Steel plate and line pipe for line pipe

A technology for pipes and pipelines, which is applied in metal rolling and other directions, can solve the problems of insufficient reduction in the recrystallization area and difficulty in ensuring characteristics, and achieve the effect of both compressive strength, excellent HIC resistance, and DWTT characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

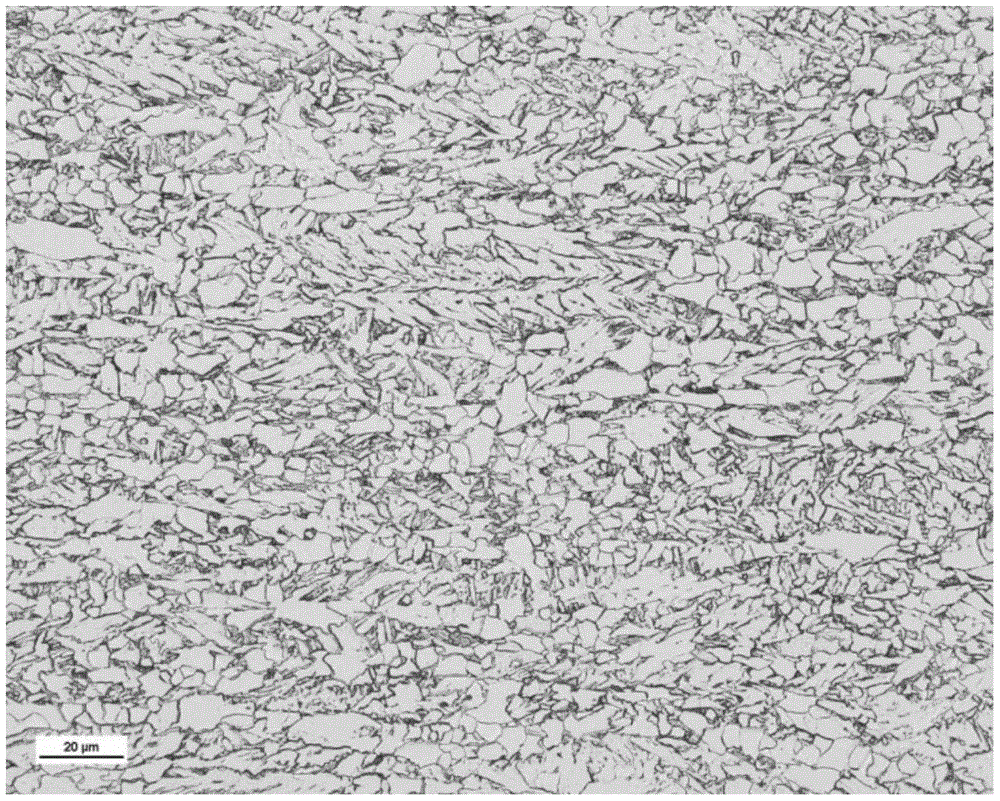

Image

Examples

Embodiment

[0231] Hereinafter, the present invention will be described in more detail through examples, but the present invention is not limited to the following examples.

[0232] [Invention Examples 1-10, Comparative Examples 1-12]

[0233]

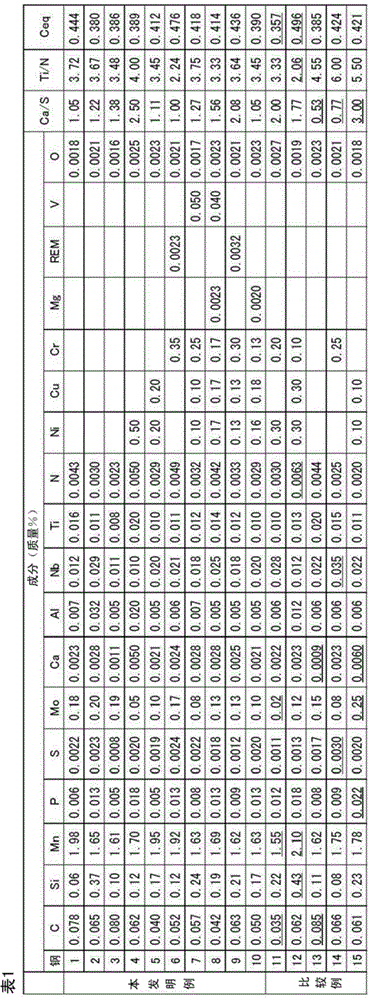

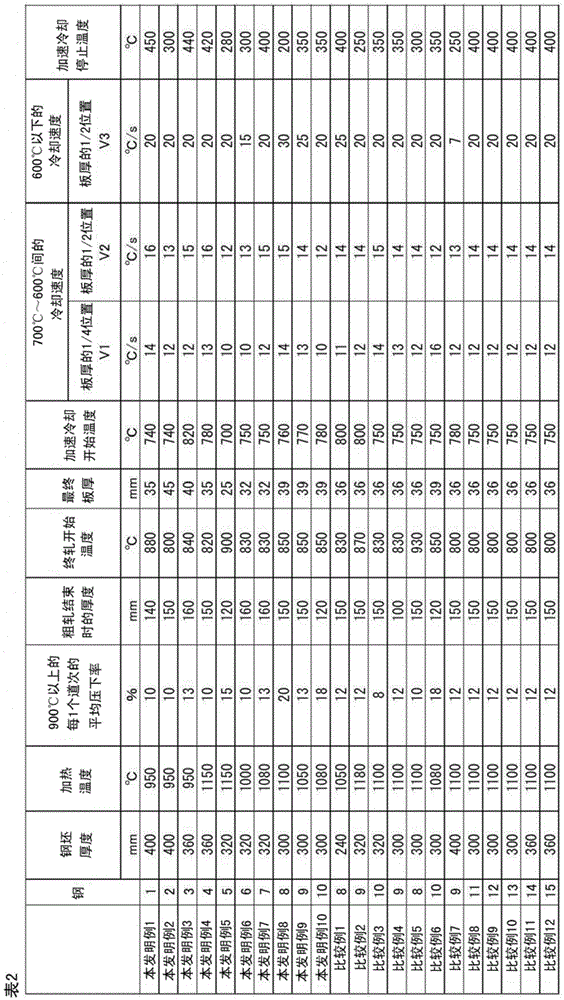

[0234] Steels (steel 1 to steel 15) having chemical compositions shown in Table 1 below were melted, and each slab having a thickness (slab thickness) shown in Table 2 below was produced by continuous casting. In continuous casting, in order to suppress the segregation of Mn in the central segregation part, light reduction at the time of final solidification is performed.

[0235] Here, in the steel, the components (remainder) other than those shown in Table 1 below are Fe and unavoidable impurities.

[0236] In addition, "REM" in Steel 6 is specifically Ce, and "REM" in Steel 9 is specifically La.

[0237] The slab obtained above was heated to 950 to 1150°C (1180°C in Comparative Example 2), and the average rolling reduction was 10% or more (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com