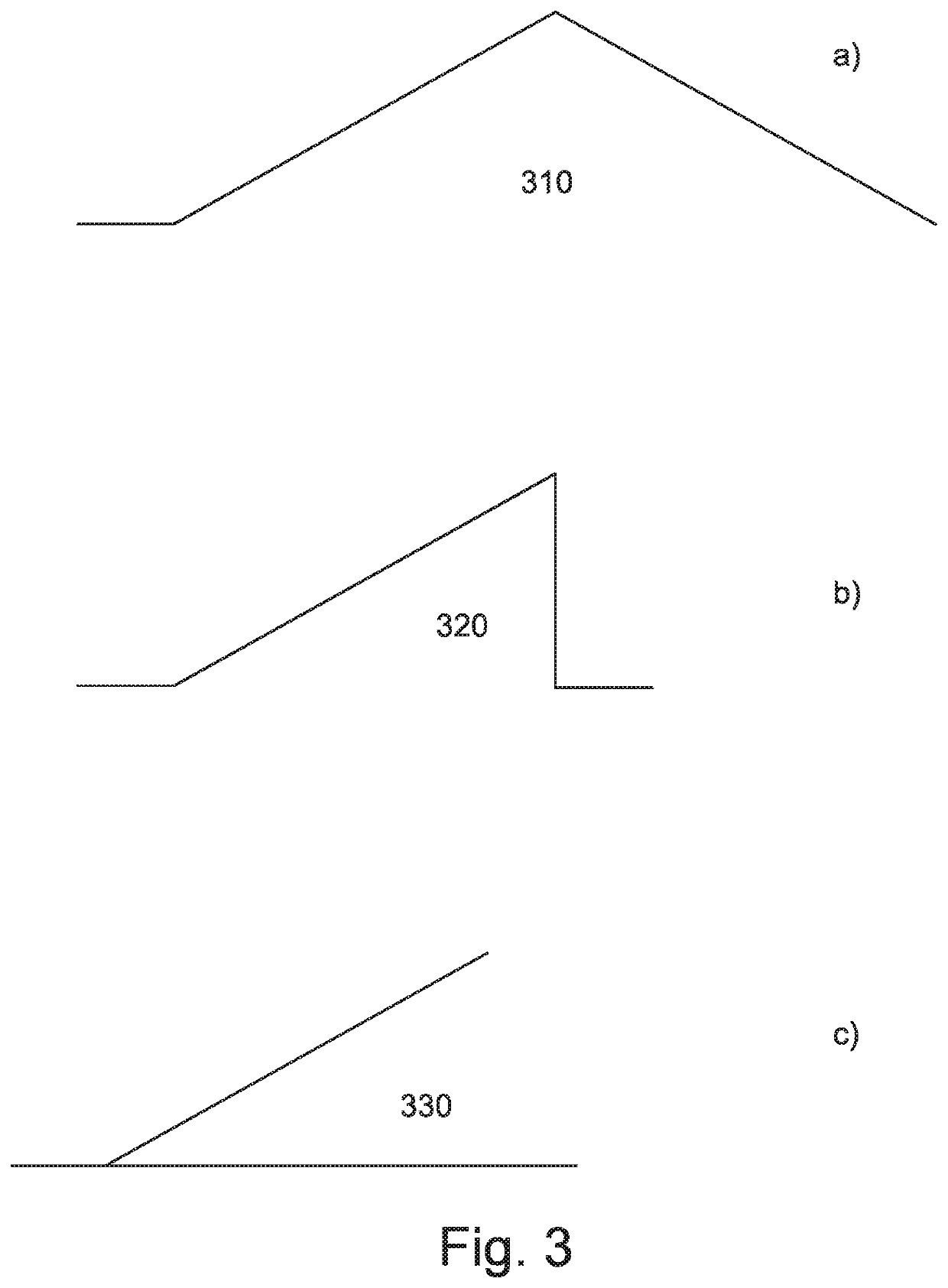

Transfer chute to maintain a density of a flow of granular material

The present invention relates to a transfer chute (100) for granular material, comprising a chute body defining a flow pathway (120) for granular material, a raised portion (110) having an inclined surface (111), and a splitter member (130) arranged proximal to the raised portion (110) for, in use, dividing a flow of granular material over the raised portion into first portion in first conduit (100) and a second portion in a second conduit (300). In some embodiments, a channel (150) is disposed between the first and second conduits (100; 300) to transpose a vertical arrangement of first and second portions of granular material within the chute (10). In this way, separation by particle size or density in the flow may be reversed.

