Method for preparing granular artificial pumice stone by taking black shale as raw material

A black shale and artificial pumice technology, which is applied in the field of granular artificial pumice processing and preparation, can solve the problems of cumbersome preparation steps, the quality of artificial pumice needs to be improved, and narrow application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

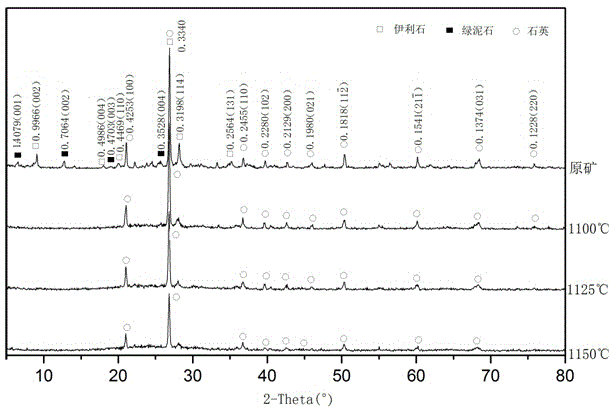

[0063] A method for preparing granular artificial pumice with black shale as raw material. In this example, black shale is used as ore raw material. The ore raw material is black, dense block, sheet-like, thin-layered bedding structure, and its chemical composition is as shown in the table 1, its mineral composition is as figure 1 As shown in (raw ore), without adding any other reagents, the optimized calcination and puffing process is used to prepare granular artificial pumice. The preparation process is carried out in the following 6 steps:

[0064] (1) Ore crushing: use crushing equipment to crush ore raw materials to -20mm;

[0065] (2) Ore screening: Use screening equipment to screen the crushed ore into materials with a particle size of 3mm-20mm;

[0066] (3) Preheating and heat preservation: In an air environment, use calcining heating equipment and a heating rate of 13°C / min to heat the screened material to 240°C and hold it for 12 minutes;

[0067] (4) Calcination and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com