High-speed rotating shaping device

A shaping device and high-speed rotation technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of insufficient speed for mass production, easy blockage of flakes and inconvenient adjustment, etc., to meet the needs of high-speed production and improve The effect of product qualification rate and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

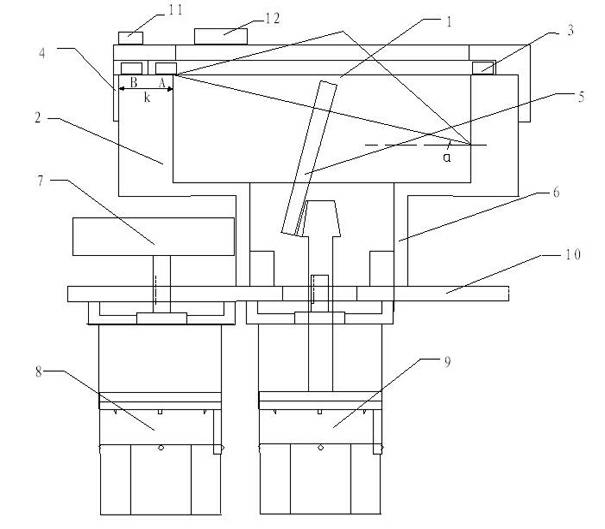

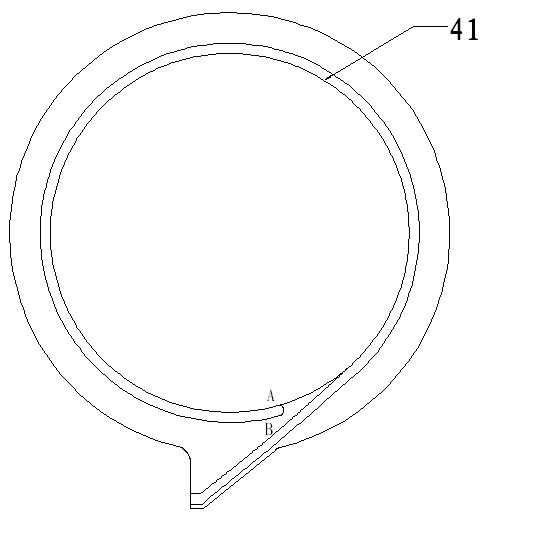

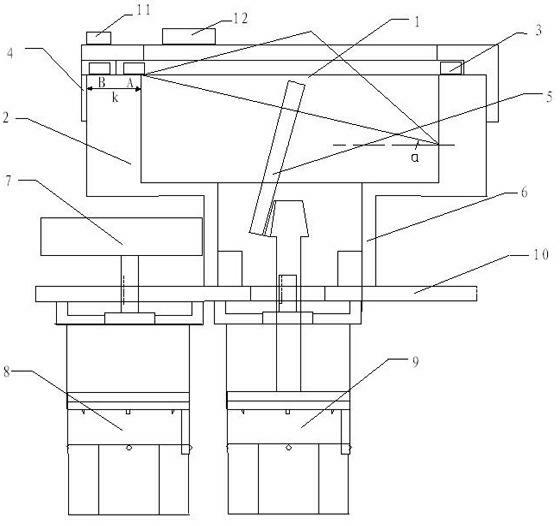

[0020] figure 1 It is a structural schematic diagram of an embodiment of the present invention; figure 2 It is a structural schematic diagram of the outer cover of the present invention.

[0021] like figure 1 and figure 2 Shown: a high-speed rotary shaping device, including a horizontal turntable 2, a cone 1, a cover 4, a driving mechanism and a fixed bracket 10, the cone 1 is arranged on the upper part of the horizontal turntable 2, and the cone 1 is inclined at an angle α to the horizontal plane , and the highest point of the rotation of the bottom surface of the cone 1 is equal to the upper edge of the horizontal turntable 2, the upper edge of the horizontal turntable 2 has a width k, and the outer cover 4 is arranged on the top of the horizontal turntable 2, It is fixed by an external bracket (not shown in the figure), and the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com