Owner:UNIV OF MANCHESTER

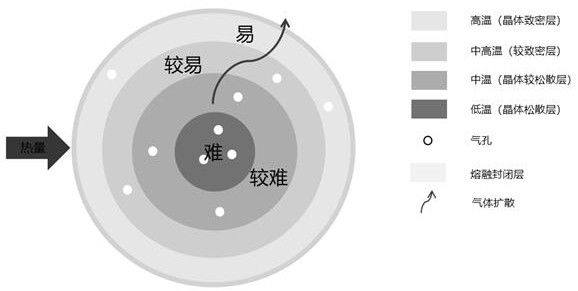

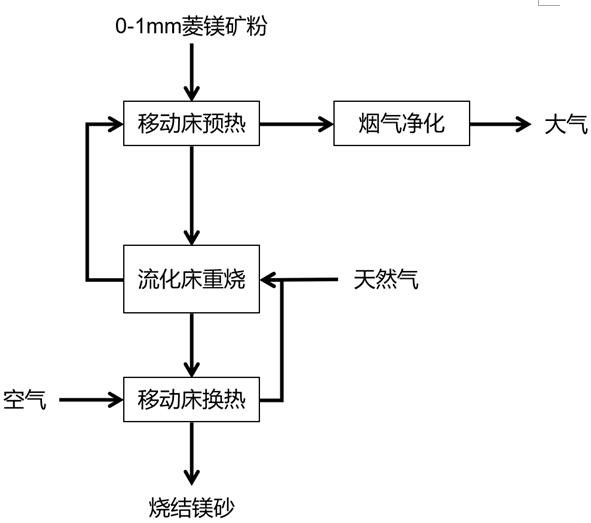

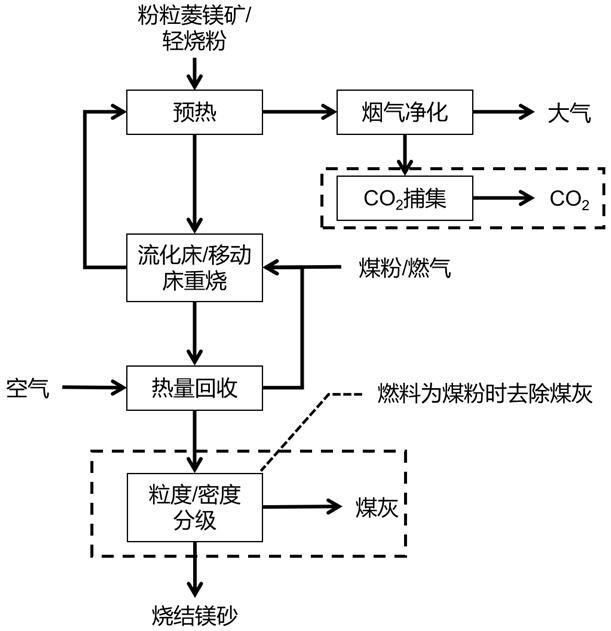

Method for preparing sintered magnesia from granular magnesite by one-step

ActiveCN112250323AImprove resource utilizationSolve the restriction that powder materials cannot be usedFlue gasFluidized bed

The invention discloses a method for preparing sintered magnesite from granular magnesite by one-step, and relates to a method for preparing sintered magnesite, and the method comprises the steps of pretreatment of magnesite raw materials, preheating, reburning, heat recovery, CO2 capture, flue gas purification and the like. The core thought of the method is that the small-particle-size magnesitetransfers heat and discharges CO2 more quickly, and the problems that blocky magnesite used in a traditional shaft kiln and an electric melting furnace transfers heat difficultly, the external temperature is higher than the internal temperature, accordingly, an external crystal form is converted into a compact structure firstly, and internal gas is difficult to discharge are solved. By utilizing the characteristics of high heat exchange rate, high yield, uniform particle heating and the like of the fluidized bed / moving bed, compared with the traditional reburning technology, the method greatlylowers the reburning temperature and shortens the reburning time, thereby enhancing the treatment capacity of the system and lowering the production cost of the sintered magnesia. Moreover, the method also solves the problem that the traditional shaft kiln and electric melting furnace process cannot use the powder magnesite, and improves the utilization rate of magnesite resources.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

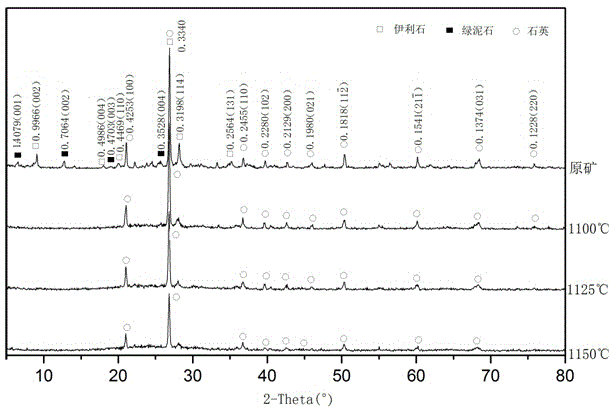

Method for preparing granular artificial pumice stone by taking black shale as raw material

