Self-pressurized valve group

A self-pressurization, valve group technology, applied in valve details, valve devices, valve operation/release devices, etc., can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with embodiment the present invention is further described:

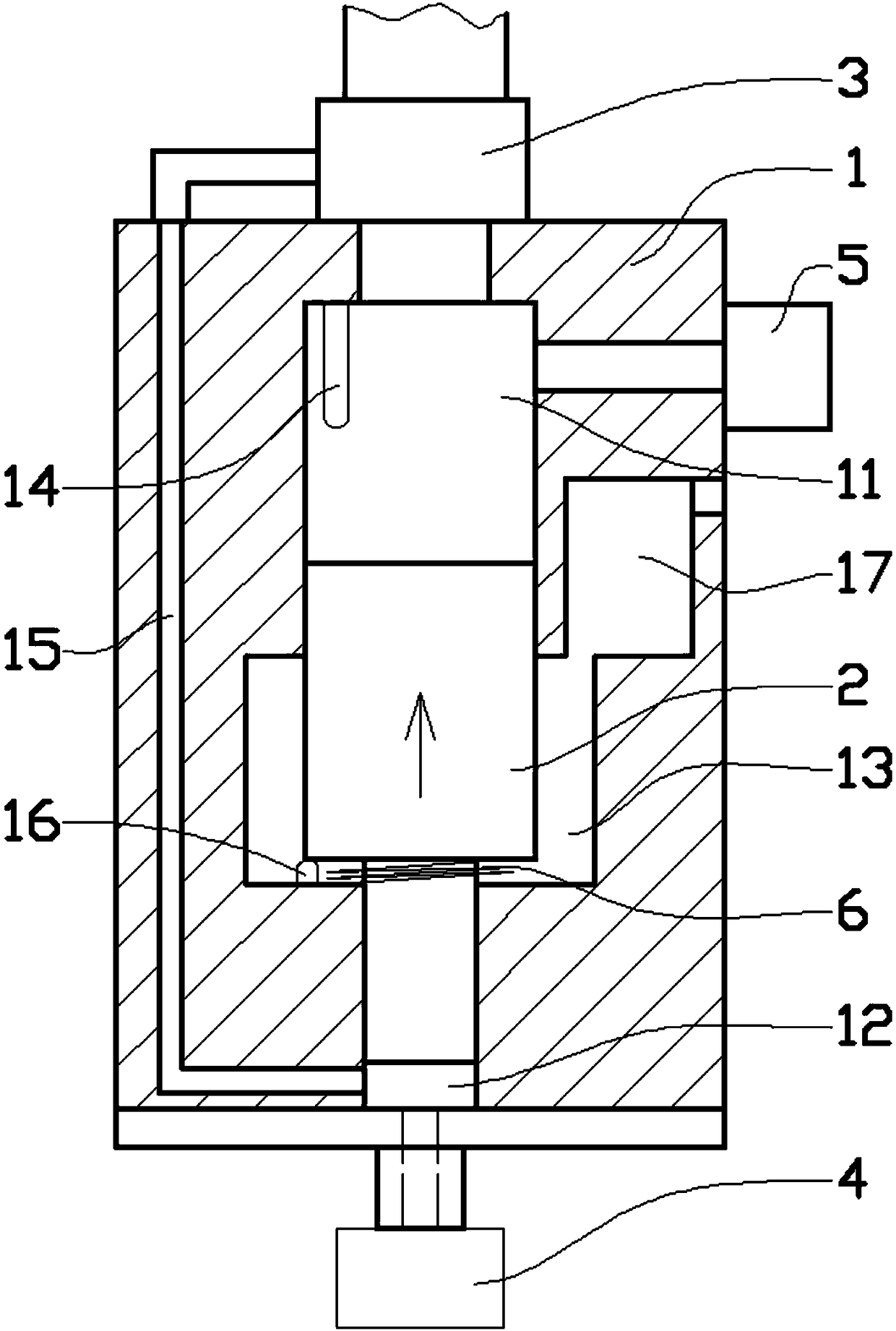

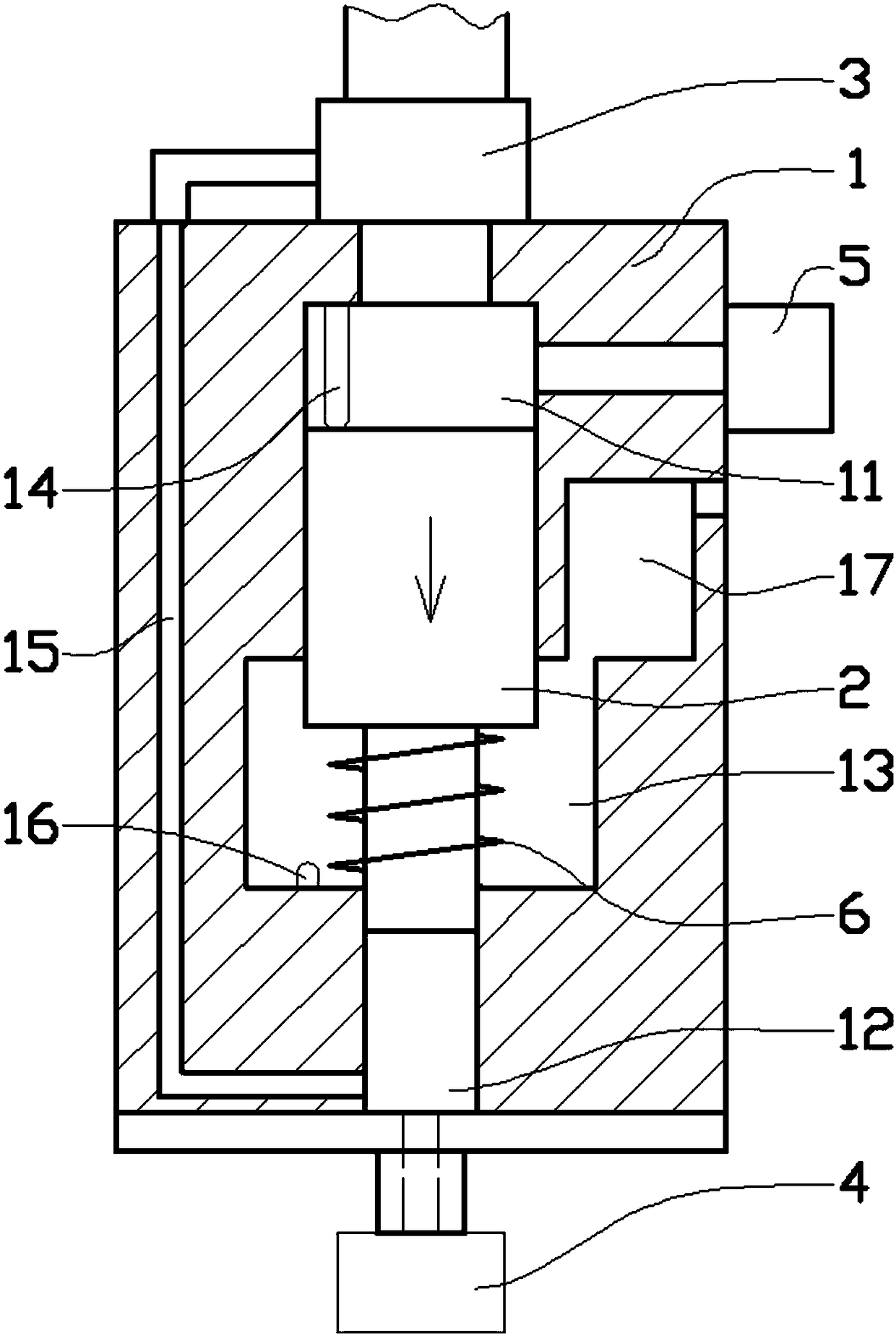

[0014] Such as figure 1 , figure 2 As shown in the embodiment, the self-pressurizing valve group includes a main valve body 1 and a pressure block 2, and the main valve body 1 is designed with a vertically coaxial cylindrical upper pressure chamber 11 and a lower pressure chamber 12. , the diameter of the upper pressure chamber 11 is larger than that of the lower pressure chamber 12, an adjustment chamber 13 with a diameter larger than that of the upper pressure chamber 11 is designed between the upper pressure chamber 11 and the lower pressure chamber 12, and the pressure block 2 is composed of two sections with different diameters Composed of coaxial cylinders, the upper cylinder of the pressure block 2 is slidingly and sealingly assembled in the upper pressure chamber 11, and the lower cylinder of the pressure block 2 is slidingly and sealingly assembled in the lower pressure chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com