Steel tube and steel sheet

A technology of steel plates and steel pipes, applied in the furnace type, furnace, heat treatment furnace, etc., can solve the problem of insufficient acid resistance, and achieve the effect of excellent HIC resistance and excellent SSC resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

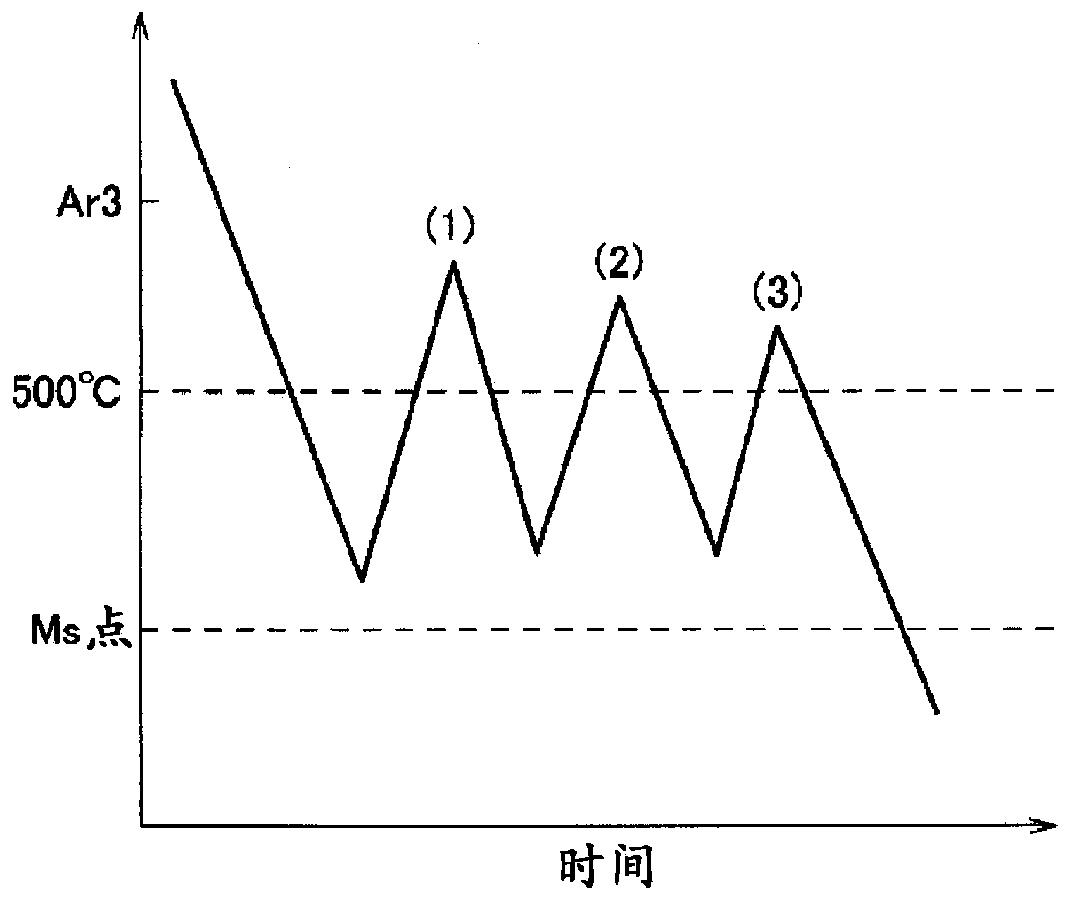

[0212] Continuous casting was performed on molten steel having the composition shown in Tables 1-1 and 1-2 to produce a 240 mm thick steel slab. Using this slab, steel sheets shown in Tables 3-1 to 3-4 were produced under the production conditions shown in Tables 2-1 and 2-2. In Table 2-1, in the column of the water cooling stop temperature of the first cooling, the so-called OK means that the water cooling stop temperature after each water cooling of the multi-stage accelerated cooling is all below 500°C, and NG means that there are cases where the cooling stop temperature exceeds 500°C example of the situation.

[0213]In addition, in the 1st cooling, only the 1st cooling rate is described about the cooling rate, but the 2nd and subsequent cooling rates are equivalent.

[0214] No.1-22, 54-56 are invention steel plates, and No.23-53 are comparative steel plates.

[0215] Table 1-1

[0216]

[0217] Underlined means outside the scope of the present invention.

[0218] ...

Embodiment 2

[0247] The steel plate shown in Table 3 is cold-worked into a cylindrical shape, and the two ends of the cylindrical steel plate are butted, using 3 electrodes or 4 electrodes, and the online energy is in the range of 2.0kJ / mm to 10kJ / mm according to the plate thickness Under the conditions of submerged arc welding (SAW), to manufacture steel pipes. The heat treatment of heating to 400 degreeC - Ac1 point was given to the welded part of some steel pipes.

[0248] A full-thickness tensile specimen was prepared along the circumferential direction from the obtained steel pipe according to the API5L standard, and after flattening, the yield strength and tensile strength were measured.

[0249] In addition, as an evaluation of SSC resistance, a 4-point bending sample was prepared, and in accordance with the NACE TM 0177 standard, various hydrogen sulfide partial pressures shown in Table 4 were carried out in a 90% test environment in a solution environment of pH 3.5. 4-point bendi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com