The invention relates to a method for preparing granular artificial pumice stone by taking black shale as a raw material. According to the method, the natural black shale is taken as an ore raw material and any other reagents are not added, and the method comprises the following steps: 1) crushing the ore raw material to -20mm by adopting a crushing device; 2) sieving crushed ore to obtain a material with the particle size of 3mm-20mm by adopting a sieving device; 3) heating the sieved material to 240 DEG C-800 DEG C by adopting a calcining and heating device and the heating rate of 10 DEG C / min-20 DEG C / min in an air environment, and performing heat preservation for 12-30min; 4) heating the material after preheating and heat preservation to 1100 DEG C-1250 DEG C by adopting the heating rate of 10 DEG C / min-20 DEG C / min in the air environment and performing heat preservation for 15-30min; 5) slowly cooling the calcined and expanded material to below 400 DEG C in the air environment; and 6) sieving the calcined, expanded and cooled material to the particle size of 5mm-25mm by adopting the sieving device, thereby obtaining the granular artificial pumice stone. The method provided by the invention has the advantages of obvious effects, good safety, simple process, easiness in popularization and application, a wide range of applications and significant social and economic benefits.

Owner:重庆金诚新材料集团有限公司

Method for consolidating heavy metal elements in copper slag

PendingCN112851169ARealize large-scale disposal of hazardous wasteHigh value-added applicationsSolid waste managementSolid matterGranulation

The invention relates to the technical field of hazardous waste disposal in the metallurgical industry, in particular to a method for consolidating heavy metal elements in copper slag. The method comprises the following steps: mixing copper slag, mineral substances and an additive, and carrying out granulating, drying, and calcining, wherein the sum of SiO2 and Al2O3 in the mineral substances accounts for more than 50% of the total amount, and the ratio of SiO2 to Al2O3 is greater than or equal to 0.5; and the additive is selected from one or more of carbonate, sulfate, silicate, bentonite, montmorillonite, limestone, calcium oxide and magnesium oxide. According to the method, the specific copper slag is solidified through a specific method, and heavy metal elements in a solid substance leachate prepared according to GB5085.3-2007 Identification Standard for Identification of Hazardous Wastes are judged as common solid wastes according to HJ / T299. The granular material can replace natural gravel aggregate, and large-scale treatment and high-added-value application of the copper slag hazardous waste are achieved.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

