High-strength steel plate for acid-resistant line pipe, method for producing the same, and high-strength steel pipe using high-strength steel plate for acid-resistant line pipe

A technology of high-strength steel plate and manufacturing method, applied in the field of high-strength steel plate for acid-resistant line pipe and its manufacture and high-strength steel pipe using high-strength steel plate for acid-resistant line pipe, capable of solving cooling stop temperature deviation, steel plate material deviation, oxidation Uneven skin thickness, etc., to achieve excellent HIC resistance and SSCC resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

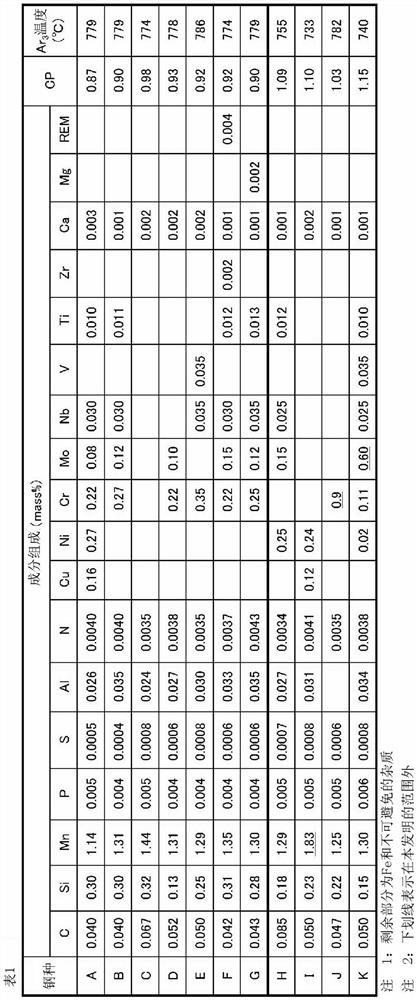

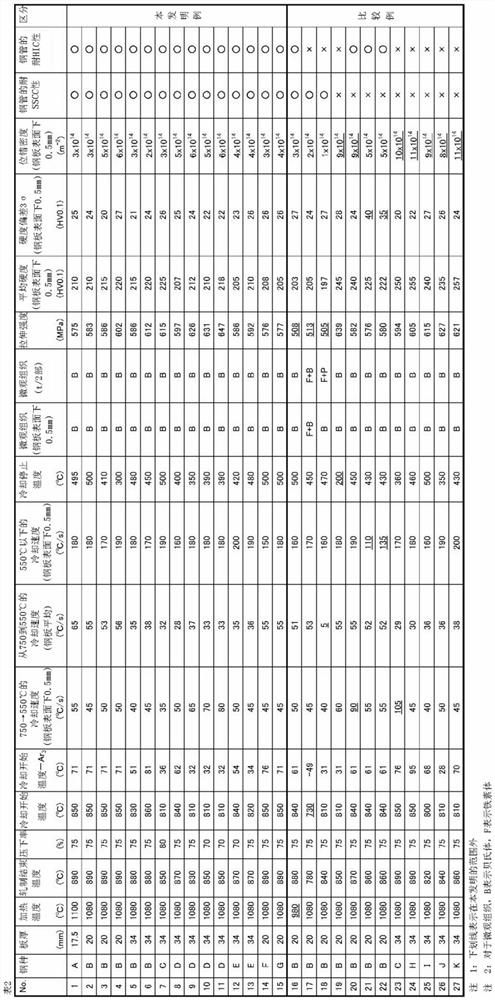

[0108] Steels (steel grades A to K) having the composition shown in Table 1 were made into slabs by continuous casting, heated to the temperature shown in Table 2, and then rolled at the end temperature shown in Table 2 Steel sheets with the thicknesses shown in Table 2 were prepared by hot rolling at the rolling reduction ratio. Then, under the conditions shown in Table 2, the cooling control of the steel plates was performed using a water-cooling type cooling control device.

[0109] [determination of organization]

[0110] The microstructure of the obtained steel plate was observed with an optical microscope and a scanning electron microscope. Table 2 shows the structure at a position 0.5 mm below the surface of the steel plate and the structure at the center of the plate thickness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com