Laboratory three-dimensional dynamic rock crushing test system and method

A three-dimensional dynamic and test system technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems that rock breaking experiments cannot be used, deep rock breaking can not be used, and high stress environments cannot be simulated. , to achieve the effect of reducing the impact and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A laboratory three-dimensional dynamic rock crushing test system and method, the steps of which are:

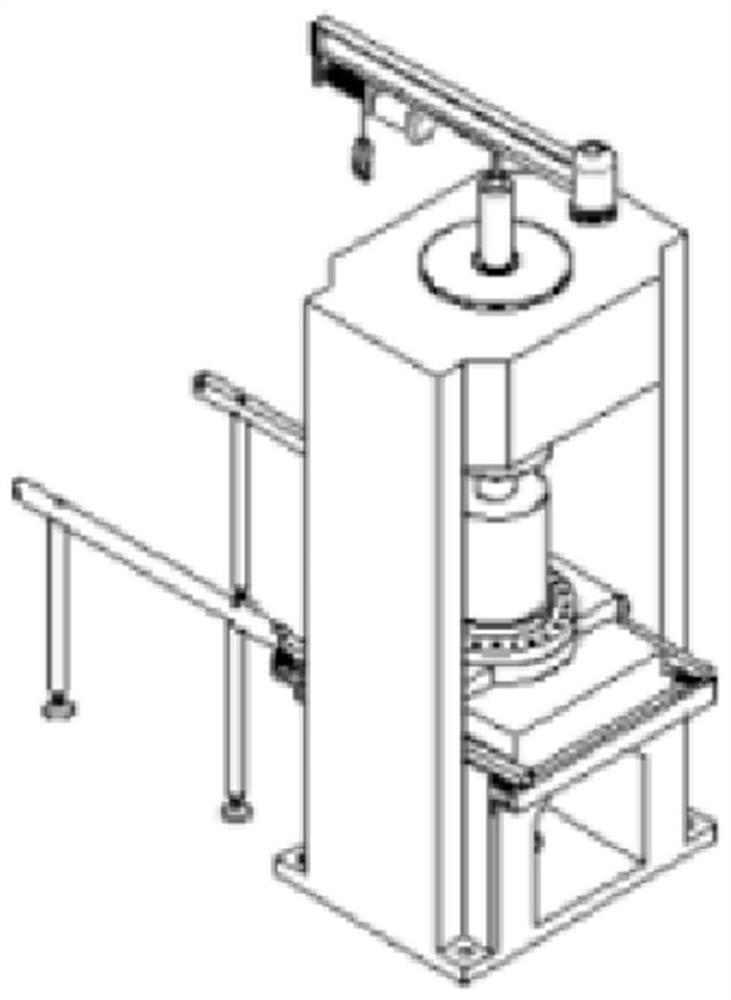

[0046] Step 1. Move the pressure chamber into the lifting guide rail, install the stopper, remove the fixing bolts between the upper part of the pressure chamber and the base, lift the upper part of the pressure chamber with the boom device, and place the prepared diameter 50mm and height 100mm. Put the rock specimen in the rubber sleeve, install the lower end of the rubber sleeve above the reserved hole in the base of the pressure chamber, lower the upper part of the pressure chamber from the cantilever device, and fix the bolts of the upper part of the pressure chamber and the base of the pressure chamber to seal the experimental chamber ;

[0047] Step 2, install the in-line chisel head on the 25KN actuator as a dynamic load loading tool, the dynamic load simulation type is impact, mechanical tunneling, etc. After installation, put the pressure chamber under the sen...

Embodiment 2

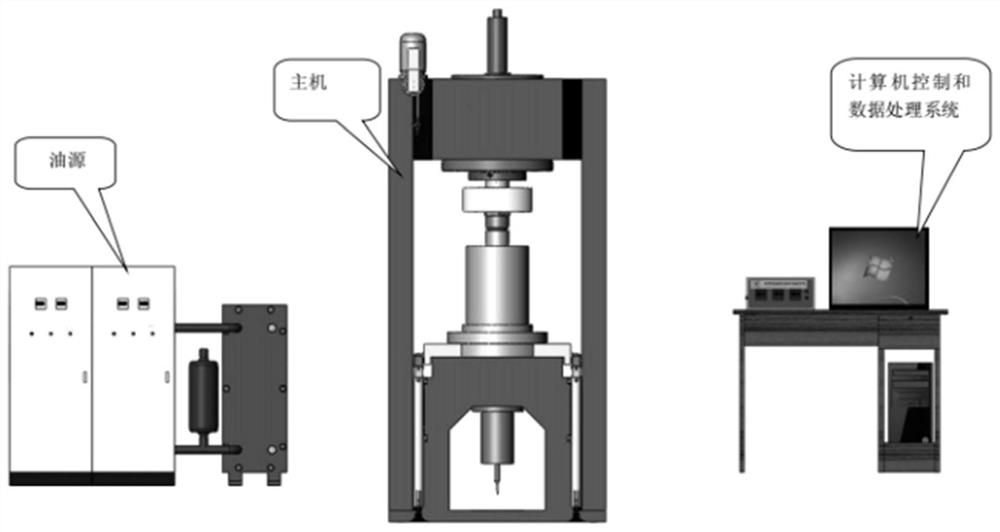

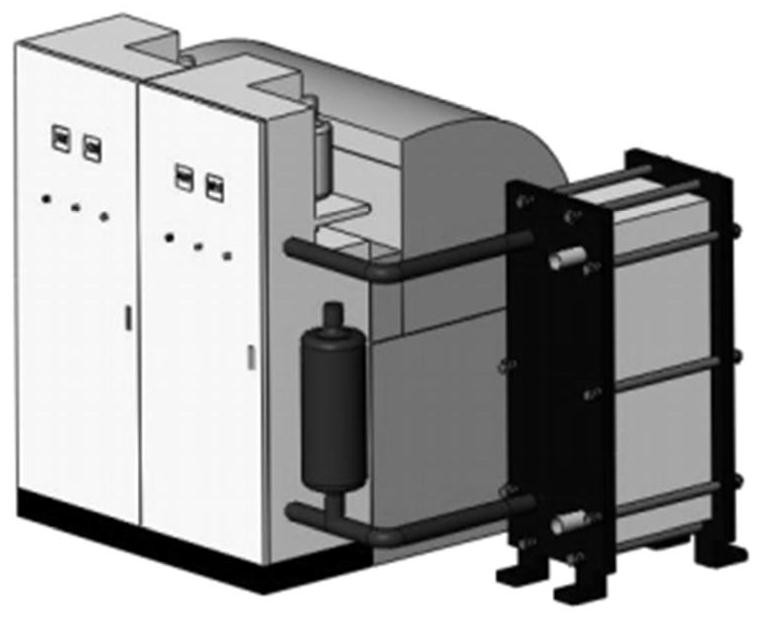

[0057] A laboratory three-dimensional dynamic rock crushing test system is composed of a main engine, a functional device, an electro-hydraulic servo axial loading system, a measurement control system, a computer control and data processing system, etc.; The boom device is composed of a lifting guide and a small cylinder. The main frame adopts an integrally cast integral door frame structure. The boom is hinged on the upper left side of the main frame and can rotate horizontally. The lifting guides are located on both sides above the base of the main frame. Four small cylinders are installed on the base of the lower host, the guide rail is installed in front, and the stopper is placed between the lifting guide rail and the guide rail; the functional device includes a self-balancing triaxial pressure chamber, a servo-controlled confining pressure loading device, and a self-balancing triaxial pressure chamber base Located above the main frame, there are two pulleys on each side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com