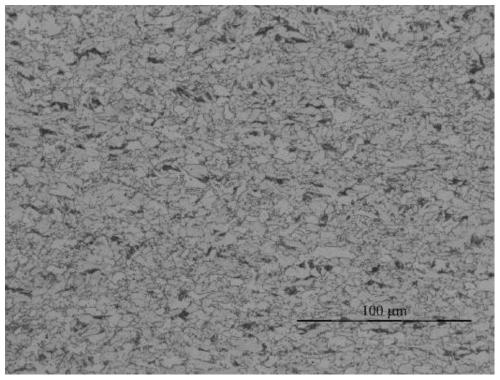

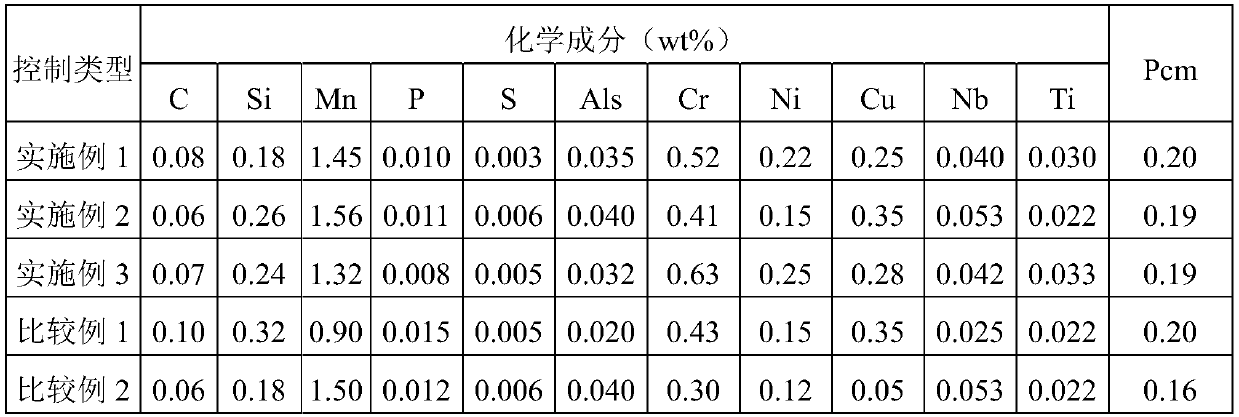

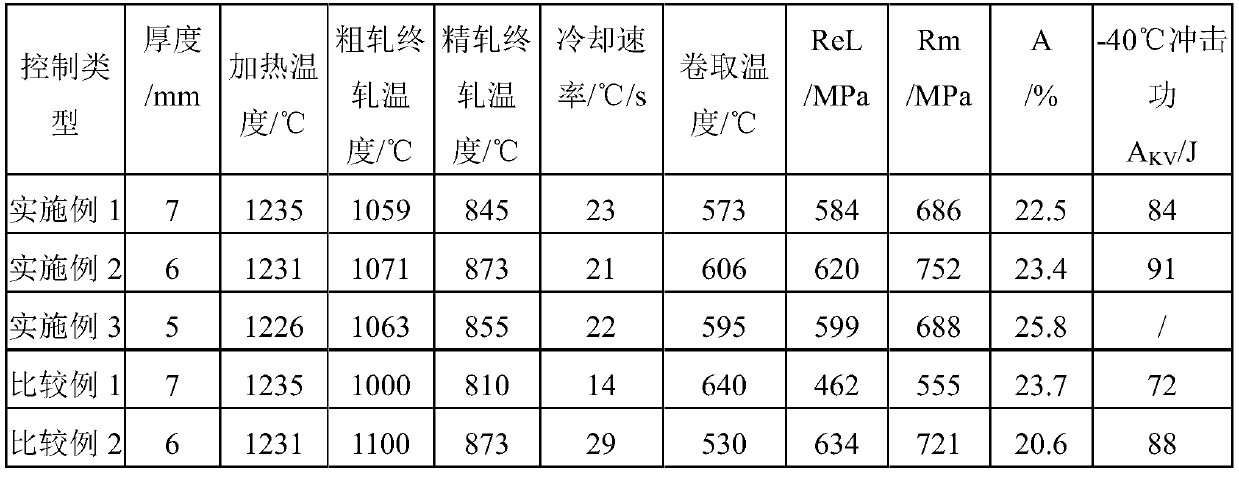

A high-toughness weather-resistant steel plate with a yield strength of 550mpa and its preparation method

ActiveCN108486466BDetrimental effects of reduced low temperature toughnessGood atmospheric corrosion resistanceChemical compositionPearlite

The invention discloses a high-toughness weather-resistant steel plate with the yield strength of 550MPa and a preparation method of the high-toughness weather-resistant steel plate. The high-toughness weather-resistant steel plate is prepared from the following chemical components by weight percent: 0.05 to 0.10 percent of C, 0.10 to 0.40 percent of Si, 1.20 to 1.70 percent of Mn, less than or equal to 0.012 percent of P, less than or equal to 0.008 percent of S, 0.40 to 0.80 percent of Cr, 0.15 to 0.40 percent of Ni, 0.25 to 0.40 percent of Cu, 0.015 to 0.040 percent of Als, 0.030 to 0.070 percent of Nb, and 0.010 to 0.040 percent of Ti, and the balance of Fe and unavoidable impurities, wherein Pcm is equal to C+Si / 30+(Mn+Cu+Cr) / 20+Mo / 15+Ni / 60+V / 10+5B and less than or equal to 0.20 percent. The microscopic tissue of the weather-resistant steel plate obtained according to the method disclosed in the invention is composite-phase tissue of ferrite, granular bainite and little pearlite,the ReL is 560 to 650MPa, Rm is 680 to 780MPa, A is 22.0 to 26.0 percent, and the longitudinal Charpy V-type impact power KV2 is greater than 70J at the temperature of -40 DEG C, and the high-toughness weather-resistant steel plate has excellent welding performance, cold bending forming performance and atmospheric corrosion resistance.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Low dusting, small clumping highly absorptive animal litter

PendingUS20210169037A1Improved dusting characteristicEasy to useAnimal housingBiotechnologyActivated carbon

Animal litter comprising composite particles including powdered sodium bentonite and powdered activated carbon, agglomerated together into the composite particles, wherein the animal litter has a particle size distribution of 16 / 50 mesh (i.e., 300 μm to 1180 μm in size). The litter may include non-composite, granular clay particles (e.g., granular sodium bentonite) having the same particle size distribution (16 / 50 mesh). Such particle size characteristics significantly reduce dusting, without the need for a de-dusting agent, reduce clump depth and / or reduce clump width at the bottom of the clump (both acting to reduce risk of clumps sticking to the bottom of the litter box) and result in more efficient use of the litter in clumping (reduced clump weight) by increasing absorbency.

Owner:THE CLOROX CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com