Method for preparing sintered magnesia from granular magnesite by one-step

A technology for sintering magnesia and magnesite, applied in the field of preparing sintered magnesia, can solve the problems of low output of dry briquetting equipment, high temperature required for re-firing, dust pollution, etc., so as to improve system processing capacity and reduce calcination temperature, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the embodiments shown in the accompanying drawings.

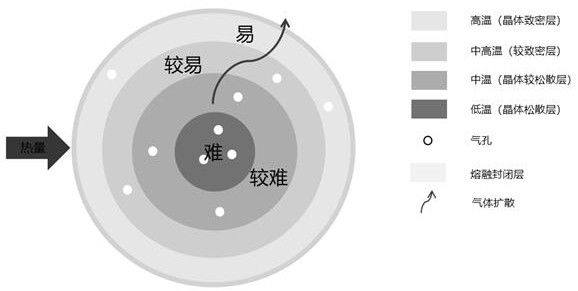

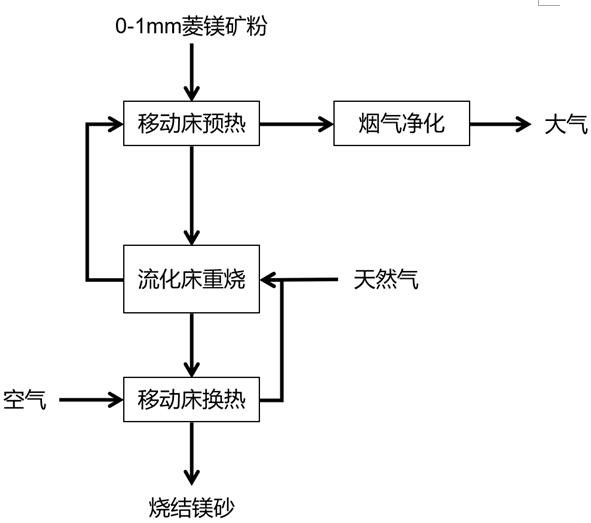

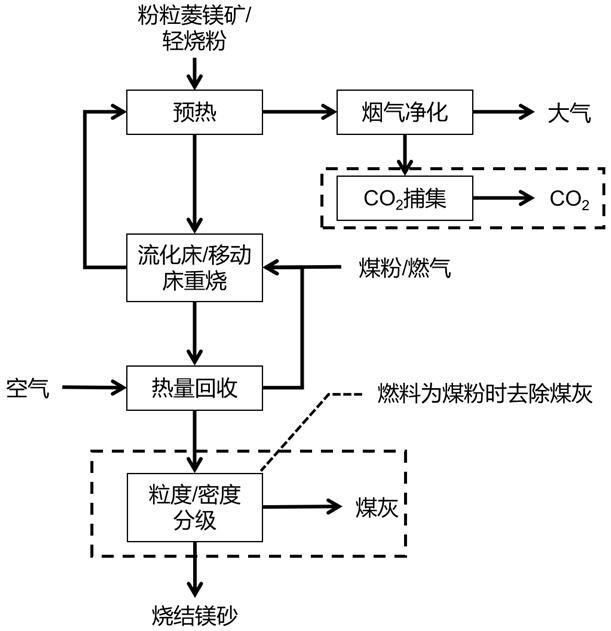

[0023] The preparation of high-density sintered magnesia by reburning magnesite depends on the transformation of crystal form, but in the final analysis, whether it is the CO produced by the thermal decomposition of magnesite inside the particle 2 The increase in density can only be achieved by gas discharge in the interstitial space of the crystal. Therefore, the applicant believes that the main reason for the slow rate of magnesite reburning (including electric melting) should be the temperature difference between the inside and outside of the particles. As we all know, magnesite light-burned powder and heavy-burned powder are refractory materials with excellent heat insulation performance, which means that it is extremely difficult to transfer heat to the inside of the particle through the outer layer of the particle, resulting in a large t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com