Solution pump system

一种溶液、溶液腔的技术,应用在溶液泵领域,能够解决不能充分起作用等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

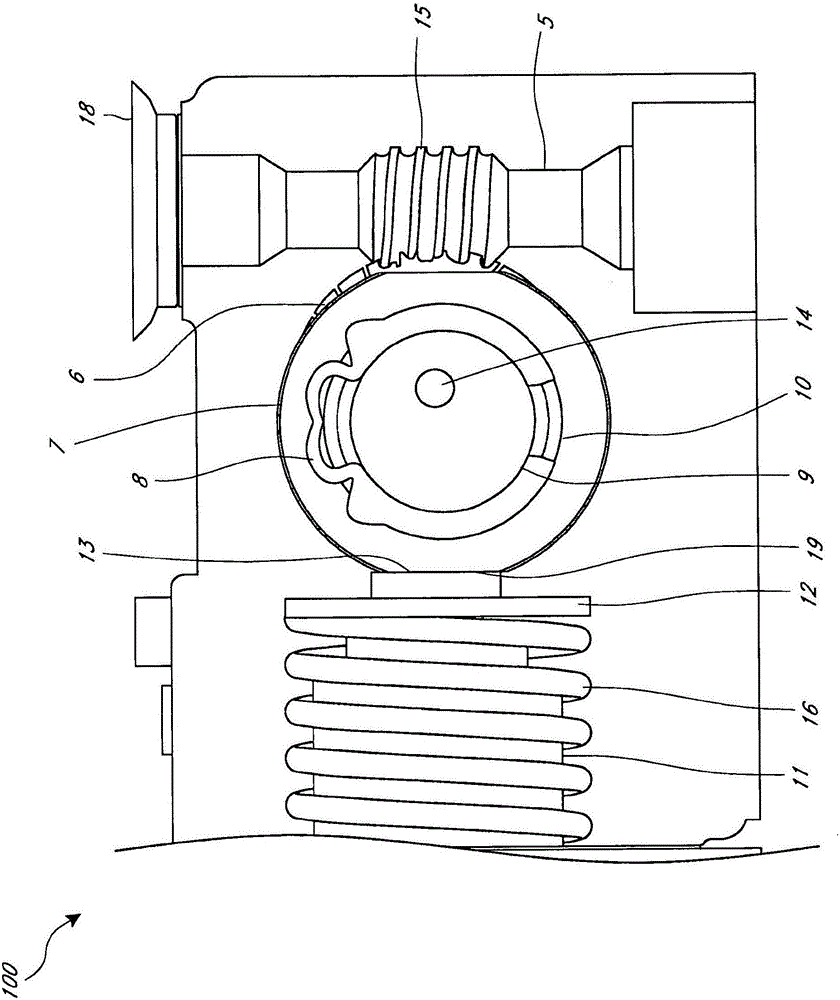

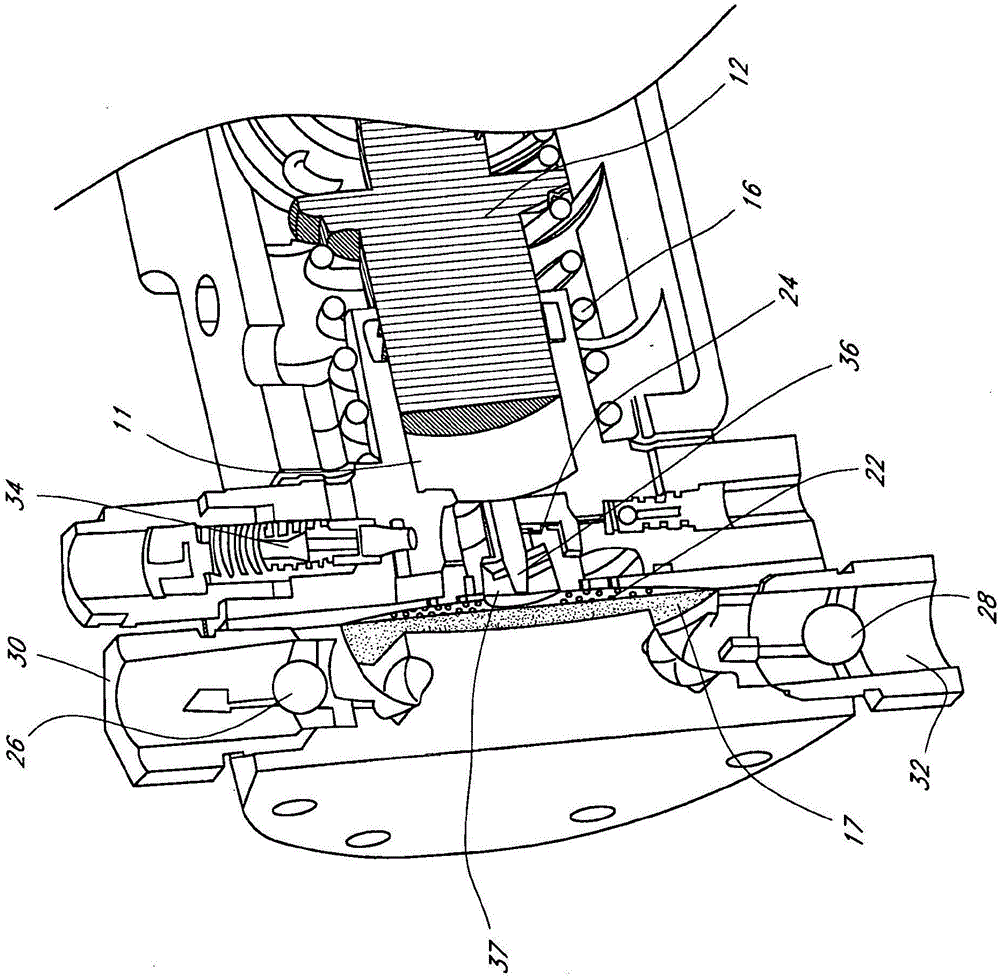

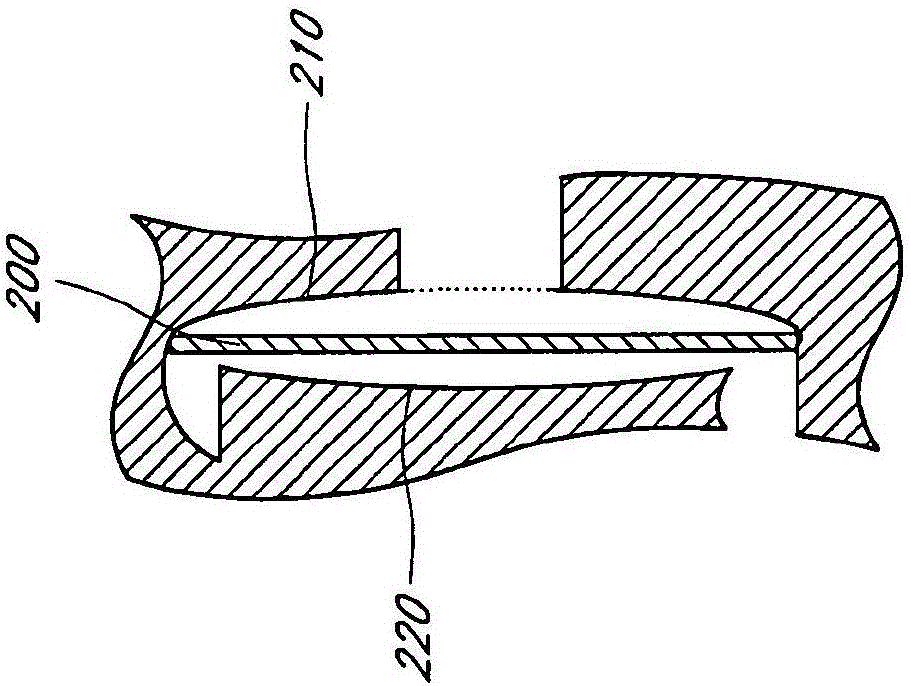

[0018] Embodiments relate to solution pumps capable of self-priming through an access tube. In some embodiments, the solution pump is a plunger driven hydraulic diaphragm solution pump having a solution chamber. In this embodiment, the membrane substantially conforms to the concave inner surface of the solution chamber. By substantially conforming to the interior surface of the solution chamber, the solution pump is able to pump vapor for an extended period of time until solution is drawn into the solution chamber. In addition, the concave inner surface of the solution chamber may include steps or ridges formed along the outer peripheral surface and limit the outer periphery of the surface adjacent to the inlet port and the outlet port. The step can help prevent deformation of the diaphragm due to the inlet and outlet ports formed in the solution chamber wall.

[0019] In this way, the step helps prevent the diaphragm from entering the inlet or outlet and deforming or bulgin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com